A method for finishing cotton yarn with antibacterial organosilicon quaternary ammonium salt

A technology of organic silicon quaternary ammonium salt and cotton yarn, which is applied in fiber treatment, biochemical fiber treatment, plant fiber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

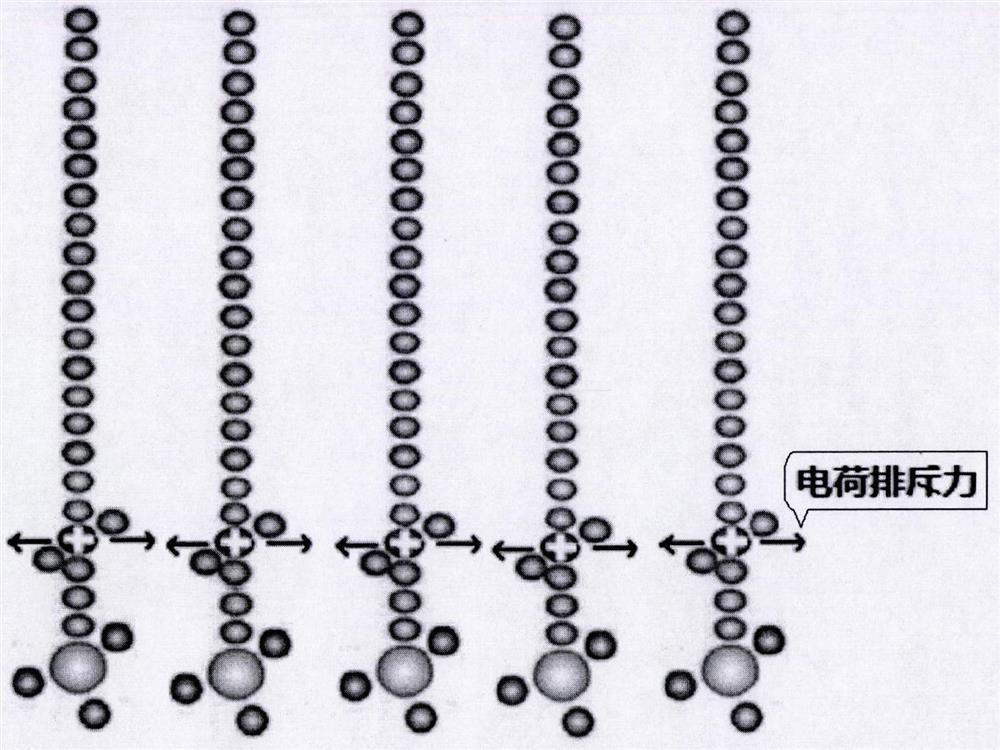

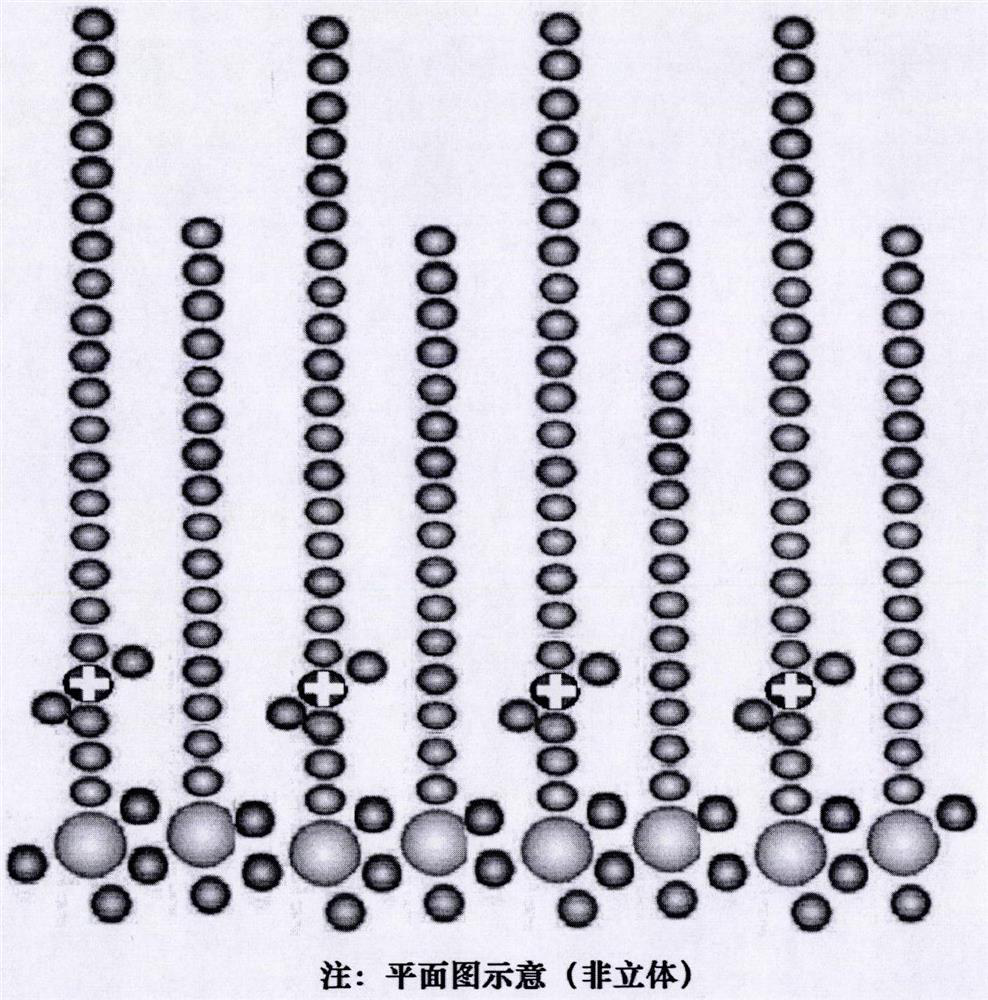

Problems solved by technology

Method used

Image

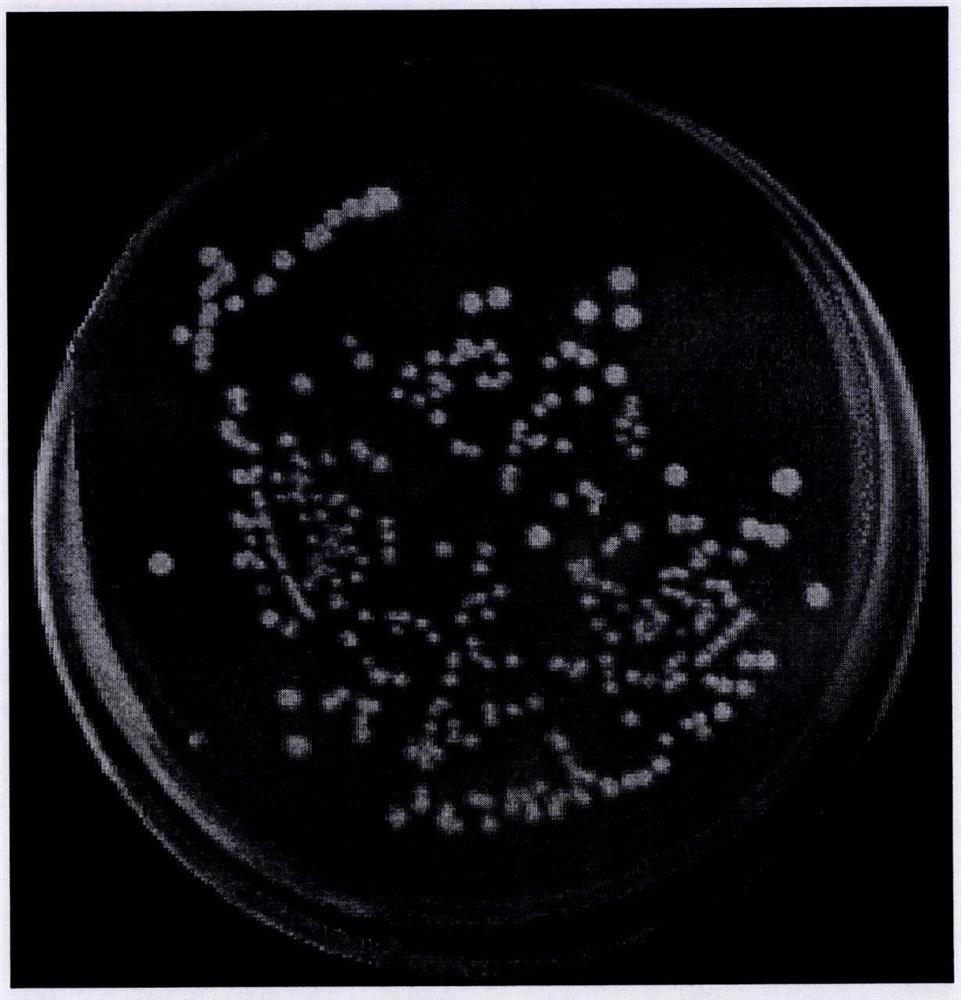

Examples

Embodiment 1

[0030] 1. Fabric: Pure cotton poplin woven fabric (40x40) after desizing, refining and bleaching;

[0031] 2. For finishing, use 5% glutamic acid aqueous solution prepared by dissolving 20mmol / L phosphate with a pH of 6.8-7.0 at 80°C, soak the fabric at 80°C for 1 hour and dry it at 50°C to make the excess rate 60%; 2% N, N-dimethyl-N-12 alkyl aminopropyl trimethoxy silicon quaternary ammonium salt and 0.5% 16 alkyl trimethoxy silane solution dissolved in 10mM phosphate buffer solution with a pH of 6.8-7.0 , soak the fabric for 1 hour and then dry it so that the excess rate is 50%, and then dry it with air at 50°C; transfer the finished cotton yarn fabric to a 20mM rinse solution with a pH of 5.0, soak it for 1 hour, drain and dry it, and then transfer it to a 20mM rinse solution with a pH of 5.0. Soak in 10mM rinsing solution for 1 hour, drain and spin dry (ie, double soaking and double tying treatment), until the residual rate is 30%; then bake at 120°C for 1 hour, then turn...

Embodiment 2

[0035] 1. Fabric: Pure cotton poplin woven fabric (40x40) after desizing, refining and bleaching;

[0036]2. For finishing, use 5% glutamic acid aqueous solution prepared by dissolving 20mmol / L phosphate with a pH of 6.8-7.0 at 80°C, soak the fabric at 80°C for 1 hour and dry it at 50°C to make the excess rate 60%; 2% N, N-dimethyl-N-14 alkyl aminopropyl trimethoxy silicon quaternary ammonium salt and 0.5% 16 alkyl trimethoxy silane solution dissolved in 10mM phosphate buffer solution with a pH of 6.8-7.0 , soak the fabric for 1 hour and then dry it so that the excess rate is 50%, and then dry it with air at 50°C; transfer the finished cotton yarn fabric to a 20mM rinse solution with a pH of 5.0, soak it for 1 hour, drain and dry it, and then transfer it to a 20mM rinse solution with a pH of 5.0. Soak in 10mM rinsing solution for 1 hour, drain and spin dry (ie, double soaking and double tying treatment), until the residual rate is 30%; then bake at 120°C for 1 hour, then turn ...

Embodiment 3

[0040] 1. Fabric: Pure cotton poplin woven fabric (40x40) after desizing, refining and bleaching;

[0041] 2. For finishing, use 5% glutamic acid aqueous solution prepared by dissolving 20mmol / L phosphate with a pH of 6.8-7.0 at 80°C, soak the fabric at 80°C for 1 hour and dry it at 50°C to make the excess rate 60%; Transfer to 10mM phosphate buffer solution with a pH of 6.8-7.0 to dissolve 2% N, N-dimethyl-N-16 alkyl aminopropyl trimethoxysilane quaternary ammonium salt and 0.5% 16 alkyl trimethoxysilane solution , soak the fabric for 1 hour and then dry it so that the excess rate is 50%, and then dry it with air at 50°C; transfer the finished cotton yarn fabric to a 20mM rinse solution with a pH of 5.0, soak it for 1 hour, drain and dry it, and then transfer it to a 20mM rinse solution with a pH of 5.0. Soak in 10mM rinsing solution for 1 hour, drain and spin dry (ie, double soaking and double tying treatment), until the residual rate is 30%; then bake at 120°C for 1 hour, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com