Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

100results about How to "Prevent thermal cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

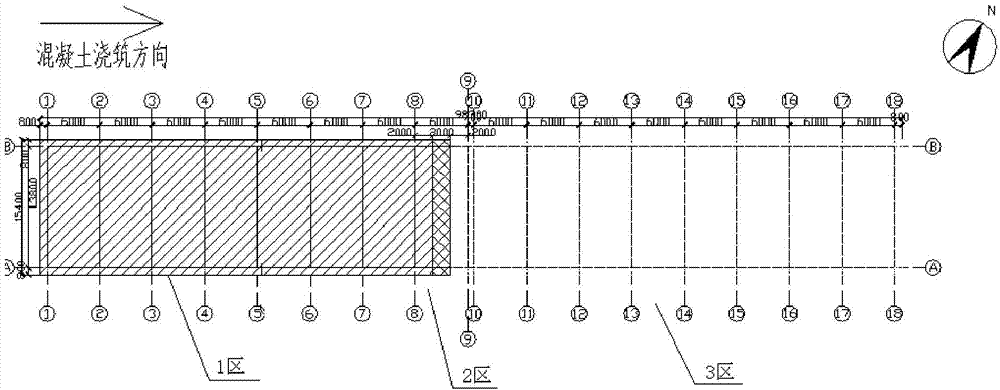

Construction method of large-volume concrete bearing platform with one-time pouring in winter

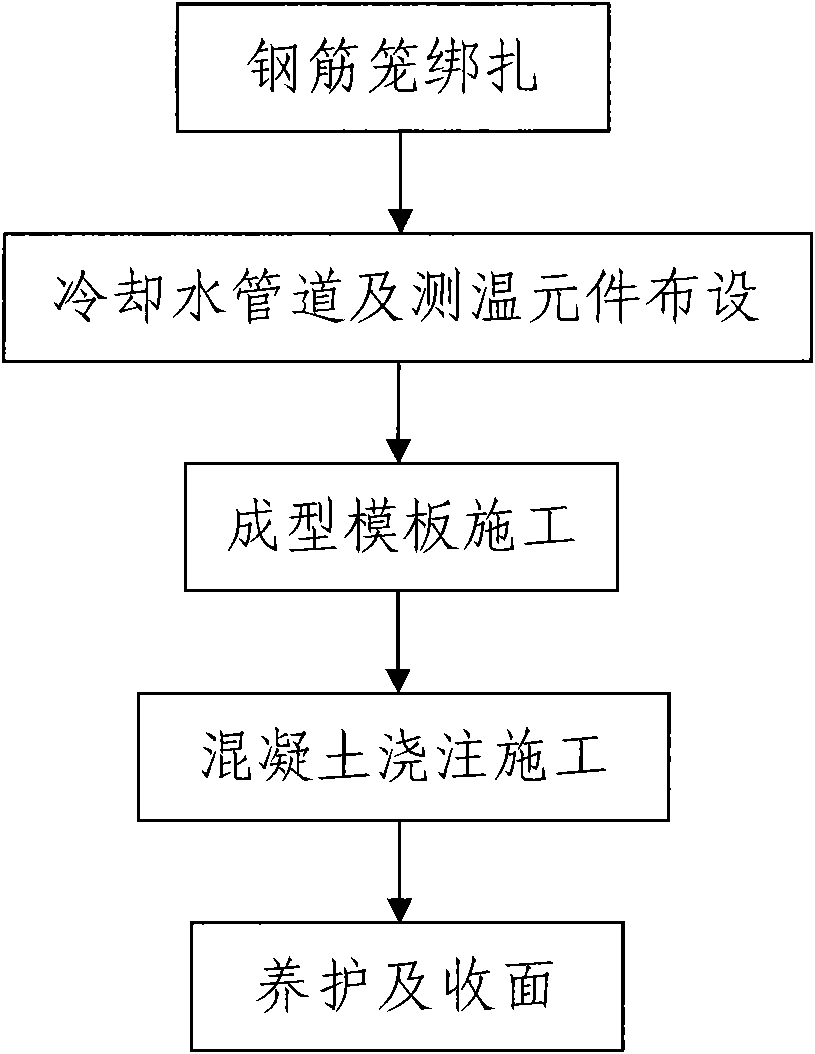

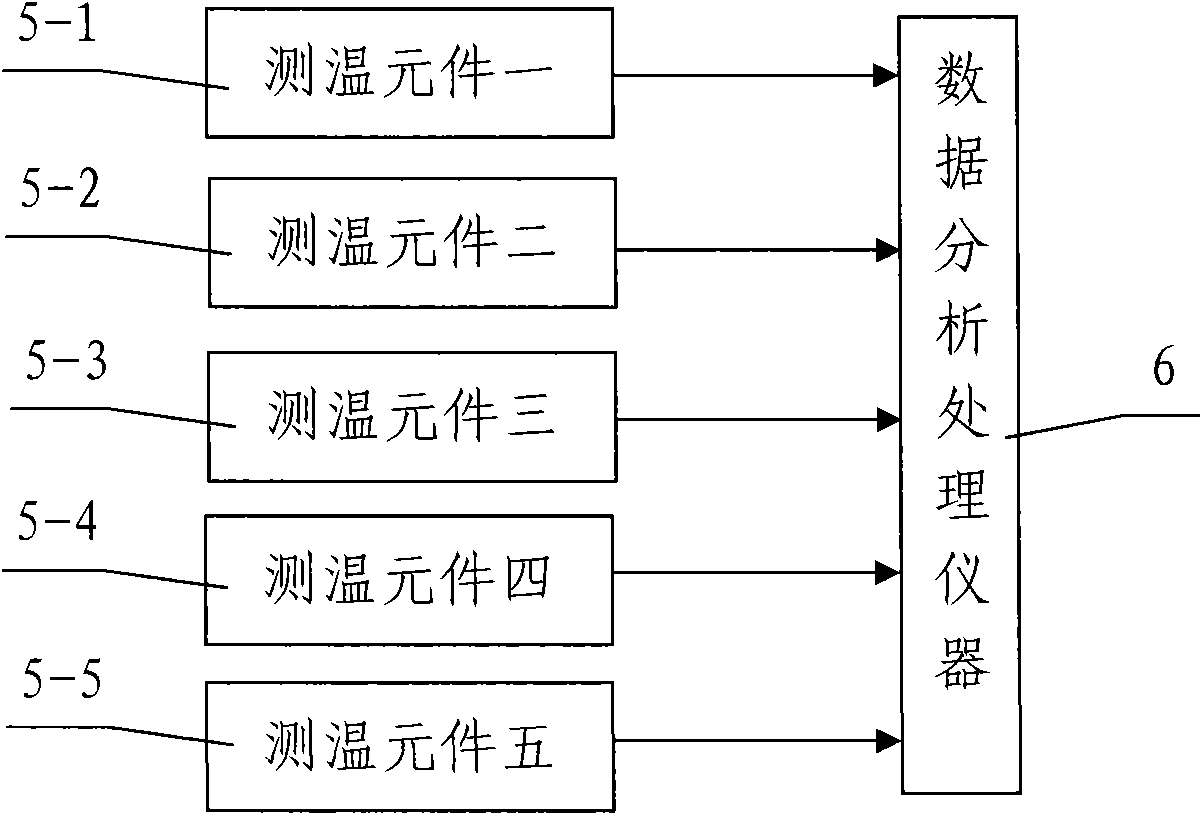

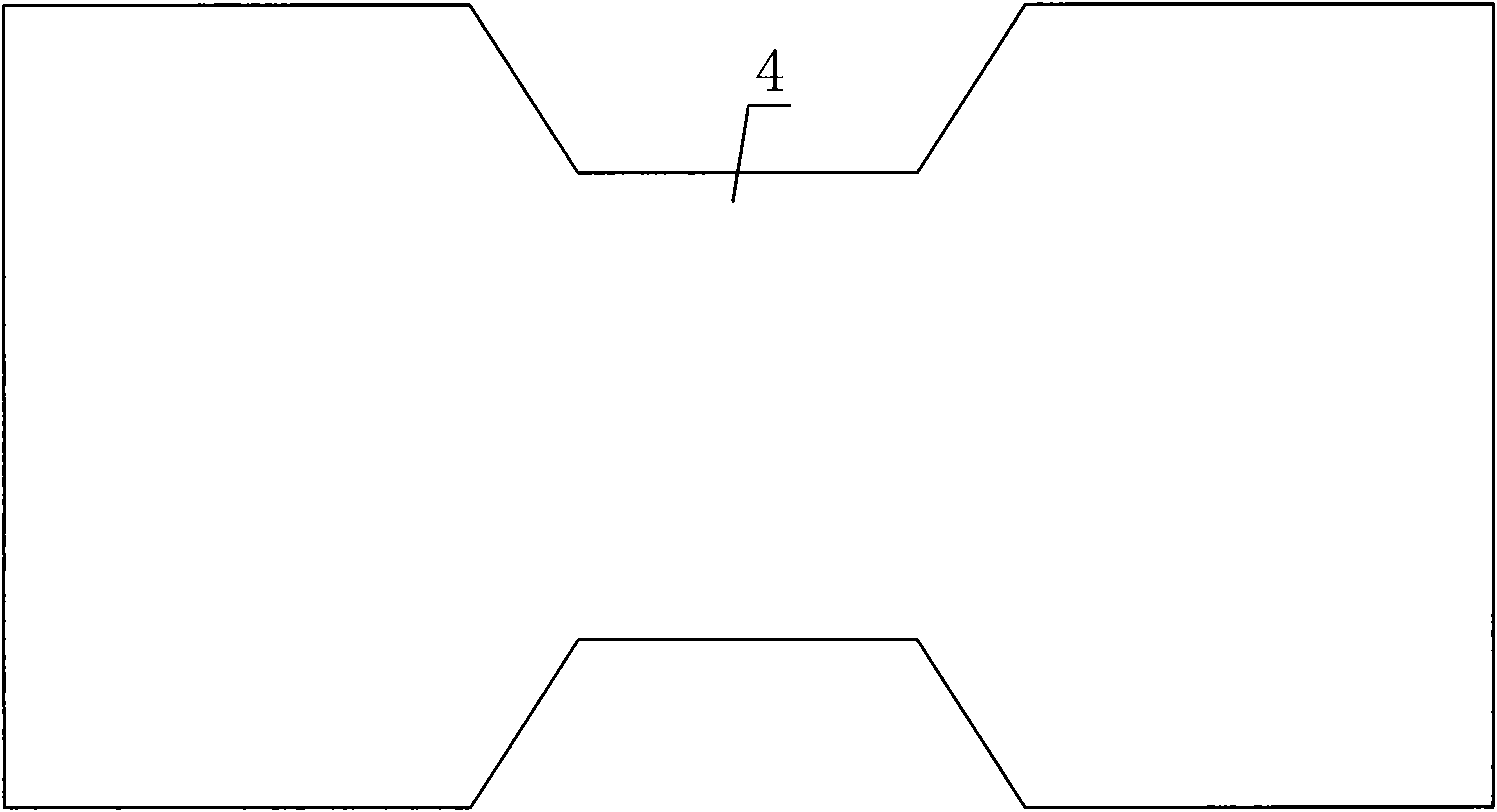

The invention discloses a construction method of a large-volume concrete bearing platform with one-time pouring in winter, comprising the following steps of: step 1, binding steel reinforcement cages; step 2, laying cooling water pipelines and temperature measuring elements; step 3, constructing formed templates, wherein the construction process comprises delimiting template lines and constructing formed brick dies; step 4, pouring concrete; and step 5, conserving and finishing surface: finishing surface in time when completing the pouring of the concrete, carrying out the surface finishing twice, carrying out the first surface finishing when pouring the concrete to the top, carrying out the second surface finishing when the concrete is initially congealed, and adopting a mode that external stores water for conserving when the concrete is initially congealed. The invention has the advantages of reasonable design, simple construction method step, convenient operation, short construction period, one-time pouring molding and strong maneuverability, the large-volume concrete bearing platform constructed for molding in winter has good quality, the poured concrete is not frozen, and the surface of the bearing platform can not have temperature cracks.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

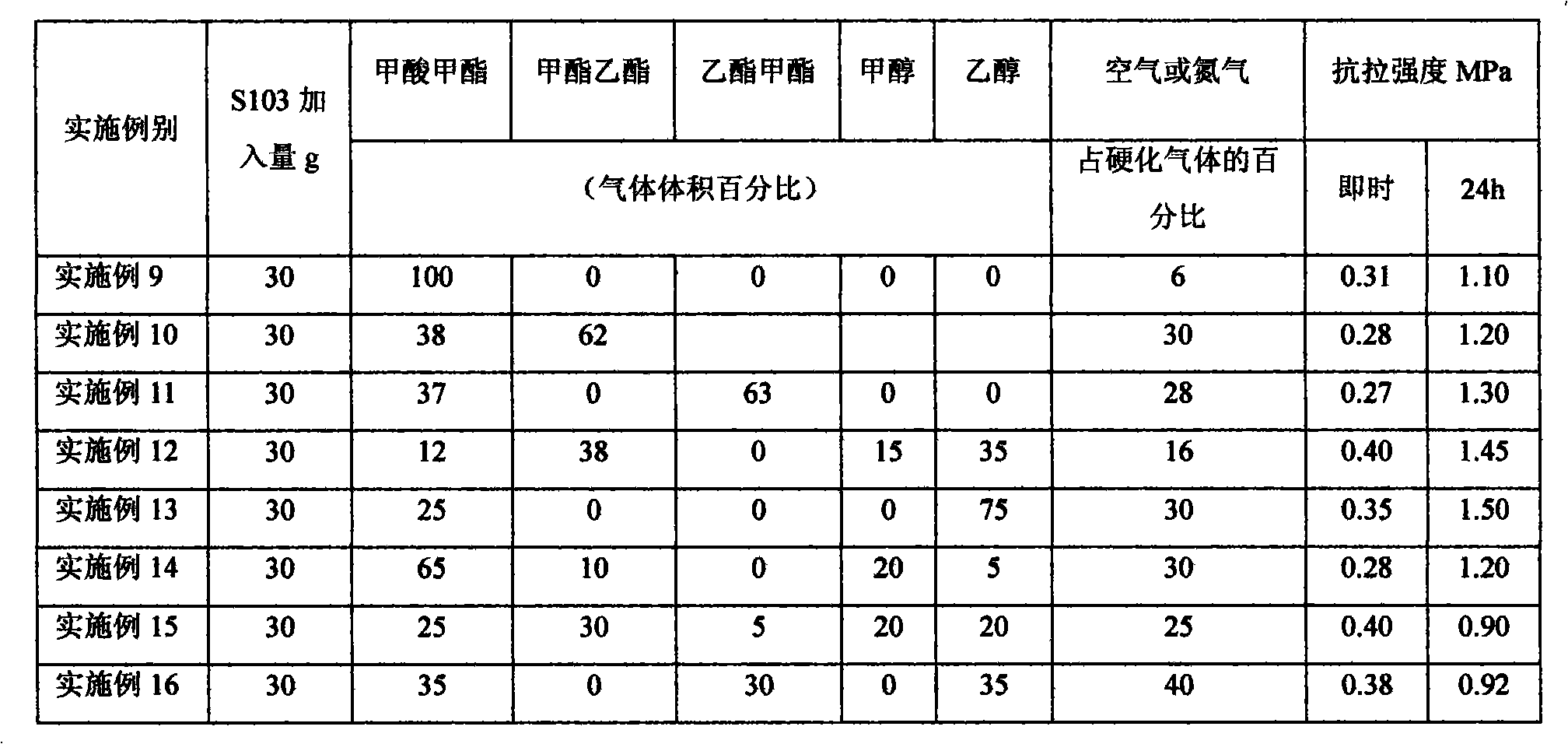

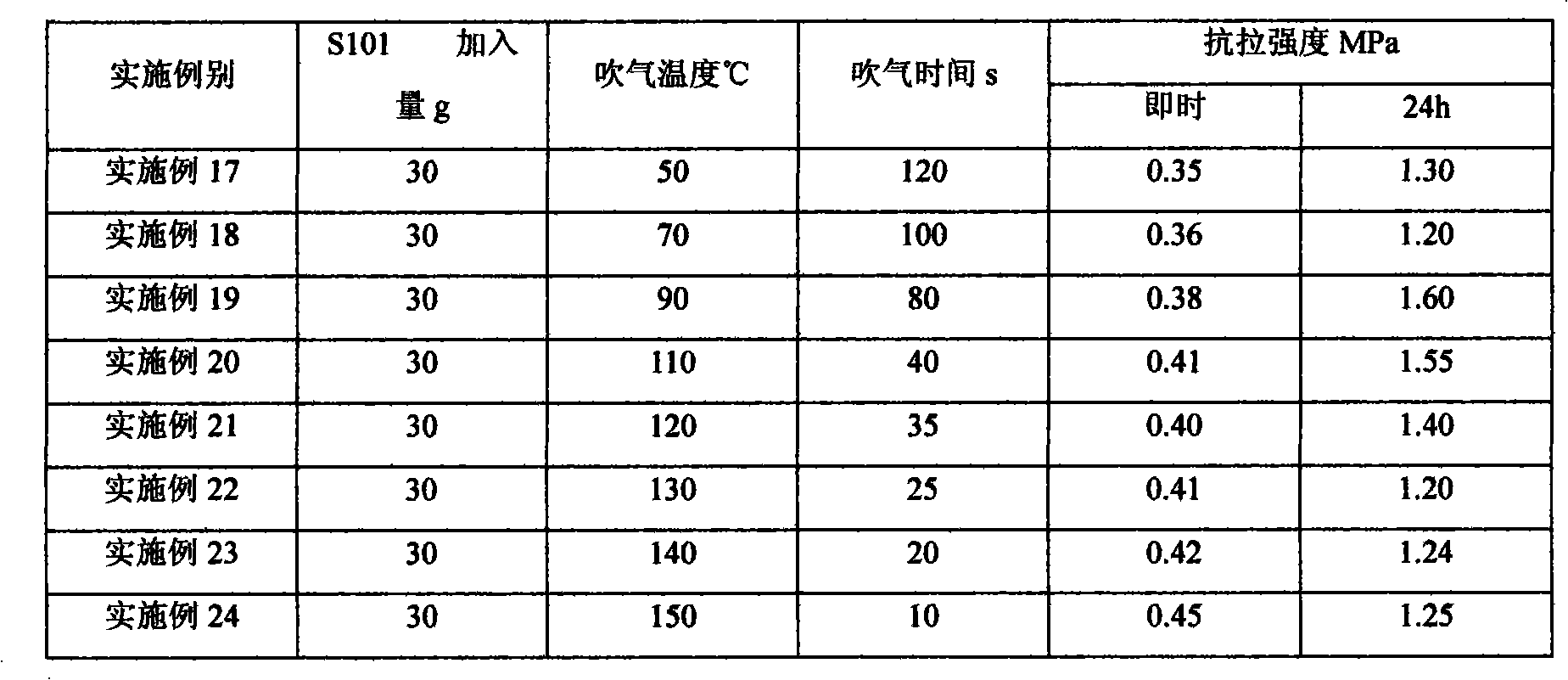

Method for making core with aeration ossification

InactiveCN101293271AWide variety of sourcesLow priceFoundry mouldsFoundry coresSoluble glassGlycerol

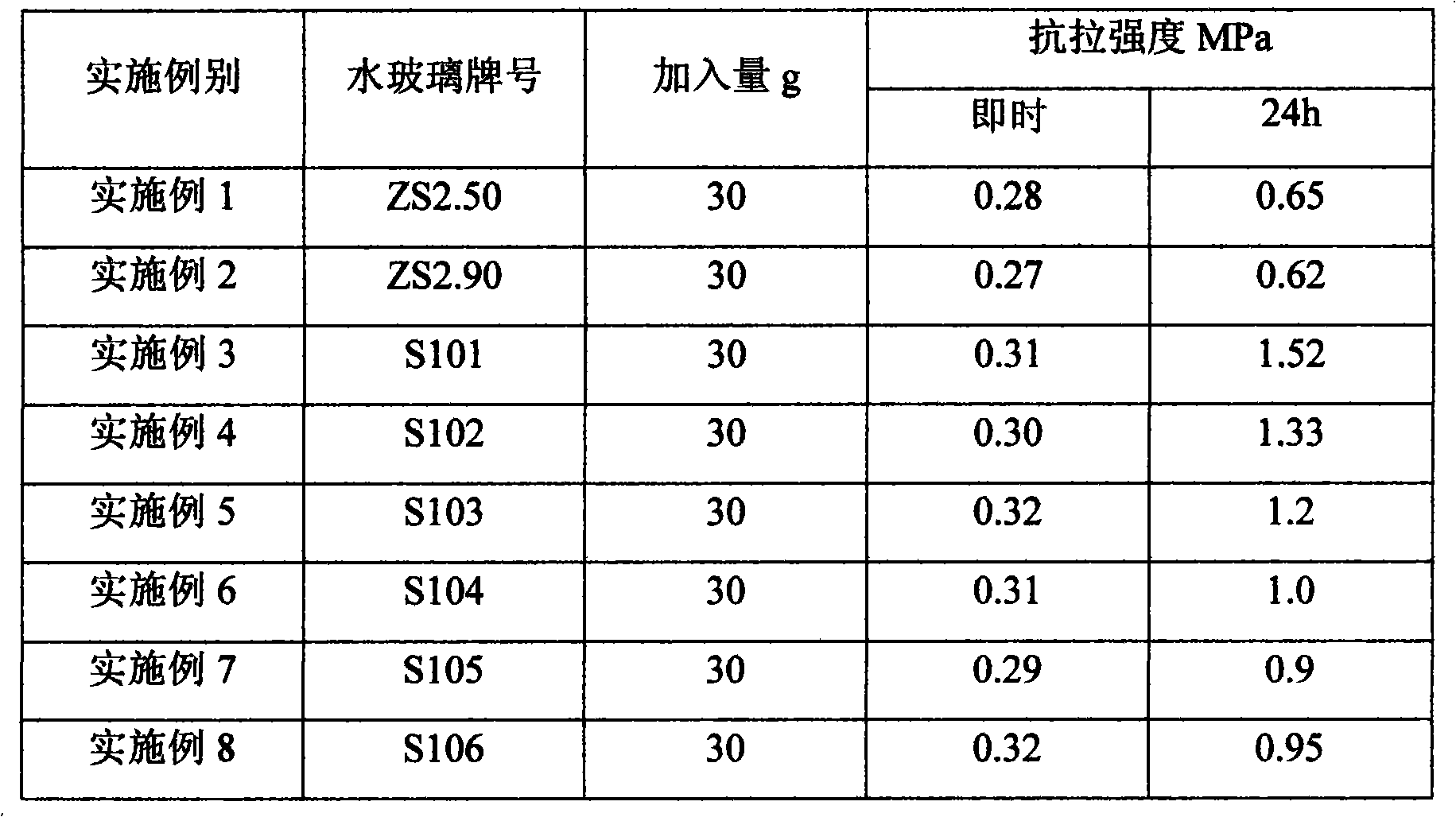

The invention discloses a core making method by gas-blowing hardening, which is characterized in that the mass percentage of mixing materials of the making core sand is as follows: 0.9-7.0 percent of soluble glass, 0.1-1.0 percent of moisture absorption resistant agent and raw sand for the rest; the used moisture absorption resistant agent can be triacetyl glycerine, diacetin, glycerol mono acetate bulk, diethylene glycol acetic ester, propylene glycol acetic ester, other polylol organic acid ester or the mixture thereof; the volume percentage of the blowing gas for hardening is as follows: 25-100 percent of C2-C4 organic ester and 0-75 percent of C1-C2 alcohols. The method of the invention has no toxicity and odor in production process, and the produced cores have better stripping strength.

Owner:SHENYANG HYATON FOUNDRY MATERIAL

Electromagnetic flexible composite deposition direct preparation forming method of multifunctional gradient component

InactiveCN102962451ARealize free and flexible creationQuality improvementMetallic material coating processesHigh energyCam

The invention relates to an electromagnetic flexible composite deposition direct preparation forming method of a multifunctional gradient component, and the method is characterized in that high-energy beams or electric arc with high efficiency and low cost are used as a basic heat source, a static magnetic field or an alternating magnetic field is introduced or the static magnetic field and the alternating magnetic field are simultaneously introduced in the electric arc three-dimensional deposition process, under the support of computer-aided design (CAD) / computer-aided manufacturing (CAM) software, a computer controls a deposition fun or a workpiece to move according to a set space orbit, an electromagnetic composite energy field acting on a molten pool and a nearby micro area is used for heating and melting a material with ideal gradient ratio, the free and flexible adjustment and control of a deposition shape and a component tissue space distribution of the multifunctional gradient component can be realized, and the multifunctional gradient component is used for the development and production of the high-performance component with multiple functions such as oxidation resistance, creep resistance, fatigue resistance in fields such as aerospace, ships, automobile engine or energy.

Owner:HUAZHONG UNIV OF SCI & TECH

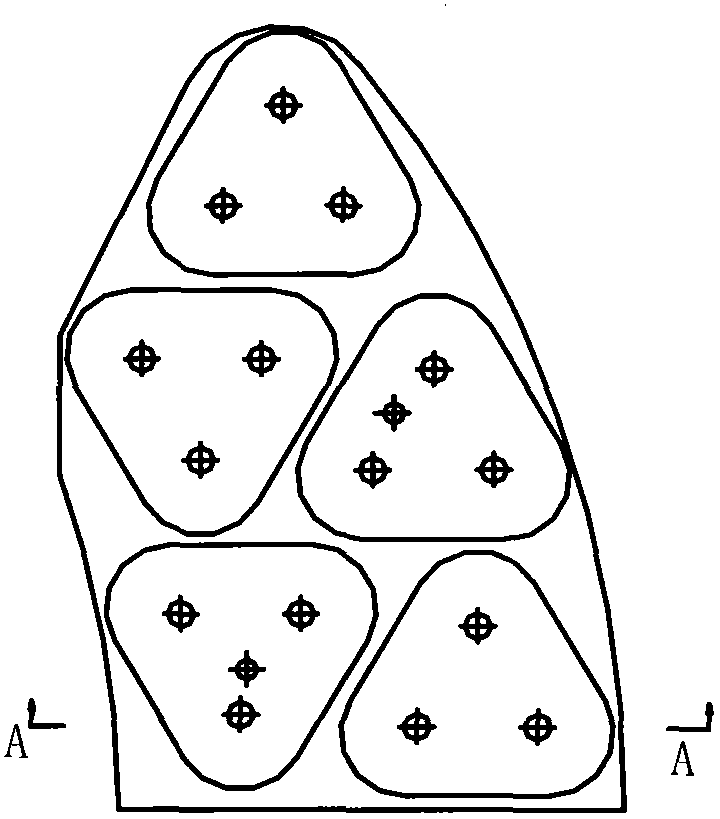

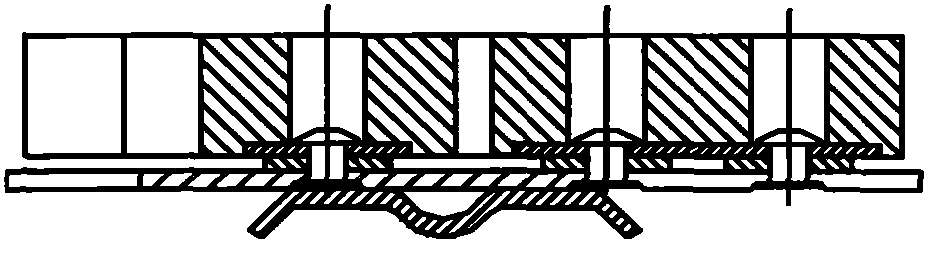

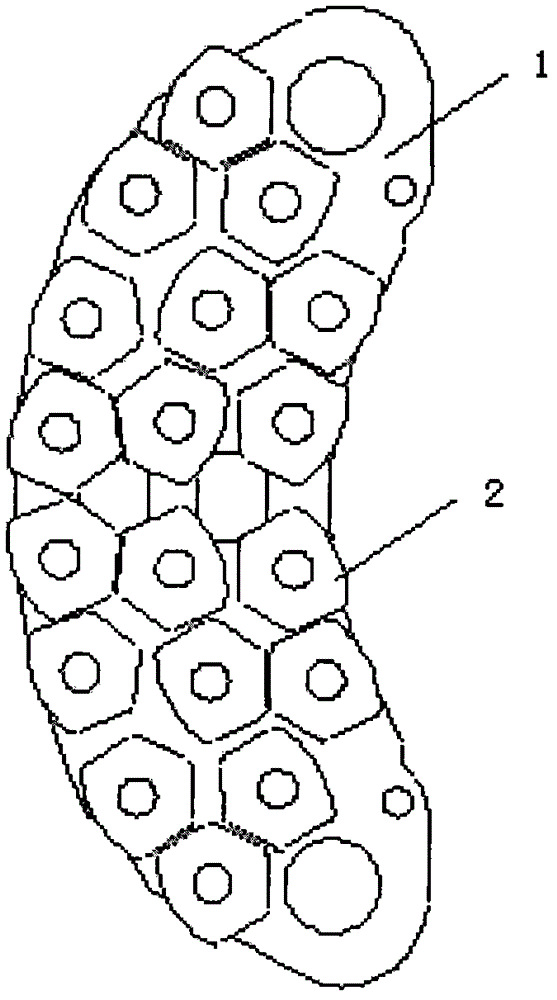

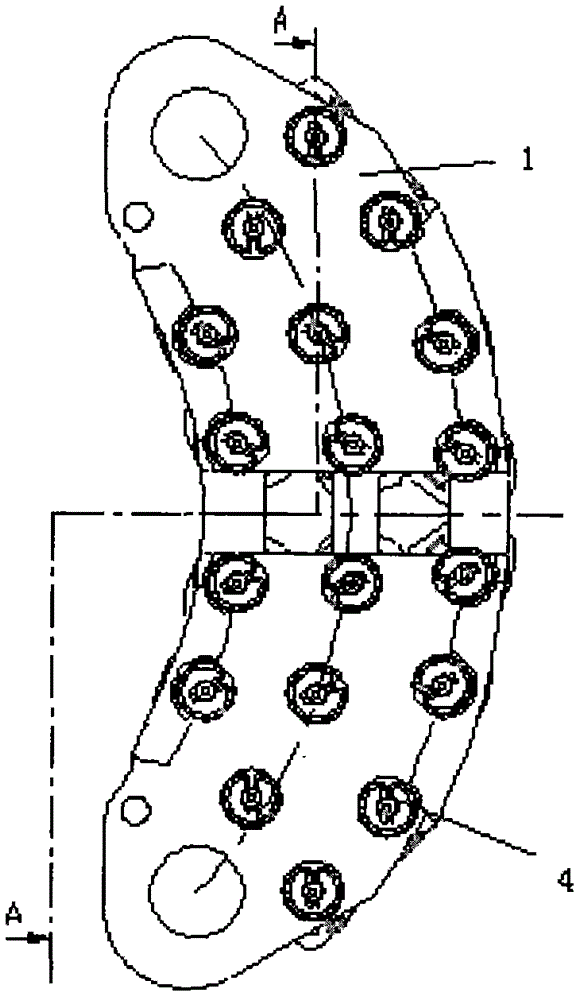

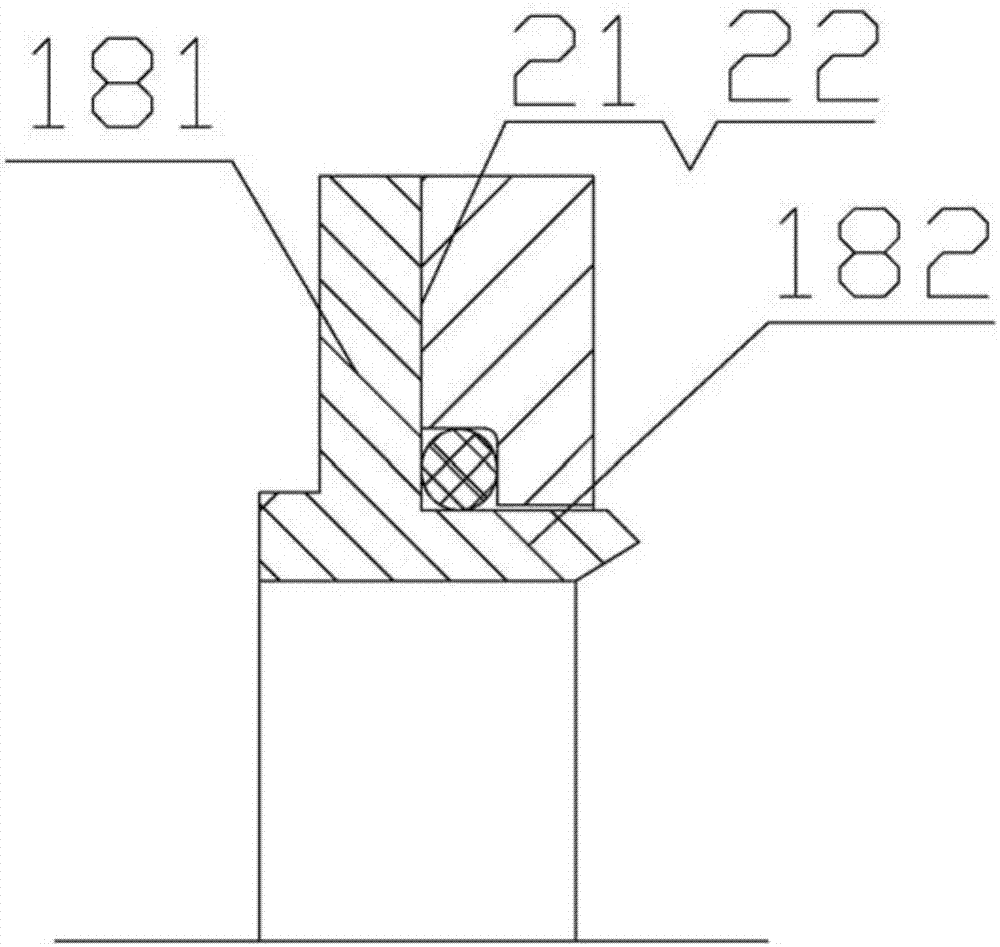

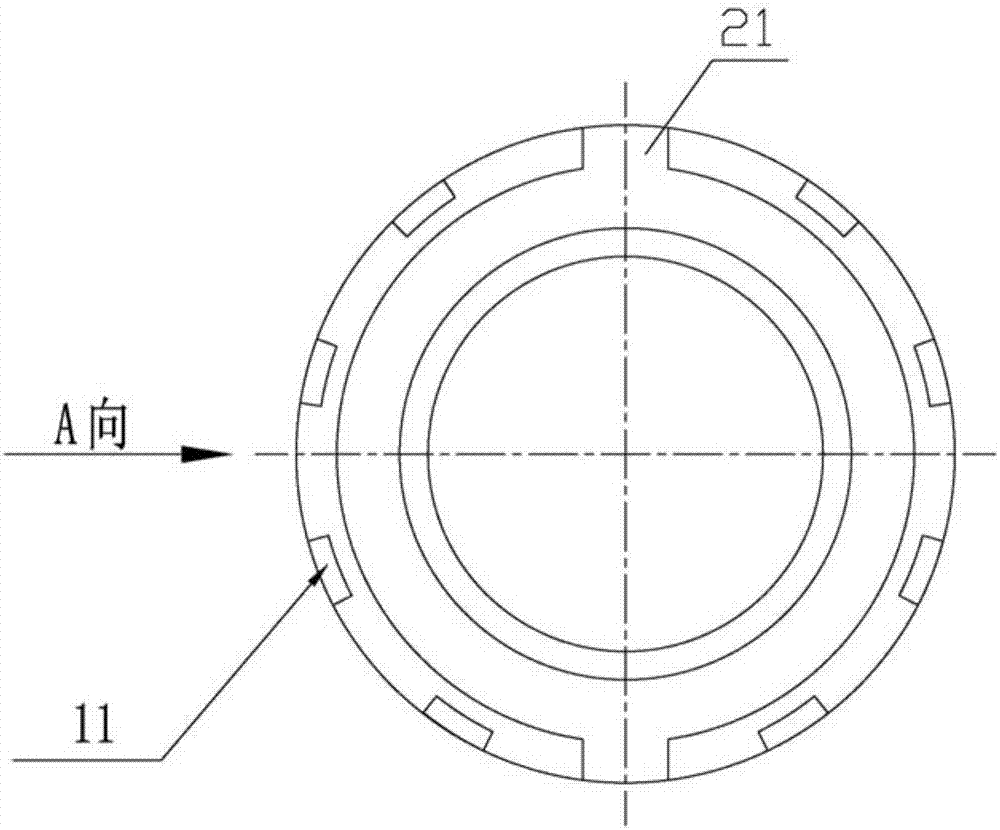

Floatation type brake pad for high speed train

InactiveCN102705405AAvoid bluePrevent thermal crackingBraking elementsVibration attenuationEngineering

The invention relates to a floatation type brake pad for a high speed train.. The floatation type brake pad is characterized by comprising a pad rear panel, a dovetail board, friction block bodies, an elastic supporting sheet and a round spring clip; the pad rear panel is in an arc half-sole structure; the elastic supporting sheet is provided with a spherical supporting surface and a center guide hole; the frication block is provided with a spherical supporting surface and a guide connection shaft with a clamping groove; the elastic supporting sheet, the round spring clip and the friction block bodies are in elastic floatation connection with the pad rear panel; the spherical supporting surface of the elastic supporting sheet and the spherical supporting surface at the root of a connection shaft of each friction block body are rotary, so that the balance of a braking force is realized; the three single-arc quadrilateral friction bodies in one group are mutually engaged and locked; and friction bodies of four cylindrical grinding column bodies are mutually engaged and locked in pairs. With the adoption of the floatation type brake pad provided by the invention, a maximum contact friction area can be obtained, so that a braking process is stable, and the functions of damping, vibration attenuation, noise reduction, heat radiation and the like can be achieved. The friction blocks are easy to replace; the operation cost is low; and the floatation type brake pad can be widely used for a braking system of the high speed train.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

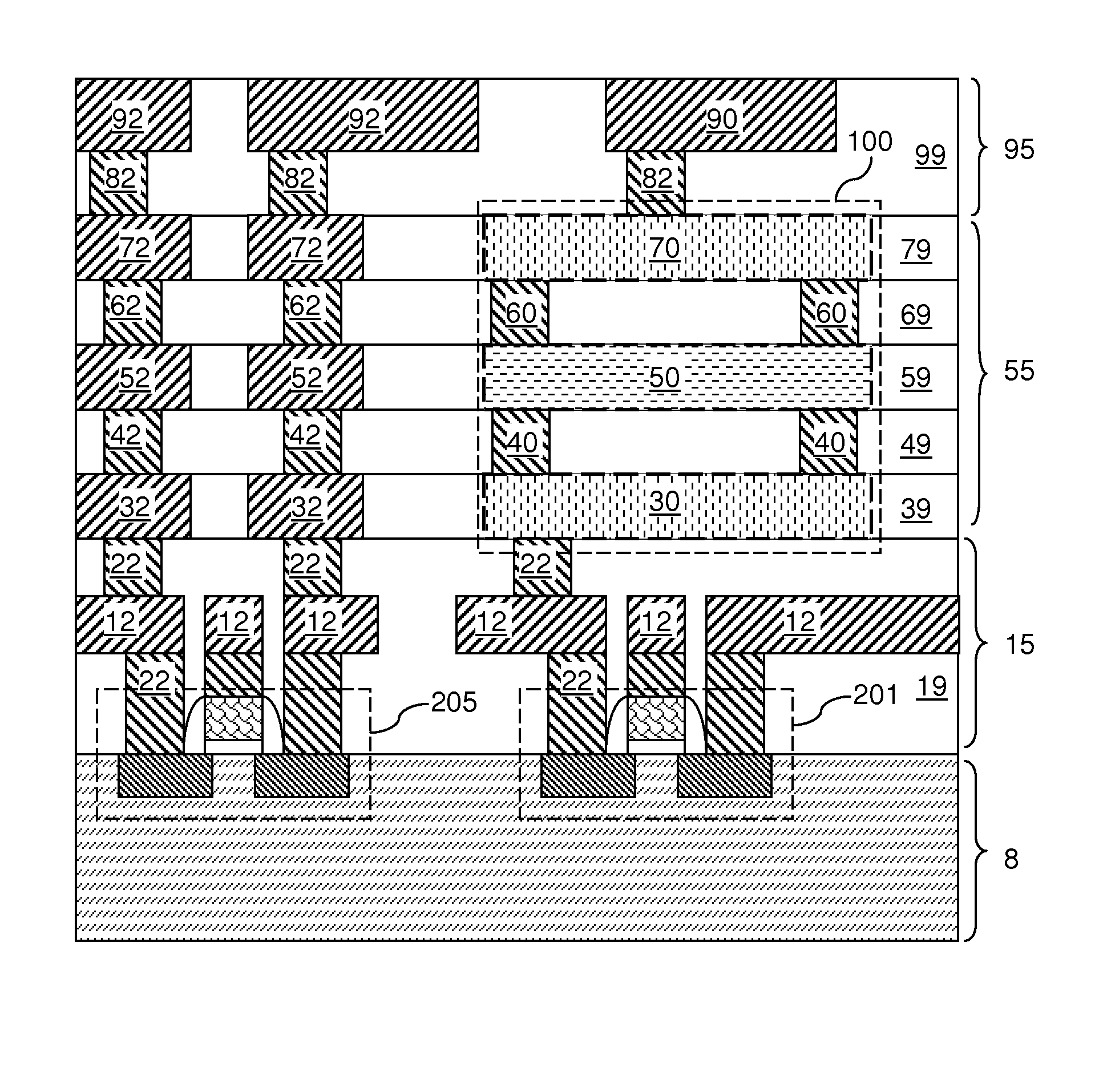

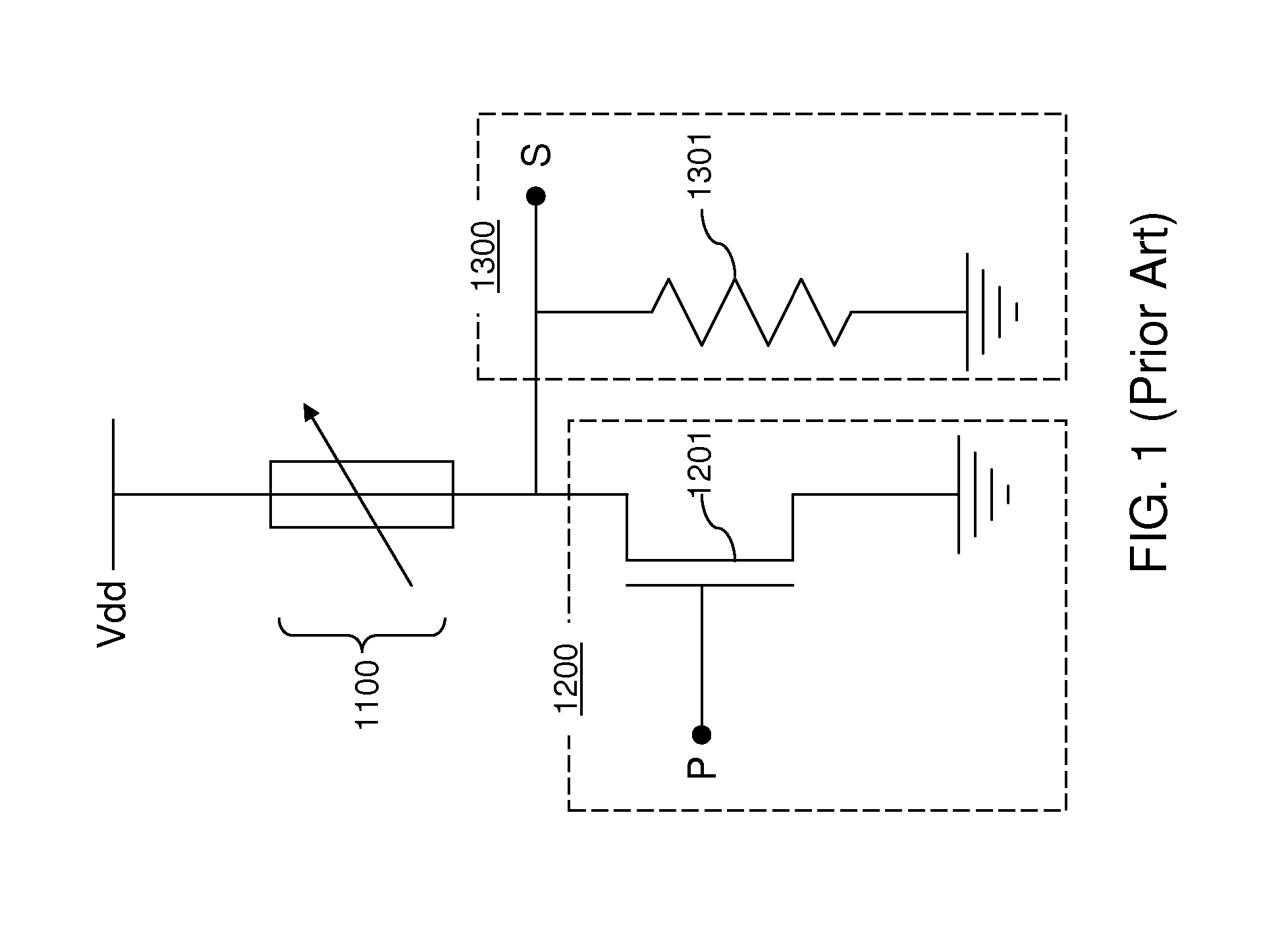

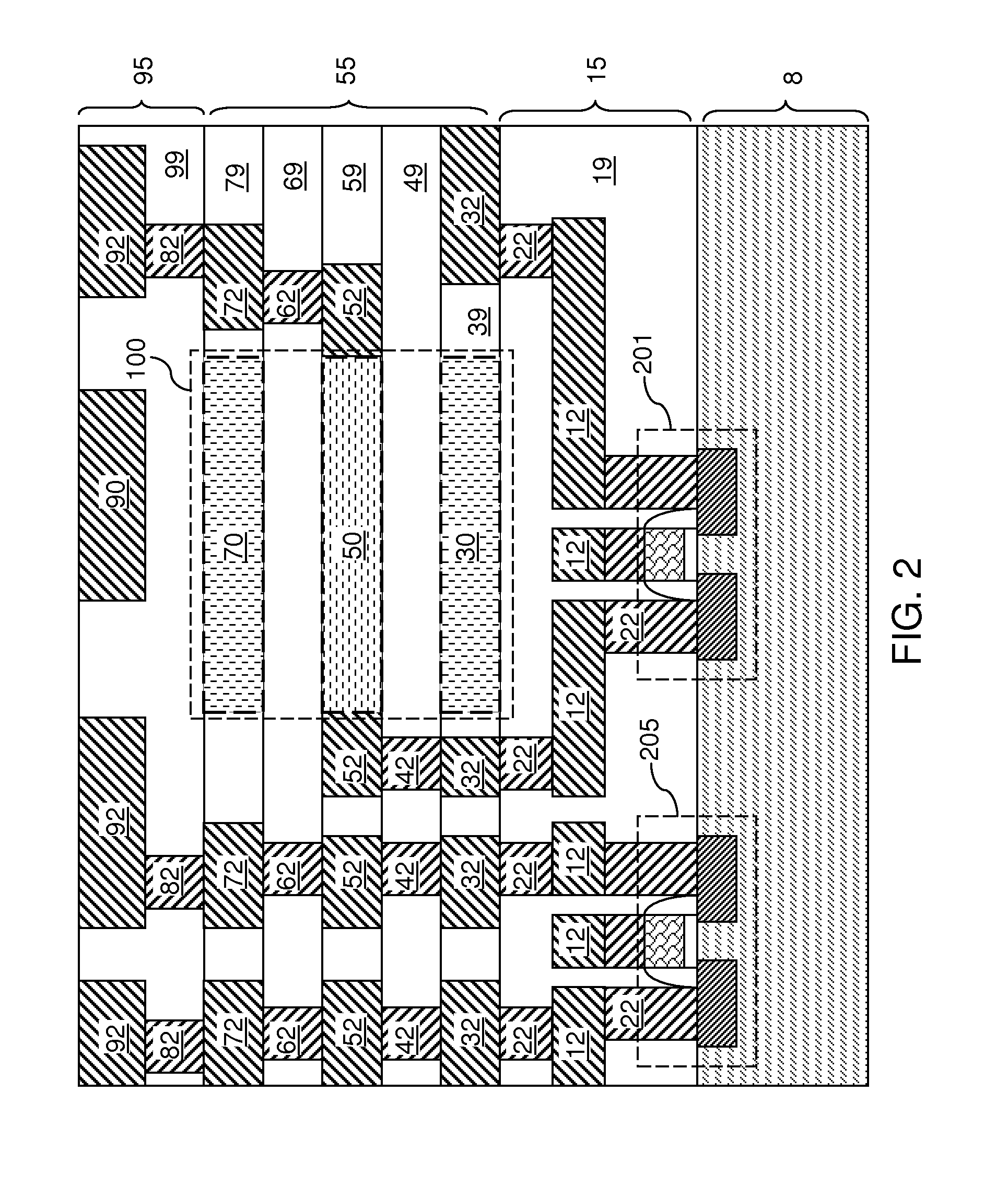

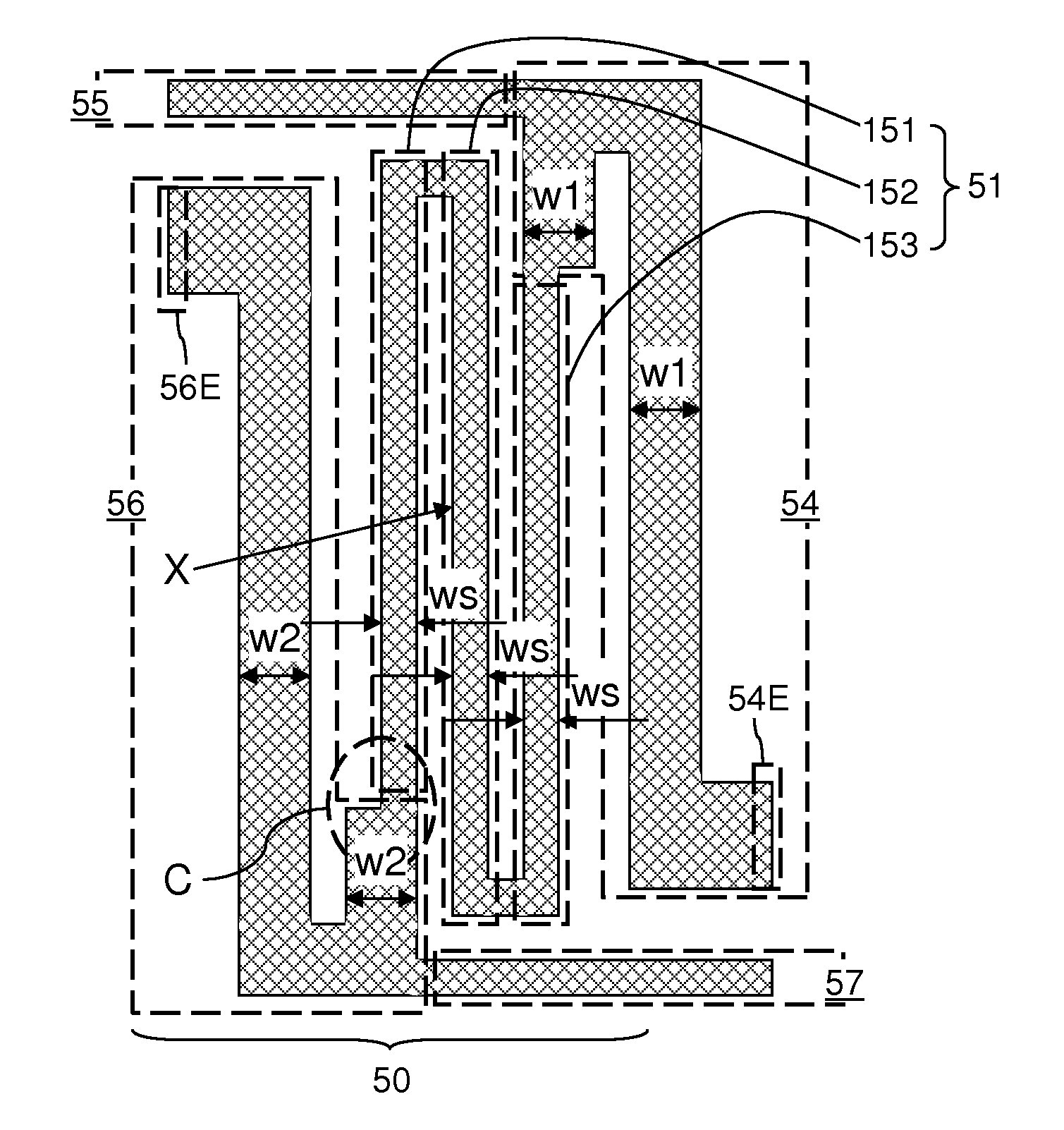

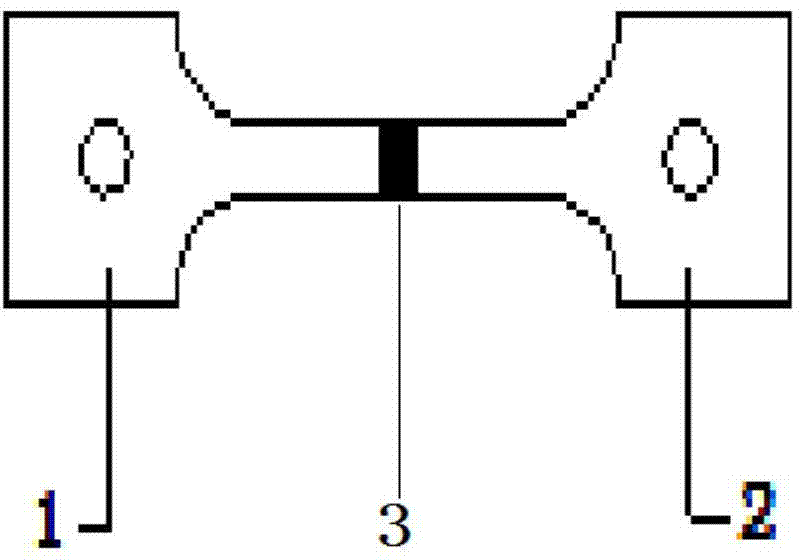

Electrically programmable metal fuse

ActiveUS8421186B2Reduce the required powerPrevent thermal crackingSemiconductor/solid-state device detailsSolid-state devicesElectricityMetal strips

A metal electrically programmable fuse (“eFuse”) includes a metal strip, having a strip width, of a metal line adjoined to wide metal line portions, having widths greater than the metal strip width, at both ends of the metal strip. The strip width can be a lithographic minimum dimension, and the ratio of the length of the metal strip to the strip width is greater than 5 to localize heating around the center of the metal strip during programming. Localization of heating reduces required power for programming the metal eFuse. Further, a gradual temperature gradient is formed during the programming within a portion of the metal strip that is longer than the Blech length so that electromigration of metal gradually occurs reliably at the center portion of the metal strip. Metal line portions are provides at the same level as the metal eFuse to physically block debris generated during programming.

Owner:GLOBALFOUNDRIES US INC

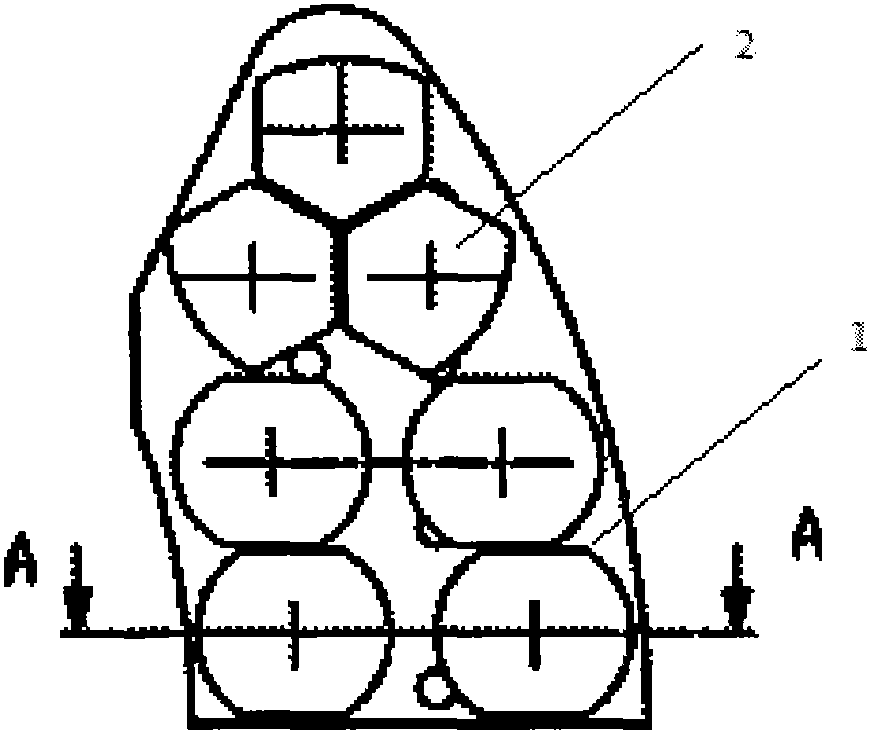

Floating type train brake lining with replaceable friction blocks

The invention relates to a floating type train brake lining with replaceable friction blocks. The train brake lining is characterized in that the train brake lining comprises a brake lining back plate, a plurality of brake lining friction block bodies, a plurality of elastic supporting pieces and a plurality of round spring clips; installation holes are arranged on the brake lining back plate; elastic supporting pieces are provided with spherical supporting surfaces and central guide holes; lower portions of friction block bodies are provided with spherical supporting surfaces and positioning connection shafts with clamping grooves, and connection shafts can penetrate through central guide holes of elastic supporting pieces and positioning holes of the back plate and are locked on the back plate by round spring clips to achieve floating connection; and friction block bodies are polygonal block bodies with blind holes in centers, and every three friction block bodies form an interlocking group, so that rotation of friction block bodies during operation of the brake lining is prevented. By the aid of the brake lining, the maximum contact friction area between the brake lining and a braking disk can be obtained during braking of a train, so that the braking process is stable, functions such as damping, vibration absorption, noise reduction and heat dissipation are provided, friction block bodies are easy to replace, the operation cost of the train is reduced, and the brake lining can be widely used in braking systems of high-speed trains.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

Electrically programmable metal fuse

ActiveUS20120306048A1Reduce the required powerPrevent thermal crackingSemiconductor/solid-state device detailsSolid-state devicesElectromigrationMetal

A metal electrically programmable fuse (“eFuse”) includes a metal strip, having a strip width, of a metal line adjoined to wide metal line portions, having widths greater than the metal strip width, at both ends of the metal strip. The strip width can be a lithographic minimum dimension, and the ratio of the length of the metal strip to the strip width is greater than 5 to localize heating around the center of the metal strip during programming. Localization of heating reduces required power for programming the metal eFuse. Further, a gradual temperature gradient is formed during the programming within a portion of the metal strip that is longer than the Blech length so that electromigration of metal gradually occurs reliably at the center portion of the metal strip. Metal line portions are provides at the same level as the metal eFuse to physically block debris generated during programming.

Owner:GLOBALFOUNDRIES US INC

Pouring method of hollow turbine guide vane

ActiveCN104308082AUniform temperature fieldEliminate casting stressFoundry mouldsFoundry coresWaxTurbine

The invention provides a pouring method of a hollow turbine guide vane. The pouring method comprises the following steps: (1) manufacturing a wax mold combination; (2) carrying out shell making on the wax mold combination to obtain a hollow turbine guide vane shell; (3) covering one layer of ceramic heat-preservation cotton on a shell vane body part; covering two layers of ceramic cotton on the whole shell; and putting the treated shell into a roasting furnace and carrying out casting, wherein in a casting process, the temperature of casting the shell is 1065-1085 DEG C and the pouring temperature is 1460-1480 DEG C. According to the pouring method of the hollow turbine guide vane, a pouring system of the hollow turbine guide vane is not changed and the shell temperature and the pouring temperature are adjusted so that the casting temperature field is changed; the two layers of ceramic cotton on the whole body and one layer of the ceramic heat-preservation cotton on the vane body part are matched so that after the temperature of the whole shell is improved, the temperature field is uniform, the casting stress is eliminated and the casting temperature is reduced; and furthermore, the temperature field on a casting vane body and an edge plate keeps uniform, the shell is effectively insulated and the casting stress is eliminated.

Owner:AECC AVIATION POWER CO LTD

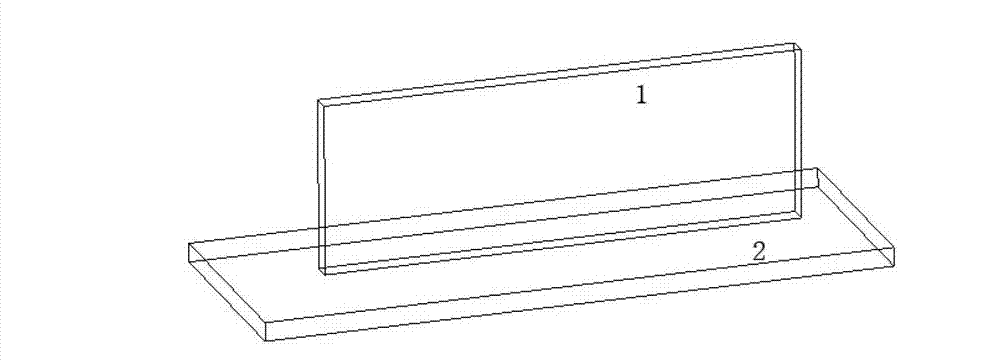

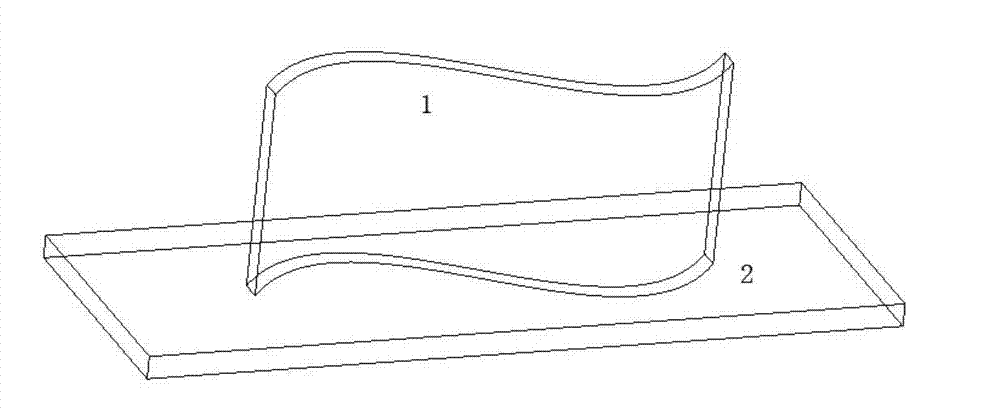

Hot bending furnace for colored glazing glass, method for preparing colored glazing toughened hot-bent glass and colored glazing toughened hot-bent glass

The invention discloses a hot bending furnace for colored glazing glass, a method for preparing hot-bent glass by using the hot bending furnace and the prepared colored glazing toughened hot-bent glass. The hot bending furnace comprises a furnace body (1), a push-pull base (2), an electric heating device (3) consisting of a fixed heating furnace wire (7) and a movable heating furnace wire (8), and an electrical appliance control device (4). In the process of performing hot bending treatment by using the hot bending furnace, the movable heating furnace wire (8) performs local auxiliary heating on the bending position of glass so as to ensure that the glass is completely attached to a mould at the bending position; the radius of a bending arc of the prepared colored glazing toughened hot-bent glass is less than or equal to 90mm, and the bending radian fully meets design requirements; multiple hot bending treatment such as single bending, continuous bending and the like can be realized; and the defects that the conventional hot-bent glass cannot be completely attached to the appropriate position of the mould, the prepared hot-bent glass has only one bending arc and the radius of the bending arc is more than 90mm are overcome.

Owner:新福兴玻璃工业集团有限公司

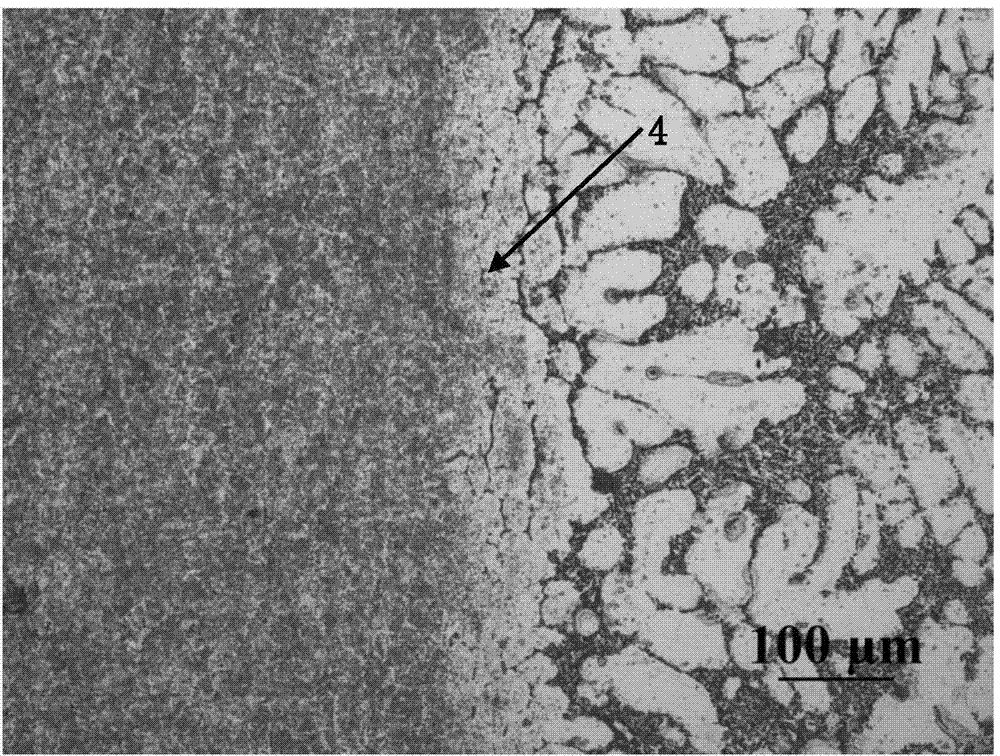

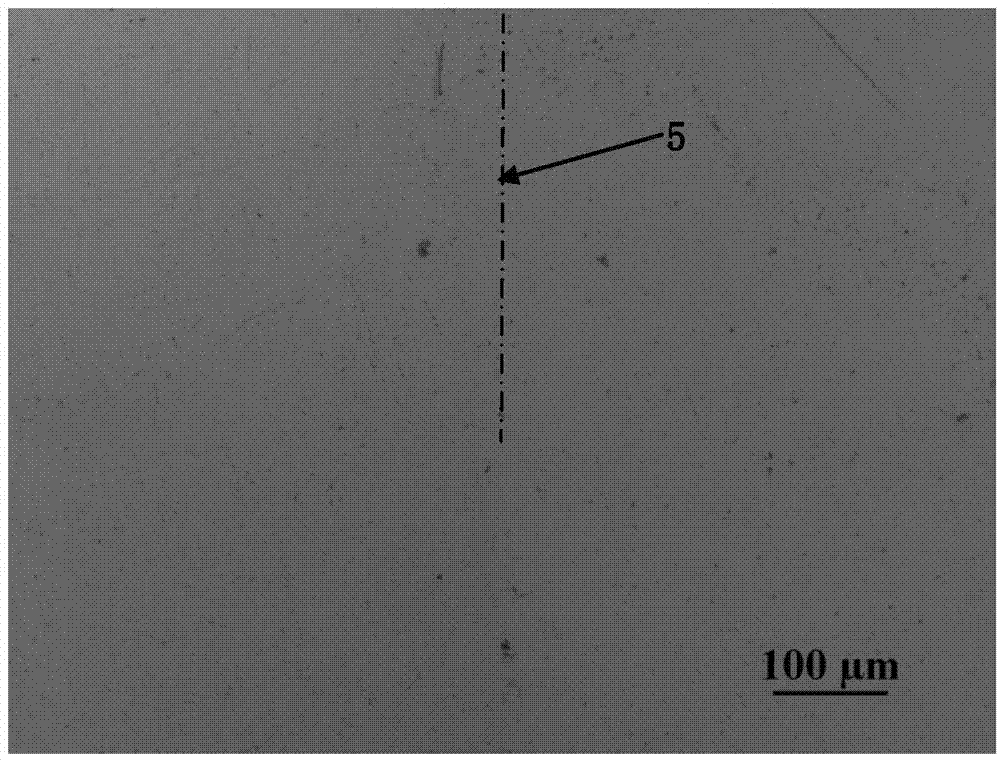

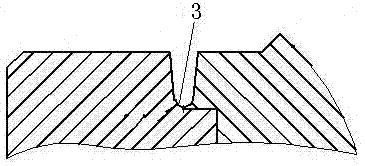

Solid-liquid connecting method of aluminum materials

InactiveCN104275469APrevent thermal crackingAvoid a series of problems such as composition segregationProcess equipmentSurface oxidation

The invention discloses a solid-liquid connecting method of aluminum materials. The solid-liquid connecting method comprises the following steps of carrying out surface zinc layer protection treatment on a to-be-connected solid-state aluminum alloy preset material; melting and refining to-be-poured aluminum alloy, and obtaining liquid-state pouring aluminum alloy; presetting the to-be-connected solid-state aluminum alloy preset material which is subjected to the surface zinc layer protection treatment in a die cavity; pouring the liquid-state pouring aluminum alloy into the die cavity, and enabling metallurgical bonding to be formed between the to-be-connected solid-state aluminum alloy preset material and the to-be-connected liquid-state pouring aluminum alloy, i.e. completing solid-liquid connection of different kinds of aluminum alloy materials. According to the solid-liquid connecting method of the aluminum materials, disclosed by the invention, a series of problems, such as oxidation, slag inclusion, air suction, hot cracking and composition segregation, which are often caused when a traditional welding method is used for connecting the aluminum alloy are solved, the difficulty that the metallurgical bonding is prevented from being formed by a surface oxidation film is overcome, the composite technological process is simple, the constraint which is limited by the appearance condition is small, the requirement on technological equipment is simple, and gas protection is not needed.

Owner:SHANGHAI JIAO TONG UNIV

Modified clay and clay-polymer composite

ActiveUS20090317627A1Prevent thermal crackingRecord information storageLight beam reproducingPolymer scienceDouble bond

A modified clay is provided, which includes a layered clay material intercalated with a modifier having a conjugated double bond and capable of producing free radicals when heated. A clay-polymer composite is also provided, which includes a polymer material and the modified clay, wherein the modified clay is dispersed in the polymer material and at least partially exfoliated. The modifier is capable of producing free radicals when heated to scavenge free radicals generated from thermal cracking or burning of the polymer material to prevent further thermal cracking of the polymer material.

Owner:GAINIA INTELLECTUAL ASSET SERVICES

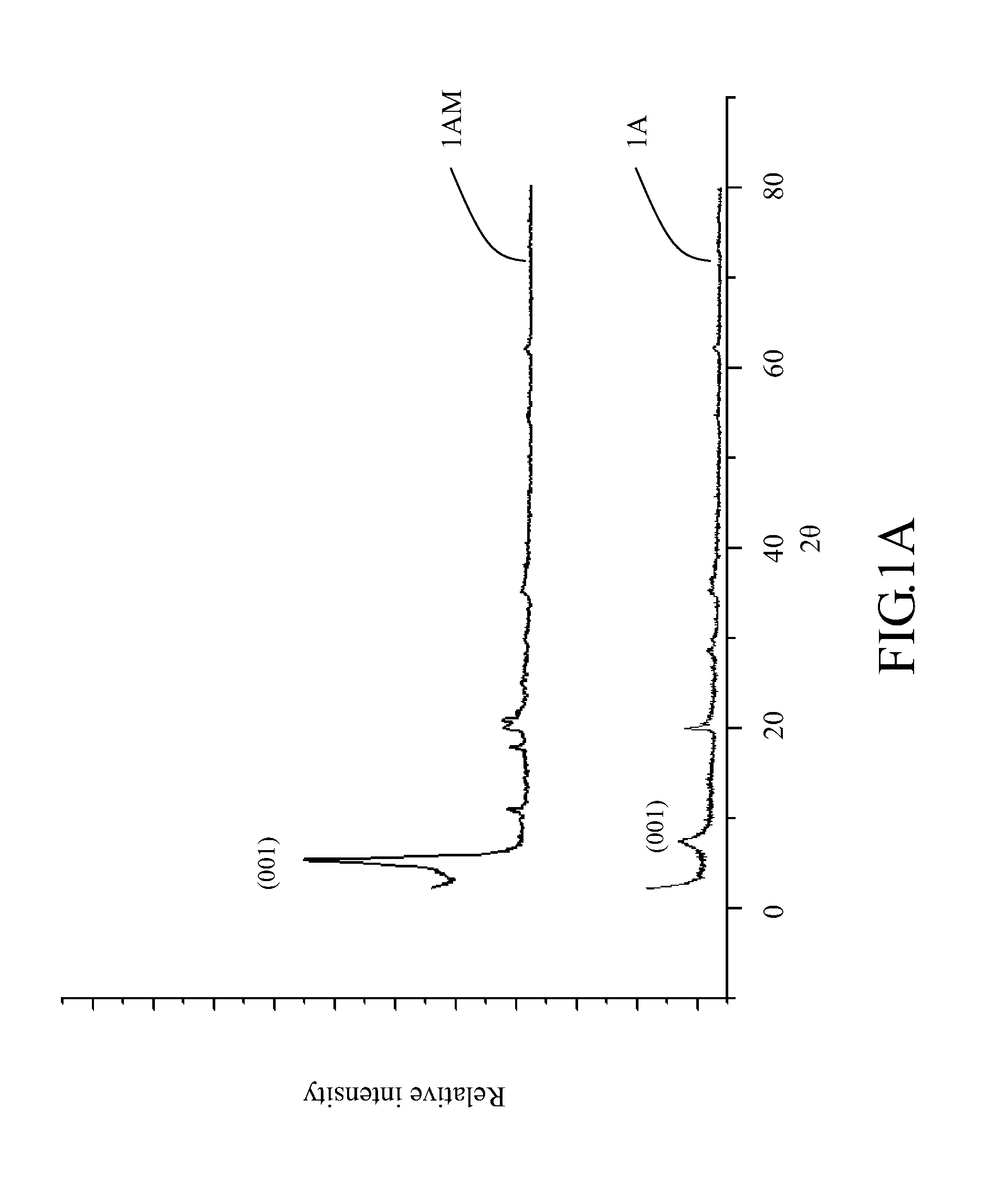

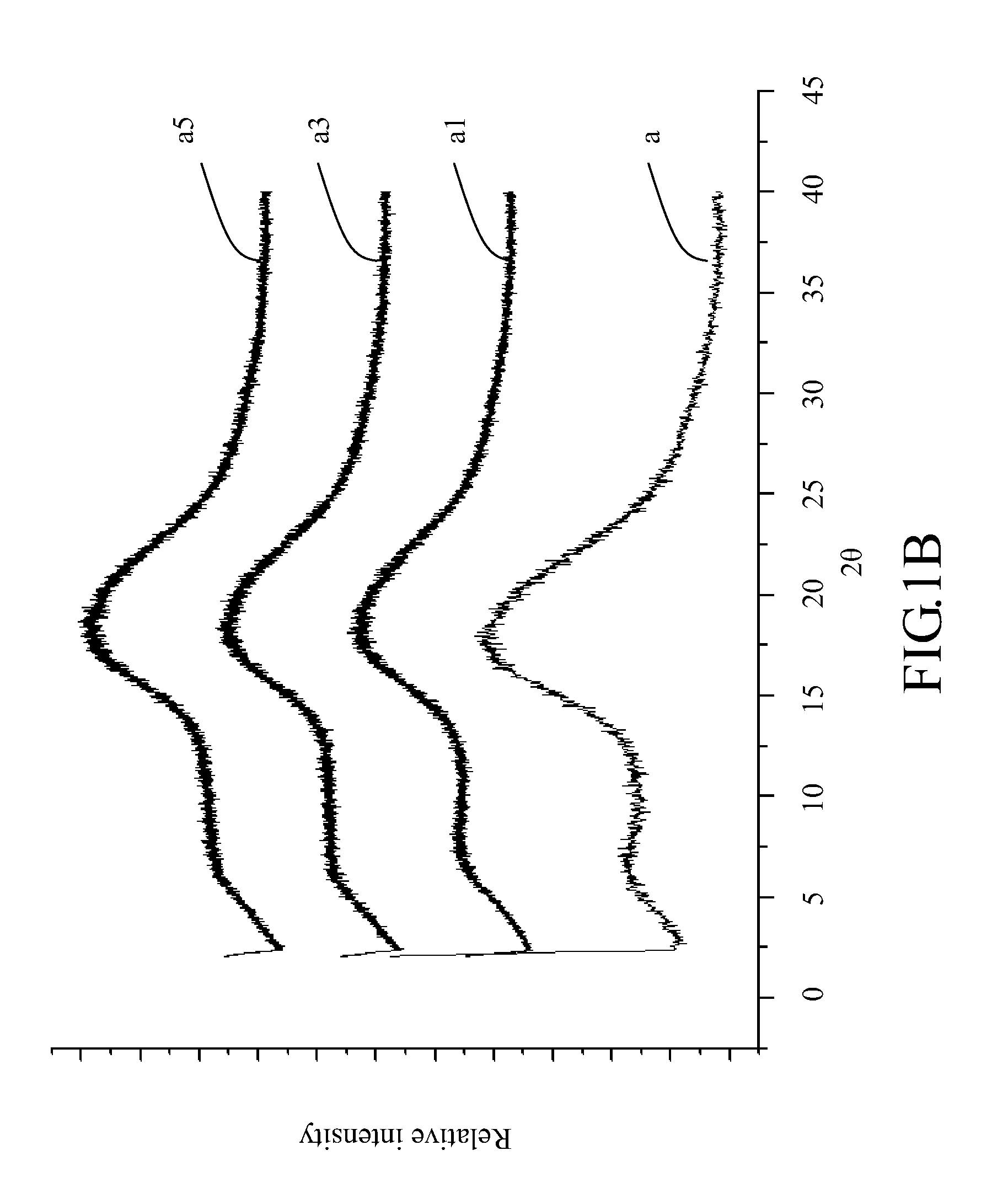

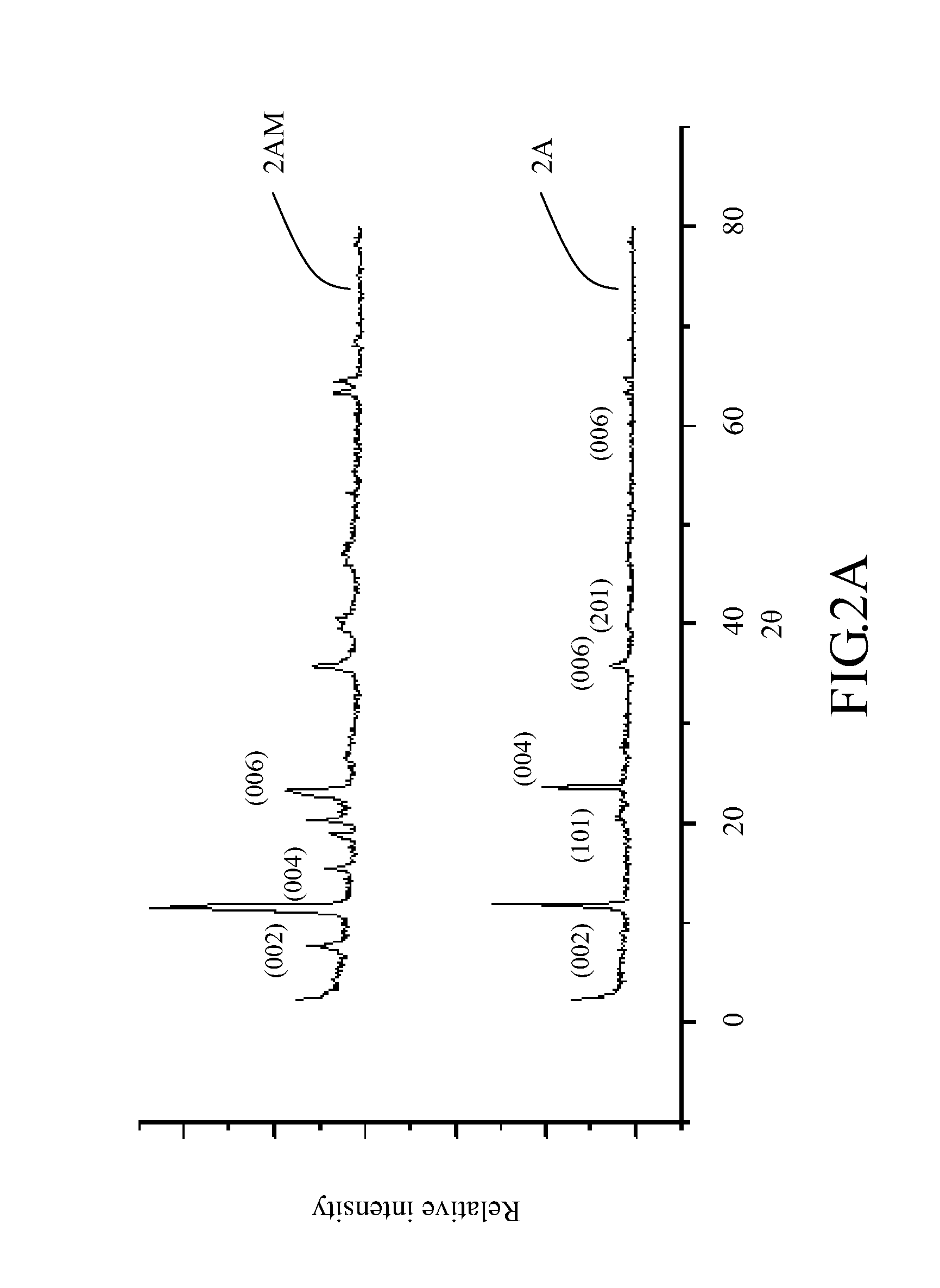

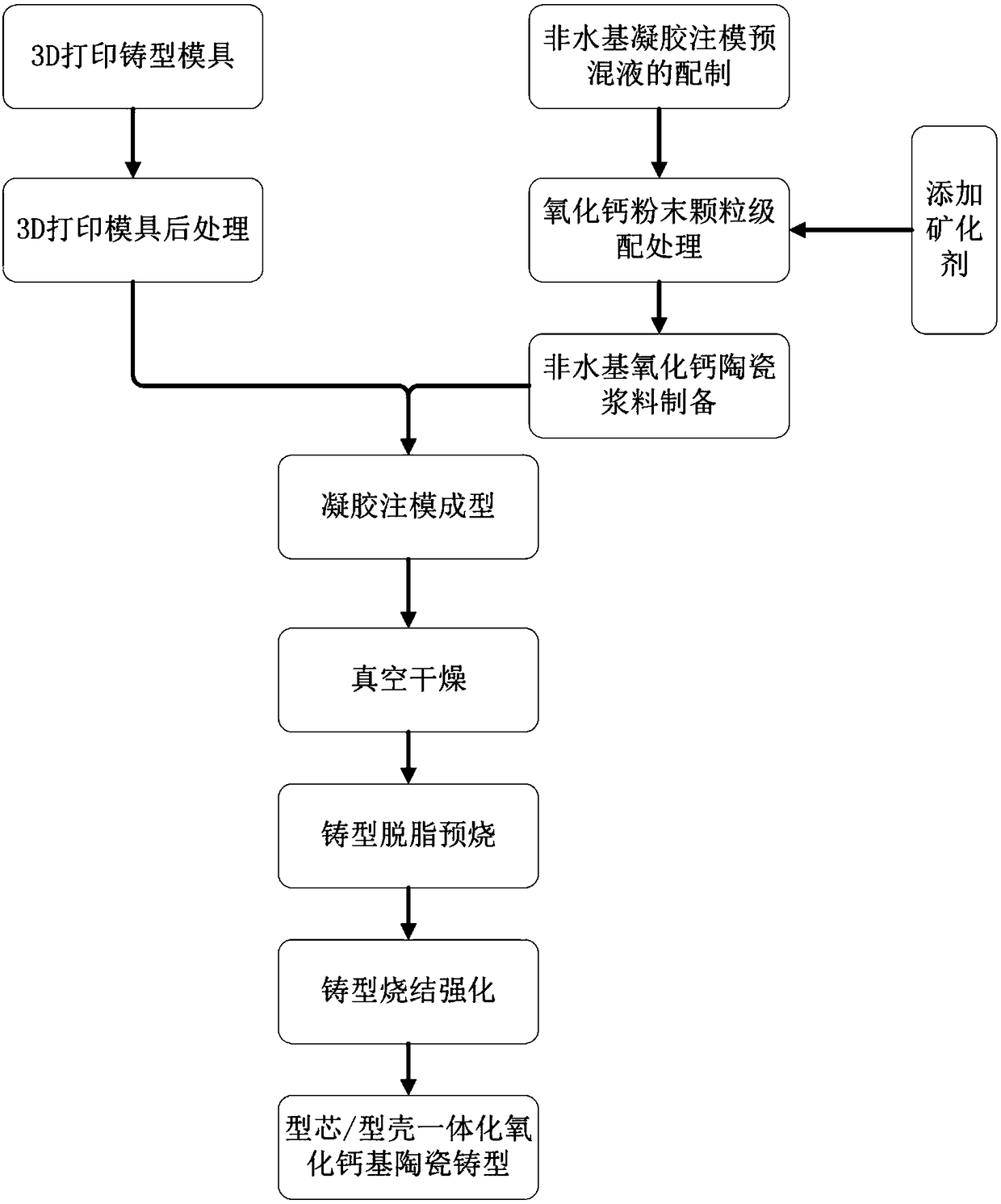

Non-water-based gel injection molding rapid-manufactured calcium oxide-based ceramic casting mold and preparation method thereof

InactiveCN108059445AInhibition of hydrationImprove sintering performanceAdditive manufacturing apparatusWater basedNiobium

The invention discloses a non-water based gel injection molding rapid-manufactured calcium oxide-based ceramic casting mold and a preparation method thereof, and belongs to the technical field of rapid precision casting. The method is characterized in that a mold required for 3D printing technology rapid manufacture is used, and simultaneously a non-water-based gel injection molding technology isapplied, so that the problem of hydration of calcium oxide powder during a casting mold preparation process is effectively solved, and the method can be successfully applied to the preparation of a mold core / mold shell integrated calcium oxide-based ceramic casting mold with complex internal structural parts and components. The manufactured calcium oxide-based ceramic casting mold has good overallperformance, and can meet the casting requirements of ultrahigh-temperature alloys such as a new generation of niobium-silicon-based high-temperature alloy and active light alloys such as titanium-aluminium alloy and magnesium-aluminium alloy, and the core removal performance is extremely excellent, so that the technical problems of difficult removal and high rejection rate of silicon oxide-basedand aluminium oxide-based mold cores are solved, therefore, the non-water based gel injection molding rapid-manufactured calcium oxide-based ceramic casting mold is a huge improvement on an existinginvestment mold precision casting and molding technology, and has broad market prospect and market value.

Owner:XI AN JIAOTONG UNIV

Profundity sterilization borehole face high-strength high-performance concrete

InactiveCN101152977AImprove carrying capacityStrong water sealingSolid waste managementChemical admixtureSlag

The present invention discloses a concrete with high strength and high performance for deeply and thickly frozen well wall. The double-doping technology of milled slag as the main mineral doping and different chemical doping is used; the invention is prepared after optimized combination and blending of mixture. The concrete is made by mixing P.0.42.5cement, machine-made sand, limestone rubble, milled rubble, I-level powder coal ash, TK-M intensifier, J851-D early strengthening high-early-strength water reducing agent, JQ-D anti-crack intensifying agent, high-efficiency water reducing agent of liquid polycarboxylic salt, and water. The present invention has the characteristics of the low preparation cost, the simple operation process, the applicability to engineering of the inside of a deeply and thickly frozen and a well wall on the outer layer, and so on.

Owner:盛天宝 +2

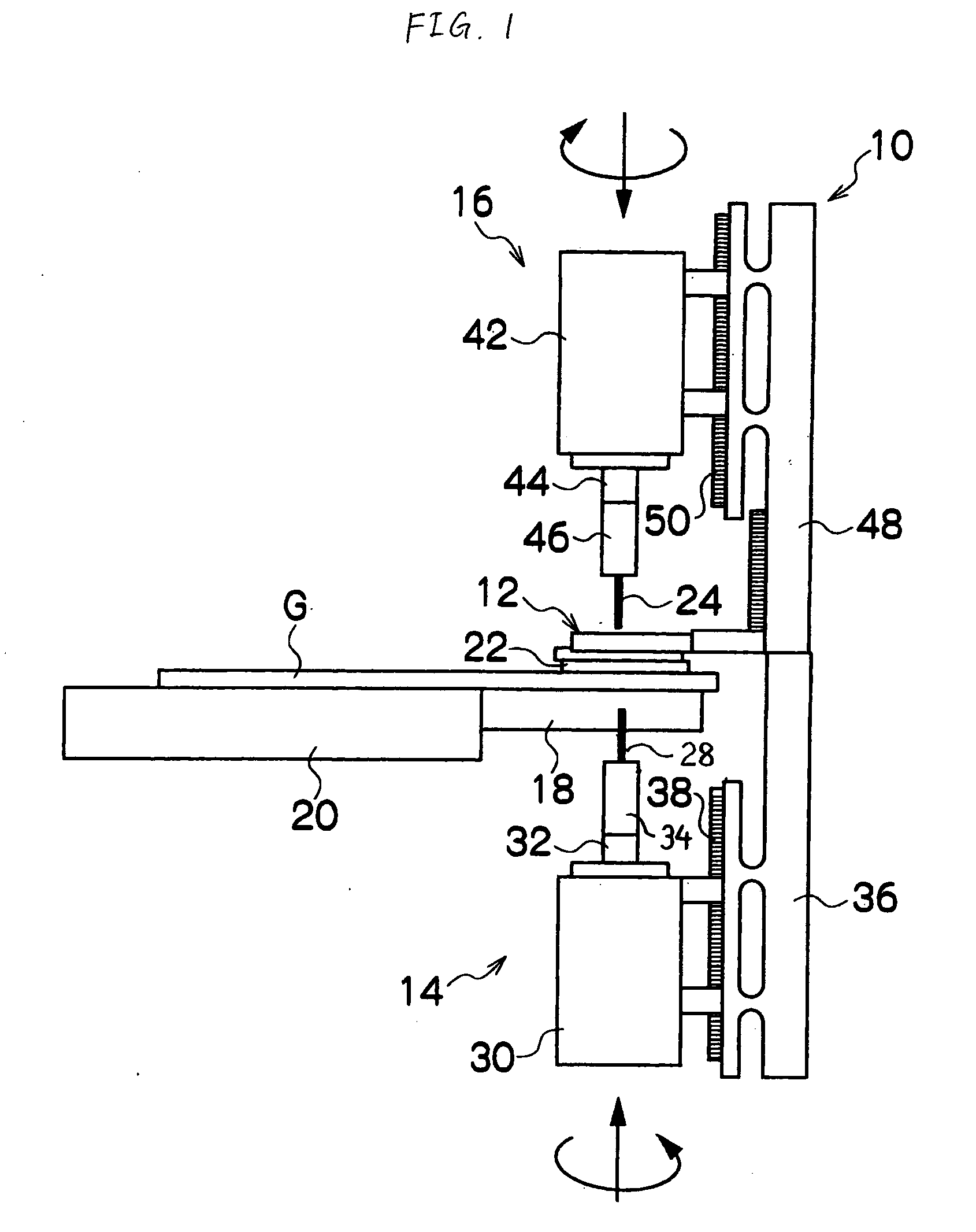

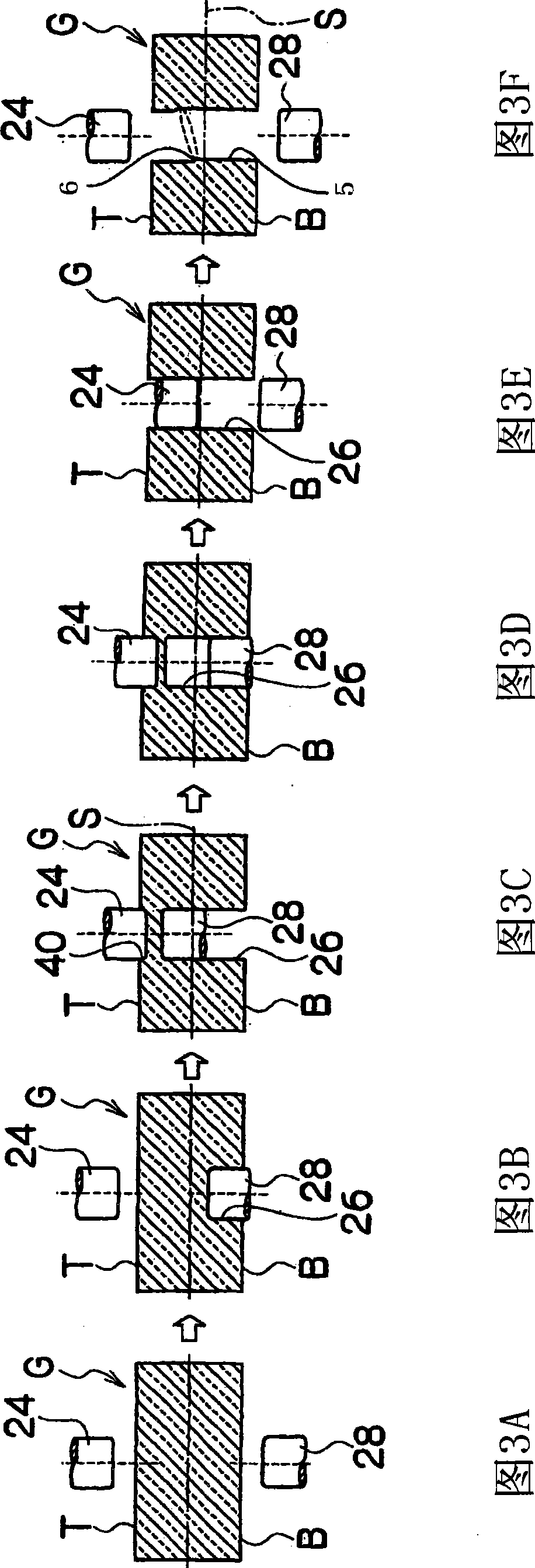

Method of boring glass substrate and glass substrate for plasma display manufactured by the method

InactiveUS20090197040A1Prevent thermal crackingAvoid it happening againLayered productsGas discharge vessels/containersDrill bitPlasma display

A first drill is pressed, in a rotating manner, against a lower surface of a glass substrate, to thus make a first hole of a predetermined depth. A second drill is pressed, in a rotating manner, against a position on an upper surface of the glass substrate opposing the first hole, to thus make a second hole, and the first hole and the second hole are brought into mutual communication with each other, to thus make a through hole in the glass substrate. A step on an internal periphery of the through hole formed as a result of the first hole and the second hole overlapping each other in a thicknesswise direction of the glass substrate is situated on the upper surface side than to the center of the glass substrate achieved in its thicknesswise direction.

Owner:ASAHI GLASS CO LTD

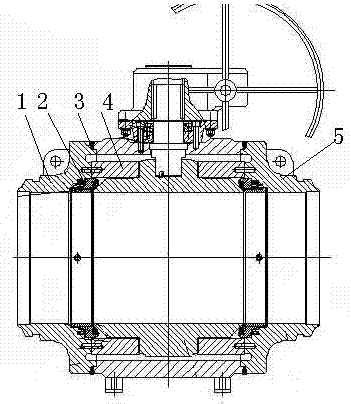

Automatic narrow-gap submerged arc welding process for all-welded fixed ball valve with medium and large calibers

ActiveCN102363239AHigh precisionHigh form factorArc welding apparatusWorkpiece edge portionsSlagEngineering

The invention discloses an automatic narrow-gap submerged arc welding process for all-welded fixed ball valves with medium and large calibers. The process comprises the following steps of: performing general assembly of products; 2) performing pre-welding preparation; 3) selecting materials; 4) selecting a weld joint, wherein the weld joint used during welding is a 'U'-shaped groove; 5) selecting process parameters; and 6) welding, namely welding the integral annular weld joint continuously at one time by a left welding method. By the process, a production process is reasonable, welding is performed after the general assembly and performance tests of the products, the process parameters which can meet the key requirements of weld penetration, low linear energy, low interlayer temperature, ultra-low welding deformation and high accuracy are selected, the materials and a welding skill are selected, and the welding groove is improved, namely a V-shaped groove and the like are changed into the 'U'-shaped groove; and by the process, slag and convenient to discharge, the key requirements of heat crack prevention, high toughness, small welding deformation and high welding accuracy are met, and the safety of a valve seat seal ring in a valve is protected effectively in the welding process.

Owner:CRETE GRP CO LTD

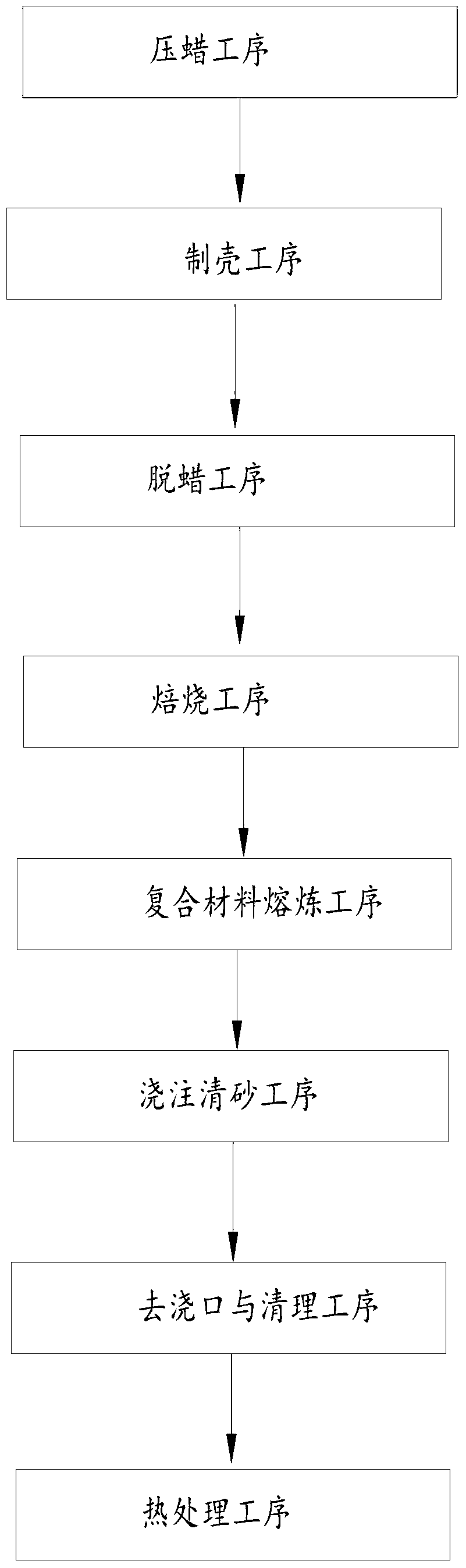

Production method of composite material stirring wing

InactiveCN103252449AImprove mechanical propertiesImprove mechanical properties; adding C can improve the compactness of the material structureFoundry mouldsFoundry coresWaxSmelting process

The invention provides a production method of a composite material stirring wing. The method comprises the following steps of: (1) wax pressing process; (2) shell making process; (3) dewaxing process; (4) roasting process; (5) composite material smelting process; (6) clean sand pouring process; (7) sprue removing and cleaning process; and (8) heat treatment process. The production method can be used for producing the stirring wing with high safety and reliability, and the high-quality composite material stirring wing can be produced by the method.

Owner:QINGDAO YUXIN VEHICLE ENG

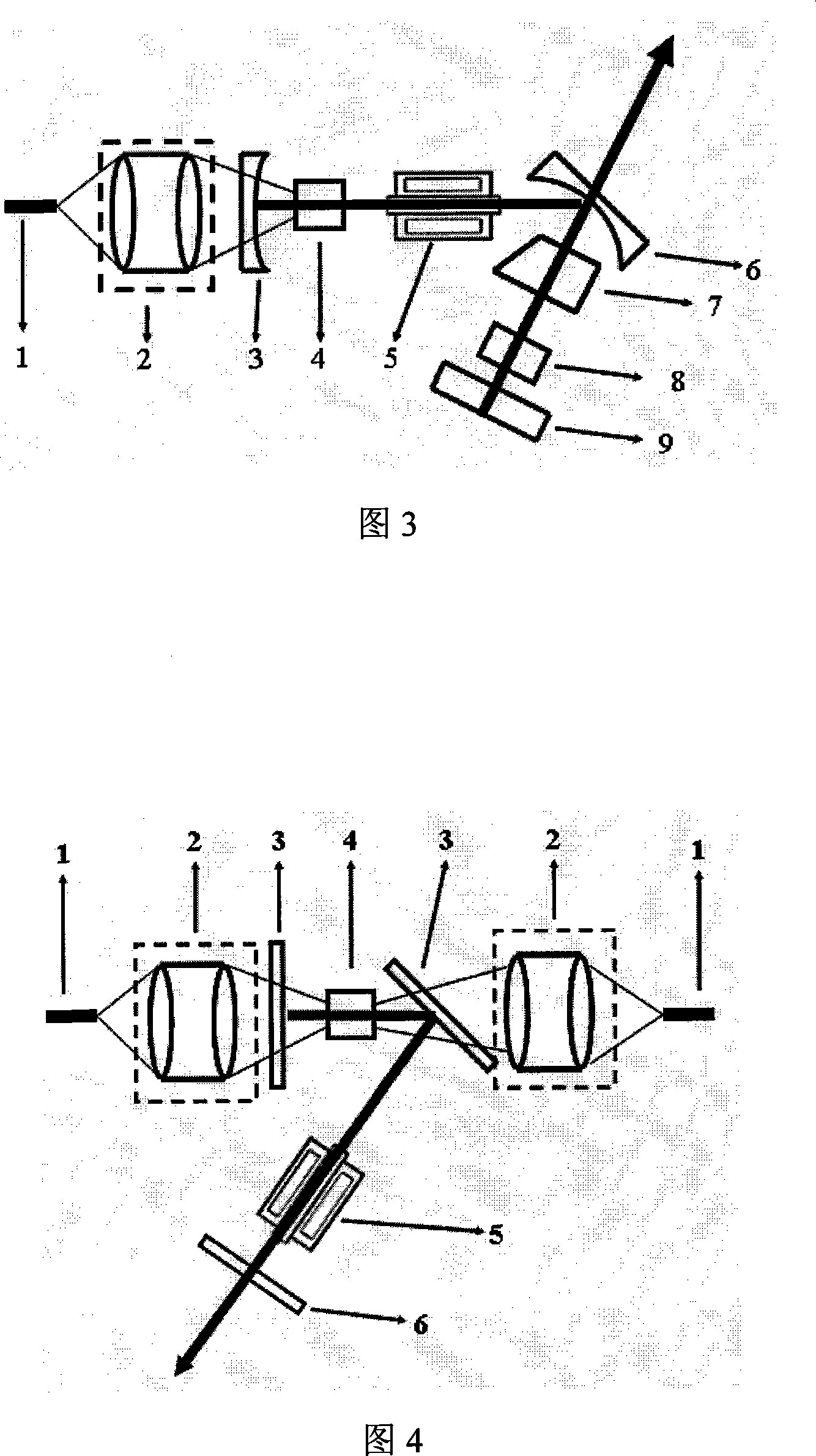

Solid laser

InactiveCN101202412AImprove conversion efficiencyQuality improvementExcitation process/apparatusOptical resonator shape and constructionResonant cavityFrequency conversion

The invention discloses a solid laser, comprising a resonant cavity which is provided with at least one end surface pumping device and at least one side pumping device at the same time. The oscillation laser in the resonant cavity is generated by lasing amplification of the gain medium of the end surface pumping device and the gain medium of the side pumping device at the same time; the gain medium of the end surface pumping device and the gain medium of the side pumping device are on the same optical axis of the resonant cavity. By the mutual relevance between the lasing amplification of the end surface pumping laser medium in the resonant cavity and the lasing amplification of the side pumping laser medium in the resonant cavity, the invention has the respective advantages of the end surface pumping type and the side pumping type, has high conversion efficiency, high quality of output beam and linear polarization, greatly improves the output power, correspondingly reduces the high thermal stress which is born by the end surface pumping laser medium and avoids the occurrence of thermal cracking. If the invention is combined with nonlinear optical and Q-adjusting elements, the invention can be widely applied to the nonlinear frequency conversion lasers and pulse lasers with great power.

Owner:SHENZHEN UNIV

Cement expansive material with harmonious coordinated development of expansion rate and concrete strength

ActiveCN104193266AIncreased durabilityStable expansionSolid waste managementUltimate tensile strengthFly ash

The invention relates to a cement expansive material with harmonious coordinated development of expansion rate and concrete strength, which is prepared from the following raw materials in parts by weight: 40-50 parts of gypsum powder, 16-25 parts of sulfoaluminate clinker, 5-15 parts of quicklime powder, 10-30 parts of fly ash, 2-8 parts of inorganic additive and 1-5 parts of inorganic retarder. The product has the advantages of simple preparation technique, no need of calcining or stirring and lower production cost, and can save abundant energies; and the early expansion character development is quick, and the medium-later expansion development is stable, so the expansion rate can be coordinated with the development of the concrete strength.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

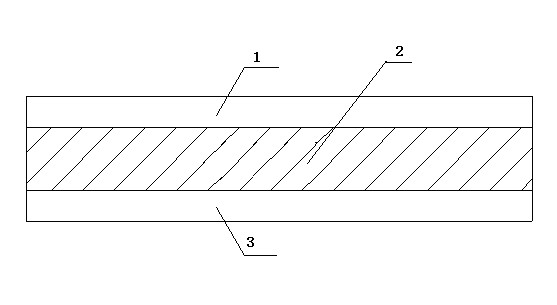

Laminated composite solder

InactiveCN102398123APrevent thermal crackingConducive to dimensional accuracy controlWelding/cutting media/materialsSoldering mediaAlloyComposite solder

The invention relates to a laminated composite solder, which is used for welding base materials such as metals, the metals and ceramics, the ceramics and the like. The composite solder consists of an upper layer, a middle layer and a lower layer in the thickness ratio of (0.5-2):(0.5-4):(0.5-2), wherein the upper layer and lower layer are made of the same precious metal alloy or a precious metal alloy respectively; the middle layer is made of oxygen-free copper or a copper-silver alloy; precious metal-based alloys on the upper and lower layers are one or two of Ag, AgCu (10-50), AgCu(10-50)Ni(0.1-0.45), AgCu(23-28)In(9-16), AgCu(20-32)Pd(5-20), Au(79-81)Cu(19-21), Au(82-83)Ni(17-18) and AuAg(2-20)Cu(10-55); and all the three layers are in a metallurgy bonding state. The composite solder has high welding performance and can meet the performance requirements of a vacuum electronic industry on solder materials.

Owner:YUNNAN WODIAN TECH DEV

Method of boring glass substrate and glass substrate for plasma display manufactured by the method

InactiveCN101522382APrevent thermal crackingGas discharge vessels/containersTube/lamp vessels exhaustionEngineeringDrill

A first hole of a predetermined depth is formed in a glass substrate by pressing a first drill against the lower surface of the glass substrate while rotating the first drill. A second hole is formed in the glass substrate by pressing a second drill against the upper surface of the glass substrate at the position facing the first hole while rotating the second drill. A through-hole is formed in the glass substrate by connecting the first hole with the second hole. Since the first and second holes are overlapped with each other in the thickness direction of the glass substrate, a step part formed on the inner peripheral part of the through hole is positioned on the upper surface side higher than the center of the glass substrate in the thickness direction.

Owner:ASAHI GLASS CO LTD

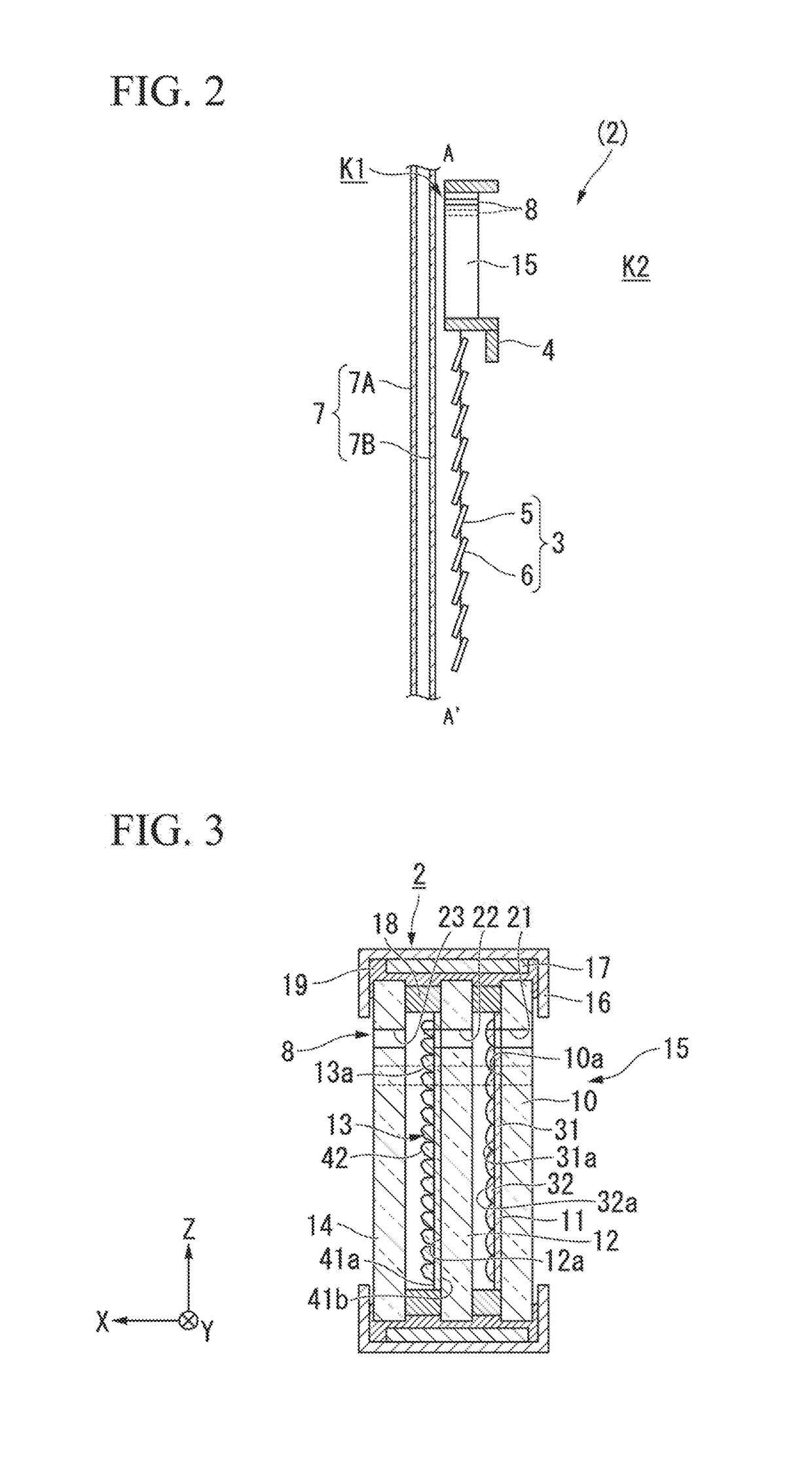

Daylighting device

InactiveUS20170362883A1Prevent thermal crackingSuppressing temperature increaseVentilation arrangementLight protection screensDaylightEngineering

A daylighting device of the present invention includes: a daylighting member including: a first light-transmitting base member; and a plurality of protruding, light-transmitting daylighting sections provided on a first face or a second face of the first light-transmitting base member; and a ventilation hole configured to enable a space on the first face to communicate with a space on the second face opposite from the first face.

Owner:SHARP KK

High-flow-state anti-cracking concrete and preparation method thereof

InactiveCN111484282AImprove crack resistanceImprove impermeabilitySolid waste managementEpoxyWater reducer

The invention relates to high-flow-state anti-cracking concrete comprising the following components in parts by weight: 220-430 parts of cement, 130-200 parts of water, 30-90 parts of fly ash, 70-130parts of mineral powder, 550-880 parts of a fine aggregate, 1100-1350 parts of a coarse aggregate, 6-15 parts of a super absorbent resin particles, 20-60 parts of sponge rubber particles, 3-15 parts of steel fibers, 2-8 parts of epoxy resin and 4-10 parts of a water reducing agent, wherein the sponge rubber particles are formed by crushing sponge rubber. The preparation method comprises the steps:S1, uniformly mixing the super absorbent resin particles with the sponge rubber particles; S2, adding the mixture obtained in the step S1 into water to enable the super absorbent resin particles andthe sponge rubber particles to pre-absorb water, so as to obtain a pre-water-absorbing mixture; and S3, mixing the cement, the fly ash, the mineral powder, the fine aggregate, the coarse aggregate, the steel fibers, the epoxy resin, the water reducing agent, water and the pre-water-absorbing mixture, and uniformly stirring to obtain the high-flow-state anti-crack concrete. The high-flow-state anti-cracking concrete is good in anti-cracking performance and has the effect of improving the durability of the concrete.

Owner:上海练定新材料科技有限公司

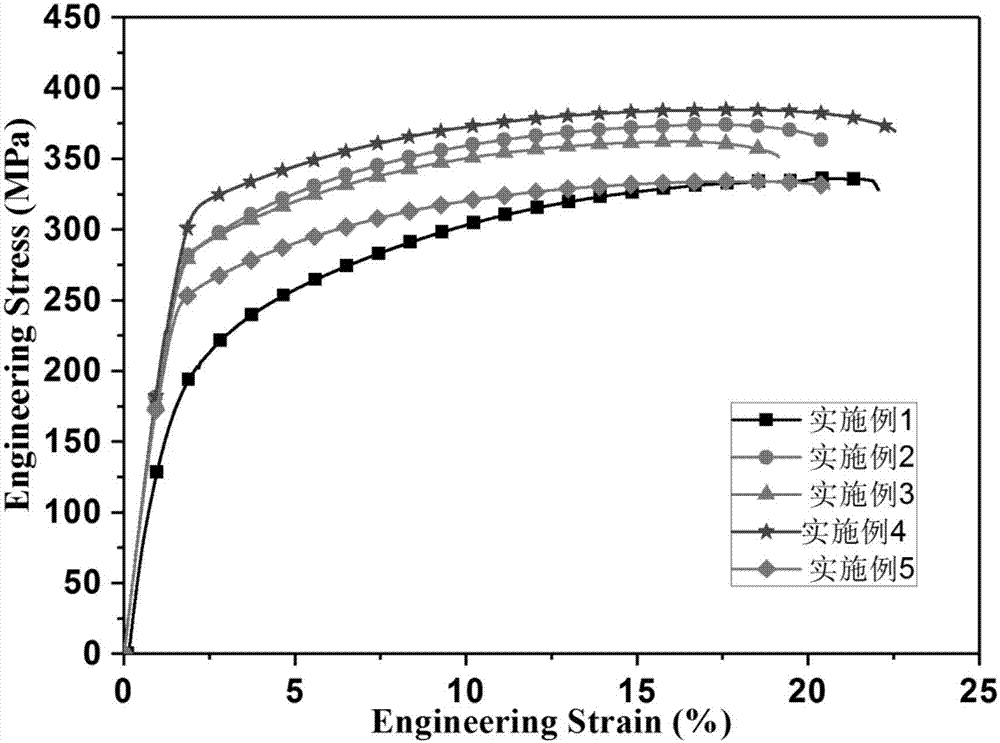

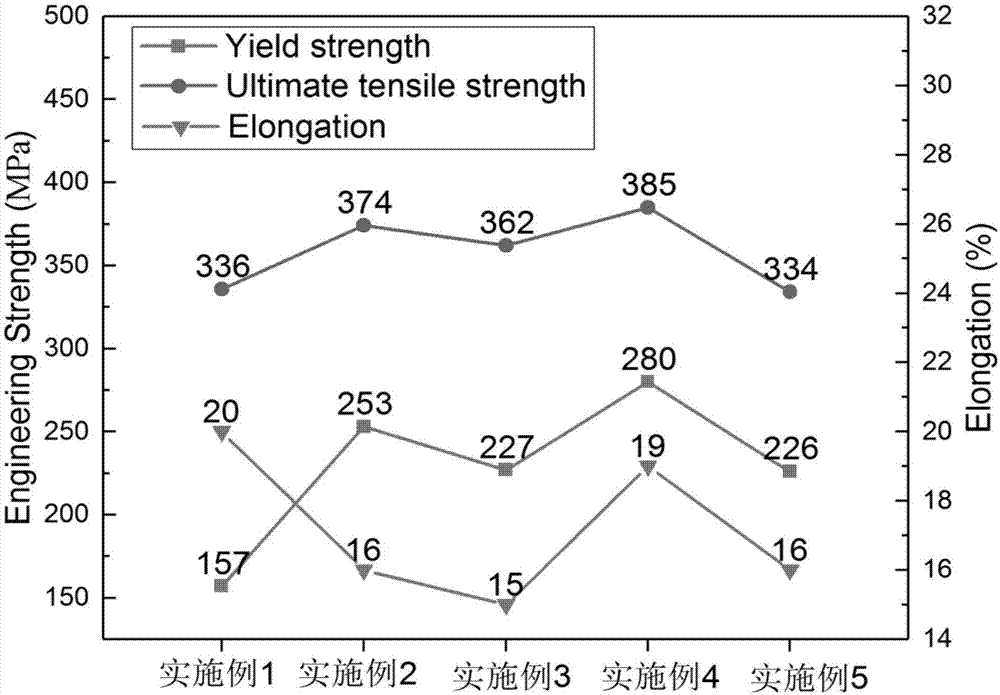

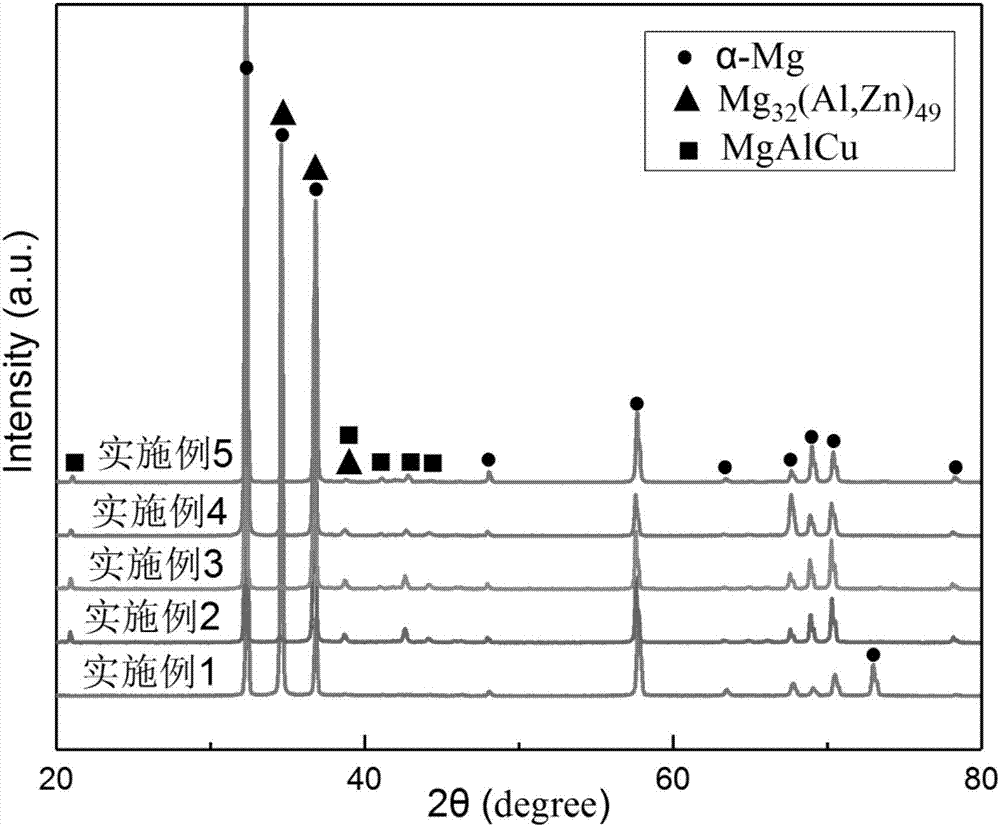

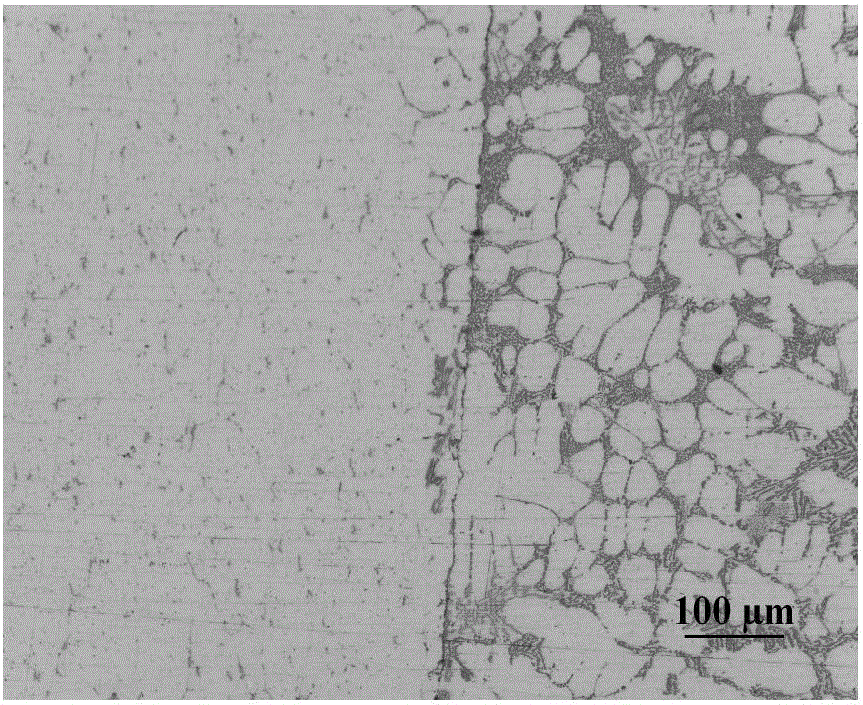

High-strength Mg-Zn-Al deformation magnesium alloy containing Cu and preparation method thereof

The invention relates to a high-strength Mg-Zn-Al deformation magnesium alloy containing Cu and a preparation method thereof, and belongs to the technical field of magnesium alloys. The magnesium alloy consists of the following components in percentage by mass: 5.5-6.5% of Zn, 2.5-3.5% of Al, 0.1-2.1% of Cu, 0.15% or less of inevitable impurities, and the balance of magnesium. 0.1-2.1% of Cu element is added in the magnesium alloy, so that low-melting-point beta-Mg17Al12 phases continuously distributed in a netty form are gradually converted to high-melting-point MgAlCu ternary phases finely scattered, formation of the beta-Mg17Al12 phases is weakened, the mechanical performances of the alloy are improved, and the alloy can serve under higher temperature; the MgAlCu ternary phases can effectively stop growth of grains in dynamic recrystallization process; and the grain size in final extrusion state is about 2 microns. The preparation method of the magnesium alloy is easy to perform, short in time consumption, low in equipment requirements and low in production cost; graphite powder is firstly used for covering when the magnesium alloy is homogenized; and then, an aluminum foil is used for packing to preferably prevent overheating or overburning of the alloy.

Owner:重庆昱华新材料科技有限公司

Solid-liquid connecting method for aluminum-aluminum metal

InactiveCN106238710AAvoid oxidation slag inclusionsAvoid inhalationFoundry mouldsFoundry coresSlagSurface oxidation

The invention provides a solid-liquid connecting method for aluminum-aluminum metal, comprising the following steps of placing a solid aluminum material into a die cavity after carrying out nickel layer protection on the surface of the solid aluminum material; and pouring the molten aluminum material into the die cavity to cast, and forming metallurgical bonding between aluminum-aluminum metal materials to finish solid-liquid connection of the aluminum-aluminum metal. Compared with the prior art, the solid-liquid connecting method has the following beneficial effects that 1, compared with the traditional welding method, the solid-liquid connecting method is used for avoiding problems such as oxidation slag inclusion, air suction, hot crack and component segregation; 2, compared with a solid-solid connecting method, the solid-liquid connecting method is constrained a little by an appearance condition and can theoretically realize any-shaped aluminum-aluminum connection; and 3, the surface oxidation film problem is favorably solved by using a composite surface treatment process, a uniform and continuous nickel layer can be formed on the surface of a solid aluminum prefabricated material, so that the aluminum-aluminum connecting strength reaches to the relatively high level.

Owner:SHANGHAI JIAO TONG UNIV

Self-forcing cooling high-temperature resisting mechanical sealing device

The invention relates to a self-forcing cooling high-temperature resisting mechanical sealing device. A movable ring, a static ring seat and a heat insulation ring of the sealing device are mounted ona rotating shaft in a sleeving mode; a flow guiding groove is formed in the movable ring; an annular shell is mounted on the heat insulation ring and the static ring seat in a sleeving mode, one sideof the annular shell and the heat insulation ring are fixed and sealed, a liquid medium annular inlet is formed by the inner wall of the other side of the annular shell and the surface of the outer circle of the static ring seat, an annular membrane piece group is mounted on the heat insulation ring in a sleeving mode, a gap is formed between the annular membrane piece group and the outer ring wall of the heat insulation ring, and the outer edges of the two sides of the annular membrane piece group and the static ring seat as well as the heat insulation ring are subjected to full-length welding in the circumferential direction, so that a cavity is formed between the annular shell and the annular membrane piece group; a small hole communicating with the cavity is formed in the outer wall of the annular shell; and a cooling channel is formed by the liquid medium annular inlet, the cavity and the small hole. The problems that unstable work, leakage of a sealing face and even sealing failure of mechanical seal occur due to the fact that vaporization appears on a liquid medium are solved by arranging the flow guiding groove and the cooling channel.

Owner:XIAN AEROSPACE PROPULSION INST

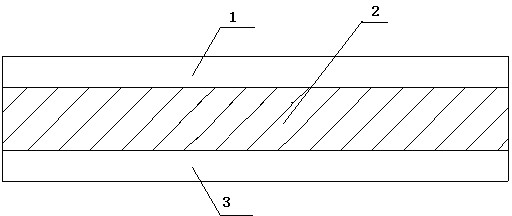

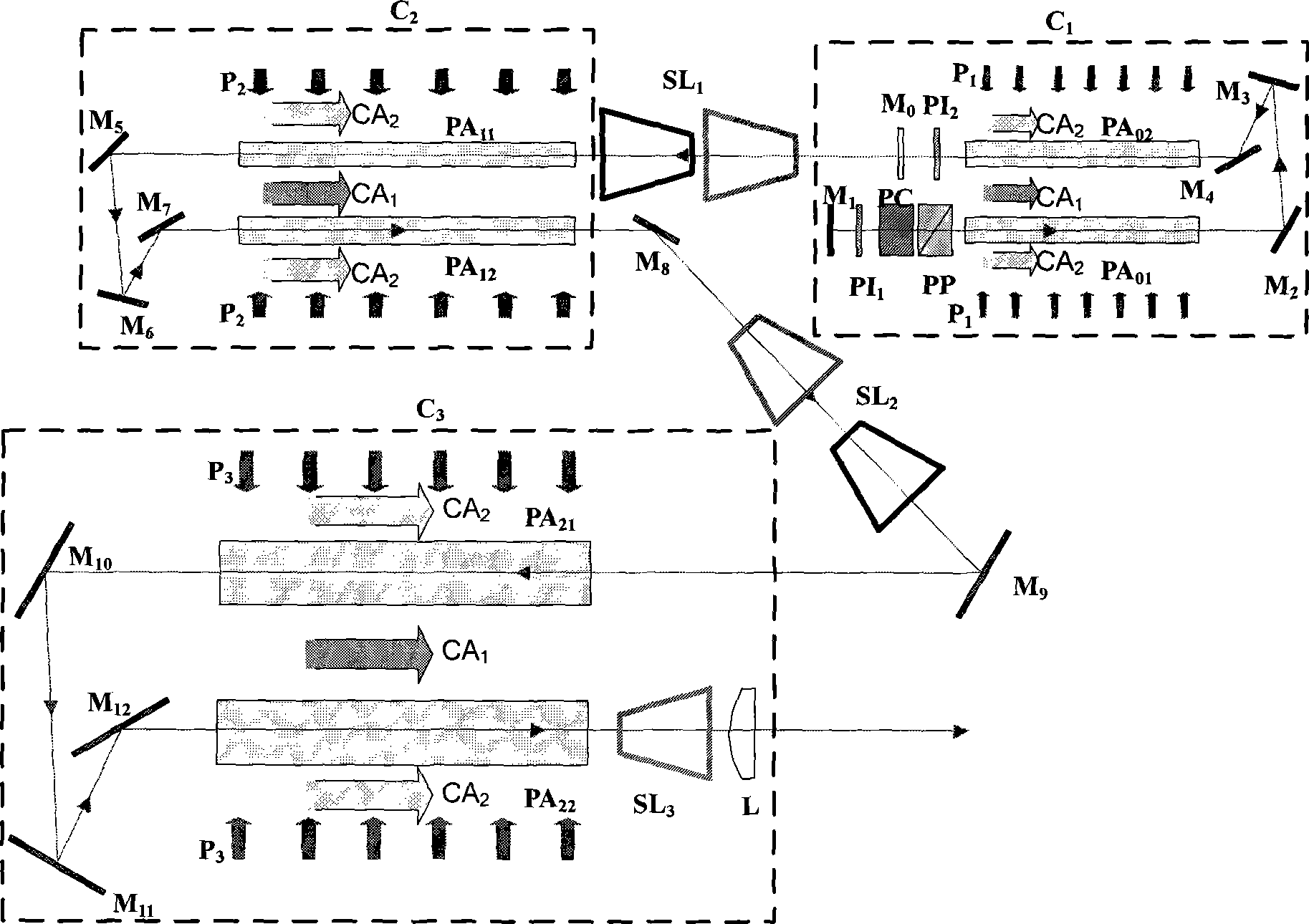

Novel high-power strip laser system

InactiveCN101399424APrevent thermal crackingImprove Optical UniformityExcitation process/apparatusOptical resonator shape and constructionHigh power lasersGlass laser

The invention relates to a novel high power slab laser system. The high power slab laser system comprises a laser cavity and an interstage beam expanding compensation lens; the laser cavity is composed of a laser oscillator C1, a preamplifier C2 and a main amplifier C3, two neodymium glass laser medium slabs which are parallel with each other and have the same size, material and property are respectively put into an embraced ceramic diffuse reflection cavity composed of the laser oscillator, the preamplifier and the main amplifier, both pumping and cooling use a mirror symmetry mode, and a laser beam goes into the other neodymium glass slab through three refractions; and an interstage beam expanding compensation lens is arranged among the laser oscillator, the preamplifier and the main amplifier. The high power slab laser system has the advantages of improving the output laser beam quality, obtaining high power laser beam, having long service life of a xenon lamp and improving the beam quality of the laser beam.

Owner:JIANGSU UNIV

Casting method of rare earth alloy copper strip

The invention discloses a casting method of a rare earth alloy copper strip; the specific of the casting method is as follows: charging-covering-smelting-blending and dregs catching-warming a converter and pouring copper water-adding rare earth-horizontally continuous casting; wherein the additive amount of the compound rare earth accounts for 0.03-0.05% of the weigh of copper material; the compound rare earth comprises lanthanum and chromium which account for 0.01-0.07% of the weigh of the rare earth; zinc accounts for 0.5-5.0% of the weigh of the rare earth; chromium accounts for 0.5-5.0% of the weigh of the rare earth; and zirconium accounts for 0.5-5.0% of the weigh of the rare earth. The casting method effectively removes various complex harmful impurities brought about by waste material and plating white material by adding compound rare earth into a heating preserving furnace. The casting method can effectively improve the form, size and distribution of sulfide, improves the machining operation performance, causes the copper strip to have good welding performance, the mechanical property of the copper strip to be increased, and the overall performance of the phosphor bronze strip to be better.

Owner:MAANSHAN TIANCHENG COPPER IND

Method for preparing double-metal compound material through combined solid-state copper solid-liquid compounding and rolling

InactiveCN105598420AAvoid oxidation slag inclusionsAvoid inhalationMetal rolling arrangementsSlagMechanical property

The invention discloses a method for preparing a double-metal compound material through combined solid-state copper solid-liquid compounding and rolling. The method includes the steps of preparing a double-metal rolled blank through solid-liquid compound casting and rolling the blank to prepare the double-metal compound material. The method has the advantages that by means of the technical means of solid-liquid connection is conducted after the surface zinc layer protection is achieved, a series of problems such as oxidation slag inclusion, air suction, heat cracking and composition segregation are solved, and the problems are prone to occurrence when copper and other materials are connected through a traditional welding method; the defect that an oxidation film is formed on the surface of copper easily at high temperature and hinders metallurgical bonding between copper and the other materials is overcome, the compound material is formed through a rolling method, intermediate compounds formed between copper and aluminum in the solid-liquid compounding process are broken, and the mechanical properties and physical properties of the double-metal compound material and a base material are improved. Gas protection is not needed, the composition technology is simple, technological conditions are lax, the requirement for technological equipment is low, the interface bonding strength is high, and conductivity is good.

Owner:SHANGHAI JIAO TONG UNIV

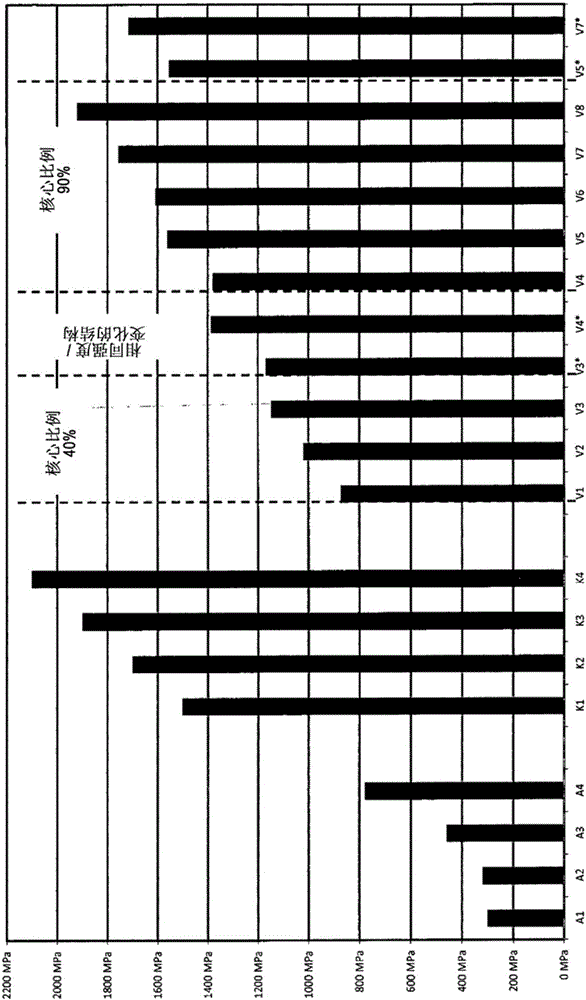

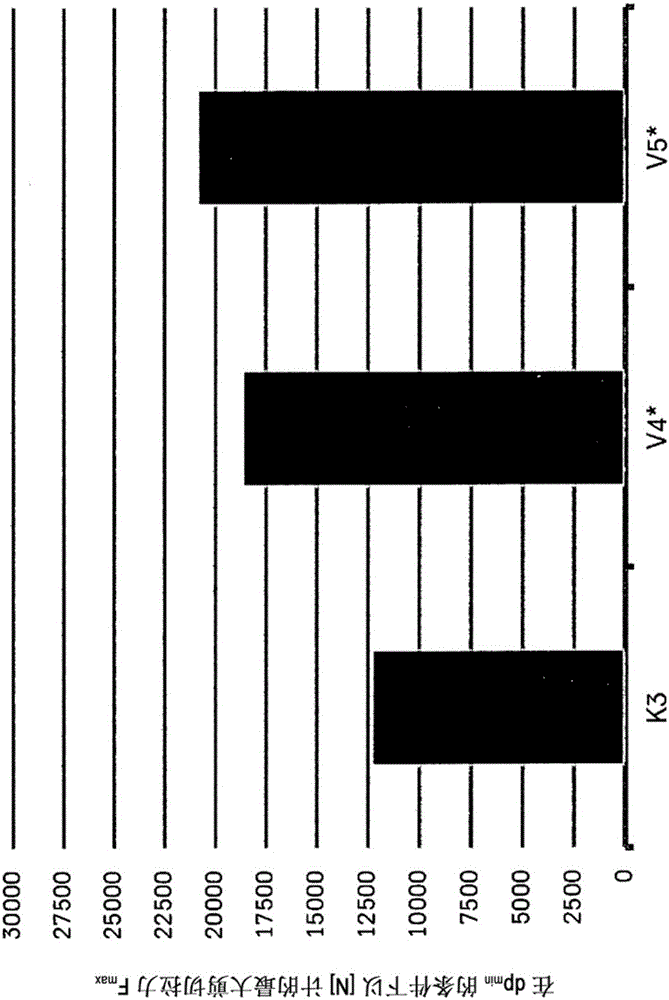

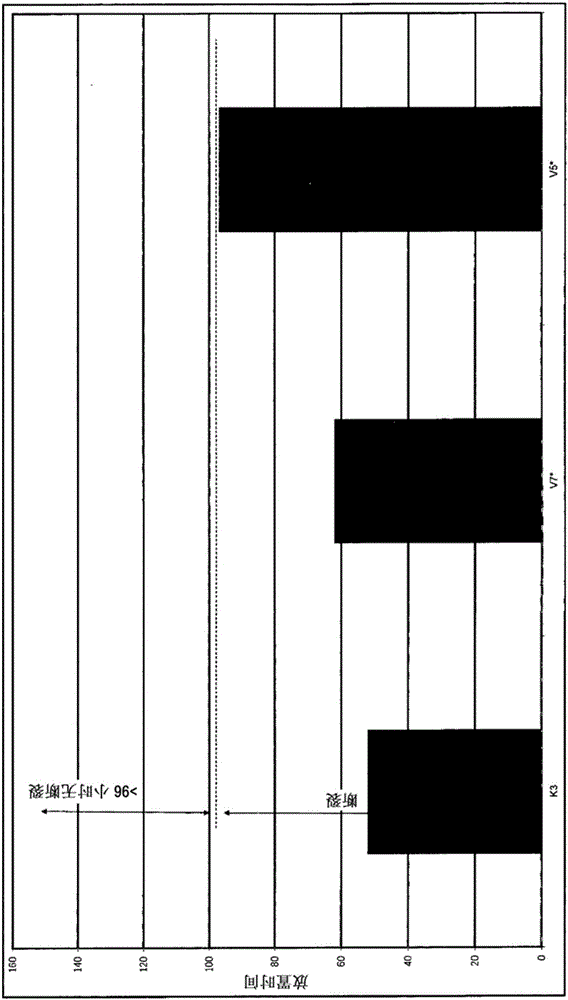

Sheet steel product, a steel component produced from such a sheet steel product, and body for a motor vehicle

InactiveCN105829095AImprove hardenabilityReduced hot cracking tendencyMetal layered productsSheet steelUltimate tensile strength

The invention relates to a sheet steel product which is particularly suitable for producing components for motor vehicle bodies by a press-hardening process. The sheet steel product is resistant against the formation of cracks and has a sufficient welding capability so as to be integrated into a welded structure while having an improved strength. According to the invention, this combination of properties is achieved in that the flat sheet steel product has a core layer, which consists of a steel that is alloyed with Mn, B, and at least 0.3 wt.% of C and has a tensile strength of more than 1500 MPa, and a top layer that is bonded to the core layer. The C content of the top layer is maximally 0.09 wt.%. In the region of the top layer, the sheet steel product has a tensile strength that maximally corresponds to half of the tensile strength of the steel of the core layer in the completely hardened state, the elongation A80 of the top layer at least corresponding to 1.5 times the elongation A80 of the core layer in the completely hardened state.

Owner:THYSSENKRUPP STEEL EURO AG

Concrete construction control method for preventing harmful cracks of wallboard

ActiveCN103485370APrevent thermal crackingShorten the construction periodArtificial islandsUnderwater structuresTemperature differenceDistortion

The invention relates to a concrete construction control method for preventing harmful cracks of a wallboard. The method includes: (1), determining initial setting time t of concrete; (2), selecting a suitable cement type, construction condition and construction concrete with appropriately dispensed additive agent according to the required initial setting time t; (3), concrete pouring from a plane direction, dividing a whole construction area into three subareas according to construction joint position, and performing construction sequentially; and (4), concrete pouring from a vertical direction, dividing the whole construction section into two subsections according to an elevation from minus 4.04m (metre) to 0.84m, and performing construction from a first subsection to a second subsection. Compared with the prior art, the method can shorten construction period, outside templates of the wallboard can not necessarily be removed in advance in order to meet the deadline of construction, and therefore, wallboard concrete can complete contraction distortion slowly under a humid environment, temperature difference cracks caused by temperature difference inside and outside the concrete resulting from removing the templates in advance are effectively prevented.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com