Method for improving compactness and conductivity of tantalum-doped garnet type solid electrolyte

A solid-state electrolyte, garnet-type technology, applied in the field of electrochemical energy storage, can solve the problems of insufficient electrical conductivity and density, and achieve the effects of improving cycle stability, low sintering cost, and eliminating hole defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

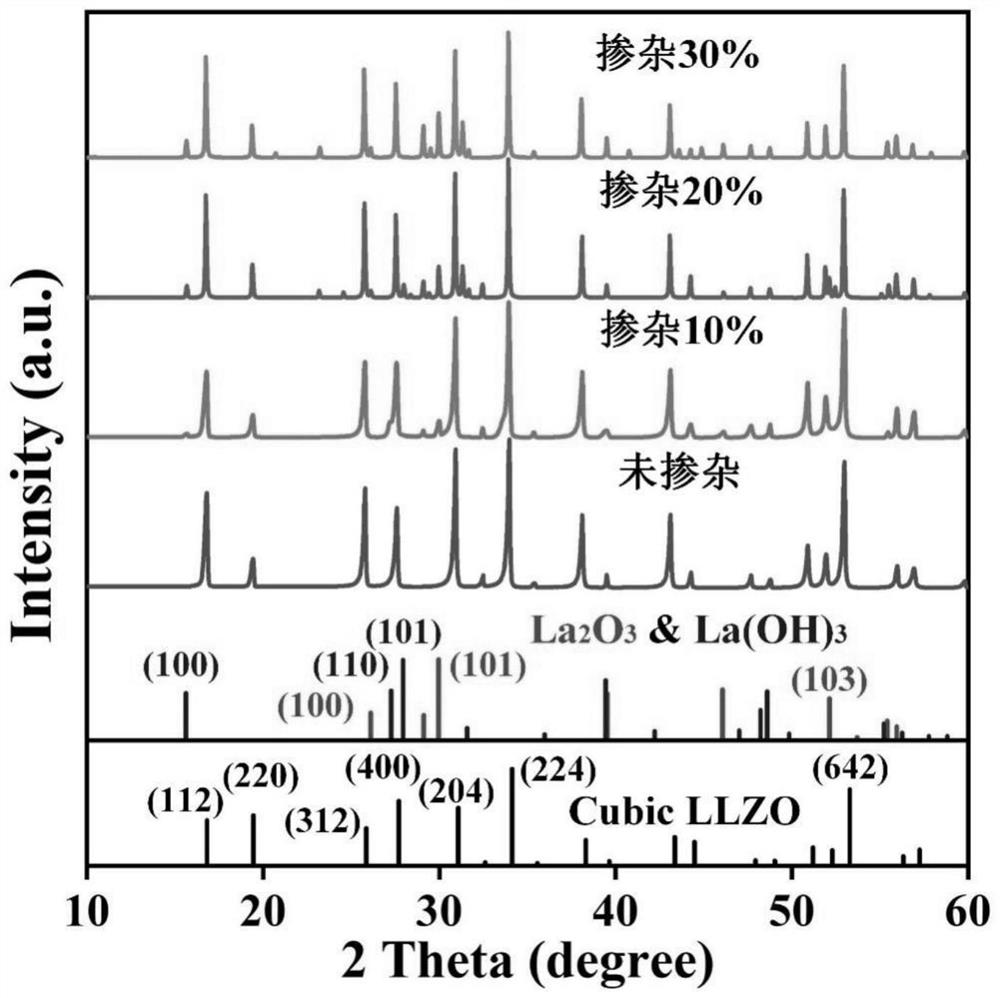

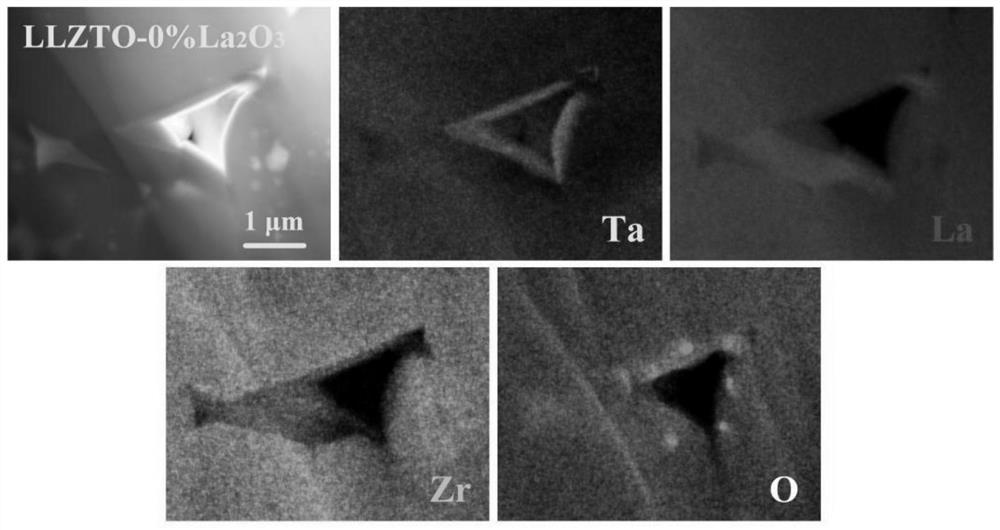

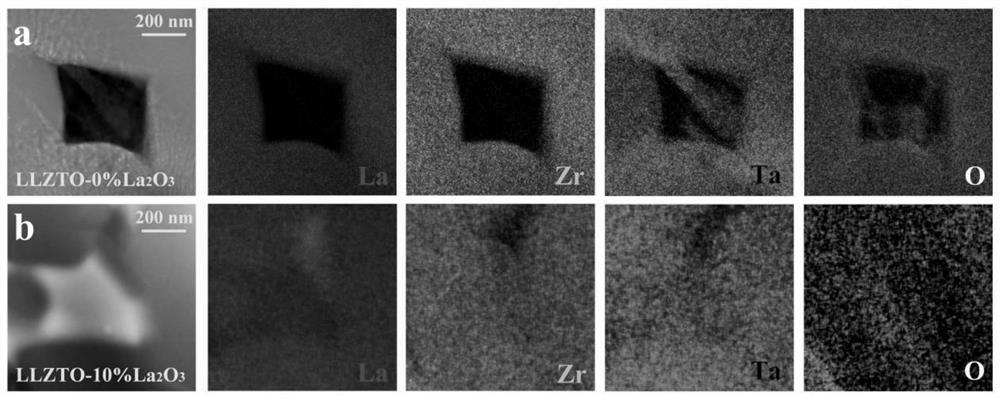

[0038] A method for improving the density and conductivity of the tantalum-doped garnet-type solid electrolyte of the present embodiment adopts the tantalum-doped garnet-type solid-state electrolyte as Li 2 CO 3 , La 2 o 3 , ZrO 2 and Ta 2 o 5 The mixed powder is solid-phase sintered, and the sintering process is obtained by adding La 2 o 3 Nanoparticles to mediate mesophase La 2 Zr 2 o 7 (LaTaO 4 ), which in turn promotes the formation of LLZTO at grain boundaries. Specifically, it is accomplished through the following steps:

[0039] Step 1. According to Li 6.5 La 3 Zr 1.5 Ta 0.5 o 12 Weigh Li 2 CO 3 , La 2 o 3 , ZrO 2 and Ta 2 o 5 Mix well after powder, Li 2 CO 3 Excessive 10wt.%, use isopropanol to carry out wet ball milling as solvent, the volume of isopropanol and the mass ratio of mixed powder are 70ml:20g, and the grinding ball is the ZrO that diameter is 4mm and 6mm 2 Balls, the mass ratio of the two balls is 1:1, the mass ratio of the mixed ...

Embodiment 2

[0046] A method for improving the density and conductivity of the tantalum-doped garnet-type solid electrolyte of the present embodiment adopts the tantalum-doped garnet-type solid-state electrolyte as Li 2 CO 3 , La 2 o 3 , ZrO 2 and Ta 2 o 5 The mixed powder is solid-phase sintered, and the sintering process is obtained by adding La 2 o 3 Nanoparticles to mediate mesophase La 2 Zr 2 o 7 (LaTaO 4 ), which in turn promotes the formation of LLZTO at grain boundaries. Specifically, it is accomplished through the following steps:

[0047] Step 1. According to Li 6.5 La 3 Zr 1.5 Ta 0.5 o 12 Weigh Li 2 CO 3 , La 2 o 3 , ZrO 2 and Ta 2 o 5 Mix well after powder, Li 2 CO 3 Excess 10wt.%, La 2 o 3 Excessive 5wt.%, use isopropanol to carry out wet ball milling as solvent, the volume of isopropanol and mixed powder mass ratio are 70ml: 20g, and grinding ball is the ZrO that diameter is 4mm and 6mm 2 Balls, the mass ratio of the two types of balls is 1:1, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com