Method for efficiently synthesizing trifluoromethyl iodide

A high-efficiency technology of trifluoroiodomethane, which is applied in the field of high-efficiency synthesis of trifluoroiodomethane, can solve the problems of large amount of reaction solvent, expensive raw materials and high cost, and achieves the advantages of reasonable design of process steps, accelerated reaction rate and improved utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

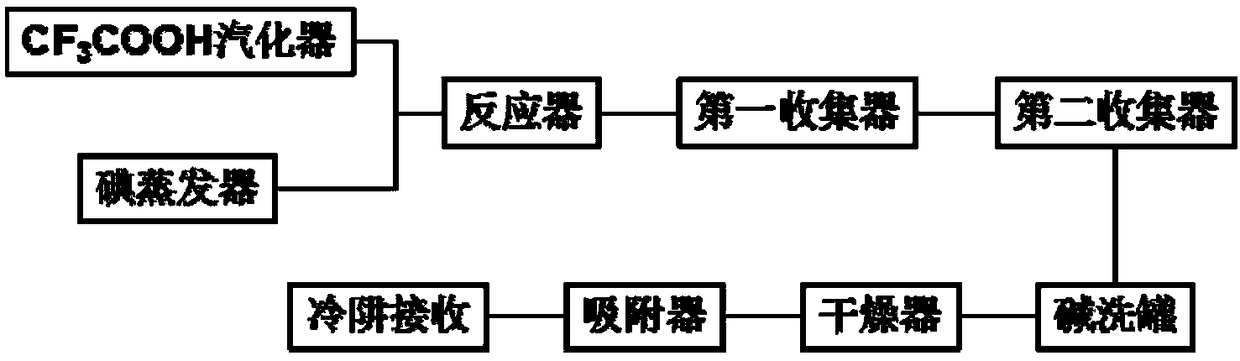

Image

Examples

Embodiment 1

[0022] 1. Synthetic catalyst: 3.0g KNO 3 and 5g RbNO 3 Dissolve in 500mL of water, add 100g of activated carbon to it, ultrasonically treat for 30min, and let it stand overnight; filter, dry the solid isolate at 100°C for 5h, and then calcinate at 500°C for 2h under a high-purity nitrogen atmosphere to prepare the catalyst.

[0023] 2. Synthesis of CF 3 I

[0024] (1) CF 3 COOH vapor and iodine vapor enter the 500°C reactor at a molar ratio of 1:1, and 100g of catalyst is installed in the reactor to control CF 3 The flow rate of COOH vapor is 20mL / min, CF 3 The reaction time of COOH and iodine is 10min to generate CF 3 I.

[0025] (2) Make the above CF 3 The I gas is passed into the first collector, the second collector, the alkali washing tank, the drier and the adsorber successively to remove H 2 O.CO 2 , HF and other impurities. 80°C water is used for circulation outside the primary collector; the lye in the alkali washing tank is 0.5% NaOH solution; the desiccant...

Embodiment 2

[0027] 1. Synthetic catalyst: 7.0g KNO 3 and 0.7g RbNO 3 Dissolve in 500mL of water, add 100g of graphene to it, sonicate for 30min, and let it stand overnight; filter, dry the solid isolate at 100°C for 5h, and then calcinate at 500°C for 2h under a high-purity nitrogen atmosphere to prepare the catalyst.

[0028] 2. Synthesis of CF 3 I

[0029] (1) CF 3 COOH vapor and iodine vapor enter the 550°C reactor at a molar ratio of 2:1, and the reactor is equipped with 100g of catalyst, and the CF is controlled 3 The flow rate of COOH vapor is 20mL / min, CF 3 The reaction time of COOH and iodine is 10min to generate CF 3 I.

[0030] (2) Make the above CF 3 The I gas is passed into the first collector, the second collector, the alkali washing tank, the drier and the adsorber successively to remove H 2 O.CO 2 , HF and other impurities. 80°C water is used for circulation outside the primary collector; the lye in the alkali washing tank is 0.5% NaOH solution; the desiccant in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com