Thermo-sensitive condom based on waterborne polyurethane and preparation method thereof

A technology of water-based polyurethane and condoms, which is applied in the direction of male contraceptives and coatings, and can solve the problems of large strength drop, poor softness and comfort, and easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

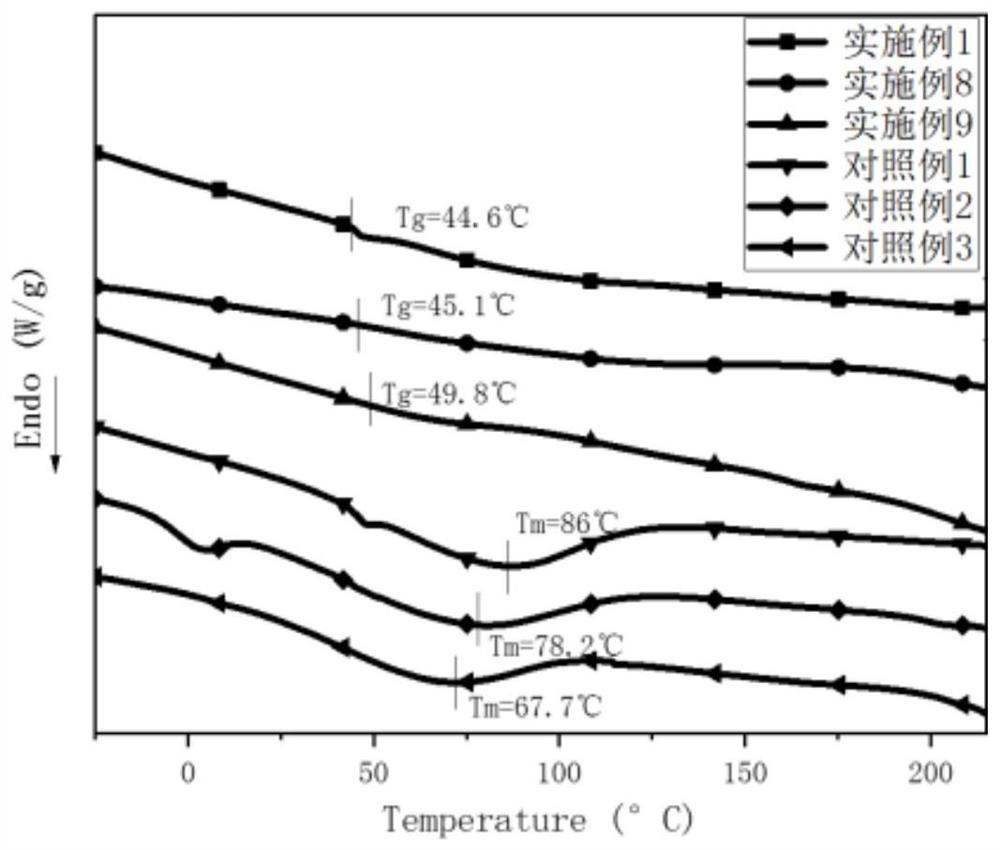

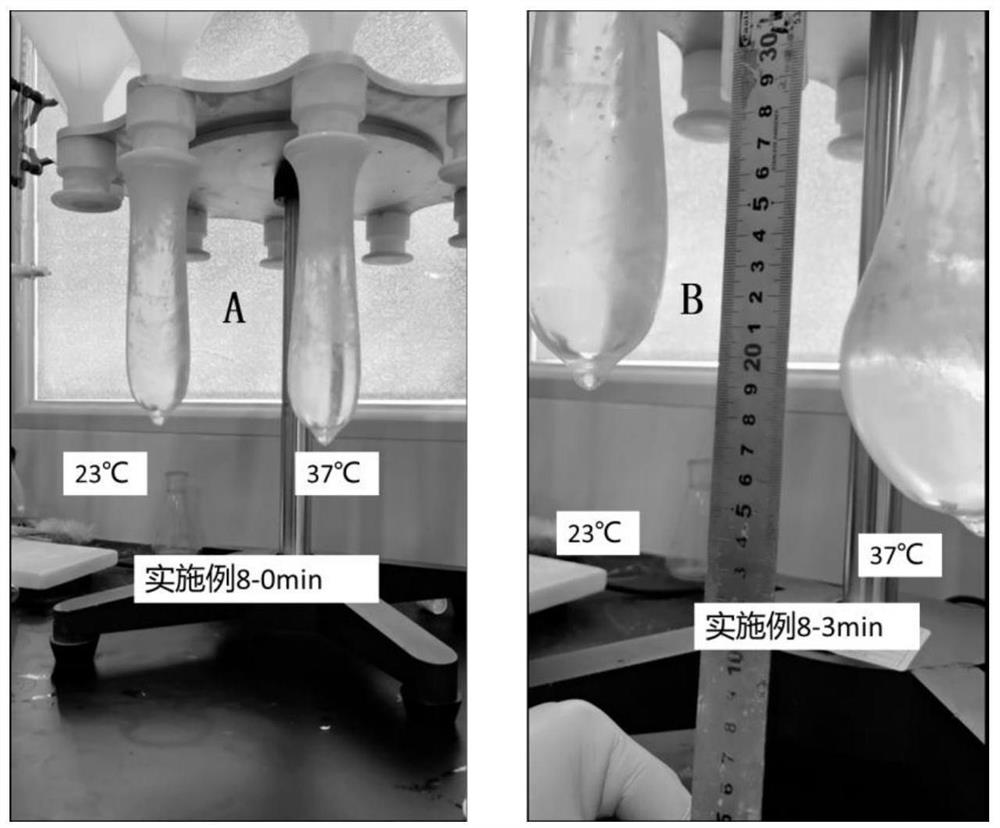

Examples

Embodiment 1

[0106] Preparation of water-based polyurethane thermosensitive condom 01:

[0107] Table 1

[0108]

[0109]Prepare water-based polyurethane heat-sensitive condom according to the formula of above-mentioned table 1, and its specific operation steps are as follows:

[0110] (1) Preparation of water-based polyurethane emulsion:

[0111] R1: During the polymerization reaction, polyether diol A (PTMG3000), polyether diol B (PTMG1000), and polyester diol (PBA2000) of different molecular weights are added according to the ratio, equipped with agitator, thermometer and nitrogen protection device In the reaction kettle, stir and heat up to 80-120°C, vacuum dehydration for 60-120 minutes, then cool down to 50-60°C, add dehydrated non-ionic hydrophilic chain extender N-120 and cross-linking agent CAPA3091, Add diisocyanate (IPDI and HMDI), and organic bismuth catalyst BiCAT81180.56g (accounting for 0.06% by weight based on the solid content of polyurethane emulsion), heat up to 80-...

Embodiment 2

[0118] Preparation of water-based polyurethane thermosensitive condom 02:

[0119] Table 2

[0120]

[0121] Prepare water-based polyurethane heat-sensitive condom according to the formula of above-mentioned table 2, and its specific operation steps are as follows:

[0122] (1) Preparation of water-based polyurethane emulsion:

[0123] R1: During the polymerization reaction, polyether diol A (PTMG3000 and PTMG2000), polyether diol B (PTMG650), and polyester diol (PBA2000) with different molecular weights are added according to the ratio and equipped with agitator, thermometer and nitrogen. In the reaction kettle of the protective device, stir and heat up to 80-120°C for vacuum dehydration for 60-120 minutes, then cool down to 50-60°C, add diisocyanate (IPDI and HMDI), and organic bismuth catalyst BiCAT81180.66g (accounting for The solid content of polyurethane emulsion is 0.06% by weight), heated up to 80-90°C, reacted for 90 minutes under stirring and nitrogen protection...

Embodiment 3

[0128] Preparation of water-based polyurethane thermosensitive condom 03:

[0129] table 3

[0130]

[0131] Prepare water-based polyurethane heat-sensitive condom according to the formula of above-mentioned table 3, and its specific operation steps are as follows:

[0132] (1) Preparation of water-based polyurethane emulsion:

[0133] R1: During the polymerization reaction, polyether diol A (PTMG3000), polyether diol B (PTMG1000), and polyester diol (PBA2000) of different molecular weights are added according to the ratio, equipped with agitator, thermometer and nitrogen protection device In the reaction kettle, stir and heat up to 80-120°C, vacuum dehydration for 60-120 minutes, then cool down to 50-60°C, add dehydrated non-ionic hydrophilic chain extender N-120, add diisocyanate (IPDI and HDI), and organotin catalyst TMG 218, 0.39g (0.04% by weight percentage of polyurethane emulsion solid content), warming up to 80-90 ° C, under stirring and nitrogen protection, react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com