Crystallizer narrow copper plate for solving continuous casting blank corner defects

A narrow-faced copper plate and crystallizer technology, applied in the field of mold narrow-faced copper plate, can solve the problems of large consumption of base metal, high cooling speed, complex processing, etc., to improve the quality of cast billets, prolong the service life, and reduce the amount of maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention relates to metallurgical continuous casting equipment, in particular to a crystallizer narrow-faced copper plate for solving the corner defects of continuous casting slabs.

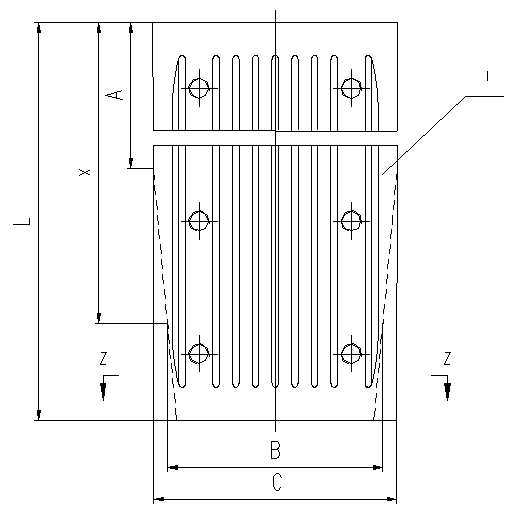

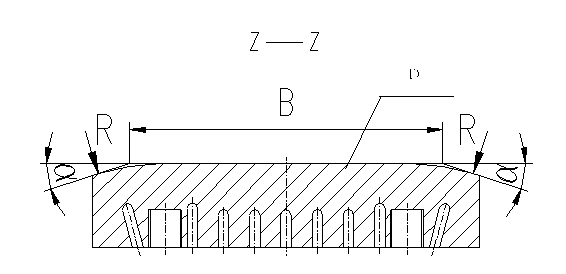

[0018] see figure 1 and figure 2 , the specific structure of a crystallizer narrow copper plate used to solve the corner defects of the continuous casting slab that the present invention relates to is:

[0019] It includes a narrow copper plate body 1, and the outer chamfers are processed on both sides of the middle and lower parts of the narrow copper plate ;

[0020] Among them, k is the solidification coefficient of steel.

[0021] The distance from the edge of the copper plate to the beginning of chamfering in the present invention ;

[0022] Among them, a is the linear coefficient, b is the linear constant, and k is the solidification coefficient of steel.

[0023] The present invention at the height x, the plane width after the outer chamfering ;

[0024] Among them,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com