Method for conducting boric sulfuric acid anodization pretreatment on 7A85-T7452 aluminum alloy aeronautical part

A technology of 7A85-T7452 and aviation parts, which is applied in the field of boron-sulfuric acid anodization pretreatment of 7A85-T7452 aluminum alloy aviation parts, can solve the problems of easy generation of network grain boundaries, adverse effects of fatigue life, and original grain boundary corrosion traces, etc. Achieve the effects of improving corrosion resistance and fatigue performance, eliminating oxide film defects, and improving compactness and continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

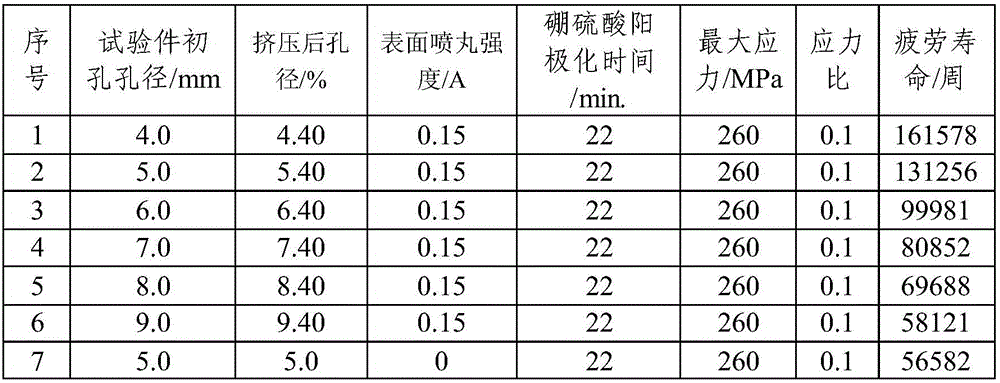

[0032] Table 1 shows the fatigue life effect of the parts prepared by the present invention through machining-hole mechanical extrusion treatment-surface shot peening treatment-boric acid anodization and other processes. in:

[0033] (1) Hole treatment, select an alloy steel rod 0.40mm larger than the initial hole, apply force to make it pass through the hole on the part, so as to complete the extrusion of the hole wall. Then the extruded holes are reamed and made to meet the requirements of the design drawings.

[0034] (3) Surface shot peening treatment

[0035] 0.70mm cast steel shot is selected as the shot peening medium, and the surface of the part is shot peened with a shot peening intensity of 0.15A and a shot peening coverage rate of 100% to 200%.

[0036] (4) surface anodized treatment

[0037] The surface anodization of parts adopts boric acid anodization process, the process parameters are: sulfuric acid concentration 40g / L sulfuric acid, boric acid concentration...

Embodiment 2

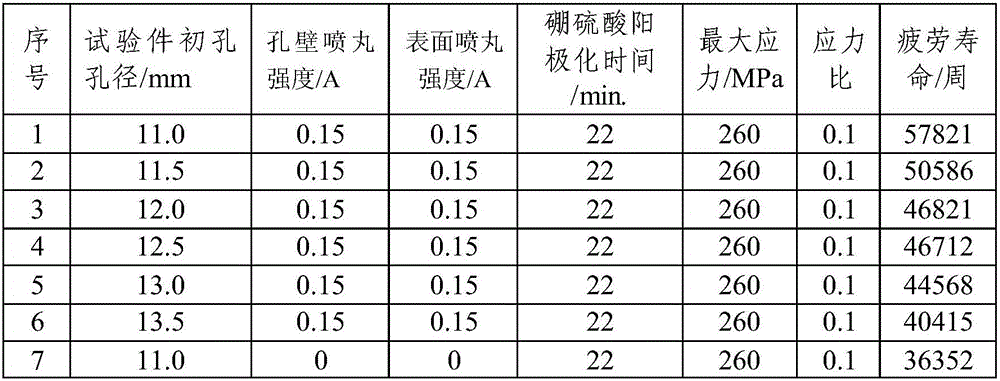

[0041] Table 2 shows the fatigue life effect of parts prepared by the process of machining-hole shot peening-surface shot peening-bororic acid anodization and other processes according to the present invention. in:

[0042] (1) hole treatment

[0043] 0.70mm cast steel shot is selected as the shot peening medium, and the hole wall is shot peened. The shot peening intensity is 0.15A, and the shot peening coverage rate is 100% to 200%.

[0044] (3) Surface shot peening treatment

[0045] 0.70mm cast steel shot is selected as the shot peening medium, and the surface of the part is shot peened with a shot peening intensity of 0.15A and a shot peening coverage rate of 100% to 200%.

[0046] (4) surface anodized treatment

[0047] The surface anodization of parts adopts boric acid anodization process, the process parameters are: sulfuric acid concentration 40g / L sulfuric acid, boric acid concentration 8g / L, bath temperature 20~25℃, oxidation time 22 minutes, oxidation voltage 13~...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com