Water-cooled type steam turbine vane

A steam turbine blade and water-cooling technology, which is applied to the supporting components of the blade, mechanical equipment, engine components, etc., can solve the problems affecting the normal operation of the equipment, the service life of the blade is reduced, and the surface of the blade is corroded, so as to achieve a uniform and stable blade structure and improve The overall impact performance and the effect of ensuring corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

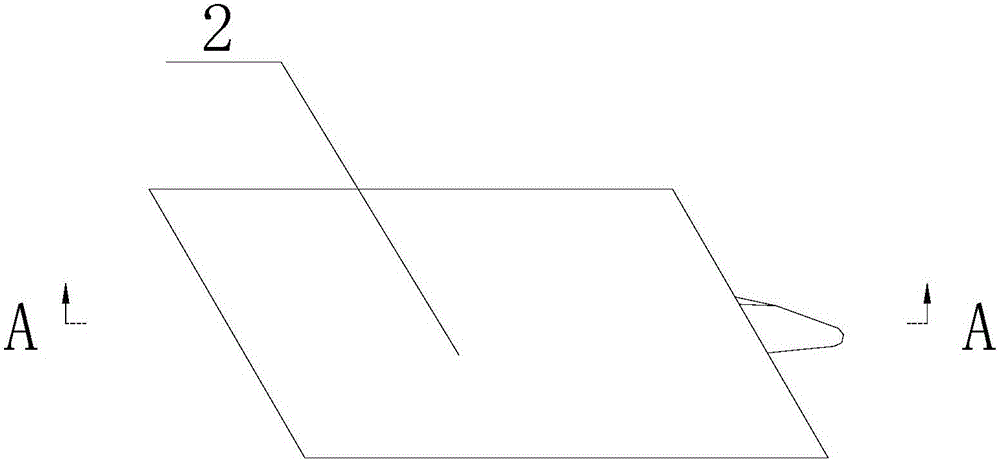

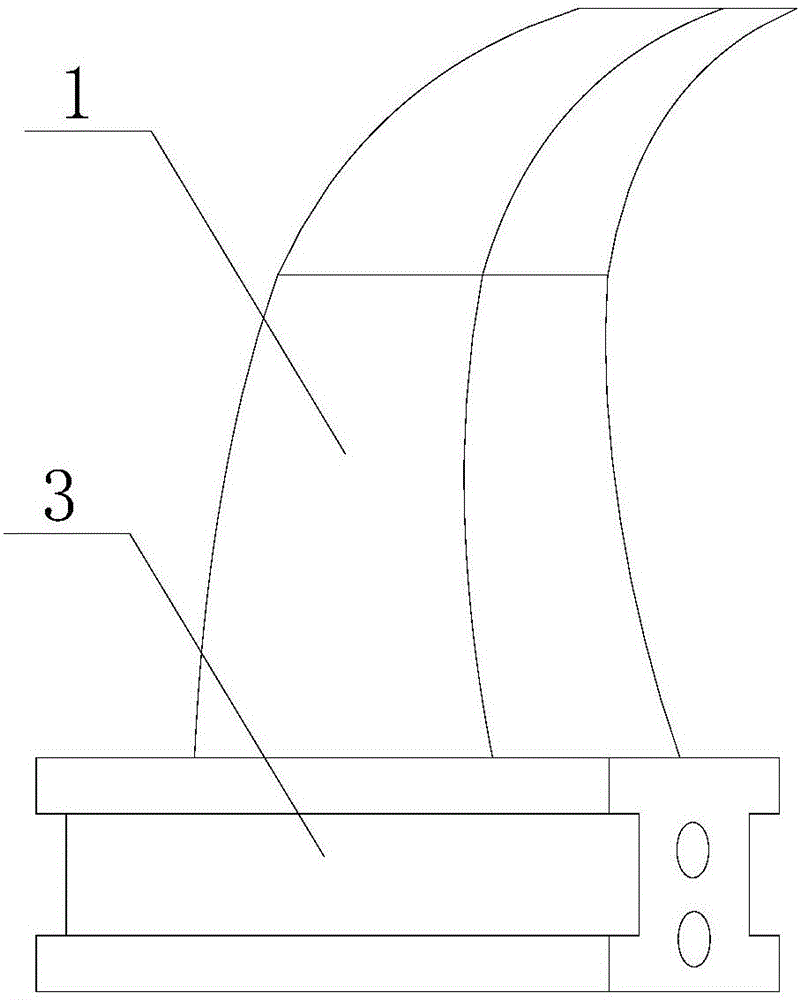

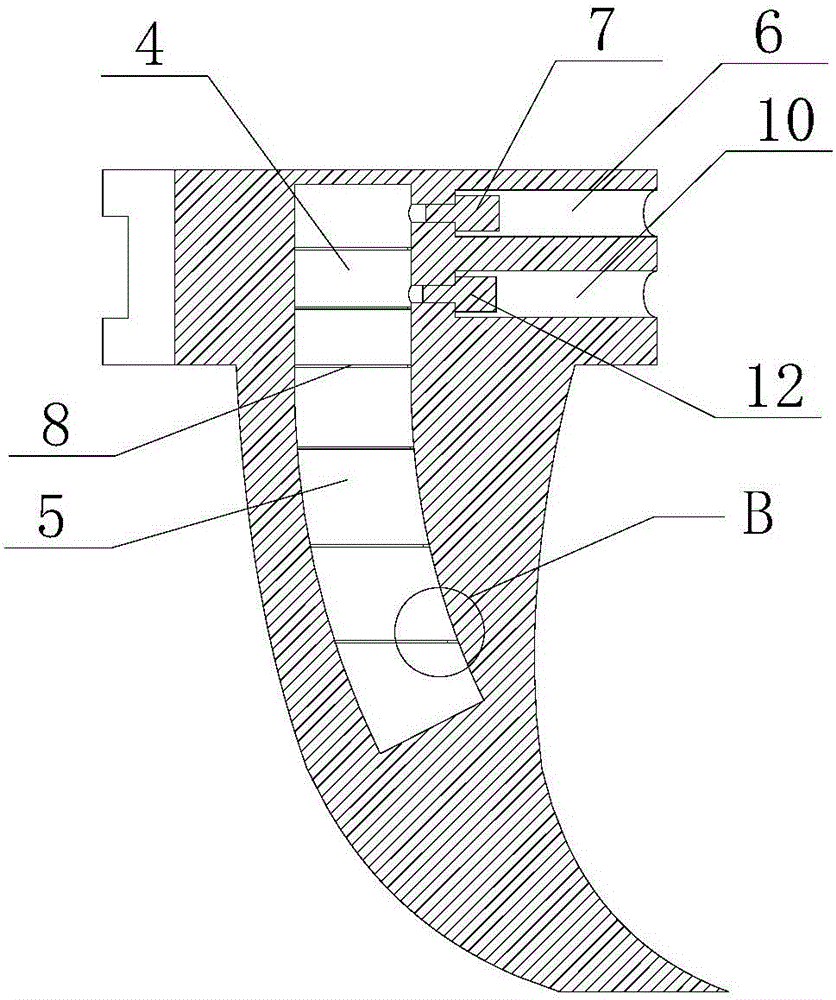

[0042] This embodiment provides a water-cooled steam turbine blade, including a blade 1 and a blade root 2, the blade root 2 is in the shape of a parallelogram, and blade root grooves 3 are respectively opened on the upper and lower sides of the blade root 2, and blade root slots 3 are respectively opened on the blade root 2. A first cavity 4 and a second cavity 5 communicating with the inside of the blade root 2 are opened respectively, a groove 6 is opened on one side of the blade root 2 along its length direction, and a groove 6 is arranged at the bottom of the groove 6 A plug 7, the groove 6 communicates with the second cavity 5, and cooling water is provided inside the first cavity 4 and the second cavity 5;

[0043] The surface of the blade 1 is provided with a high-temperature-resistant metal coating, and the composition of the high-temperature-resistant metal coating is: C: 0.03%, Si: 0.17%, Mn: 0.25%, Cr: 5.36%, Ni: 8.12 %, Cu: 1.32%, Mo: 0.16%, Co: 0.12%, V: 0.36%, Z...

Embodiment 2

[0057] This embodiment provides a water-cooled steam turbine blade, the structure of which is the same as that in Embodiment 1, wherein the surface of the blade 1 is provided with a high-temperature-resistant metal coating, and the composition of the high-temperature-resistant metal coating is: C: 0.05%, Si: 0.19%, Mn: 0.28%, Cr: 5.39%, Ni: 8.14%, Cu: 1.35%, Mo: 0.18%, Co: 0.15%, V: 0.45%, Zn: 0.8%, Al: 0.30%, Ti: 0.18%, B: 0.10%, Mg: 0.48%, S: 0.03%, P: 0.05%, additives: 0.36%, and the balance is Fe;

[0058] The chemical composition mass percentage of the additives is: Ce: 14%, Pr: 5%, Nd: 8%, Pm: 5%, Gd: 7%, Lu: 9%, Dy: 6%, Eu: 5% , Ho: 15%, Er: 8%, Ni: 0.5%, Zn: 0.8%, Cu: 0.9%, and the balance is La;

[0059] The preparation method of the auxiliary agent: first put Ce, Pr, Nd, Pm, Gd, Lu, Dy, Eu elements into the reaction furnace, increase the temperature to 990 ° C, keep the temperature for 5 hours, then air cool to room temperature, and then put Pulverize in a ball mil...

Embodiment 3

[0070] This embodiment provides a water-cooled steam turbine blade, the structure of which is the same as that in Embodiment 1, wherein the surface of the blade 1 is provided with a high-temperature-resistant metal coating, and the composition of the high-temperature-resistant metal coating is: C: 0.04%, Si: 0.18%, Mn: 0.27%, Cr: 5.38%, Ni: 8.13%, Cu: 1.33%, Mo: 0.17%, Co: 0.14%, V: 0.40%, Zn: 0.7%, Al: 0.29%, Ti: 0.17%, B: 0.09%, Mg: 0.46%, S: 0.02%, P: 0.04%, additives: 0.34%, and the balance is Fe;

[0071] The chemical composition mass percentage of the additives is: Ce: 13%, Pr: 4%, Nd: 6%, Pm: 4%, Gd: 6%, Lu: 5%, Dy: 5%, Eu: 4% , Ho: 13%, Er: 7%, Ni: 0.4%, Zn: 0.7%, Cu: 0.8%, and the balance is La;

[0072]The preparation method of the auxiliary agent: first put Ce, Pr, Nd, Pm, Gd, Lu, Dy, Eu elements into the reaction furnace, increase the temperature to 986 ° C, keep the temperature for 4 hours, then air cool to room temperature, and then put Pulverize in a ball mill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com