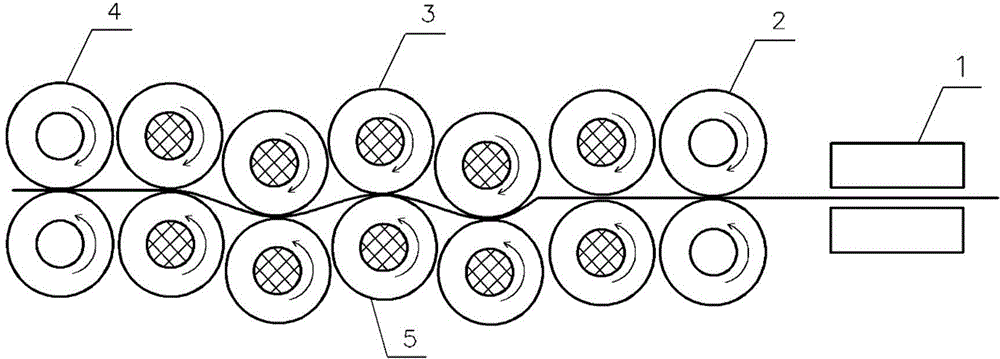

Biaxial bending deformation device and processing method for processing welded joint

A technology of welding joints and bending deformation, which is applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of discontinuous joint structure, uneven joint structure, and reduced mechanical properties of joints, and achieve the elimination of welding residual stress and unsatisfactory Effects of Continuity and Stress Concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

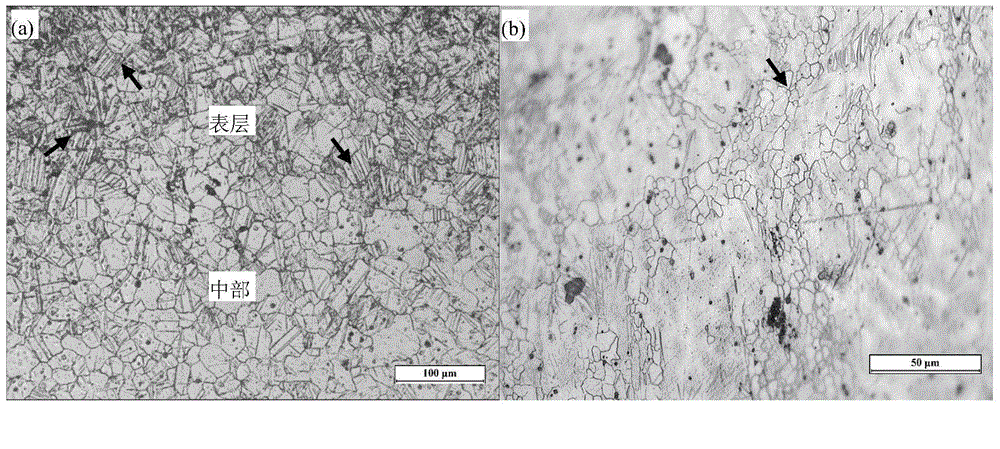

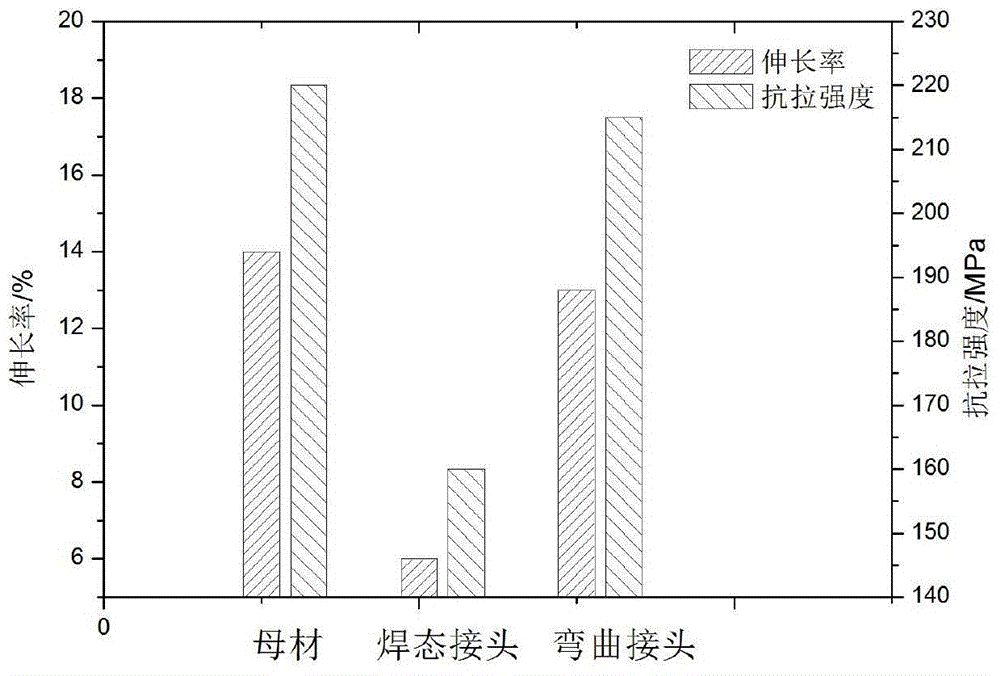

[0041] The invention is especially suitable for welded joints with low mechanical properties, such as magnesium alloy welded joints and aluminum alloy welded joints. In order to illustrate the treatment effect of the welded joints of the present invention, the author chooses the Mg-Al series AZ31 magnesium alloy plate provided by Shandong Yinguang Magnesium Industry Co., Ltd. as the base material for the test.

[0042] 1) Selection of raw materials

[0043]The size of the test plate is 2000mm×600mm×2mm, and the welding material is AZ31 magnesium alloy welding wire with the same quality as the base metal provided by the company, and the specification is φ3.0mm. The main chemical composition and mechanical properties of the magnesium alloy base metal are shown in Table 1 and Table 2:

[0044] Table 1 Chemical composition of AZ31 magnesium alloy (wt.%)

[0045]

[0046] Table 2 Mechanical properties of AZ31 magnesium alloy

[0047]

[0048] 2) Welding method and equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com