A kind of all-combined or composite water-based polyurethane condom

A water-based polyurethane and condom technology, applied in the direction of synthetic resin layered products, layered products, rubber layered products, etc., can solve the problem of inability to remove water-soluble protein in natural latex condoms, inability to completely prevent HIV penetration, elastic elongation And softness is not good enough, to achieve the effect of no special smell, good mechanical properties, small molecular gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] Concrete preparation method comprises the following steps:

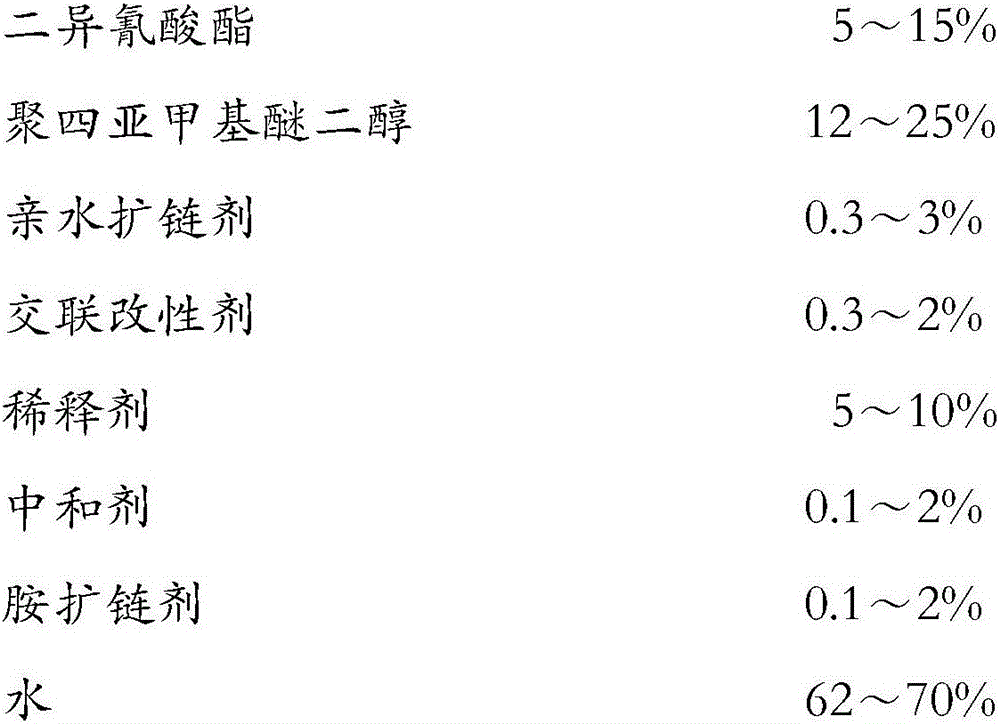

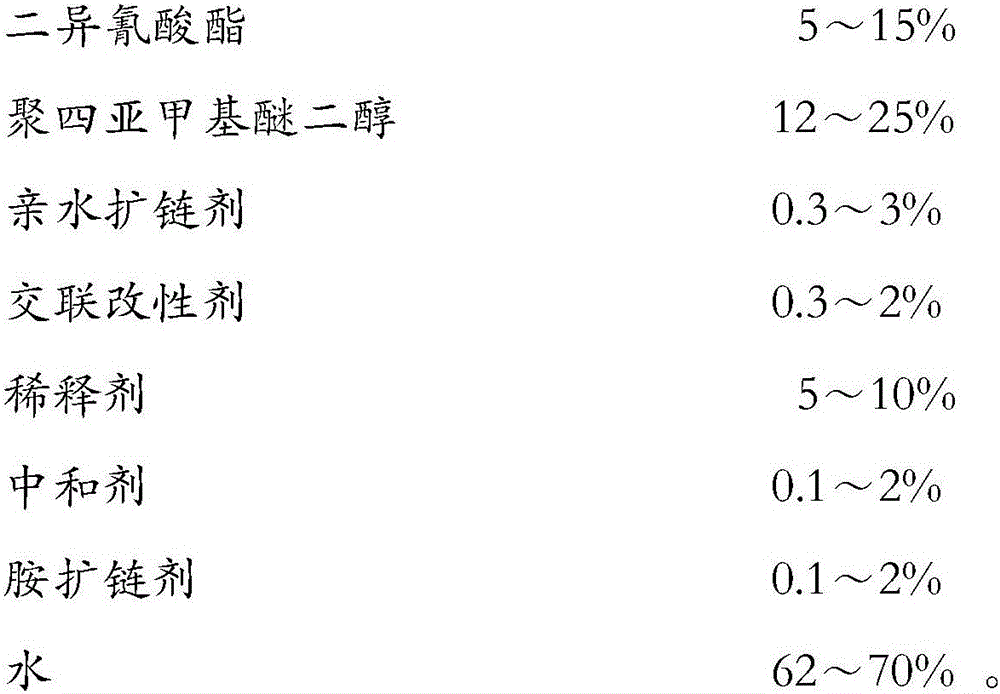

[0046]Step 1, prepolymerization reaction: at room temperature, add diisocyanate and polytetramethylene ether glycol (PTMG) sequentially in proportion, stir and mix and heat up to 50-90°C, after 2 hours of reaction, add hydrophilic chain extender and Diluent, continue to react for 2 hours, then cool down to 40-70°C, then add cross-linking modifier and diluent, continue to react for 2 hours, cool down to below 55°C, add diluent to adjust the viscosity of the system to less than 100Pa·s, Prepare the prepolymer;

[0047] Step 2, emulsification process: add neutralizer and ice-water mixture into the reactor, turn on the stirring, keep the material at -5°C ~ 20°C, slowly add the prepolymer into it, and quickly increase the stirring speed to 2000r / min, emulsification After 10-30 minutes, add an amine chain extender to extend the chain, slowly add the amine chain extender dropwise and finish adding in one hour, and c...

Embodiment 1

[0055] Prepolymerization reaction: at room temperature, add 122g of toluene diisocyanate (TDI) and 120g of polytetramethylene ether glycol (PTMG) with a molecular weight of 1000 into a stirred reactor, stir and mix and heat up to 50-60°C, and react After 2 hours, add 3gDMPA and 10g acetone, continue to react for 2 hours, then cool down to 40°C, then add concentration is 30g of acetone diluent of 10% neopentyl glycol and trimethylolpropane mixture (i.e. neopentyl glycol and trimethylolpropane The quality of methylol propane mixture is 3g, acetone is 27g), after continuing reaction for 2 hours, cool down to below 55 ℃, add 13g acetone to adjust system viscosity, make prepolymer.

[0056] Emulsification process: Add 1g NaOH and 691g ice-water mixture into a 1000ml reactor, turn on the stirring, keep the temperature of the material at -5°C ~ 0°C, slowly add the prepolymer into it, and quickly increase the stirring speed to 2000r / min after the addition. Emulsify for 10 minutes, add...

Embodiment 2

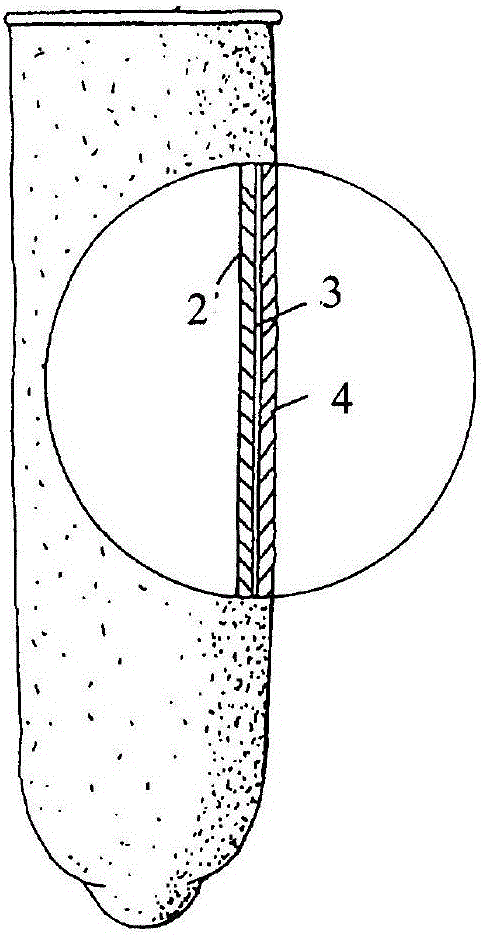

[0064] The prepolymerization reaction and the emulsification process are the same as the steps of the above-mentioned embodiment 1, but in the secondary dipping when the condom is made, it is immersed in the latex, that is, the material of the inner layer 2 and the outer layer 4 is water-based polyurethane, and the material of the middle layer 3 is water-based polyurethane. The material is latex.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com