Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Reduce molecular gap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

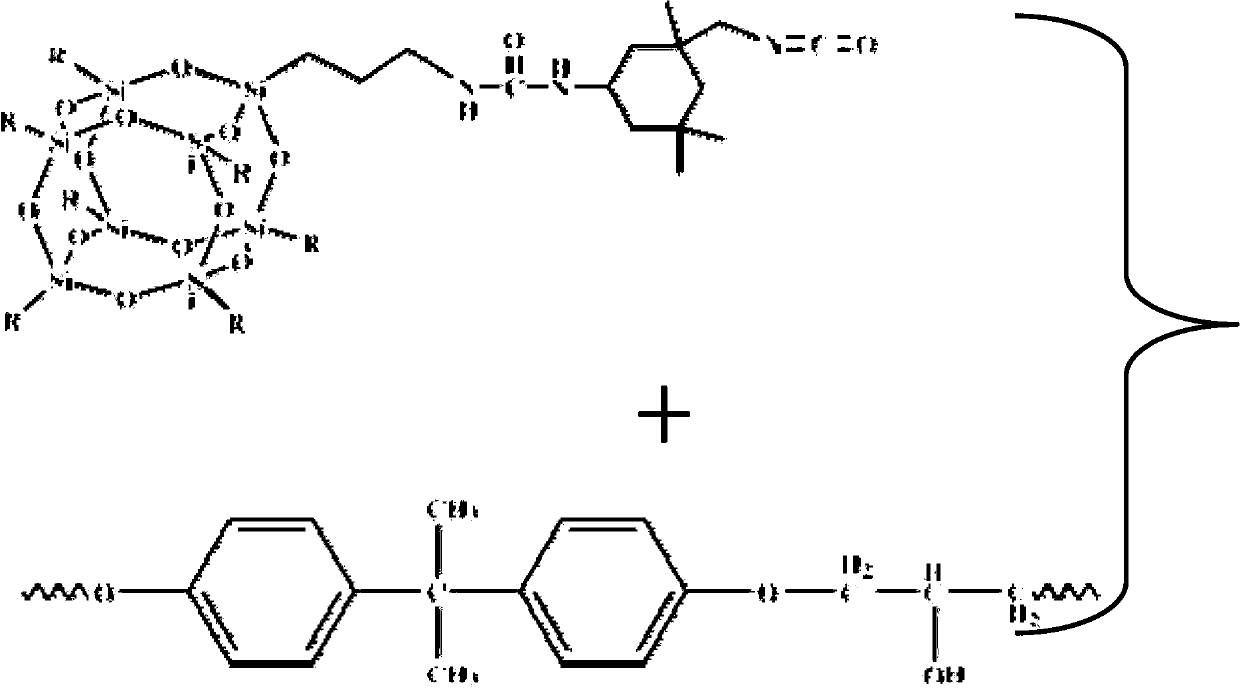

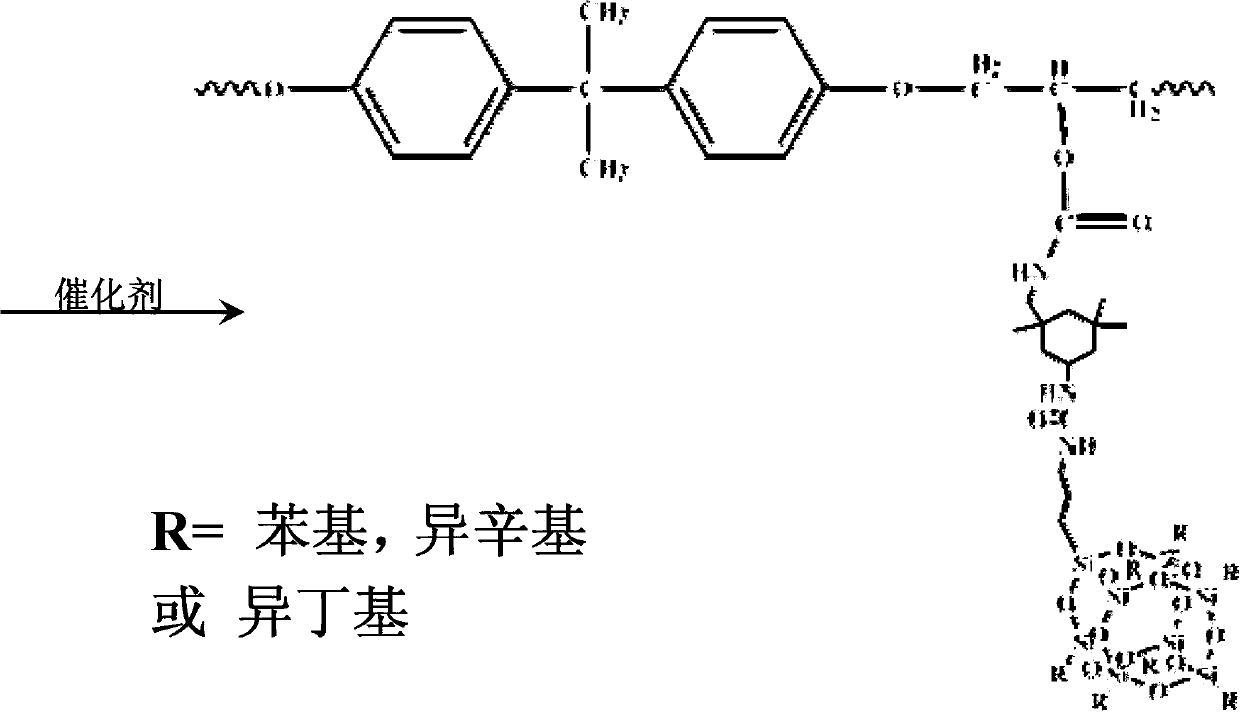

Epoxy resin-POSS hybrid resin and preparation method of its composite material

ActiveCN102815071AImprove compatibility issuesAvoid POSS reunion phenomenonSynthetic resin layered productsLaminationMolecular levelIsocyanate

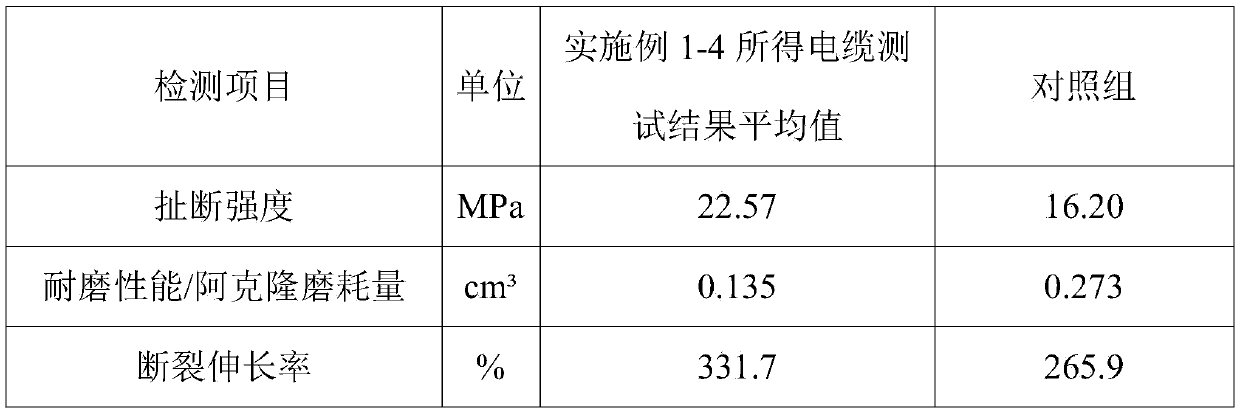

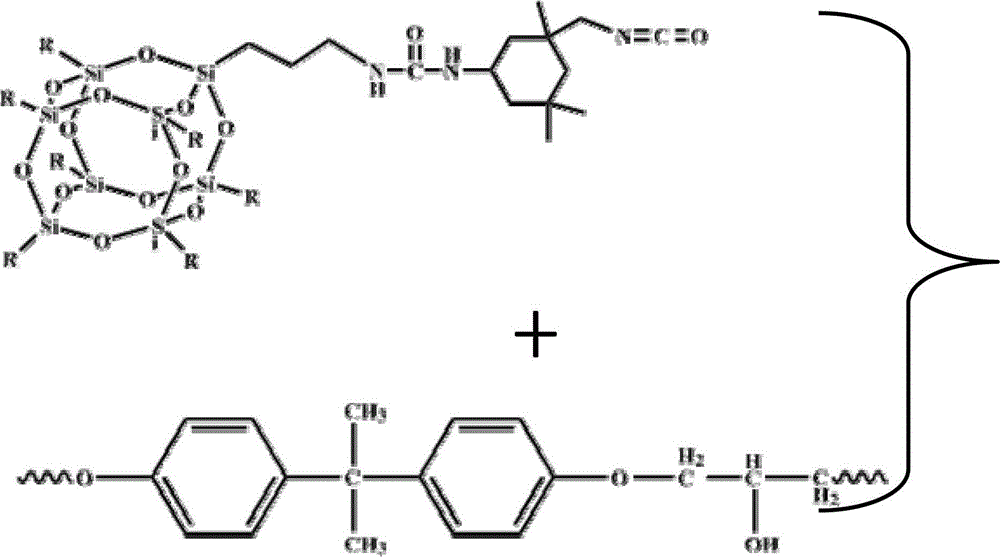

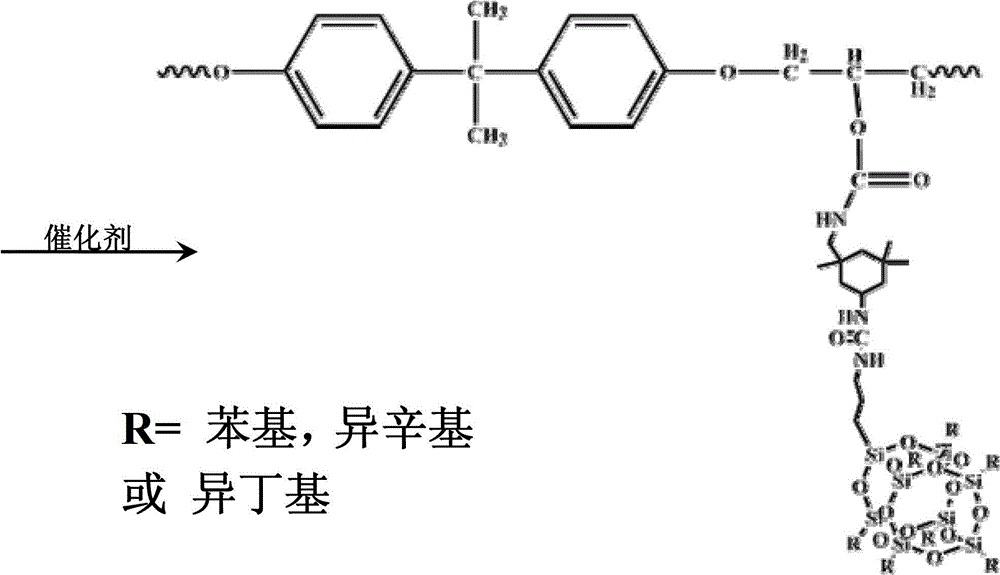

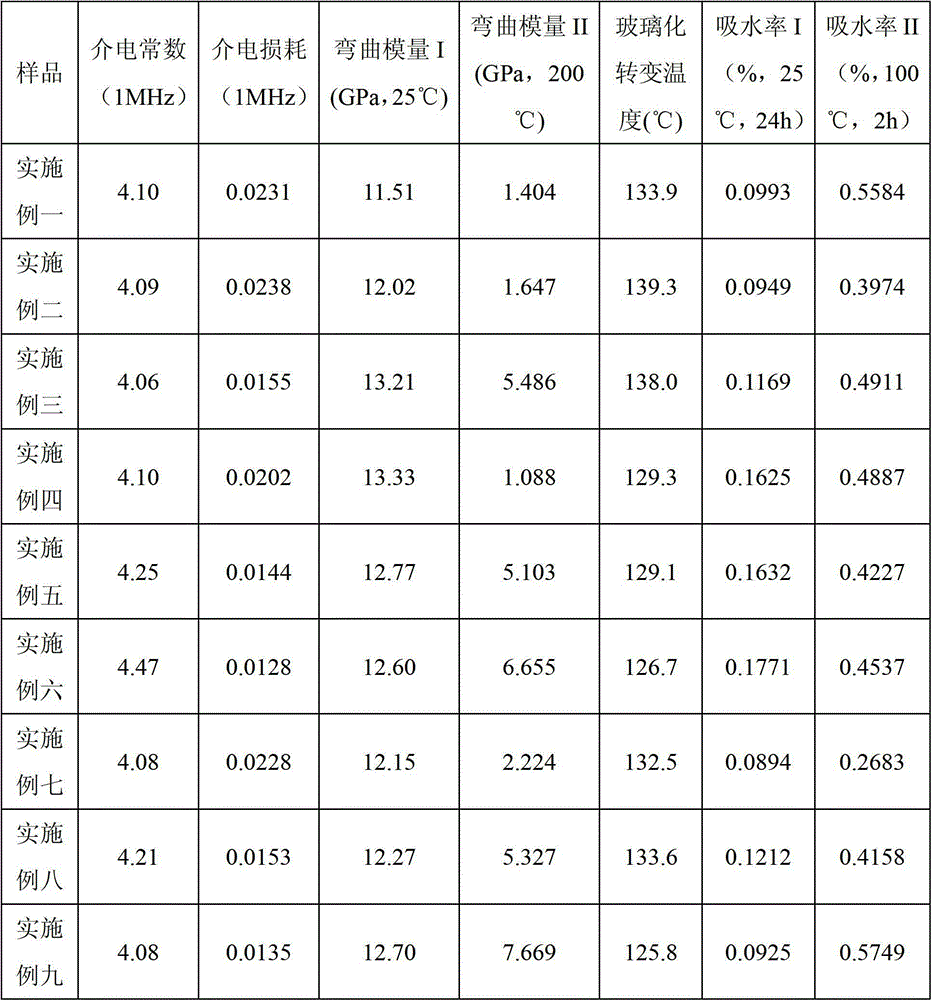

Disclosed are an epoxy resin-POSS hybrid resin and a preparation method of its composite material. The epoxy resin-POSS hybrid resin is applied in an advanced electronic packaging baseplate material. At present, it is very hard to greatly raise comprehensive properties of resin simply through molecular design of epoxy resin, and some performance is raised at the expense of other performance. Traditional POSS modified epoxy resin is mainly prepared by two modes of physical blending and participation copolymerization. Through grafting modified epoxy resin, unique mono-isocyanate polyhedral oligomeric silsesquioxane is adopted to be dispersed on main chain of resin molecules at the molecular level instead of participating in copolymerization as a crosslinking point, so as to obtain high heat-resistant and low dielectric resin for advanced electronic packaging baseplates. The cured hybrid resin has smaller intermolecular distance and lower segment slip capability, and thermal performance, dielectric properties, moisture absorption resistance and mechanical properties of a resin-based composite material copper-clad plate are raised in different degrees.

Owner:BEIJING UNIV OF CHEM TECH

Formula of non-gelatin soft capsule shell

InactiveCN104337793AEasy to shrinkFacilitated releasePharmaceutical non-active ingredientsCapsule deliveryAntioxidantPlasticizer

The invention discloses a formula of a non-gelatin soft capsule shell. The soft capsule shell is prepared from the following components in percentage by weight: 25-75 percent of modified starch, 10-30 percent of carrageenan, 10-25 percent of a plasticizer, 40-50 percent of water, 2-12 percent of a thickening agent and the balance of pigment which can be added according to the required color of the soft capsule pill. According to the formula, the main component gelatin of a traditional capsule shell material is replaced by modified starch and carrageenan, so that multiple defects of gelatin can be overcome, the modified starch has the characteristics of film performance, air resistance, adhesion and the like, has high safety performance and good elasticity, and has the dissolving speed superior to that of gelatin; the soft capsule prepared from modified starch and carrageenan has stable property, and cannot easily perform a crosslinking phenomenon; and the soft capsule prepared by using gelatin replacing materials does not have the problem of oxidation crosslinking, and an antioxidant does not need to be added.

Owner:ZHEJIANG CHUNBAO CAPSULES

Formula of soft capsule shell

InactiveCN102225055AControl migrationIncreased chance of being oxidizedCapsule deliveryWater contentChemistry

The invention relates to a formula of a soft capsule shell, which comprises gelatin, water, glycerol and sorbitol. The formula is characterized in that the proportion of a plasticizer (namely glycerol) and sorbitol is adjusted, and the components are as follows by weight percentage: gelatin 80-100%, water 60-80%, plasticizer 40-60%, antioxidant 0.2-1.2%, and PEG-400 (polyethylene glycol-400) 5-15%. Due to high requirements of soft capsules for the plasticity of shell materials, the moisturizing property of sorbitol is considered and the shell is ensured not to cause softening, deformation, adhesion, liquid leakage and other problems of the soft capsule due to excessive water content, so that the plasticizer is mixed for use to ensure the stability of the capsule. The antioxidant can prevent crosslinking due to oxidation reactions among the substances in the shell material, so as to cause time delay in disintegration of the soft capsule. The addition of the antioxidant in the formula provided by the invention can effective inhibit oxidation, so as to ensure the disintegration of the soft capsule and improve the quality of the shell material.

Owner:贵州地道药业有限公司

Marine high-performance rubber material

The invention discloses a marine high-performance rubber material which is prepared from the following raw materials in parts by weight: 50-65 parts of chlorinated polyethylene 135B, 25-30 parts of styrene-butadiene rubber, 20-30 parts of ethylene propylene diene monomer, 0.5-1.2 parts of metal oxide vulcanization system, 1.2-1.8 parts of bismaleimide, 1-3 parts of vulcanizing agent BIBP, 2-5 parts of magnesium oxide, 1-3 parts of calcium stearate, 1-3 parts of barium stearate, 30-40 parts of white carbon black, 15-20 parts of nano calcium carbonate, 13-24 parts of talcum powder, 35-45 parts of calcined argil, 1-3 parts of phenyl alkyl sulfonate, 1-3 parts of dioctyl phthalate, 0.8-1.3 parts of anti-aging agent RD, 1-1.65 parts of anti-aging agent 4040NA, 1-1.3 parts of tetramethyl-thiuram disulfide and 1.5-2 parts of N-cyclohexyl-2-benzothiazolyl sulfenamide.

Owner:天长市远洋船舶设备股份有限公司

Soft-capsule wall material formula

InactiveCN104324016AEasy to shrinkFacilitated releasePharmaceutical non-active ingredientsCapsule deliveryPolyethylene oxideAntioxidant

The invention discloses a soft capsule wall material formula including 20-40% by weight of polyvinyl alcohol (PVA), 10-40% by weight of a plasticizer, 40-50% by weight of water and 5-15% by weight of a thickening agent, a pigment is added according to color needed by a soft capsule glue ball. By replacement of main component gelatin of the traditional capsule wall material by the polymer polyvinyl alcohol (PVA), many shortcomings of the gelatin are overcome, safety is high, performance is relatively stable, and the crosslinking phenomenon is not easy to occur. No oxidation crosslinking problem occurs, the soft capsule wall material formula is in no need to add antioxidants; the soft capsule wall material formula is added with sorbitol which has excellent moisturizing effect and can effectively prevent drying and aging of soft capsules, when glycerol and sorbitol as a plasticizer are mixed for use, oxygen reaction and matter transport can be prevented, and by addition of thickener sodium alginate, hydroxypropyl methyl cellulose and poly ethylene oxide to improve the glue liquor viscosity, the prepared soft capsule can be sealed without heating.

Owner:ZHEJIANG CHUNBAO CAPSULES

High-reinforced high-mechanical capacity rubber material

The invention discloses a high-reinforced high-mechanical capacity rubber material. The high-reinforced high-mechanical capacity rubber material comprises, by weight, 50 to 55 parts of butyl rubber, 25 to 32 parts of ethylene propylene diene monomer, 15 to 22 parts of polyacrylate rubber, 0.8 to 1.3 parts of tert-butyl cumyl peroxide, 0.5 to 1 part of 2-mercaptoimidazoline, 0.8 to 1.5 parts of silane coupling agent, 1 to 1.5 parts of N-Cyclohexyl-2-benzothiazolesulfenamide, 1 to 3 parts of nano-zinc oxide, 30 to 42 parts of montmorillonite, 30 to 40 parts of modified heavy calcium carbonate, 20 to 25 parts of ultrafine talcum powder, 15 to 22 parts of calcined clay, 1 to 2 parts of antioxidant 4020, 1 to 2 parts of antioxidant NBC, 1 to 2 parts of trioctyl trimellitate, and 0.5 to 1 part of dioctyl phthalate. The high-reinforced high-mechanical capacity rubber material is excellent in mechanical properties, excellent in reinforcing properties, and excellent in material compatibility.

Owner:合肥市再德高分子材料有限公司

3D (Three-dimensional) high-density product printing mode

The invention discloses a 3D (Three-dimensional) high-density product printing mode. A high pressure pump and a high pressure chamber are adopted for applying uninterrupted high pressure to a printed product, and the molecule gaps of a material are reduced, so that products made of different materials can be achieved in a high pressure environment.

Owner:郭靖

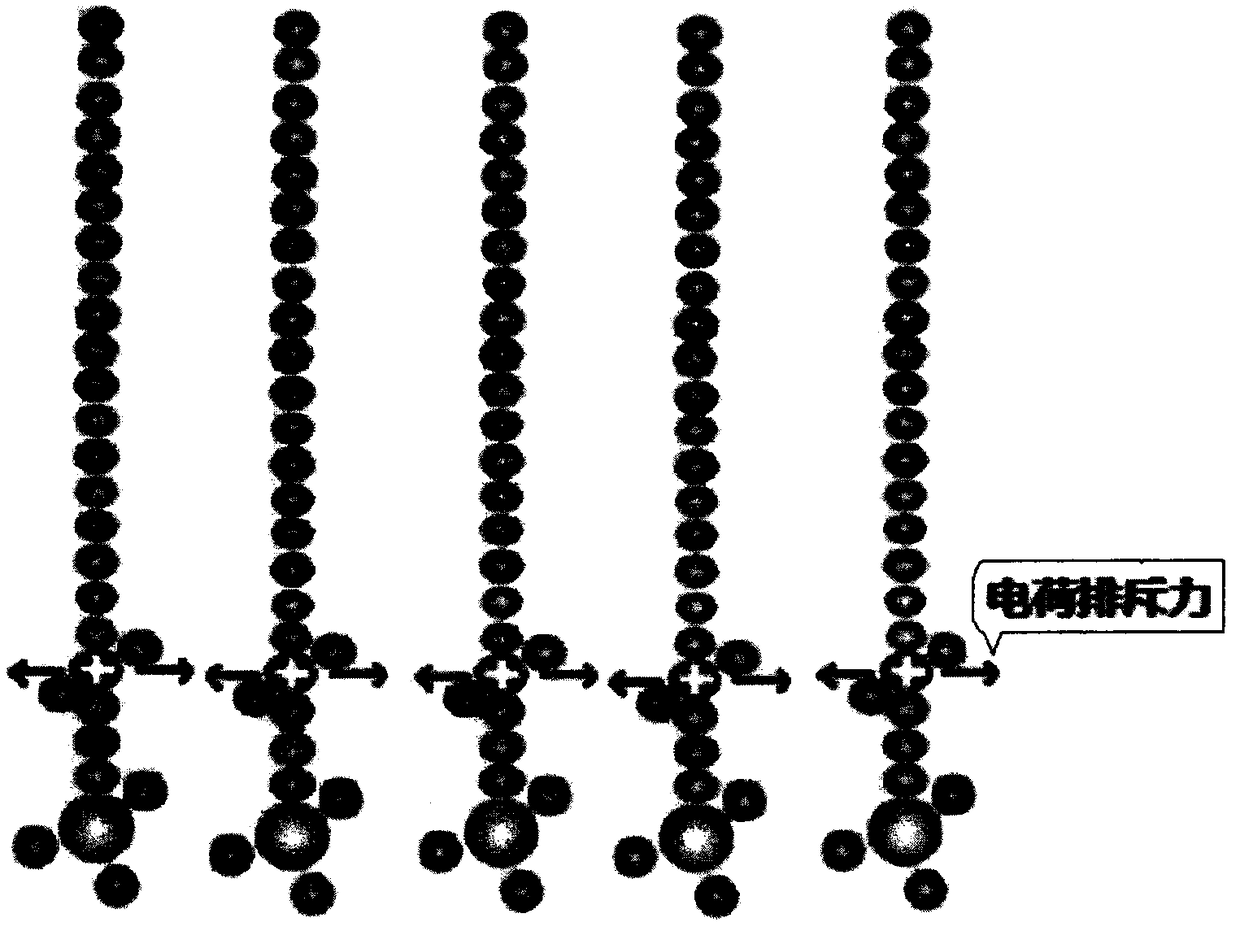

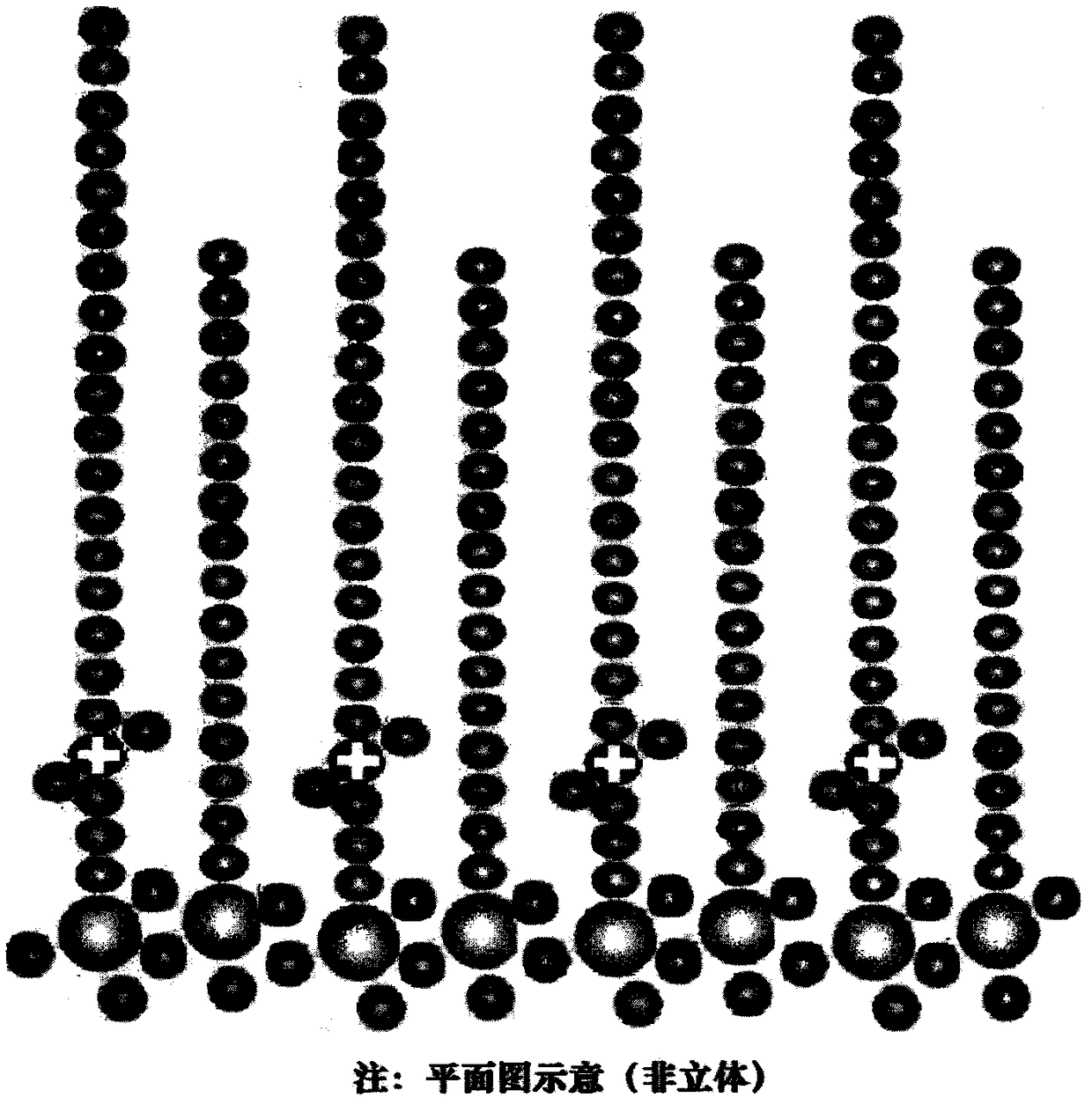

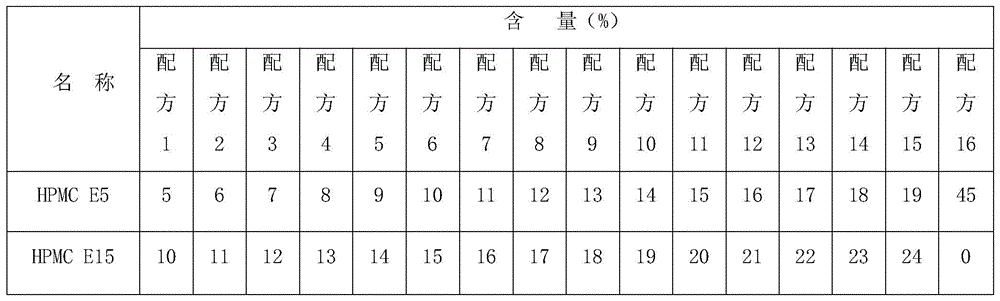

Organosilicon quaternary ammonium salt finishing method for antibacterial treatment of cotton yarn

ActiveCN108625166AImprove permeabilityReduce rejection and evacuationBiochemical fibre treatmentVegetal fibresYarnFiber

The invention discloses an organosilicon quaternary ammonium salt finishing method for the antibacterial treatment of a cotton yarn, and belongs to the technical field of textile chemistry. The methodstrengthens the adhesion density of the organosilicon quaternary ammonium salt on a fiber of the cotton yarn and the antibacterial property of the cotton yarn is improved after finishing. The cottonyarn is sequentially leached in a neutral glutamic acid solution, a compound organosilicon quaternary ammonium salt, and a weak acid rinsing solution, and is finally baked to finish finishing, the neutral glutamic acid with the concentration of 5% is used to pretreat to charge the fiber with the negative charge, the electric adhesion of the organosilicon quaternary ammonium salt with the positivecharge is improved, the compound quaternary ammonium salt with the concentration of 2% is used in finishing to achieve dense adhesion, then the weak acid rinsing solution is used to rinse to remove the glutamic acid, and the negative charge is removed by baking and coking the adhered glutamic acid. The adhesion speed, the adhesion density and the adhesion efficiency of the fiber of the cotton yarnon the organosilicon antibacterial quaternary ammonium salt are improved after finishing, the antibacterial property of the finished cotton yarn fabric is strengthened, and meanwhile, the appearanceperformances like softness and moisture retention of the finished cotton yarn fabric are improved. The process is simple, the operation is convenient, the consumption is low, the efficiency is high, and the method has an application value in the aspect of filtering and blocking bacteria and killing bacteria and viruses.

Owner:北京卡尼尔科技有限公司

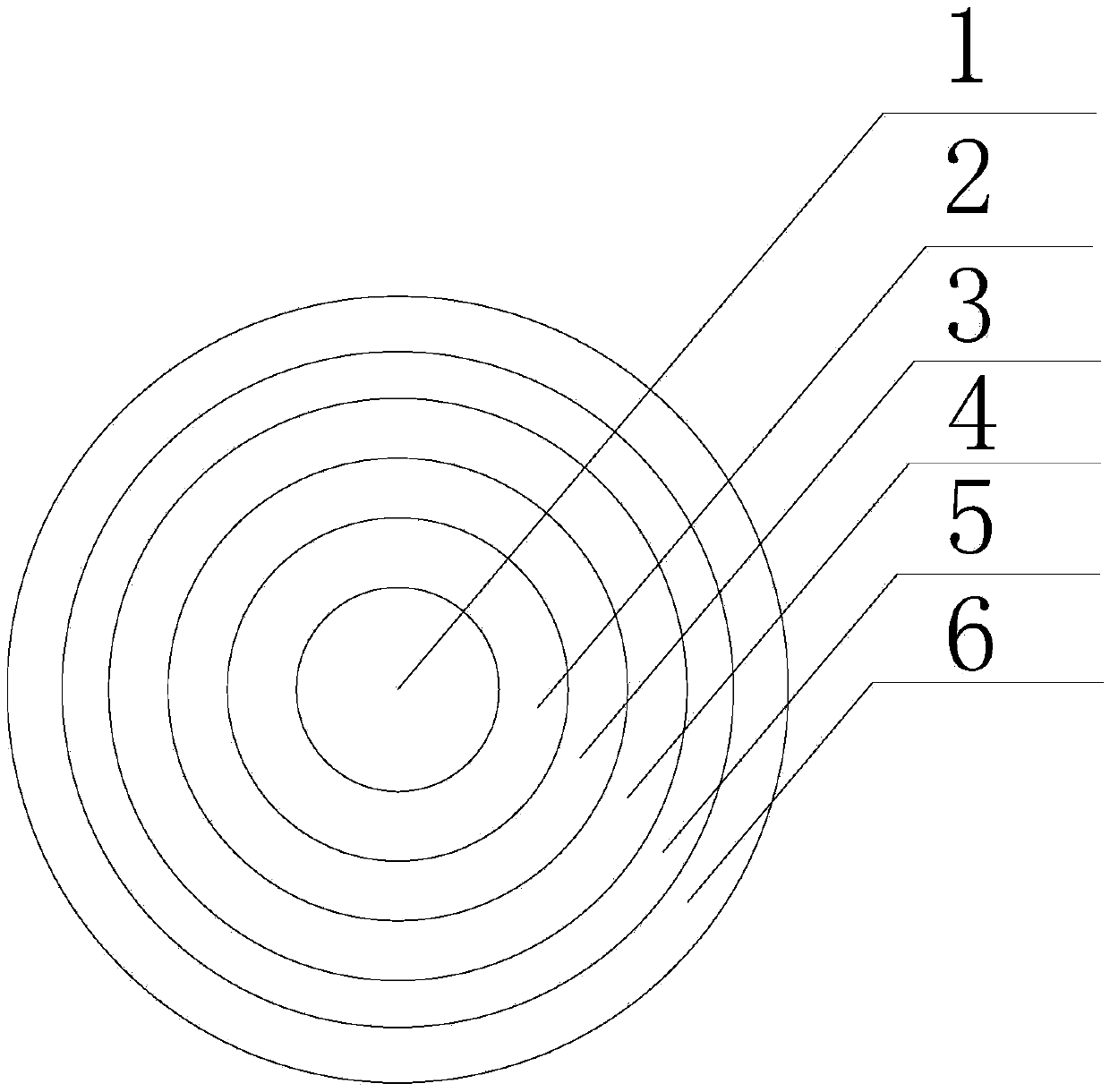

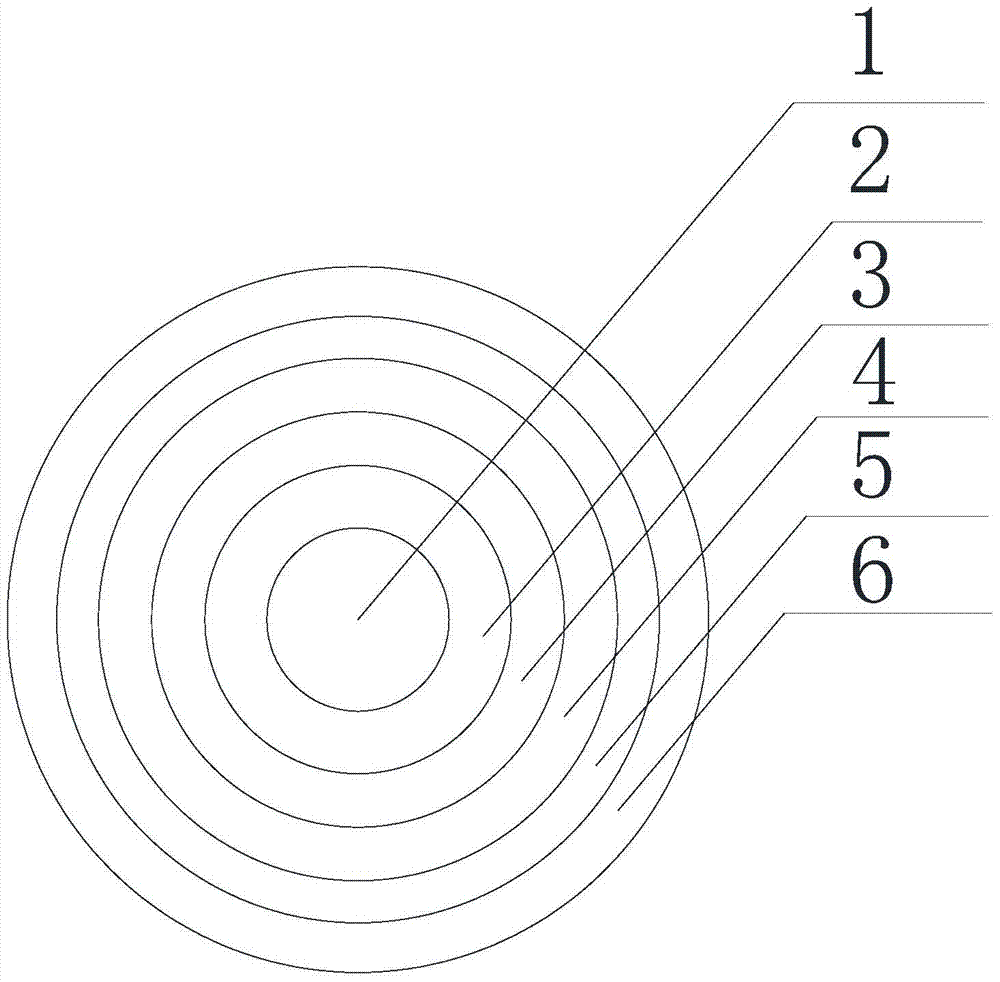

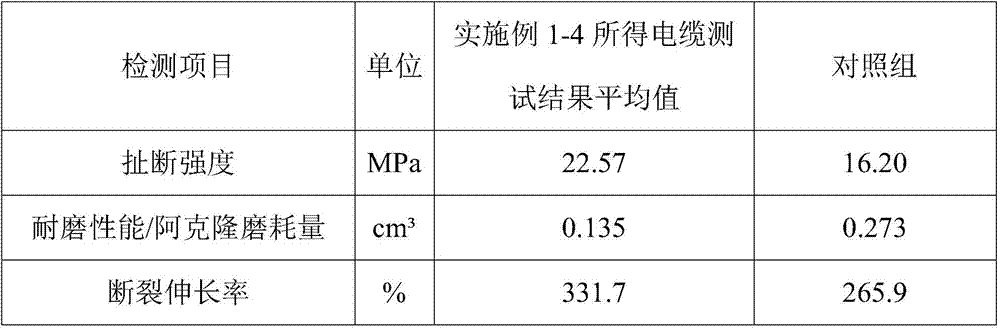

High-toughness abrasion-resistant damping cable used for ships

ActiveCN105374439APromote precipitationAvoid failureInsulated cablesInsulated conductorsWear resistantSulfur

The invention discloses a high-toughness abrasion-resistant damping cable used for ships. The high-toughness wear-resistant damping cable comprises a conductor, an insulating layer, a filling layer, a shielding layer, an armored layer and an external sheath. The raw material of the external sheath includes the following parts by weight: 50-60 parts of polybutadiene rubber, 20-25 parts of EPDM rubber, 15-18 parts of chlorinated polyethylene 140B, 8-12 parts of high-toughness high-heat-insulation performance gel, 1-1.5 parts of sulfur powder, 1.4-1.7 parts of promoter DM, 2.1-2.4 parts of promoter TMTM, 5-7 parts of trioctyl trimellitate, 2-3.5 parts of tributyl citrate, 25-28 parts of barite powder, 17-20 parts of high-abrasion-resistant carbon black, 12-15 parts of nano calcium carbonate, 7-10 parts of ultrafine talcum powder, 6-9 parts of hard pottery clay, 5-8 parts of kaolin, 2-4 parts of red phosphorus, 0.3-0.6 part of NOBS, 0.5-1 part of antioxidant RD and 2.5-4 parts of antioxidant RD.

Owner:ANHUI NANYANG NEW MATERIAL TECH CO LTD

Impact-resistant wear-resistant rubber material

The invention discloses an impact-resistant wear-resistant rubber material. The material comprises the following raw materials by weight: 40 to 70 parts of silicone rubber, 15 to 25 parts of ethylene-propylene-diene rubber, 10 to 20 parts of fluororubber, 1.5 to 2 parts of tert-Butyl peroxy benzoate, 1.5 to 2.3 parts of 2-mercaptoimidazoline, 1 to 2 parts of a silane coupling agent, 1 to 2 parts of N-cyclohexyl-2-benzothiazole sulfonamide, 3 to 6 parts of nanometer zinc oxide, 40 to 60 siliceous earth, 15 to 20 parts of modified heavy calcium carbonate, 13 to 18 parts of fly ash, 20 to 30 parts of calcined clay, 1 to 1.4 parts of an antiaging agent OD, 1 to 1.5 parts of an antiaging agent NBC, 1 to 1.5 part of trioctyl trimellitate and 1 to 2 parts of dioctyl phthalate. The impact-resistant wear-resistant rubber material provided by the invention has good mechanical property, excellent reinforcing property and good compatibility among materials.

Owner:合肥市再德高分子材料有限公司

Tear-resistant plug connecting wire of low-voltage charger

InactiveCN107722636AImprove stabilityImprove the lubrication effectRubber insulatorsSodium BentoniteLow voltage

The invention discloses a tear-resistant plug connecting wire of a low-voltage charger. The tear-resistant plug connecting wire comprises a lead and an outer sheath, wherein the outer sheath comprises, by weight, 90-100 parts of methyl vinyl silicone rubber, 40-60 parts of natural rubber, 3-7 parts of cross-linking agents, 2-4 parts of zinc oxide, 2-4 parts of lauric acid, 6-12 parts of Dimethyl diethoxy silicane, 4-8 parts of plasticizers, 10-30 parts of hydrotalcite compounds, 20-40 parts of white mica powder, 30-40 parts of bentonite, 40-50 parts of coal ash, 10-20 parts of vermiculite and2-4 parts of anti-aging agents. The hydrotalcite compounds are prepared by the process: uniformly stirring polylactic acid, polyethylene glycol and dichloromethane; adding and stirring lanthanum citrate, zinc stearate and magnesium aluminum carbonate hydrotalcite; spraying epoxidized soybean oil in a stirring state; continuing stirring; adjusting a system to be neutral; removing methylene dichloride and water to obtain the hydrotalcite compounds.

Owner:天长市平康电子科技有限公司

Epoxy resin-POSS hybrid resin and preparation method of its composite material

InactiveCN102815071BLow dielectric constantReduce lossSynthetic resin layered productsLaminationEpoxyMolecular level

Disclosed are an epoxy resin-POSS hybrid resin and a preparation method of its composite material. The epoxy resin-POSS hybrid resin is applied in an advanced electronic packaging baseplate material. At present, it is very hard to greatly raise comprehensive properties of resin simply through molecular design of epoxy resin, and some performance is raised at the expense of other performance. Traditional POSS modified epoxy resin is mainly prepared by two modes of physical blending and participation copolymerization. Through grafting modified epoxy resin, unique mono-isocyanate polyhedral oligomeric silsesquioxane is adopted to be dispersed on main chain of resin molecules at the molecular level instead of participating in copolymerization as a crosslinking point, so as to obtain high heat-resistant and low dielectric resin for advanced electronic packaging baseplates. The cured hybrid resin has smaller intermolecular distance and lower segment slip capability, and thermal performance, dielectric properties, moisture absorption resistance and mechanical properties of a resin-based composite material copper-clad plate are raised in different degrees.

Owner:BEIJING UNIV OF CHEM TECH

Aging-resistance rubber material for boats

The invention discloses an aging-resistance rubber material for boats. The material comprises the following components in parts by weight: 55-70 parts of chlorinated polyethylene 130B, 22-30 parts of chlorosulfonated polyethylene, 1-3 parts of a metallic oxide vulcanization system, 1.5-3 parts of trimethylolpropane trimethacrylate, 0.5-1.2 parts of an organosilicon compound, 2-5 parts of magnesium oxide, 1-2 parts of lead stearate, 2-4 parts of chlorinated paraffin, 1-2.5 parts of EPO, 20-25 parts of white carbon black, 6-13 parts of magnesium carbonate, 18-24 parts of superfine talc powder, 35-40 parts of calcined clay, 1.8-2.5 parts of dioctyl sebacate, 1-3 parts of dioctyl phthalate, 0.8-1 part of an antiager RD, 1-1.5 parts of an antiager MB, 0.5-0.85 part of an antiager HS-911, 1-1.3 parts of tetramethyl thiuram disulfide and 1.5-2 parts of N-cyclohexyl-2-benzothiazole sulfenamide.

Owner:天长市远洋船舶设备股份有限公司

A kind of oil-resistant stomach-soluble film coating premixed auxiliary material and preparation method thereof

ActiveCN103893773BGood compatibilitySolve the problem of oozing coating filmPharmaceutical delivery mechanismPharmaceutical non-active ingredientsMethyl cellulosePolyethylene glycol

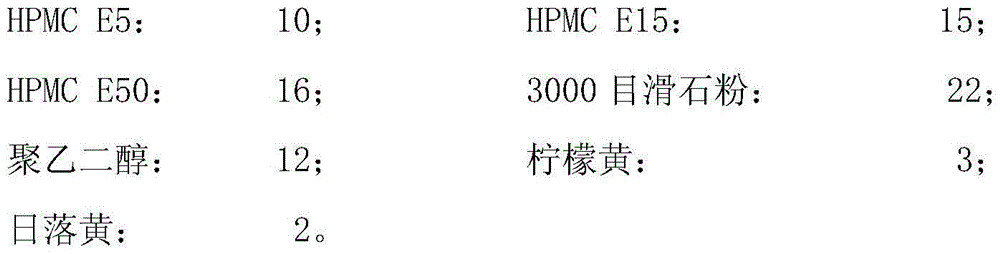

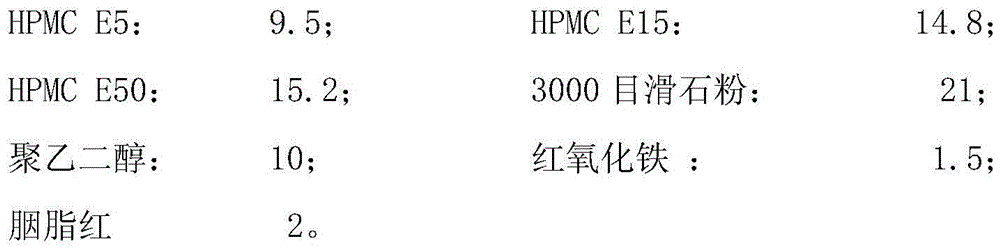

The invention discloses an oil-resistant gastric-soluble type film coating premix auxiliary material and a preparation method thereof. The oil-resistant gastric-soluble type film coating premix auxiliary material is prepared from the following raw materials in parts by weight: 9-10 parts of HPMCE (medicinal hydroxypropyl methyl cellulose) 5, 14-15 parts of HPMCE 15, 15-16 parts of HPMCE 50, 20-22 parts of talcum powder, 9-12 parts of polyethylene glycol and 3-5 parts of pigment. The preparation method for the oil-resistant gastric-soluble type film coating premix auxiliary material comprises weighing, pre-mixing, crushing, preparing and spraying. The oil-resistant gastric-soluble type film coating premix auxiliary material prepared by the preparation method disclosed by the invention plays a moistureproof role on medicines such as extracts, successfully solves the problem of the seepage of coating films of the traditional Chinese medicines such as extracts due to damp and hot influence, prevents the medicines from being affected with damp and hardened, prevents the loss of efficacy, and has oil resistance; the preparation method for the oil-resistant gastric-soluble type film coating premix auxiliary material has the advantages of being simple to operate, convenient to prepare, high in production efficiency and low in energy consumption, and is suitable for large-scale factorial production.

Owner:CHENGDU KETE COATING TECH

Preparation method of charger plug connecting wire sheath

InactiveCN107760009ANo pollutionImprove securityPlastic/resin/waxes insulatorsPolymer scienceLow voltage

The invention discloses a preparation method of a charger plug connecting wire sheath. The preparation method comprises the following steps: uniformly mixing polyurethane rubber, isoprene rubber, C9 petroleum resin and coumarone resin to obtain preformed material; adding stearic acid, a silane coupling agent, vermiculite powder, attapulgite, coal gangue, ground calcium carbonate and zeolite powderinto the preformed material; heating and stirring; heating, and performing vacuum stirring to obtain a rubber compound; adding tert-butyl hydroperoxide, magnesium oxide, an anti-aging agent DFC-34 and an antioxidant TPP into the rubber compound; vulcanizing and moulding to obtain the charger plug connecting wire sheath. According to the preparation method disclosed by the invention, the obtainedsheath has the advantages of remarkably high tensile strength and elongation at break, strong resistance to aging and tearing and high toughness, and avoids the phenomenon of electric leakage on a low-voltage side caused by a high-voltage side, thus the safety of a charger is enhanced, and a user feels safer to use the charger.

Owner:天长市平康电子科技有限公司

Corrosion and aging resistant rubber material for ships

The invention discloses a corrosion and aging resistant rubber material for ships. Raw materials for preparing the corrosion and aging resistant rubber material comprise, by weight, 50-70 parts of chlorinated polyethylene 140B, 25-30 pars of natural rubber, 20-30 parts of chlorosulfonated polyethylene, 1.5-2 parts of a metal oxide vulcanization system, 0.5-1.5 parts of sulfur, 2-5 parts of magnesium oxide, 20-30 parts of high abrasion furnace black, 15-20 parts of nanometer calcium carbonate, 15-20 parts of superfine talcum powder, 30-40 parts of calcined potter's clay, 1.5-2 parts of trimellitate, 1-2 parts of dicapryl phthalate, 1-1.5 parts of an antioxidant 1010, 1-1.5 parts of an antioxidant MB, 0.5-1 part of an antioxidant RD, 1-1.5 parts of 1,2-ethylene thiourea, and 0.8-1.3 parts of NOBS. The corrosion and aging resistant rubber material has good mechanical properties, and excellent aging resistance, wear resistance, high temperature resistance, oil resistance and corrosion resistance, and can be used in the complex environment of ships.

Owner:天长市远洋船舶设备股份有限公司

A method for finishing cotton yarn with antibacterial organosilicon quaternary ammonium salt

ActiveCN108625166BImprove permeabilityReduce rejection and evacuationBiochemical fibre treatmentVegetal fibresYarnFiber

Owner:北京卡尼尔科技有限公司

Pipe for discharging sewage and preparation method of pipe

The invention discloses a pipe for discharging sewage. The pipe is prepared from the following raw materials in parts by weight: 60-90 parts of unsaturated polyester resin, 13-19 parts of polyphenylene sulfide, 6-14 parts of liquid polyisoprene rubber, 3-9 parts of calcium carbonate, 2-6 parts of asbestos powder, 4-9 parts of sodium selenite, 2-6 parts of polychlorotrifluoroethylene, 3-6 parts of basalt fibers, 2-9 parts of polyvinyl acetate, 2-5 parts of epoxidized linseed oil, 1.5-7 parts of a POE (polyolefin elastomer), 1-4 parts of an anticorrosive agent and 1-3 parts of a dispersant. The pipe has the advantages that a preparation method is simple and easy to implement, the cost is lower, and raw materials are available; the unsaturated polyester resin, polyphenylene sulfide, the liquid polyisoprene rubber, calcium carbonate and the like are mixed to be used as materials of the pipe; the unsaturated polyester resin has excellent chemical stability, heat and cold resistance, weather resistance, hydrophobicity and low surface tension and does not produce substances polluting the environment, and the anticorrosive agent is added, so that corrosion resistance of the inner surface of the pipe can be significantly improved.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

A high toughness wear-resistant shock-absorbing cable for ships

ActiveCN105374439BPromote precipitationAvoid failureInsulated cablesInsulated conductorsWear resistantSulfur

The invention discloses a high-toughness wear-resistant shock-absorbing cable for ships, which comprises a conductor, an insulating layer, a filling layer, a shielding layer, an armor layer and an outer sheath; the raw materials of the outer sheath include: butadiene rubber 50 ‑60 parts, EPDM rubber 20‑25 parts, chlorinated polyethylene 140B 15‑18 parts, high toughness and high heat insulation gel 8‑12 parts, sulfur powder 1‑1.5 parts, accelerator DM 1.4‑1.7 2.1-2.4 parts of accelerator TMTM, 5-7 parts of trioctyl trimellitate, 2-3.5 parts of tributyl citrate, 25-28 parts of barite powder, 17-20 parts of high wear-resistant carbon black, 12-15 parts of nano calcium carbonate, 7-10 parts of superfine talc, 6-9 parts of hard clay, 5-8 parts of kaolin, 2-4 parts of red phosphorus, 0.3-0.6 parts of NOBS, 0.5-1 parts of anti-aging agent RD parts, antioxidant RD 2.5‑4 parts.

Owner:ANHUI NANYANG NEW MATERIAL TECH CO LTD

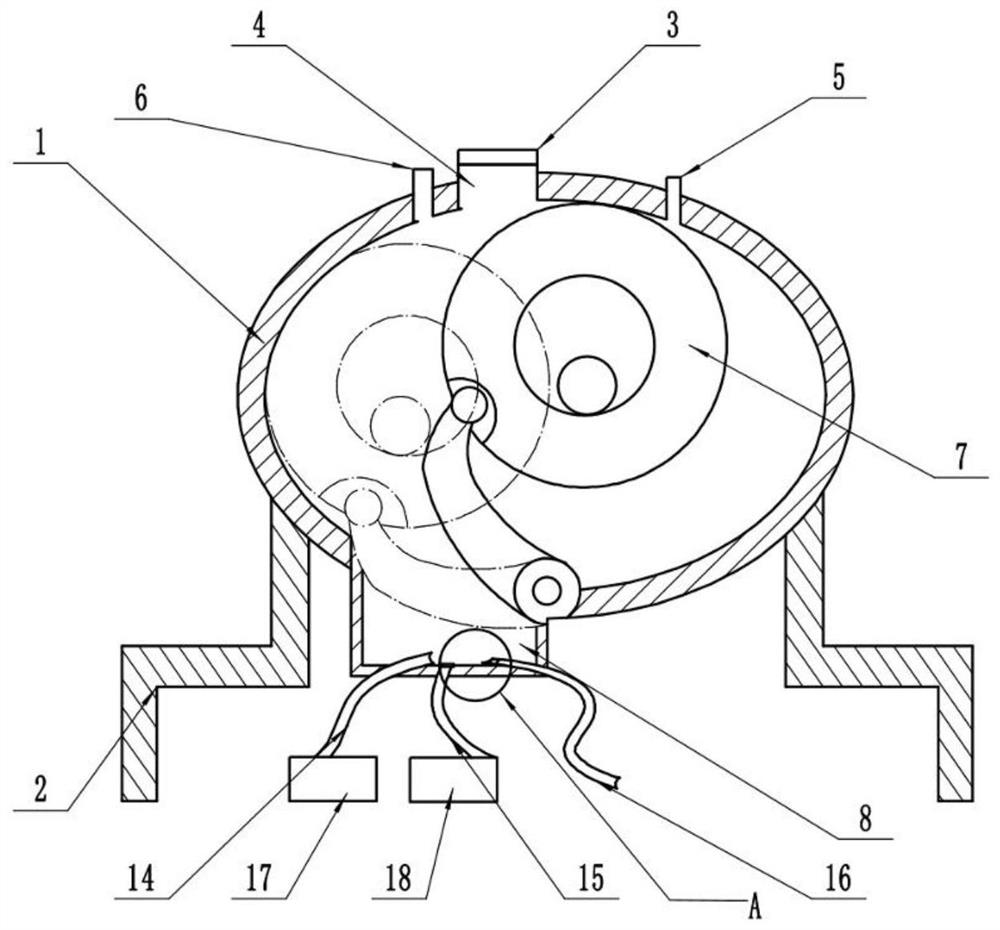

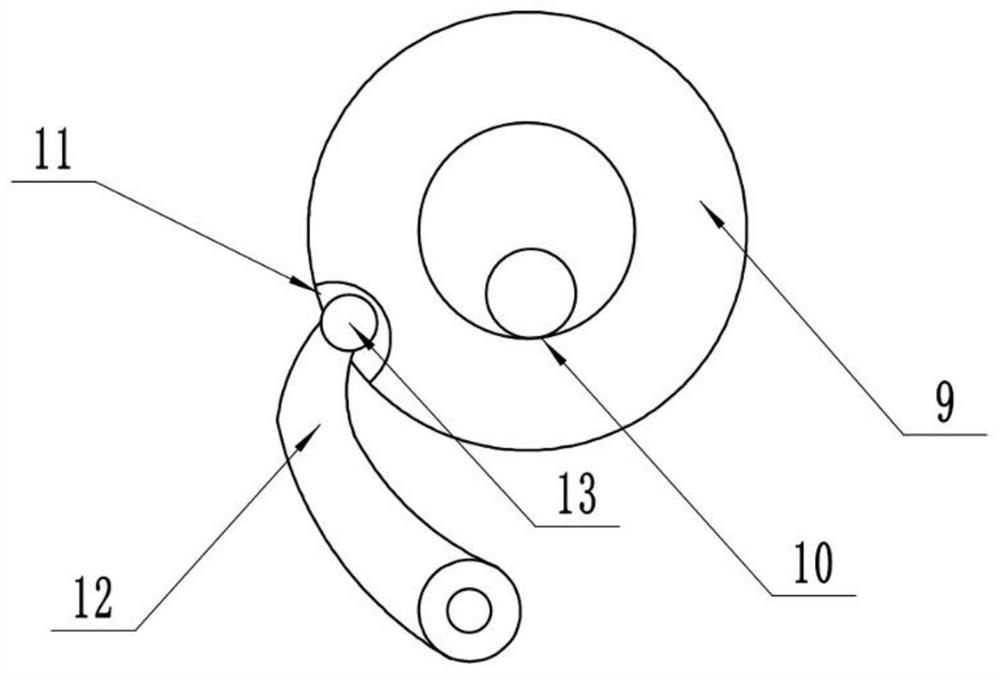

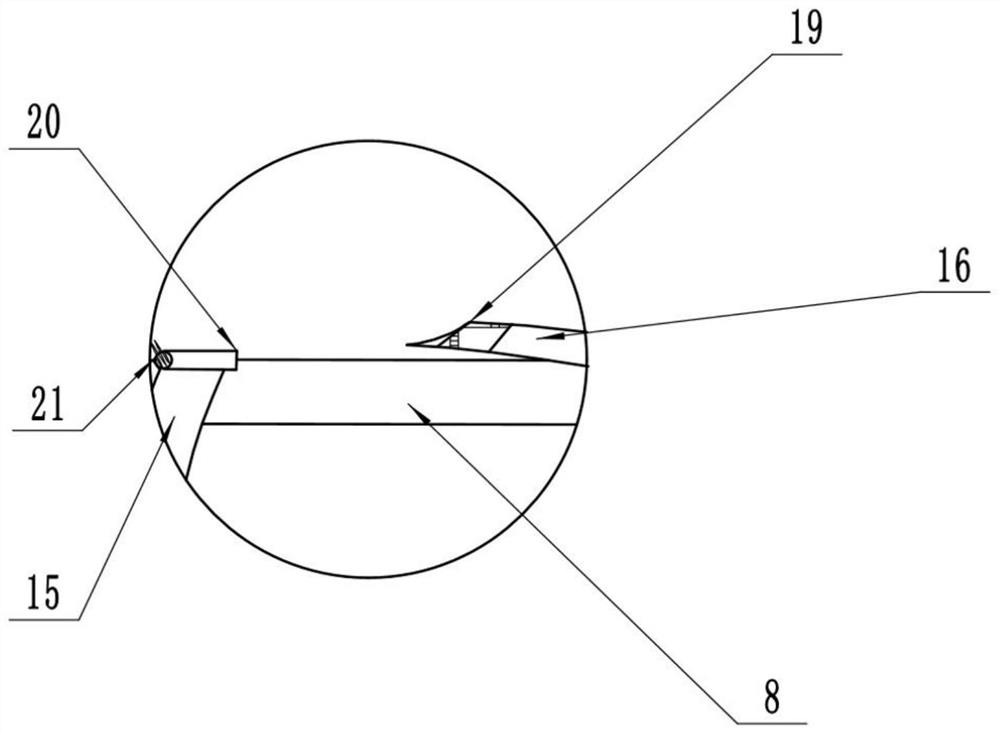

A magnesium alloy refining crucible with improved purity

The invention discloses a magnesium alloy refining crucible with improved purity and its application in the field of metal processing, in order to overcome the disadvantages in the prior art that the magnesium alloy is only in the preliminary processing state and the metal performance of the magnesium alloy is not up to standard, in order to overcome this defect The technical solution includes a refining crucible body with an elliptical cross-section, and the refining crucible body is provided with a feed inlet, a stirring and diverting device, and a cryogenic treatment chamber in sequence along the material supply direction, and the stirring and diverting device includes a circular cross-section The inner ring rotor and the circular gear driving the inner ring rotor, the inner ring rotor meshes with the circular gear, and the bottom end of the inner ring rotor has an arc-shaped notch, and an arc-shaped rotating plate is fixedly connected to the inside of the notch. Compared with the traditional refining crucible, the technical solution utilizes the circumferentially rotating inner ring rotor to perform hot rolling treatment on the magnesium alloy, which reduces the molecular gap inside the magnesium alloy and improves the metal properties of the magnesium alloy.

Owner:NANYANG INST OF TECH

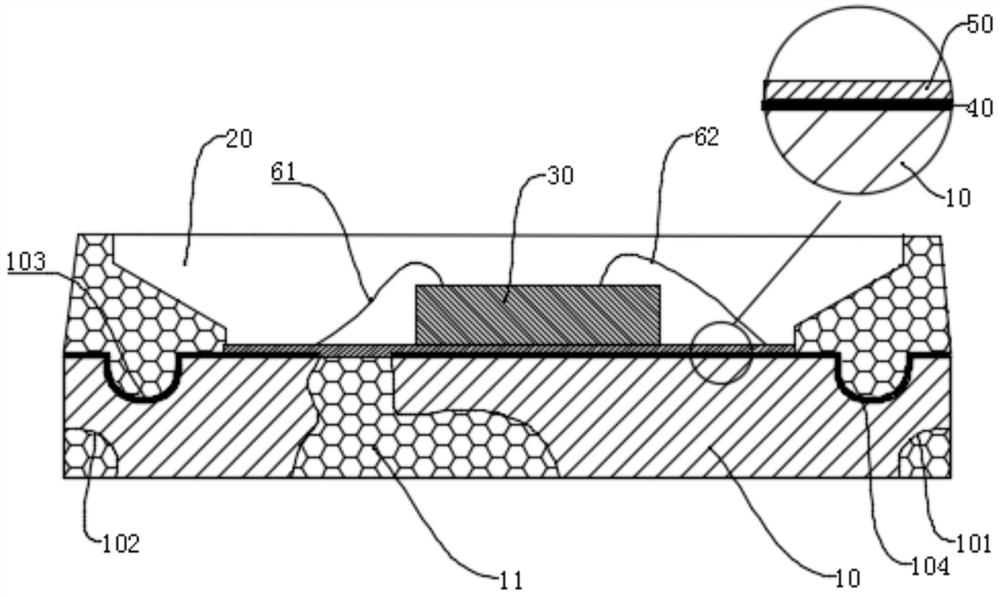

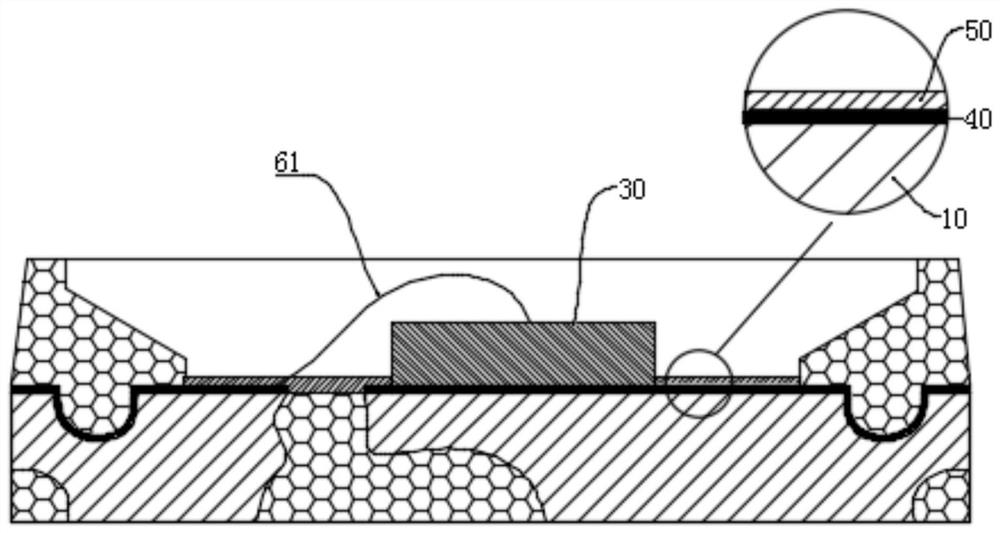

Anti-vulcanization LED lamp bead

PendingCN111834507AImprove moisture resistanceImprove sealingSemiconductor devicesEngineeringSilica gel

The invention discloses an anti-vulcanization LED lamp bead, which comprises a bracket, an LED accommodating cavity with an open top, and an LED chip, wherein the LED accommodating cavity is formed byenclosing an insulating material positioned at the top of the bracket and the top of the bracket together, the LED chip is positioned in the LED accommodating cavity, the top of the bracket is covered with a gold plating layer, the bottom of the LED accommodating cavity is divided into a fixed area and a light reflecting area, the bottom of the LED chip is fixed to the fixed area, and the light reflecting area is provided with a light reflecting layer. According to the invention, the vulcanization resistance of a product can be greatly improved, the reliability is high, and the service life of the product can be greatly prolonged; pits are respectively formed in the top and the bottom of the bracket, and even the side surface of the isolation gap can be an uneven curved surface, so that harmful gas and water vapor are more difficult to enter the chip from the contact surface of the bracket and the thermosetting plastic; and the LED accommodating cavity is filled with the modified silica gel, so that the molecular gap is small, the air tightness is good, and the vulcanization resistance is high.

Owner:SHENZHEN DATE ENG TECH

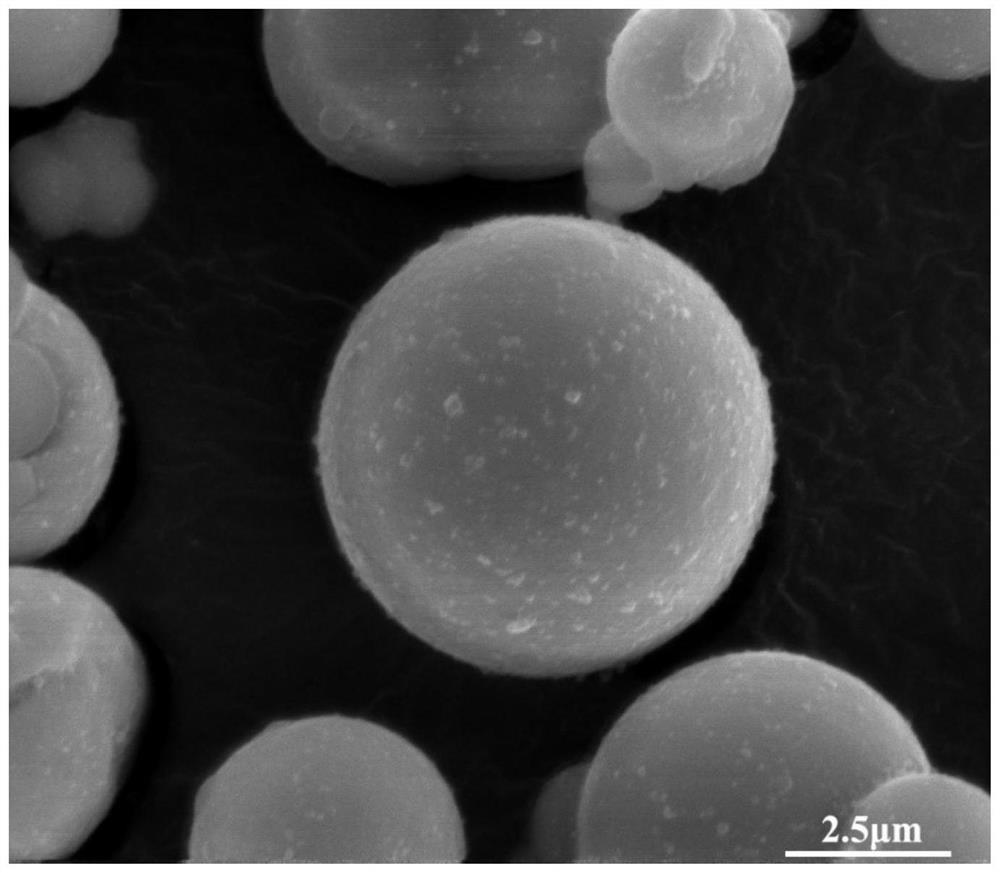

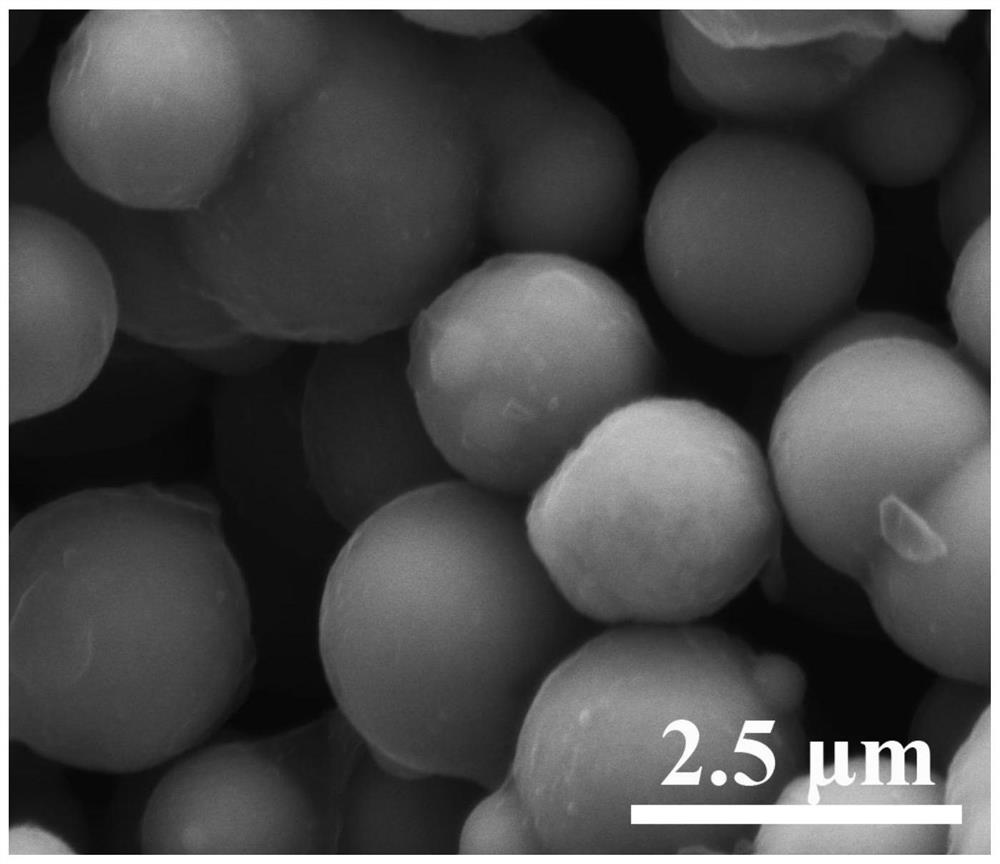

Iron-based magnetic powder with double coating layers as well as preparation method and application of iron-based magnetic powder

PendingCN114664509ASolubility suitableImprove heat resistanceInorganic material magnetismCores/yokesImideO-Phosphoric Acid

The invention discloses iron-based magnetic powder with double coating layers as well as a preparation method and application of the iron-based magnetic powder. The iron-based magnetic powder with the double coating layers comprises an iron-based magnetic powder inner core, a phosphate coating layer and a bismaleimide resin coating layer from inside to outside. The preparation method of the iron-based magnetic powder with the double coating layers comprises the following steps: 1) dispersing the iron-based magnetic powder into a phosphoric acid solution, and carrying out surface modification to obtain the iron-based magnetic powder with a phosphate coating layer; and 2) dispersing the iron-based magnetic powder with the phosphate coating layer into a bismaleimide resin solution, and carrying out surface coating to obtain the iron-based magnetic powder with double coating layers. A magnetic powder core prepared from the iron-based magnetic powder with the double coating layers has the advantages of being good in heat resistance, low in loss and low in preparation cost.

Owner:SOUTH CHINA UNIV OF TECH

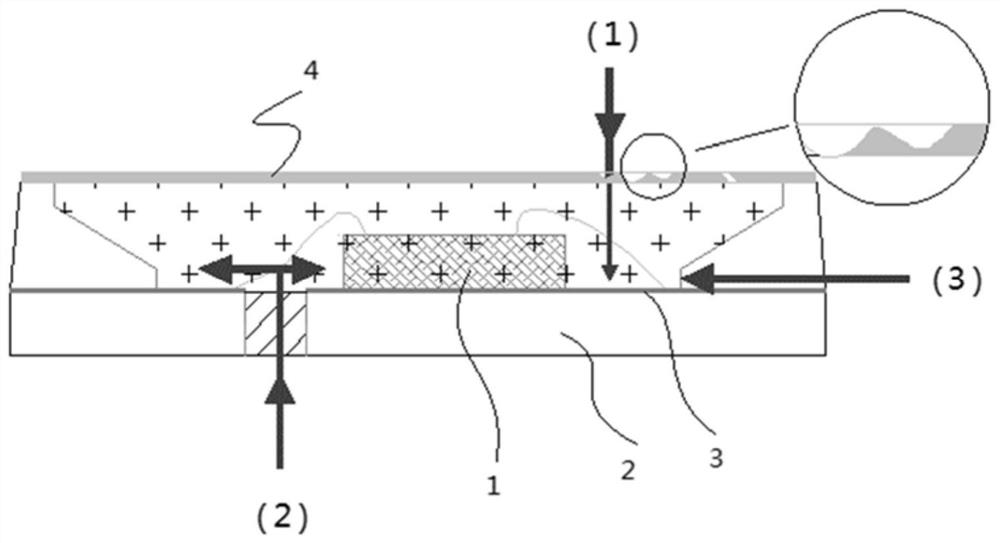

Preparation method of nanoscale carbon material

InactiveCN112850688AImprove finished product qualityImprove stabilityNano-carbonPtru catalystMetallurgy

The invention discloses a preparation method of a nanoscale carbon material, which relates to the technical field of nano carbon material preparation. The preparation method of the nanoscale carbon material comprises the following raw materials in parts by weight: 10-50 parts of hydrocarbon, 10-50 parts of an oxygen element-containing compound and 1-3 parts of transition metal, and comprises the eight steps of raw material dilution, solution mixing, raw material crystallization, grinding into powder, high-temperature reaction, taking out and soaking, drying and grinding. According to the preparation method of the nanoscale carbon material, any catalyst does not need to be added in the preparation process, so that impurities in the catalyst are prevented from influencing the finished product quality and performance of the nanoscale carbon material, the stability of the prepared nanoscale carbon material is improved, the raw materials are mixed more uniformly, and the raw materials are separated out by utilizing a crystallization method after mixing, and a raw material with better purity is obtained; the molecular gaps among the raw materials can be effectively reduced, so that the raw materials are more pure while being mixed more uniformly, and the finished product quality of the nanoscale carbon material is improved.

Owner:成都市丽睿科技有限公司

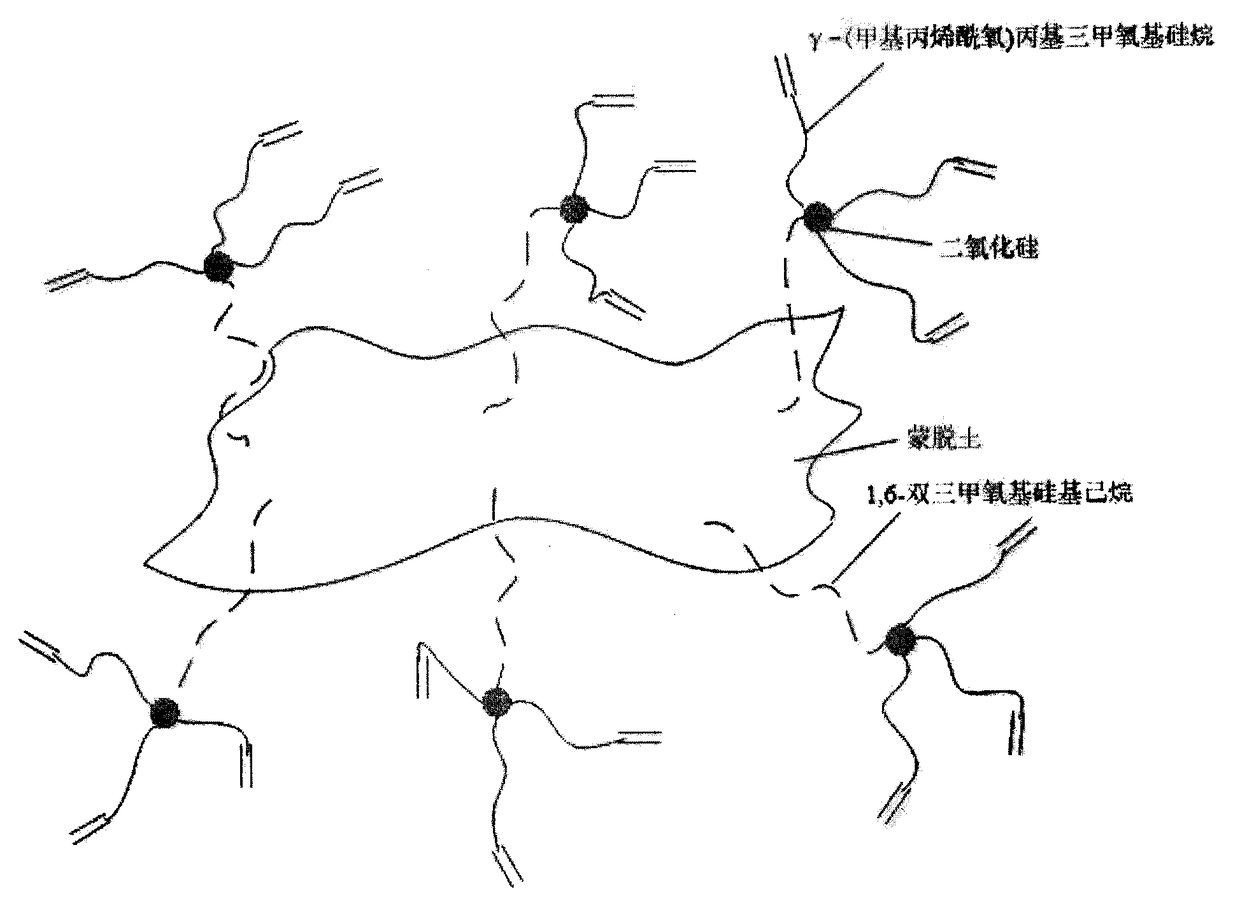

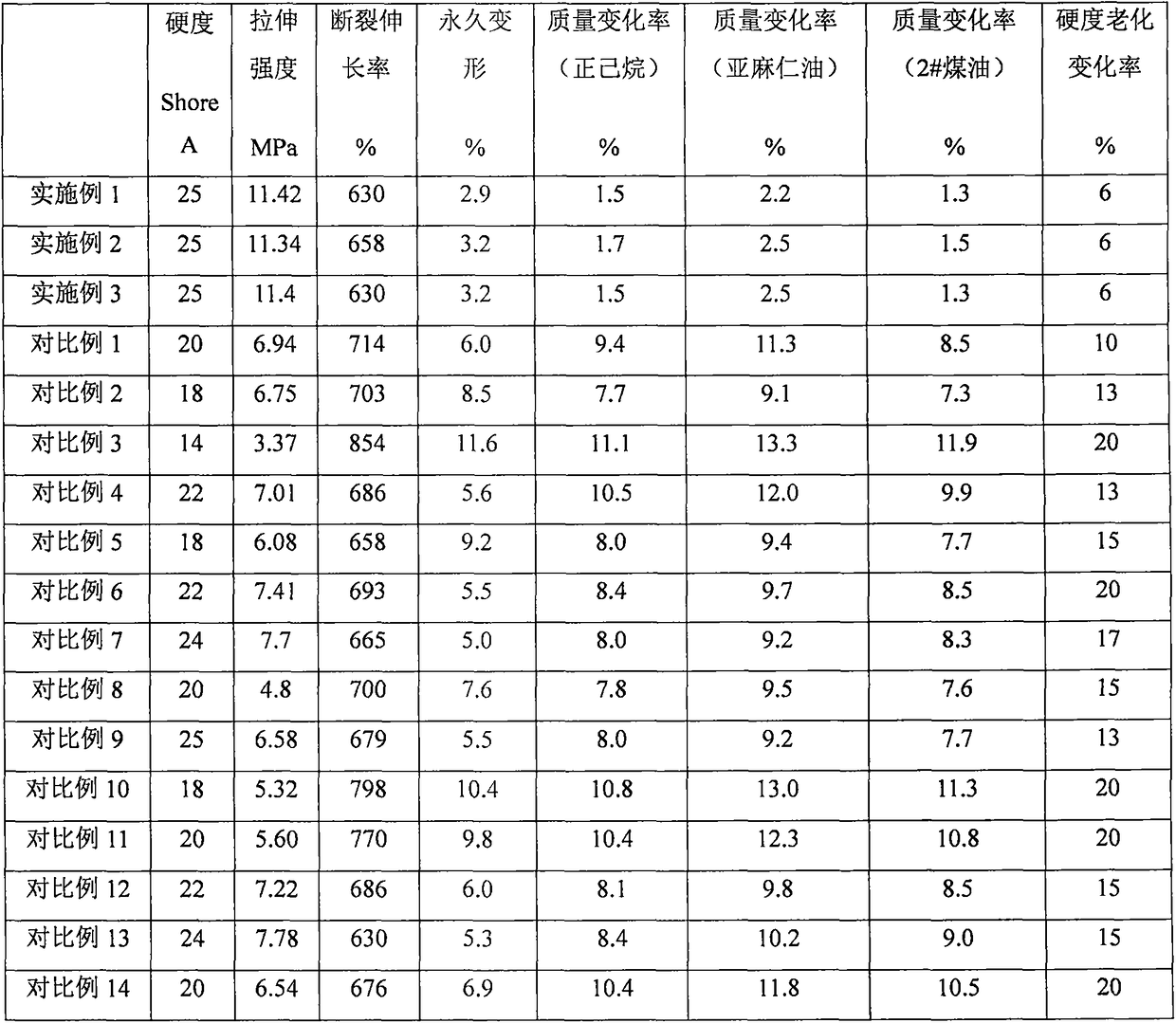

Light-colored solvent-resistant natural rubber vulcanized rubber and preparation method thereof

The invention relates to light-colored solvent-resistant natural rubber vulcanized rubber and a preparation method thereof. The preparation method is characterized by utilizing a modification processof double filler agent compounding and stepwise filler addition so as to prepare montmorillonoid / silicon dioxide functional hybrid filler, and further carrying out processes of film orientation, prevulcanization, stress stretching and vulcanization formation, so as to obtain the light-colored solvent-resistant natural rubber vulcanized rubber, wherein the rubber has a good filler-rubber mutual effect and a small cross-linked network molecular gap and comprises an effective organic solvent blocking layer.

Owner:镇江市江冠电器有限公司

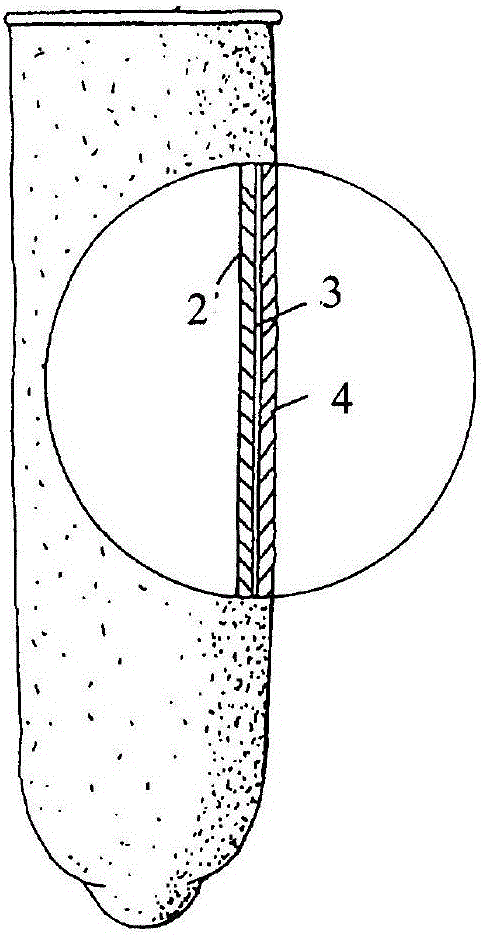

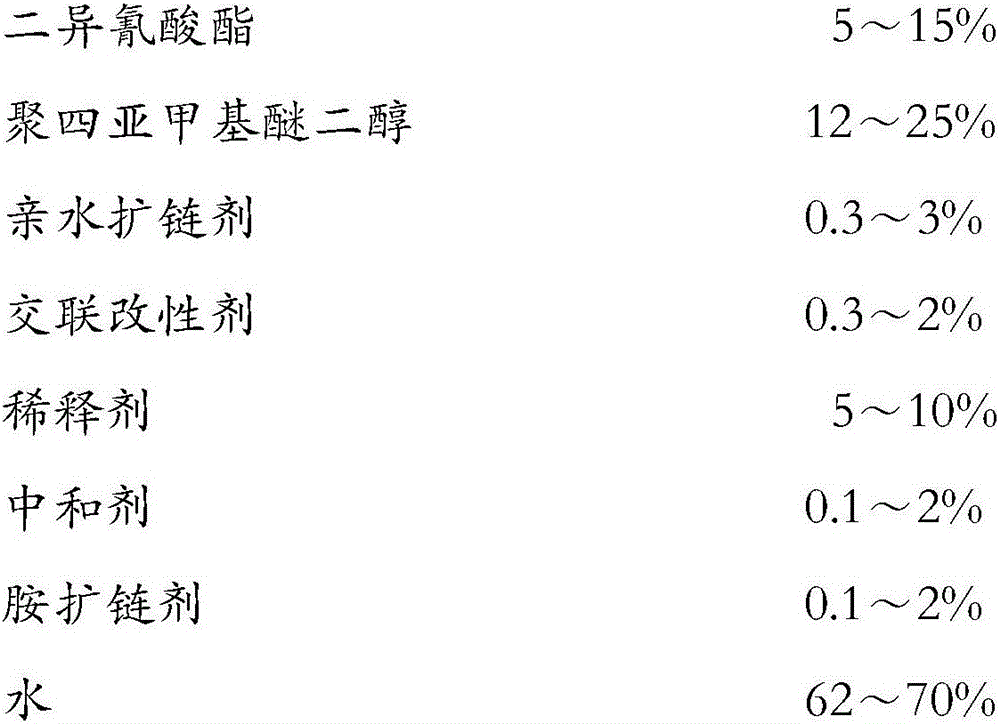

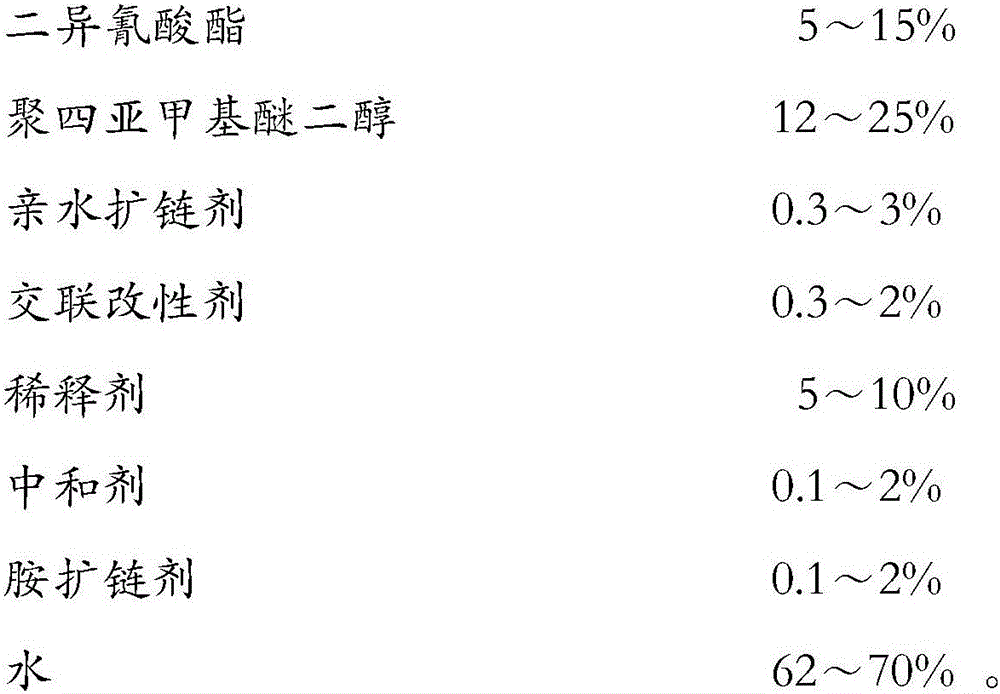

A kind of all-combined or composite water-based polyurethane condom

ActiveCN103692733BNo special smellNon-allergenicSynthetic resin layered productsRubber layered productsWater basedEther

The invention discloses a full-synthetic or composite water-based polyurethane condom. The full-synthetic or composite water-based polyurethane condom comprises an inner layer, a middle layer and an outer layer, wherein at least two of the three layers are made of water-based polyurethane composite materials. The full-synthetic or composite water-based polyurethane condom comprises the following materials in percentage by weight: 5-15% of diisocyanate, 12-25% of polytetramethylene ether glycol, 0.3-3% of hydrophilic chain extender, 0.3-2% of crosslinking modifying agent, 5-10% of diluting agent, 0.1-2% of a neutralizing agent, 0.1-2% of an amine chain extender and 62-70% of water. The full-synthetic or composite water-based polyurethane condom disclosed by the invention has the beneficial effects of no toxicity, no special smell, no sensitization, high strength, thinner effect and the like, and is capable of blocking viruses of venereal diseases. Compared with the existing polyurethane material, the full-synthetic or composite water-based polyurethane condom disclosed by the invention has the advantages that after film forming, the elongation is higher, the modulus is lower and the strength is higher; the elongation of the film is not less than 980%, the tensile strength is not less than 1900psi and the bursting pressure of the condom is not less than 1.0kPa.

Owner:山东惠沃盛健康科技有限公司

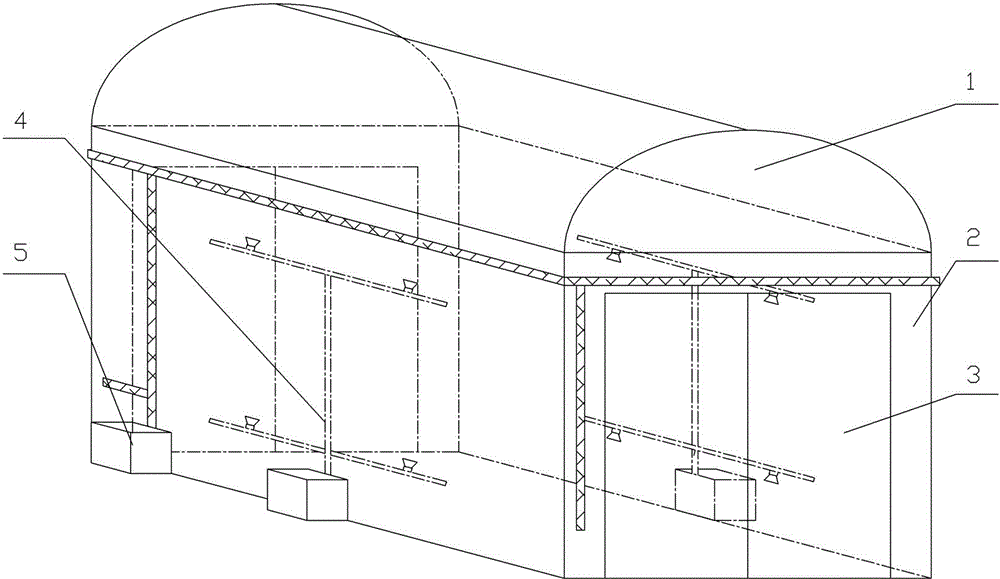

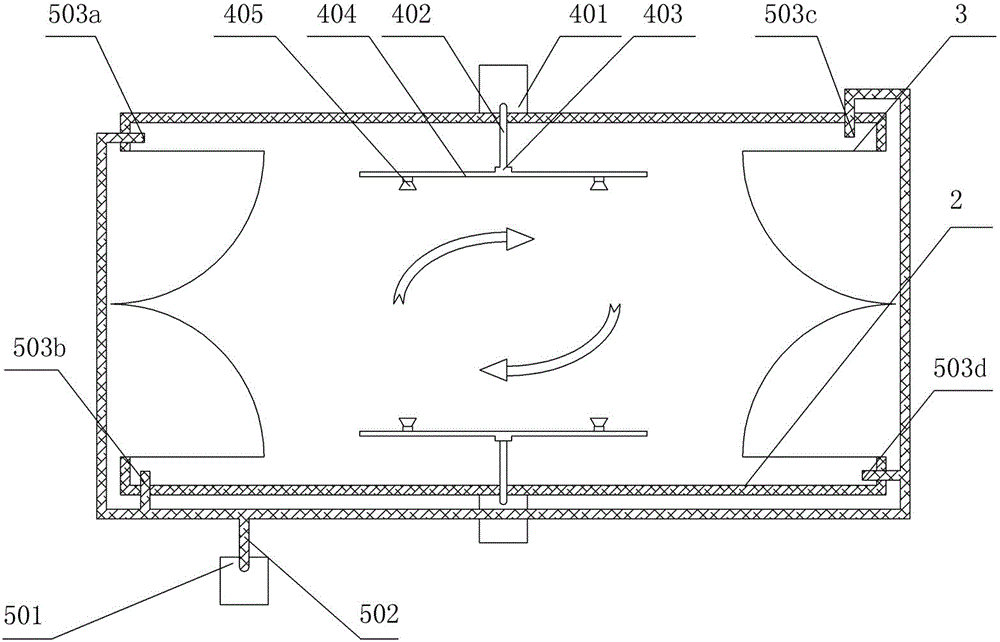

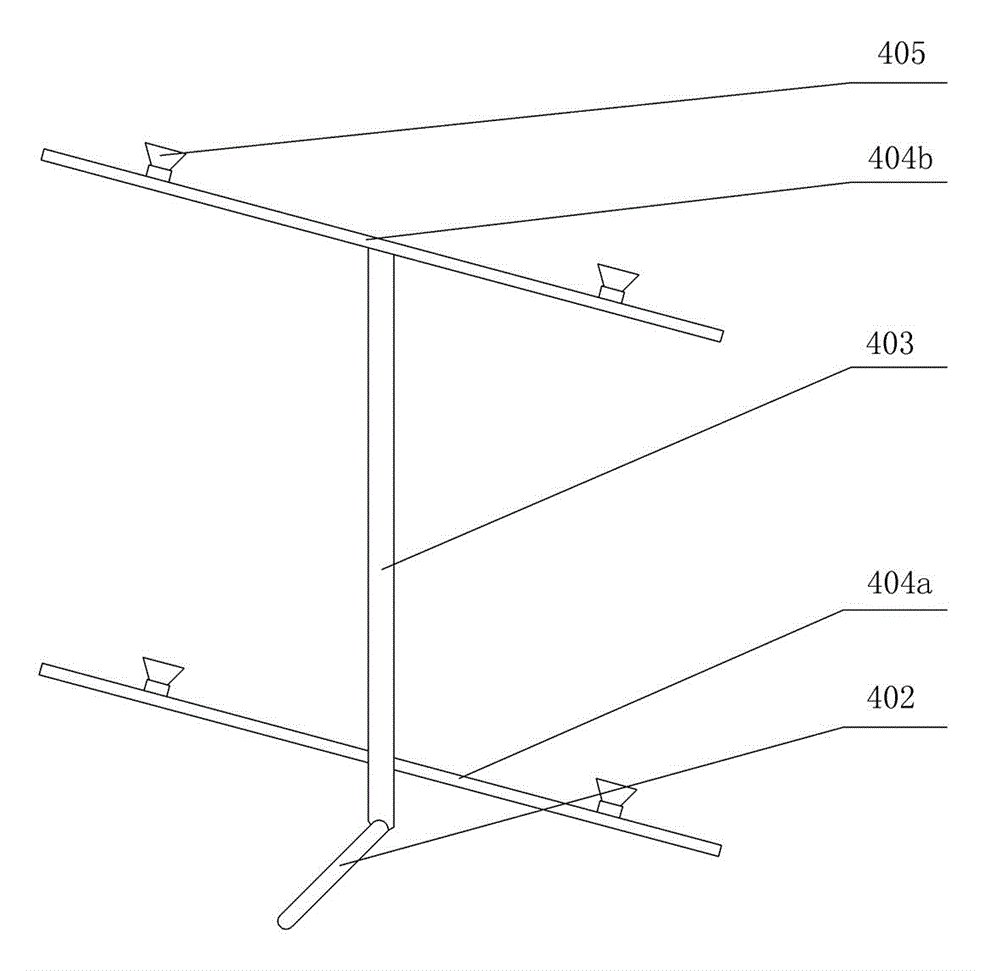

Closed pressurized aerosol disinfection channel

The invention discloses a closed pressurized aerosol disinfection channel which comprises a main frame structure, spray mechanisms and a pressurization mechanism. The main frame structure comprises a roof, walls and doors which are combined with one another; the spray mechanisms comprise external spray disinfectors, gas outlet pipes, vertical pipes, transverse pipes and mist spray nozzles, the spray sterilizers are communicated with the gas outlet pipes, the gas outlet pipes penetrate the walls and are communicated with the vertical pipes in a channel, the transverse pipes are communicated with the tops and the bottoms of the vertical pipes, the corresponding mist spray nozzles are arranged on two sides of the each transverse pipe, and the internal pressures of the mist spray nozzles are higher than the pressure of the channel; the pressurization mechanism comprises an external air compressor, a compressed air pipeline and pressurization openings, the compressed air pipeline penetrates the walls, and the pressurization openings are formed in four corners in the channel. The closed pressurized aerosol disinfection channel has the advantages that the closed disinfection channel can be pressurized, accordingly, movement of molecules can be intensified, the molecules can be quickly diffused to optional positions of the channel, excellent transport vehicle disinfection effects can be realized, and transport vehicles can be thoroughly disinfected.

Owner:刘龙君 +1

Preparation method of rubber diaphragm used for temperature sensing element of temperature control valve

The invention discloses a preparation method of a rubber diaphragm used for a temperature sensing element of a temperature control valve. The method includes the following steps that urea and water are mixed evenly, sodium hydroxide is added into the mixture, the mixture is stirred evenly and heated, the mixture is dropwise added into a magnesium chloride aqueous solution, stirring continues, sodium oleate, talcum powder and titanate are added, stirring continues, and after suction filtration, washing, drying and grinding, a prefabricated material is obtained; polyurethane rubber, epichlorohydrin rubber and methyl phenyl silicone rubber are plasticated, then coconut fibers, calcium sulfate whiskers, the prefabricated material, medical stone powder, an active agent and an antioxidant are added, kneaded and put into an open mill, tetramethylthiolam monosulfide, tert-butyl hydrogen peroxide, 4,4'-dithiomorpholine and toner are added and mixed, thin-passing is conducted, sheet forming is conducted, and a vacuum plate vulcanizing machine is used for first vulcanization and then secondary vulcanization to obtain the rubber diaphragm used for the temperature sensing element of the temperature control valve. The obtained rubber diaphragm has small compression deformation at high temperature and good sealing effects, no leakage occurs, the service life is long, the preparation method issimple and the cost is low.

Owner:谭八一

Formula of soft capsule shell

InactiveCN102225055BControl migrationIncreased chance of being oxidizedCapsule deliveryPEG 400Plasticizer

The invention relates to a formula of a soft capsule shell, which comprises gelatin, water, glycerol and sorbitol. The formula is characterized in that the proportion of a plasticizer (namely glycerol) and sorbitol is adjusted, and the components are as follows by weight percentage: gelatin 80-100%, water 60-80%, plasticizer 40-60%, antioxidant 0.2-1.2%, and PEG-400 (polyethylene glycol-400) 5-15%. Due to high requirements of soft capsules for the plasticity of shell materials, the moisturizing property of sorbitol is considered and the shell is ensured not to cause softening, deformation, adhesion, liquid leakage and other problems of the soft capsule due to excessive water content, so that the plasticizer is mixed for use to ensure the stability of the capsule. The antioxidant can prevent crosslinking due to oxidation reactions among the substances in the shell material, so as to cause time delay in disintegration of the soft capsule. The addition of the antioxidant in the formula provided by the invention can effective inhibit oxidation, so as to ensure the disintegration of the soft capsule and improve the quality of the shell material.

Owner:贵州地道药业有限公司

A kind of preparation method of all-combined or composite water-based polyurethane condom

The invention discloses a preparation method of a fully composite or composite water-based polyurethane condom. Acetone is used as a diluent, and diisocyanate and polytetramethylene ether glycol are added in proportion, mixed and reacted, and then a hydrophilic chain extender and a cross-linking agent are added. Combine modifier to prepare prepolymer; then add neutralizer and cool down with ice-water mixture, finally add amine chain extender to prepare water-based polyurethane emulsion, and finally make it with mold. Beneficial effects of the present invention: the composite or all-composite water-based polyurethane condom prepared by the present invention is non-toxic, has no special smell, has no sensitization, has high strength, can be thinner, has smaller molecular gaps, and can more effectively block venereal disease viruses, etc. . At the same time, the defects of low elongation after film formation, high modulus and poor strength existing in the existing polyurethane material and its preparation method are solved. Moreover, the method is simple, the operation is easy, the process conditions are mild, and there is no special requirement for equipment. The production of the condom can be carried out by using a traditional assembly line, which is convenient for mass processing.

Owner:山东惠沃盛健康科技有限公司

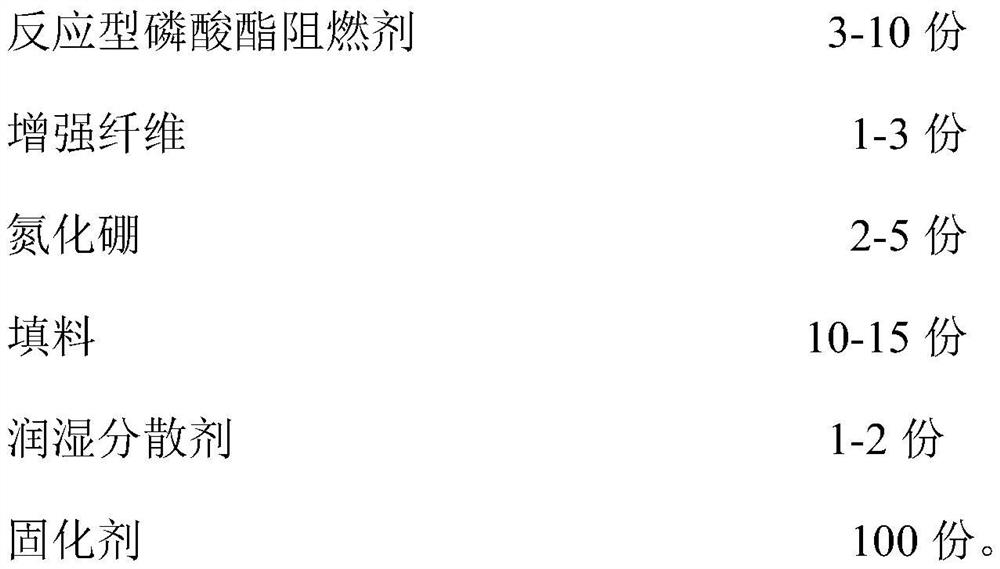

Polyaspartic acid ester, preparation method thereof and application of polyaspartic acid ester in sealing coating

ActiveCN113480730AImprove mechanical propertiesAnti-electron activation effectFireproof paintsNuclear energy generationPolyaspartic acidEthyl ester

The invention discloses a polyaspartic acid ester. The polyaspartic acid ester is prepared by polymerizing a mixture of 2, 4-diamino-3, 5-dimethylthiotoluene and 3, 3 '-dimethyl-4, 4'-diamino-dicyclohexylmethane and diethyl maleate. The invention also discloses a preparation method of the polyaspartic acid ester and a sealing coating taking the polyaspartic acid ester as a raw material. According to the polyaspartic acid ester disclosed by the invention, the toughness and the tensile strength are improved by the 2, 4-diamino-3, 5-dimethylthiotoluene, and meanwhile, a benzene ring structure of the 3, 3 '-dimethyl-4, 4'-diamino-dicyclohexylmethane has an electron activation resisting effect, so that the polyaspartic acid ester has excellent gamma-ray irradiation resistance. The sealing coating disclosed by the invention has flexibility and strength, also has excellent gamma-ray irradiation resistance and shielding barrier property, and can prevent air leakage; and meanwhile, the sealing coating has durability and flame retardance, and still has strong flame propagation resistance after being irradiated for a long time.

Owner:T&H NOVEL MATERIALS (SUZHOU) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com