Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Reasonable design of process steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technology for processing CrNiMo series steel material

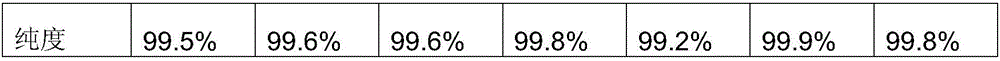

ActiveCN102877073AGuaranteed purityHigh strengthSolid state diffusion coatingIngotMaterials processing

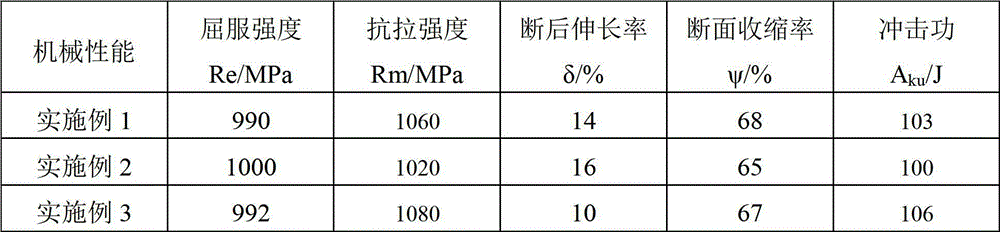

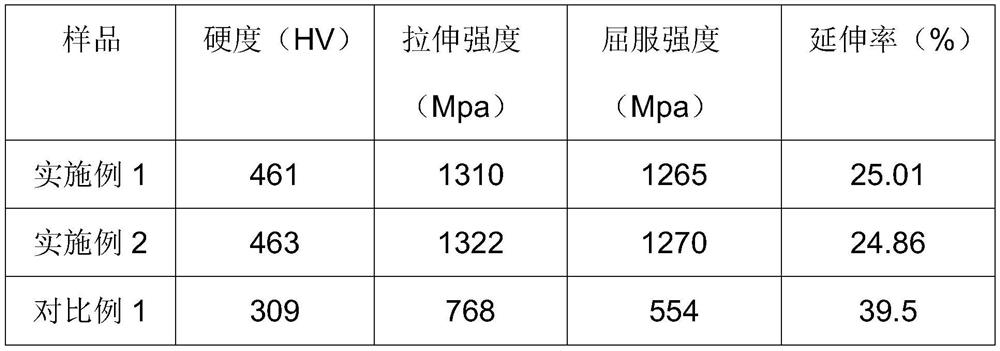

The invention discloses a technology for processing a CrNiMo series steel material. The technology comprises the steps of adopting an electroslag remelting technology to obtain a steel ingot which contains 0.14-0.19% of C, 1.5-1.8% of Cr, 0.17-0.35% of Si, 0.4-0.6% of Mn, 0.25-0.36% of Mo, 1.4-1.7% of Ni, 0-0.035% of P and 0-0.030% of S according to percent by weight, forging the steel ingot, then carrying out normalizing and high temperature tempering, carburizing, high temperature tempering and oil quenching, and finally, carrying out low temperature tempering to complete the processing. According to the technology, a heat treatment processing technology which is simple and easy to operate is utilized to ensure the product quality, the problem that a loading part of a coal machine fails to work is solved, the service life of a product is prolonged, and the producing and processing costs are lowered.

Owner:常熟天地煤机装备有限公司

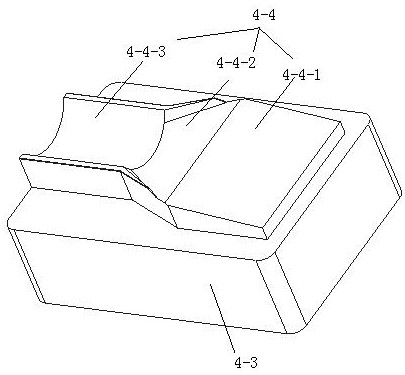

Processing technology for prolonging service life of guiding slide shoes

ActiveCN101608546AReasonable design of process stepsSimple and efficient operationFoundry mouldsSlitting machinesEngineeringHardness

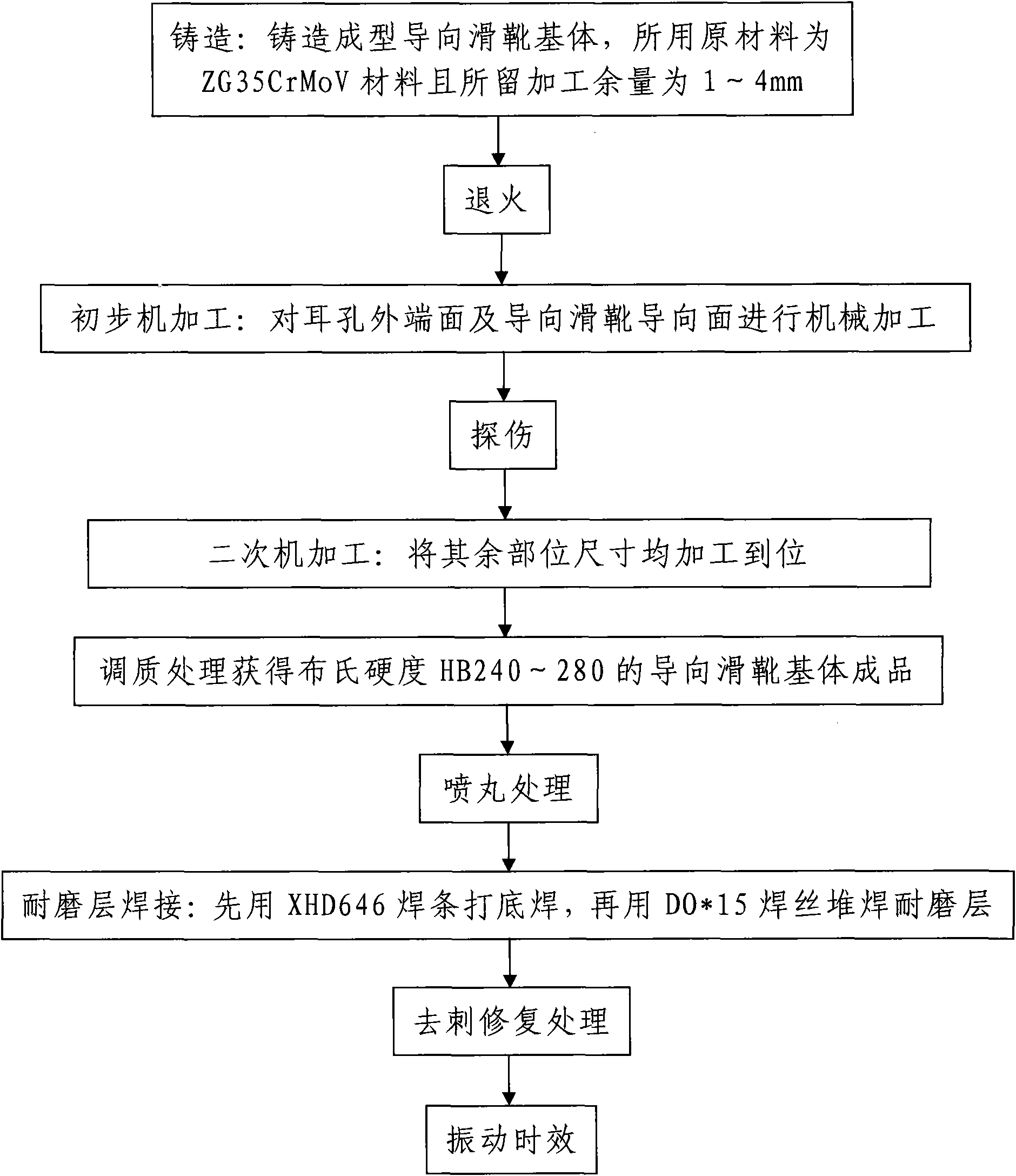

The invention discloses a processing technology for prolonging the service life of guiding slide shoes. The processed guiding slide shoes consist of guiding slide shoe base bodies and wear-resisting layers, wherein the wear-resisting layers are welded on guiding surfaces. The technology comprises the following steps: firstly, casting: the guiding slide shoe base bodies are cast and shaped, the raw material is ZG35CrMoV, and the remained processing tolerance is from 1 mm to 4 mm; secondly, annealing; thirdly, primary machining: the outer end surfaces of lugs and the guiding surfaces are machined; fourthly, fault detection; fifthly, secondary machining: the rest part size is respectively machined; sixthly, quality regulation treatment: the finished guiding slide shoe base bodies with the brinell hardness of 240 to 280 are obtained; seventhly, peening treatment; eighthly, welding of wear-resisting layers: XHD646 welding bars are used for carrying out bottom welding firstly, and then DO*15 is used for carrying out surface welding on the wear-resisting layers; ninthly, deburring and repairing treatment; and tenthly, vibration aging. The invention has the advantages of reasonable design and convenient operation, and the processed guiding slide shoes have the advantages of high quality and long service life.

Owner:XIAN COAL MINING MACHINERY

Preparation method of extracts of effective fractions of lychee seeds

ActiveCN102526315AHigh extraction rateReasonable design of process stepsAntipyreticMetabolism disorderTanninMacroporous resin

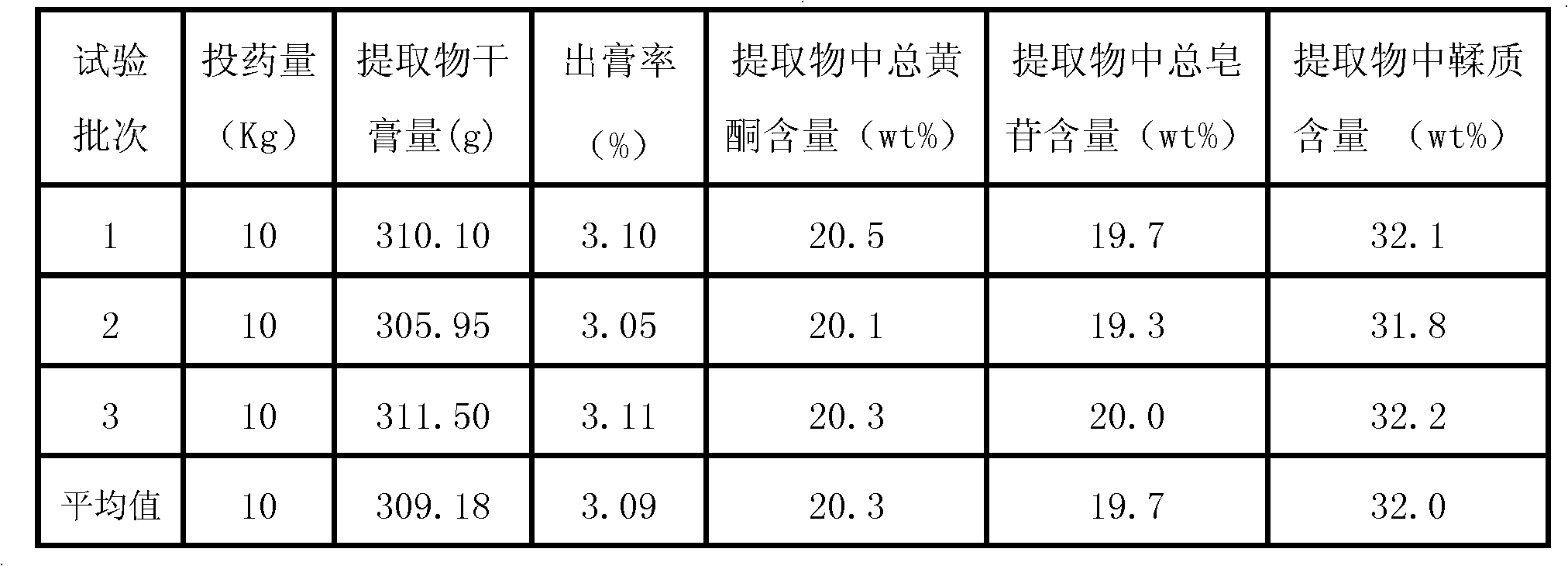

The invention belongs to the technical field of extraction and purification of traditional Chinese medicines, and particularly relates to a preparation method of extracts of effective fractions of lychee seeds. The method comprises the following steps of: (1) crushing the lychee seed medicinal material, adding ethanol and performing ultrasonic extraction; (2) recycling ethanol from the extract solution and diluting the extract with water, standing still and filtering; (3) adsorbing the filtrate by use of AB-8 macroporous resin, and eluting with water and ethanol later; (4) collecting the ethanol eluent, recycling ethanol and then concentrating to obtain thick paste; and (5) drying the extractum to obtain the extracts of the effective fractions of lychee seed. According to the invention, the extracts of the effective fractions, comprising the total flavones, total saponins and tannins of the lychee seeds are obtained at the same time by use of the sufficient extraction effect of ethanol on the effective components of the lychee seeds and the selection effect of the high-selectivity macroporous resin, and the total content of the total flavones, total saponins and tannins reaches over 70%; the process is simple and stable, and the quality is controllable; and the obtained extracts of the effective fractions of the lychee seeds conform to the requirements of the traditional Chinese medicine theory and the traditional Chinese medicine modernization.

Owner:GUANGZHOU HOSPITAL OF TRADITIONAL CHINESE MEDICINE

Canned green mullets containing tomato juice and preparation technology of canned green mullets

InactiveCN104413469AReasonable design of process stepsTender meatMeat/fish preservationFood preparationBiotechnologySpray dried

The invention relates to canned green mullets containing tomato juice and a preparation technology of the canned green mullets, belonging to the field of food processing. The preparation technology comprises the following steps: selecting high-quality green mullets, sorting, cleaning, carrying out spray drying, slicing, curing, carrying out high-temperature steam sterilization, dehydrating, pouring soup onto the green mullets, soaking, feeding drinking water, mixing, sealing cans in a vacuum way, standing still, and storing to obtain the canned green mullets containing the tomato juice. The products are reasonable in design of processing steps; the cans prepared by the technology are delicious in meat flavor, tender in meat quality and rich in nutrient elements such as proteins, vitamin E, calcium, phosphorus, potassium, magnesium, zinc, selenium, thus having a tonifying function for the human body; the canned green mullets containing the tomato juice are red and bright in color, tasty in sourness and sweetness, rich in tomato flavor, convenient to carry and eat, and easy to store.

Owner:刘宜霞

Functional bacterial flora establishment method applicable to black and odorous water body treatment and method for treating black and odorous water body with bacterial flora

InactiveCN109678257AGood chromaIncrease turbidityBiological water/sewage treatmentContaminated waterways/lakes/ponds/rivers treatmentFloraWater quality

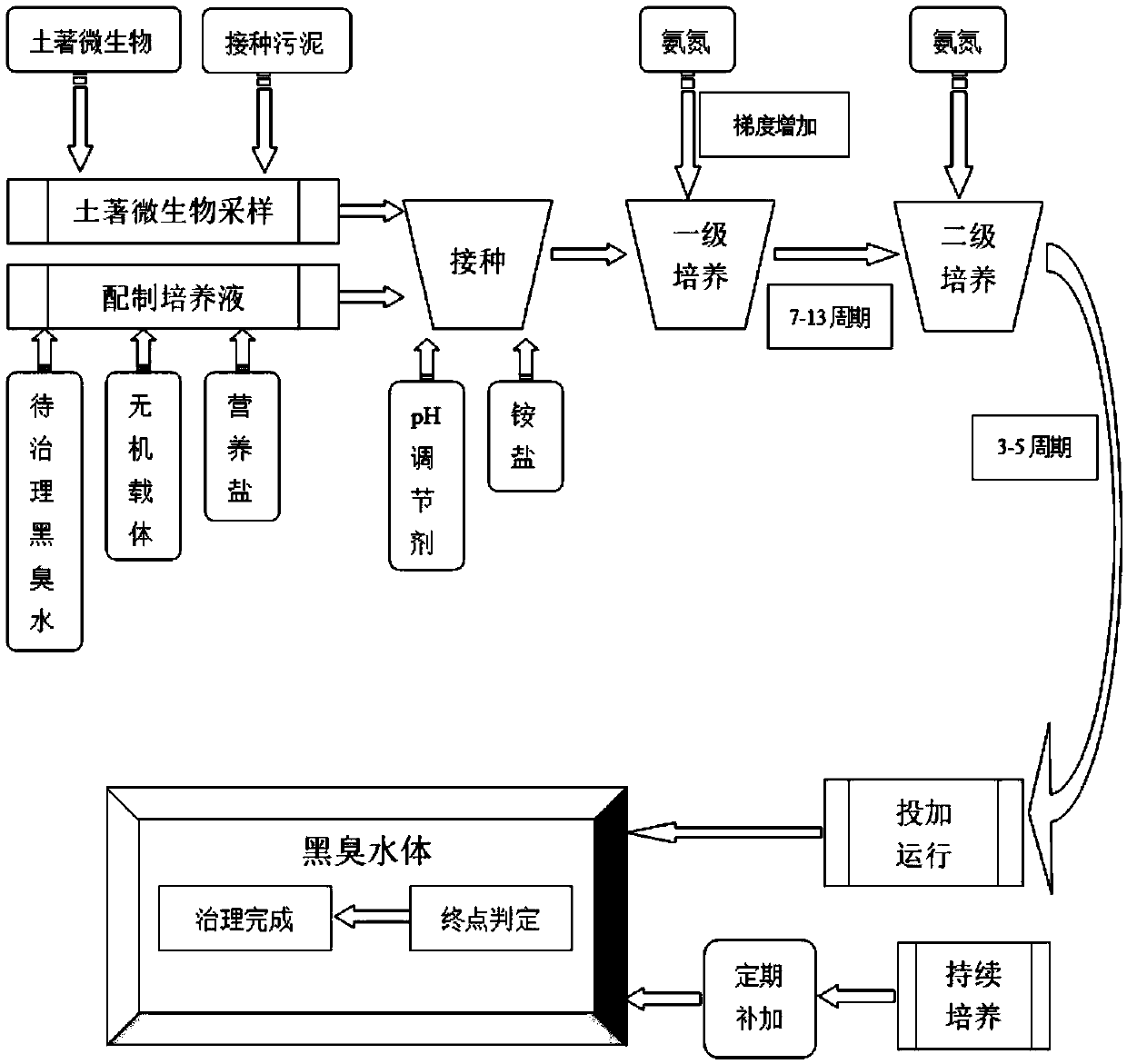

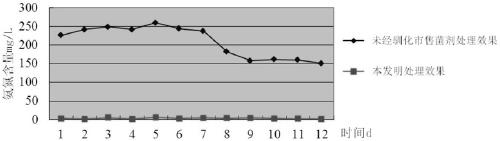

The invention provides a functional bacterial flora establishment method applicable to black and odorous water body treatment and a method for treating black and odorous water bodies with bacterial florae. The functional bacterial flora establishment method mainly comprises the following steps: (1) sampling indigenous microorganisms; (2) establishing functional bacterial florae in a black and odorous water environment, namely preparing a nutrient liquid, inoculating, and carrying out primary culture and secondary culture. The method for treating black and odorous water bodies with the bacterial florae mainly comprises the following steps: (1) carrying out feeding and operation; (2) replenishing the functional bacterial florae at regular time, and culturing continuously. By adopting the method, a set of complete functional bacterial flora 'continuous culture-regular replenishing' integral procedures are established on a black and odorous water body treatment site, and ammonia nitrogen removal effects on treated water bodies are continuously intensified. The method has wide applicability to various black and odorous river channels, black and odorous lakes, polluted field black and odorous ground surface, and the like, the functional bacterial florae are established in an original water quality environment, the bacterial florae constitution is dynamically changed, and the method is good in applicability, remarkable in effect and particularly applicable to implementation on various black and odorous water body treatment sites.

Owner:BEIJING GEOENVIRON ENG & TECH +1

Emulsified vegetable oil as well as preparation method and application thereof

InactiveCN109534517AQuick effectWide varietyWater contaminantsFatty-oils/fats refiningVegetable oilGroundwater remediation

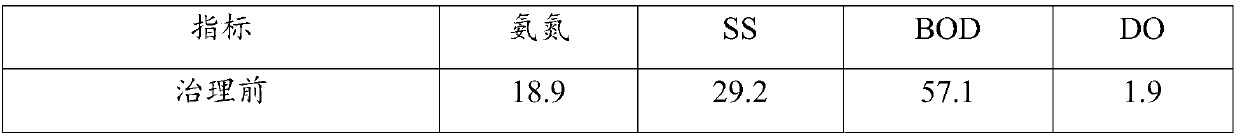

The invention belongs to the technical field of underground water remediation, and particularly relates to emulsified vegetable oil as well as a preparation method and application thereof. The emulsified vegetable oil is prepared from the following components in percentage by weight: 45 to 75 percent of edible vegetable oil, 2 to 12 percent of a surfactant and 20 to 45 percent of water and is alsoprepared from an optional common substrate and / or a pH (Potential of Hydrogen) regulator. The preparation method of the emulsified vegetable oil comprises the following steps of: mixing and dissolving of a soluble substrate, mixing and stirring of oil and water, and the like. An application method of the emulsified vegetable oil comprises the following steps of: injection well building, emulsified oil working solution preparation, indigenous microorganism activity evaluation, emulsified oil working solution injection and the like, thus realizing standardized remediation of chlorinated organicmatter polluted underground water. After the emulsified vegetable oil prepared by the invention is injected, the effect can be quickly obtained and is stable and lasting, and the emulsified vegetableoil can continuously take effect within 3 to 5 years after injecting once and requires no continuous addition for a long term; the technology is reasonable, raw materials are easy to obtain, the costis low, popularization and implementation are easy, and the environmental benefit, the economic benefit and the social benefit are good.

Owner:BEIJING GEOENVIRON ENVIRONMENT RESTORATION CO LTD

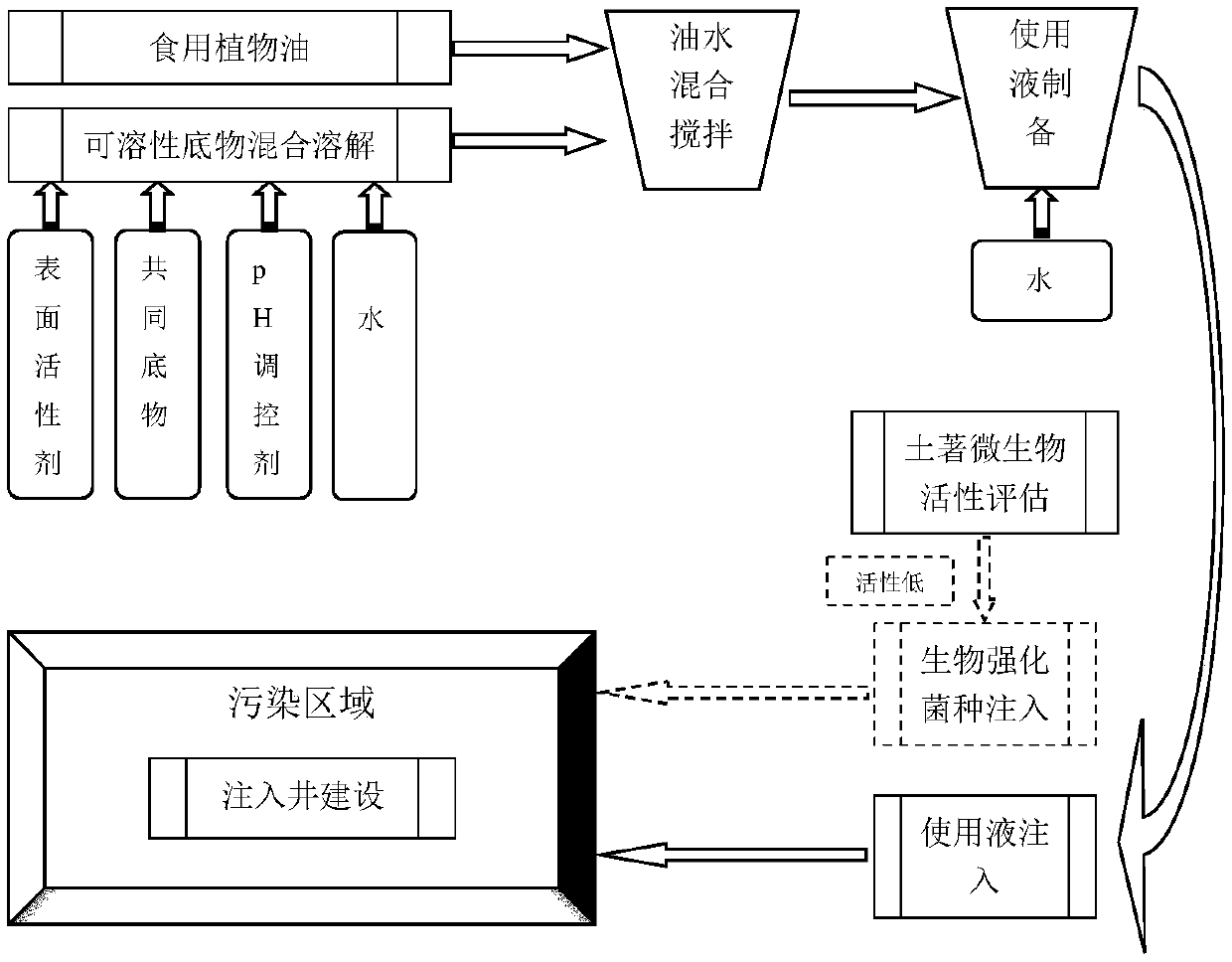

Flexible monocrystalline silicon solar cell manufacturing technique

InactiveCN103872171AReasonable design of process stepsImprove sealingFinal product manufacturePhotovoltaic energy generationWafer dicingWork in process

The invention discloses a flexible monocrystalline silicon solar cell manufacturing technique. The technique comprises the following steps: wafer sorting, wafer splicing, wafer welding, welding detection, low-temperature solidification of a cell and a substrate, low-temperature bonding of a front film, semi-finished product detection, high-temperature laminating, detection, trimming, wire outlet box pasting, positive and negative electrode soldering, glue pouring, assembling, top cover installation, and the like. As the technique comprises such steps as low-temperature solidification of the cell and the substrate, low-temperature bonding of the front film and high-temperature laminating, the technical steps are reasonable in design, and the manufactured products are good in sealing performance, flexibility and weatherability.

Owner:XIAMEN TOPUNIVE TECH

Liquid forging process for main reduction gear used for automobile transmission

InactiveCN106086619AImprove corrosion resistanceImprove forging efficiencyFoundry mouldsSolid state diffusion coatingHardnessAutomotive transmission

The invention provides a liquid forging process for a main reduction gear of an automobile transmission. The process comprises the steps of (1) smelting; (2) mould designing; (3) liquid forging; (4) normalizing; (5) turning; (6) carburizing and quenching; (7) tempering; (8) grinding; (9) shot blasting and flaw detecting; and (10) phosphorus saponification treatment, cleaning, polishing and anti-rust oil coating. According to the process, the liquid forging method is adopted for conducting gear machining and forging, labor and energy are saved, the material utilizing ratio is high, a blank is approximate to a final machined gear of the main reduction gear, the forging quality is high, the obtained gear hardness is high, the abrasion resistance is good, the corrosion resistance is high, the forging cost is low, and the forging process is environmentally friendly.

Owner:JIANGSU BAOJIE FORGING

Method for making braised mackerel cans

The invention provides a method for making braised mackerel cans. The method comprises the following steps: selecting raw materials, unfreezing, treating the raw materials, salting, frying, preparing soup, canning, exhausting, sealing, sterilizing and the like. The braised mackerel can made according to the method disclosed by the invention has a special flavor of braised fishes in brown sauce and is full in soup, dark red in color, tender in fish meat, moistened in dry flavor and strong in five-spice flavor, nutritional ingredients of the mackerel are fully remained, the process steps are reasonable in design, and the problem that the mackerel becomes hardened in meat and low in elasticity and chewing property in the sterilization process is solved, so that the meat keeps intrinsic elasticity and flavor, and the defect that the mackerel is inconvenient for long-term preservation and long-term transport is effectively overcome.

Owner:GUANGXI NANYIZAI SCI & TECH CO LTD

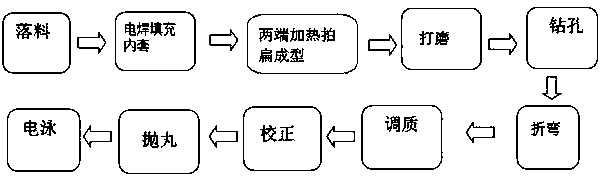

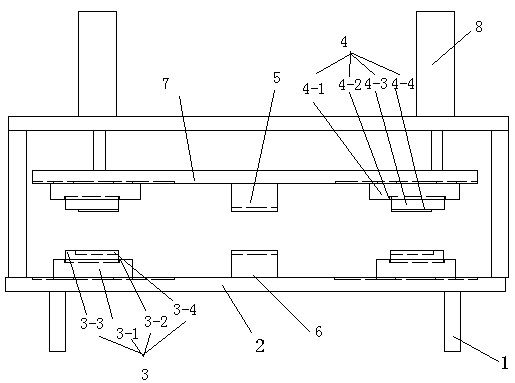

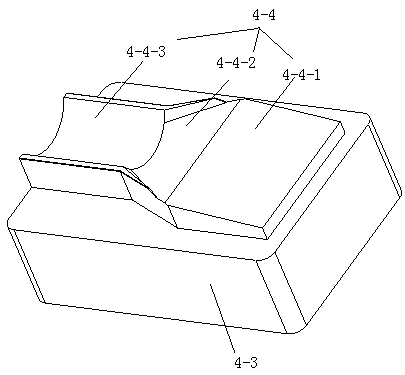

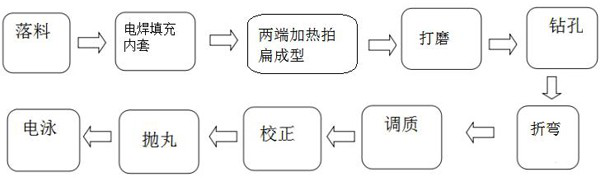

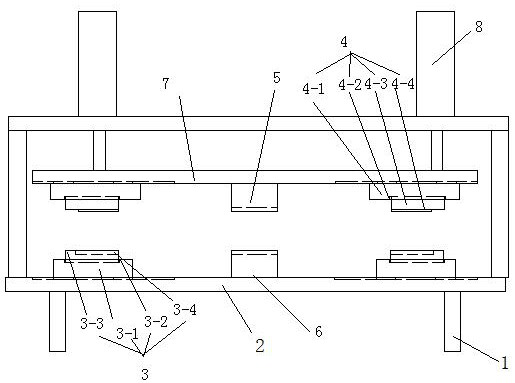

Hollow stabilizer bar producing process

ActiveCN110802378ASimplify the production processReduce the number of operatorsPhysicsMoulding device

The invention discloses a hollow stabilizer bar producing process. The process specifically includes the following steps of firstly, performing blanking; secondly, performing electric welding on filling inner sleeves, inserting the filling inner sleeves in the two ends of a blanked bar correspondingly, ensuring that the end faces of the filling inner sleeves are slightly 2-3 mm inward than the endfaces of a bar body, and then fixing the filling inner sleeves to the end faces through a spot welding method; thirdly, performing heating, flattening and forming on the two ends, putting the two ends, provided with the filling inner sleeves in the second step, of the bar body into an induction coil to be heated at the same time, transferring the heated workpiece onto a flattening and forming device at a flattening station, and performing extrusion forming on the two ends of the workpiece at the same time; fourthly, performing grinding; fifthly, performing drilling; sixthly, performing bending; seventhly, performing tempering; eighthly, performing correcting; ninthly, performing shot blasting; and tenthly, performing electrophoresis. The process is reasonable in step design, the whole production process is simplified, operators are reduced, operation intensity is lowered, and production efficiency is improved; and by performing flattening on the two ends at the same time, it can be ensured that the two ends are consistent in flatness, and the product quality is ensured.

Owner:ANQING HUITONG AUTOMOTIVE PARTS

Plastic bottle blowing process

InactiveCN107650361AReasonable design of process stepsReasonable designDomestic articlesEngineeringProcess engineering

The invention discloses a plastic bottle blowing process. The process comprises the following steps that a preform mould is manufactured; an integrated bottle blowing machine is selected; a preform automatic feeding mechanism is arranged; a preform star wheel is arranged on the integrated bottle blowing machine; preforms are fed into a heating mechanism, and the preforms are heated; then the preforms are fed into the bottle blowing machine; and bottle blowing operation is performed, the preheated preforms are placed in the well made mould, high-pressure air inflation is performed on the interior of the mould, the preforms are taken out of the bottle blowing machine, bottle product detection is performed, and qualified products are counted by a counting system and then guided into a finished product box. According to the plastic bottle blowing process, the process steps are reasonable in design, capable of saving energy, and efficient.

Owner:ZHANGJIAGANG WANJIN MACHINERY CO LTD

Method for preparing scomberomorus sinensis cans

InactiveCN105725107ASolve the darkening of colorFix graying outMeat/fish preservation by heatingFood ingredient as taste affecting agentAdditive ingredientChewiness

The invention provides a method for preparing scomberomorus sinensis cans. The method comprises the steps of raw material selection, unfreezing, raw material treatment, color keeping treatment, pickling, frying, soup preparation, canning, air discharging, sealing, sterilization and the like. The method has the benefits that the problem that after the scomberomorus sinensis cans are prepared, along with time lapse, the scomberomorus sinensis flesh turns dark and grey in color and luster is effectively solved, the problem that the scomberomorus sinensis flesh turns hard in the sterilization process, and is poor in elasticity and chewiness is also solved, and the flesh quality can be kept with inherent elasticity and flavor. The scomberomorus sinensis cans prepared according to the method has the peculiar flavor of braised fish in brown sauce, is rich in soup and dark red in color and luster, sufficiently keeps the nutritional ingredients of scomberomorus sinensis, is delicate in scomberomorus sinensis quality, dried, delicious, nutritious, spiced and highly seasoned; the processing steps in the method are reasonable in design, and the defect that the scomberomorus sinensis is inconvenient to preserve and transport for a long time is effectively overcome.

Owner:GUANGXI NANYIZAI SCI & TECH CO LTD

High-performance chromium plating process used for hardware product

InactiveCN106757233AImprove corrosion resistanceFast depositionElectrolytic coatingsWaxCopper plating

The invention discloses a high-performance chromium plating process used for a hardware product. The process comprises the steps of degreasing, steam treatment, shot blasting treatment, dewaxing, oil removal, acid copper plating bottoming, nickel plating bottoming, gold plating nickel brightening, chromic acid bath return etching, chromium plating, passivation, blowing and baking; in the process, repeated cleaning and acid activation are carried out. According to the high-performance chromium plating process used for the hardware product, the plating layer deposition speed is high, the number of plating layer micro-cracks is more, the plating has the better corrosion resistance, the chromium plating layer treated through the process is higher than a traditional standard chromium plating layer in hardness, under the condition that the combination force is qualified, the better wear resistance and corrosion resistance are achieved, and the service life of a workpiece can be obviously prolonged.

Owner:SHAOXING KOUFU FOOD

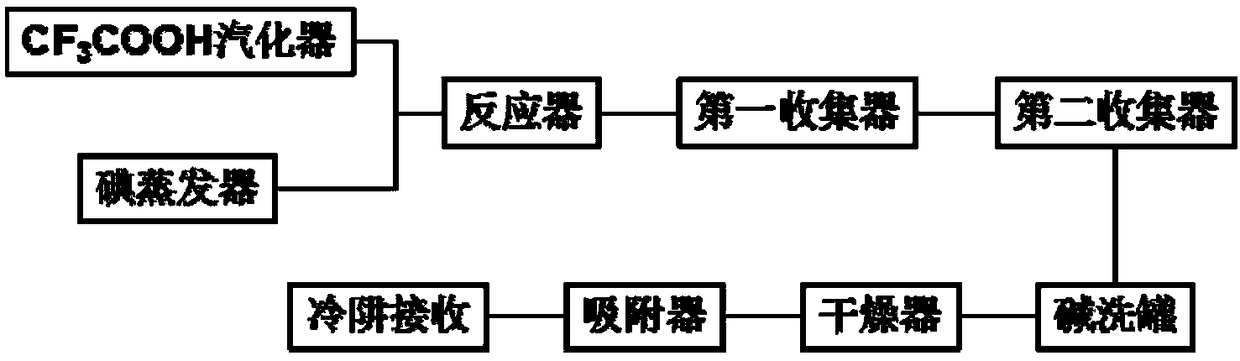

Method for efficiently synthesizing trifluoromethyl iodide

ActiveCN108246277AIncrease profitHigh yieldHalogenated hydrocarbon preparationMetal/metal-oxides/metal-hydroxide catalystsReaction rateIodide

The invention discloses a method for efficiently synthesizing trifluoromethyl iodide. The method comprises the following steps: reacting CF3COOOH vapor with iodine vapor under the action of a catalystto generate the trifluoromethyl iodide, wherein the catalyst is a catalyst which selects activated carbon or graphene as a carrier and is loaded with 1 to 10 weight percent of KNO3 and 2 to 7 weightpercent of RbNO3; then effectively removing impurities and moisture in CF3I by a NaOH solution, silica gel and a molecular sieve in sequence, thus efficiently collecting high-purity CF3I products. Themethod has the advantages of fast reaction rate, good selectivity, high yield, high reactant utilization and energy conservation; the method is expected to realize industrialized production and meetscurrent market demands.

Owner:DALIAN KELIDE OPTOELECTRONICS MATERIALS CO LTD

Canned tilapia in tomato sauce and processing technology thereof

InactiveCN104413455AReasonable process stepsReasonable designMeat/fish preservationFood preparationUnsaturated fatty acidBiotechnology

The invention relates to a canned tilapia in tomato sauce and a processing technology thereof, and belongs to the technical field of food processing. The processing technology comprises the following steps: selecting tilapias, cleaning, drying, slicing, curing, high-temperature steam sterilizing, dehydrating, soaking in soup, mixing with drinking water for people, vacuum canning, static storing, and obtaining finished products. The processing technology steps are reasonably designed, and cans processed by the technology have features of delicious canned tilapia, tender fish meat, various kinds of unsaturated fatty acids and rich proteins, red and bright color, sweet, sour and delicious taste, rich tomato flavor, convenient carryover and eating and easy preservation.

Owner:刘宜霞

High-strength corrosion-resistant bolt and production process thereof

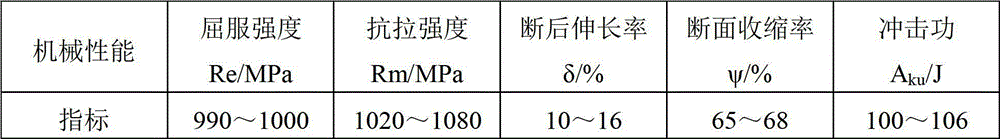

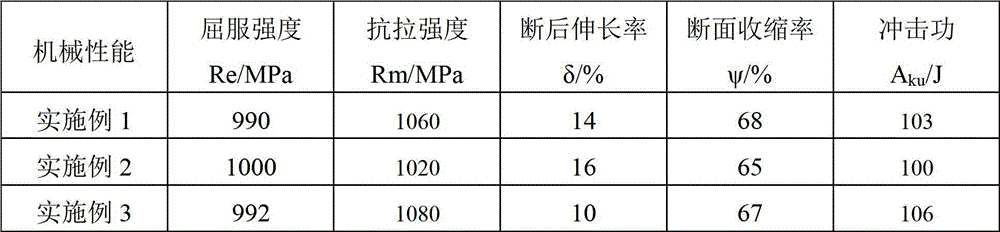

PendingCN114183448AReasonable formula designPrevent thermal crackingNutsBoltsSolution treatmentCarbide

The invention discloses a high-strength corrosion-resistant bolt and a production process thereof. Raw materials for manufacturing the high-strength corrosion-resistant bolt comprise the following components in parts by weight: 45-50% of Ni, 16-18% of Cr, 4-5% of Nb, 2-3% of Mo, 0.5-0.8% of Ti, 0.2-0.4% of Al, less than or equal to 0.03% of C, less than or equal to 0.01% of S and the balance of Fe. According to the high-strength and corrosion-resistant bolt and the production process thereof, the formula design is reasonable, the high-strength and corrosion-resistant bolt is an alloy with Ni-Cr-Fe as a matrix and is composed of an austenite matrix phase gamma, a main strengthening phase gamma '', an auxiliary strengthening phase gamma ', a stable phase delta and a small amount of MC type carbide, the high-strength and corrosion-resistant bolt raw material is prepared, the process step design is reasonable, and the production cost is low. The high-strength corrosion-resistant bolt raw material is obtained through pretreatment, smelting, solution treatment and aging heat treatment, then the bolt raw material is processed, and the prepared bolt finished product has excellent strength and corrosion resistance and is wide in application prospect.

Owner:苏州昭伍亿精密五金有限公司

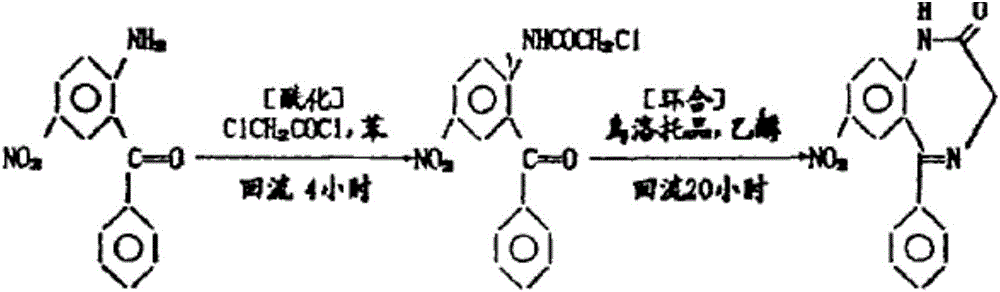

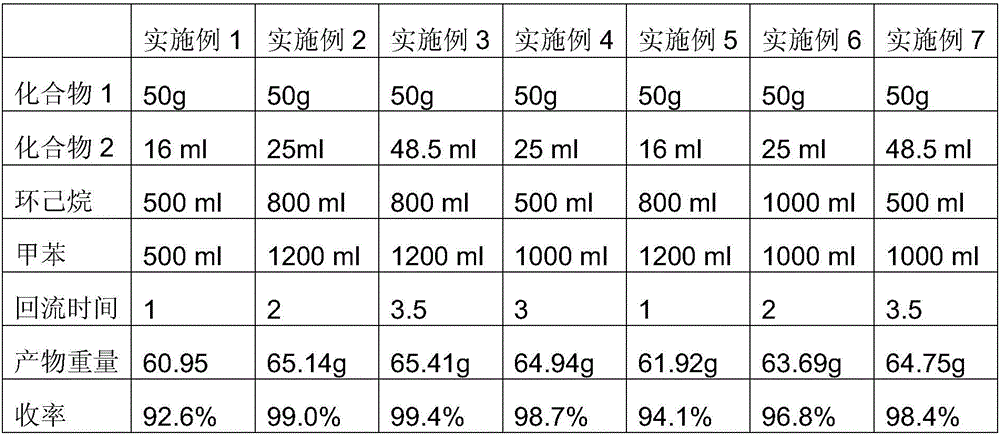

Preparation method of 2-chloracetylamino-5-nitro benzophenone

InactiveCN106397210AReasonable design of process stepsEasy to operateOrganic chemistryOrganic compound preparationOrganic solventFiltration

The invention provides a preparation method of 2-chloracetylamino-5-nitro benzophenone. The method comprises: taking 2-amino-5-nitro benzophenone and chloroacetyl chloride as raw materials, and performing an acylation reaction in an organic solvent for 1-3.5 h, wherein the acylation reaction is carried out in a reflux condition, the raw material ratio of 2-amino-5-nitro benzophenone to chloroacetyl chloride to the organic solvent is 50 g to (16-48.5) ml to (1000-2000) ml, and the organic solvent is a mixed solvent of cyclohexane and toluene with the volume ratio of cyclohexane to toluene being 1:1-2; and after the acylation reaction is finished, reducing the temperature to the room temperature, performing filtration, washing the obtained filter residue with water till the filter residue is neutral, and performing drying to obtain 2-chloracetylamino-5-nitro benzophenone. Compared with a preparation method in the prior art, the preparation method is reasonable in processing step design, good in operability, and less in by-products. The obtained product is high in purity and yield, and the method can meet industrial application requirements.

Owner:枣阳凤泽环化科技有限公司

Cantonese mooncake and manufacture process thereof

InactiveCN106212615AReasonable and effective combination of componentsReasonable design of process stepsDough treatmentBakery productsDietary RequirementsArachis hypogaea

The invention relates to Cantonese mooncake and a manufacture process thereof. The mooncake comprises a peel and stuffing, wherein the peel is prepared from the following components: 4kg of syrup, 0.05kg of alkaline, 0.02kg of cake oil, 1.5kg of peanut oil, 0.3kg of custard powder, 2kg of white lotus seed paste and 5kg of flour. The manufacture process comprises the following steps: firstly, uniformly stirring syrup and alkaline, adding cake oil, peanut oil and custard powder, uniformly stirring, adding white lotus seed paste and flour, uniformly stirring, and standing for half an hour to obtain the peel for later use; secondly, selecting stuffing; and thirdly wrapping according to a ratio of peel to stuffing being 2:8, pressing into a mould for molding, and baking until the cake is golden brown. The manufacture process has the advantages of reasonable combination, reasonable process step design, low manufacture cost and the like, is delicious, can meet the dietary requirement of people, has relatively low cost, and is convenient to process.

Owner:无为县三星食品厂

Preparation method of 2-chloride-5-nitrobenzoic acid

InactiveCN106397209AReasonable design of process stepsStrong maneuverabilityOrganic compound preparationNitro compound preparationDichloromethaneChemistry

The invention provides a preparation method of 2-chloride-5-nitrobenzoic acid. The preparation method comprises the following steps: mixing concentrated nitric acid and fuming sulphuric acid with the SO3 concentration of 20 percent according to the mass ratio of 1:(2-3), and controlling the temperature of the solution to be less than 10 DEG C in a mixing process; dripping 2-chloride trichlorotoluene, controlling the temperature of reaction liquid to be 0 to 10 DEG C, and continuously stirring at the end of dripping till the reaction is completed; pouring the reaction liquid into ice water, extracting with dichloromethane, washing an organic phase with a saturated sodium bicarbonate solution, and concentrating and drying to obtain 2-chloride-5-nitro trichlorotoluene; preparing concentrated sulfuric acid with the concentration of 85 weight percent, heating to 60 to 65 DEG C, adding the 2-chloride-5-nitro trichlorotoluene in batches, and preserving the heat till the reaction is completed; cooling the reaction liquid, adding water into the reaction liquid for dilution, extracting with ethyl acetate, taking an organic phase, and performing washing and concentration to obtain 2-chloride-5-nitrobenzoic acid. The technological steps are more reasonable in design and high in operability; the number of byproducts is small; the prepared product is relatively high in purity and can meet the requirement on industrial application.

Owner:枣阳凤泽环化科技有限公司

Canned spiced Scomberomorus niphonius and processing technology thereof

The present invention relates to a canned spiced Scomberomorus niphonius and a processing technology thereof, which belongs to the field of food processing. The processing technology is composed of the following steps: selecting the high-quality Scomberomorus niphonius and other materials, cleaning and drying the materials, filleting, pickling, frying, pickling and boiling the Scomberomorus niphonius, soaking the Scomberomorus niphonius in the pour-in soup, vacuum sealing and statically storing the soaked Scomberomorus niphonius and thereby obtaining the finished products. The processing technology has a rational design of process steps and the canned spiced Scomberomorus niphonius is rich in nutrition, has a delicate and tender fish meat, a fragrant and moisturizing smell and a spicy and sour taste, and is easy to carry, eat and preserve.

Owner:刘宜霞

Chromium-plating manufacturing method for metal product

InactiveCN106637324AImprove corrosion resistanceFast depositionMetallic material coating processesCopper platingHardness

The invention discloses a chromium-plating manufacturing method for a metal product. The method comprises the steps of degreasing, vapor treatment, shot blasting treatment, wax removal, oil removal, acidic-copper plating for bottoming, nickel plating for bottoming, golden nickel plating, returned etching conducted through a chromic acid plating solution, chromium plating, passivation, blowing and baking, wherein in the process, cleaning and acid activation are conducted for multiple times. When the method is applied to a high-performance chromium-plating process of the hardware product, a plating layer of the hardware product is high in deposition speed; the plating layer has a greater number of microcracks and better corrosion resistance; the hardness of the chromium-plating layer treated through the process is far higher than that of a chromium-plating layer treated according to traditional standards; and under the circumstance that binding force is qualified, better abrasion resistance and corrosion resistance are achieved, and the service life of a workpiece can be remarkably prolonged.

Owner:新昌县优优机械有限公司

Printing and dyeing process for pure silk with hollow-out and pearl effects

ActiveCN100344827CReasonable design of process stepsGood effectDyeing processTextile printerPolymer science

Owner:ZHEJIANG FURUN DYEING & PRINTING

Manufacture of high performance binding Sr ferrite magnet powder from iron scales

InactiveCN1330604CReasonable design of process stepsLow costInorganic material magnetismIntegrated processingRaw material

A process for preparing the adhesive magnetic powder from iron scales in order to prepare high-performance Sr ferrite includes such steps as granulating, oxidizing, ball grinding, proportionally and mechanically mixing it with other raw materials, pressing filtering, baking, grinding, sphericizing, low-temp sintering and annealing. Its advantages are high performance and low cost.

Owner:ANTE MAGNETIC MATERIAL CO LTD

Production method of langasite crystal element

ActiveCN101834270BReasonable design of process stepsEasy to operatePiezoelectric/electrostrictive device manufacture/assemblyLapping machinesCouplingCrystal orientation

The invention relates to a production method of a langasite crystal element, which is characterized by taking a raw material langasite crystal, and cutting into strip-shaped crystal materials; then carrying out crystal orientation angle measurement; using a multi-knife cutting machine for cutting the strip-shaped crystal materials into pieces according to the orientation angle measurement requirements, carrying out rounding treatment and obtaining chip-like crystal materials; sequentially carrying out coarse grinding, medium grinding and fine grinding treatment on the chip-like crystal materials for achieving the respective grinding thickness requirements; carrying out double-sided silver coating treatment on the chip-like crystal materials after grinding, using a vacuum micro-adjustment machine for carrying out frequency adjustment on the chip-like crystal materials after silver coating, and obtaining frequency chips required by manufacturing the crystal element; and placing the frequency chips on a crystal element base, dispensing, fixing, packaging and obtaining the langasite crystal element. The production method has reasonable design of process steps and strong process maneuverability; and the prepared langasite crystal element has large low electrical coupling coefficient, good temperature stability and relatively steep band edge, and can be applied in filters, high-temperature sensors and other aspects.

Owner:JIANGSU HAIFENG ELECTRONICS

Porcelain aluminium oxide decorative board and its producing method

The decorative porcelain aluminia board is produced through sound wave treatment, electrolysis to eliminate oil, water washing, neutralizing, porcelain oxidation to form glaze-like oxide layer on the surface and electrophoresis coloring to form dulling silver gray. As a new generation of green decorative material, the present invention is colorful, non-deflective, non-toxic, insulated, anticorrosive and durable and it has no negative effect on human body and environment. The present invention may be used as building decorating material as well as ink kitchen wave, storage rack, etc.

Owner:湛江市威龙实业有限公司

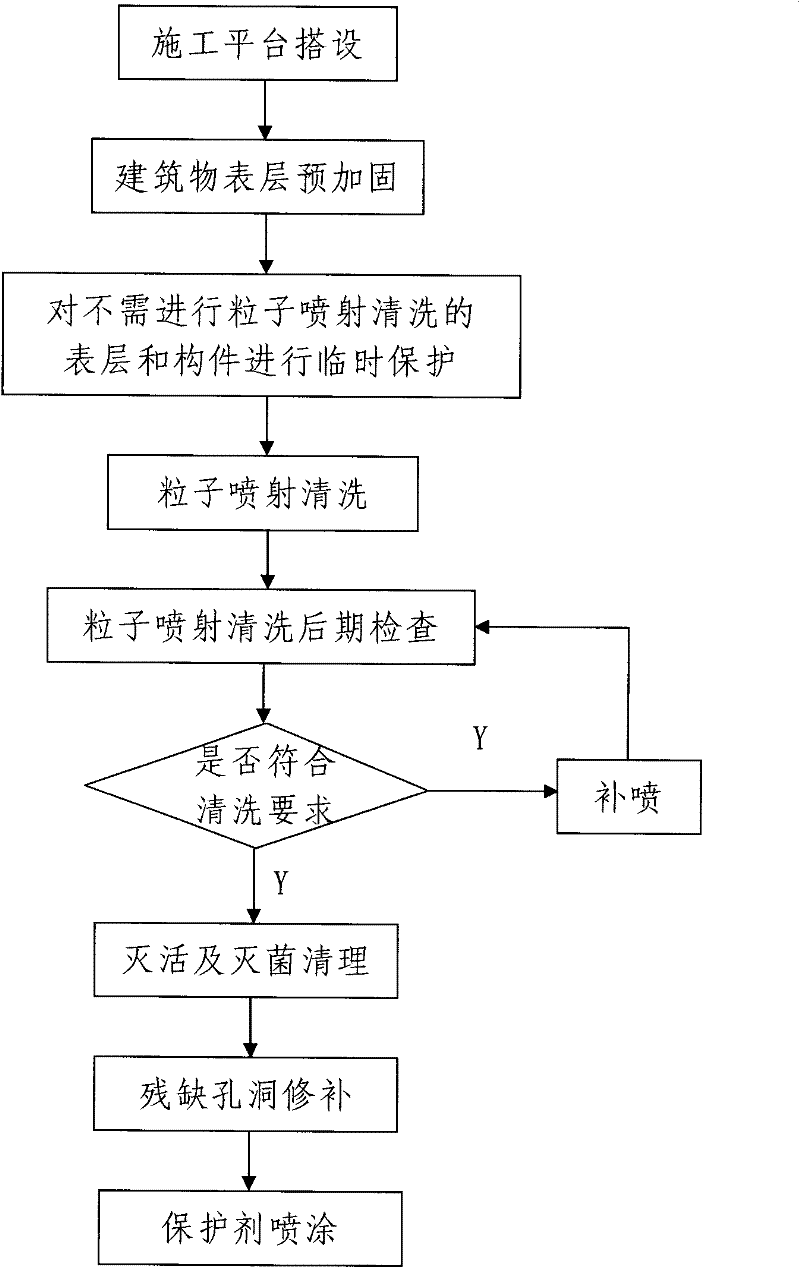

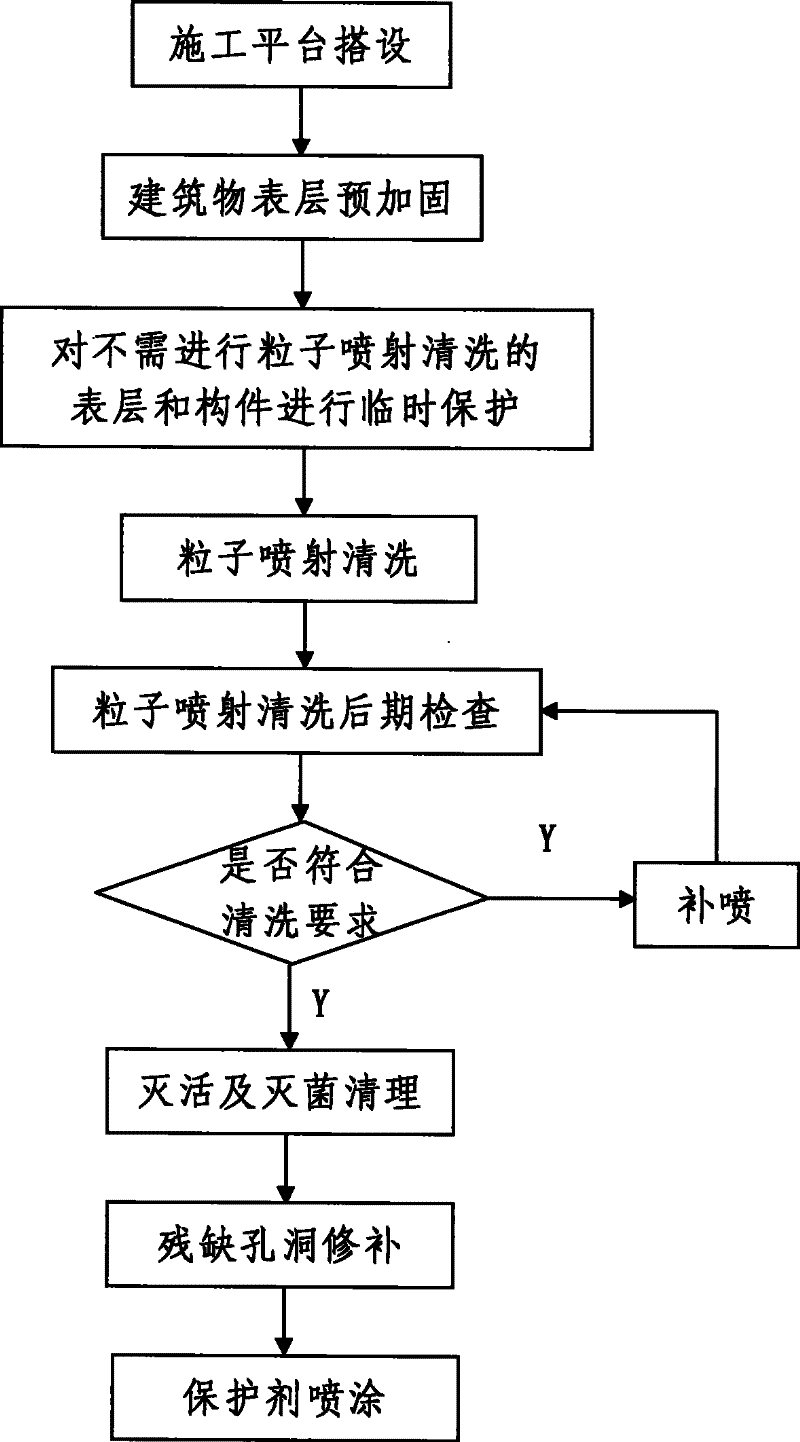

Masonry type building surface particle spraying retreading construction method

InactiveCN101806141BSave resourcesEasy constructionBuilding constructionsSocial benefitsEconomic benefits

The invention discloses a masonry type building surface particle spraying retreading construction method, which comprises the following steps: 1. building a construction platform; 2. spraying and cleaning particles (a pneumatic spray gun is adopted for carrying out particle spraying and cleaning construction at a uniform speed on the surface of masonry type buildings to be treated from top to bottom or from left to right, the caliber of the pneumatic spray gun is between 3 and 5 mm, the sprayed airflow outlet pressure is between 8 and 12 Pa, and in addition, the air outlet amount is between 1m<3> / min and 3 m<3> / min); 3. carrying out later stage checking and supplementary spraying after the particle spraying and cleaning; 4. carrying out inactivation and sterilization cleaning; 5. patching defective holes; and 6. spraying and coating protective agents. The invention has the advantages of convenient construction, low construction cost, short construction period, high construction efficiency, good construction effect and high retreading quality, at the same time, the invention can not cause great pollution to external environment, and the invention has high economic benefits and social benefits.

Owner:陕西建工集团有限公司 +1

Porcelain aluminium oxide decoration plate and production method thereof

The invention discloses a porcelain aluminium oxide decoration plate and a production method thereof. The porcelain aluminium oxide decoration plate comprises the following raw materials: aluminium plate, sodium hydroxide, sodium carbonate, trisodium phosphate, water glass, nitric acid, butyric anhydride, boric acid, resin, color paste, clear water and pure water. The method comprises the following steps: carrying out sound wave, electrolysis oil removal, washing, neutralization and ceramic oxidization on a pure aluminium plate to enable the surface of the pure aluminium plate material to generate one layer of oxidization film so as to enable the pure aluminium plate material to have the appearance of ceramic glaze, and carrying out electrophoresis coloring till the plate is silver gray. The porcelain aluminium oxide decoration plate has reasonable technical step design, can be applied to building decoration materials and also can be popularized and applied to the surface of industrialand daily aluminium products of aluminium and aluminium alloy, such as elevator room walls, kitchenware, countertops, disinfection cabinet shells, goods shelves and the like.

Owner:RUGAO HUAYANG ALUMINUM PROD

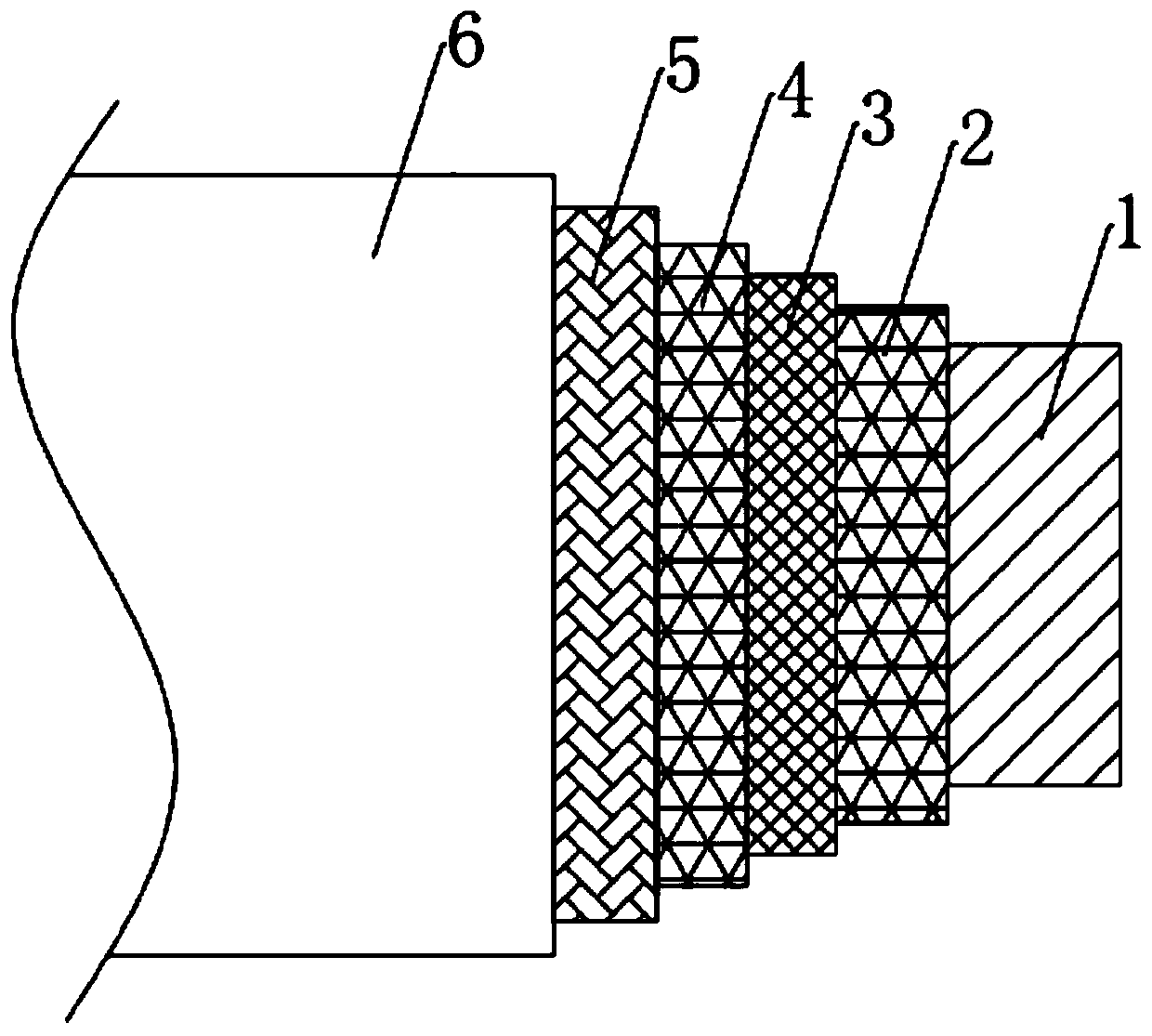

A high-strength aging-resistant high-pulse flame-retardant hydraulic hose and its preparation method

The invention discloses a high-strength aging-resistant anti-high-pulse flame-retardant hydraulic rubber pipe, and belongs to the technical field of novel materials. The pipe comprises an inner rubberlayer, a first glass fiber layer, a steel wire winding reinforcement layer, a second glass fiber layer, a steel wire braiding reinforcement layer and an outer rubber layer which are sequentially arranged from inside to outside; and the winding directions of the first glass fiber layer and the second glass fiber layer are opposite. According to the pipe, inner rubber plays a role in sealing underthe action of a high-pressure medium so that the pipe can be good in oil resistance, good in fatigue resistance and pulse resistance, relatively high in stress at definite elongation and tearing resistance, relatively small in stress relaxation, relatively good in process performance and relatively high in physical and mechanical performance; outer rubber mainly plays a role in protecting the inner rubber layer, the first glass fiber layer, the steel wire winding enhancement layer, the second glass fiber layer and the steel wire braiding reinforcement layer against the external environment influence so that the pipe can have wear resistance, aging resistance (ozone and hot air), good adhesion and good flexibility; and the process steps of a preparation method of the pipe are reasonable indesign, the working efficiency is improved by 20%, and the product quality of the hydraulic rubber pipe is improved.

Owner:南通美莱达科技有限公司

Technology for processing CrNiMo series steel material

ActiveCN102877073BGuaranteed purityHigh strengthSolid state diffusion coatingIngotMaterials processing

Owner:常熟天地煤机装备有限公司

A hollow stabilizer bar production process

The invention discloses a production process of a hollow stabilizer bar, which specifically includes the following steps: (1) blanking, (2) filling the inner sleeve by electric welding, inserting the filled inner sleeve at both ends of the blanking rod respectively, so as to ensure that the end surface of the inner sleeve is filled Slightly 2~3mm inward with the end face of the rod body, and then each end face is fixed with a filled inner sleeve by spot welding; (3) both ends are heated and flattened, and both ends of the rod body with the filled inner sleeve after step (2) are simultaneously Put it into the induction coil for heating, transfer the heated workpiece to the flattening device at the flattening station, and extrude both ends of the workpiece at the same time; (4) Grinding, (5) Drilling, (6) Bending, (7) quenching and tempering, (8) correction, (9) shot blasting, (10) electrophoresis. The invention has reasonable process step design, simplifies the whole production process, reduces the number of operators, lowers the operation intensity, and improves the production efficiency, and the simultaneous flattening of both ends can ensure the flatness of the two ends to ensure the product quality.

Owner:ANQING HUITONG AUTOMOTIVE PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com