Concrete construction control method for preventing harmful cracks of wallboard

A control method and concrete technology, which is applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve problems such as leakage, prevent temperature difference cracks, and save construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

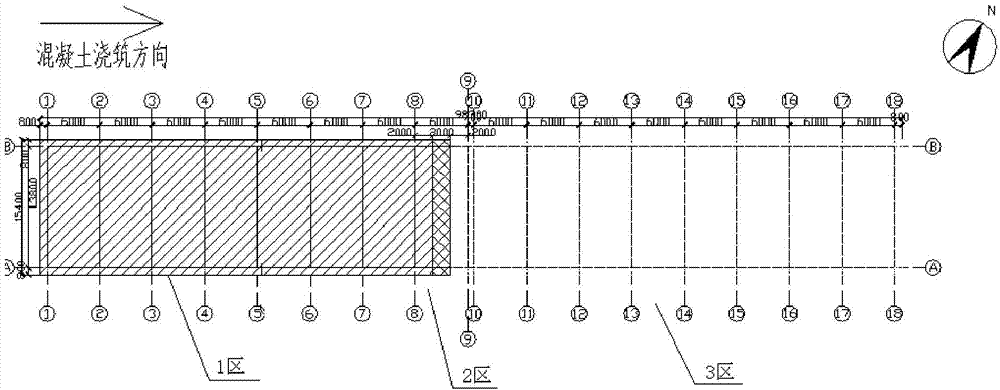

[0018] In this embodiment, the concrete pouring in the basement of the 220kV and 110kV power distribution equipment building is taken as an example, such as figure 1 Shown, a kind of concrete construction control method that prevents the harmful crack of wallboard, it is characterized in that, comprises the following steps:

[0019] (1) Determine the concrete initial setting time t;

[0020] (2) According to the required initial setting time t, select suitable cement types, construction conditions and admixtures to prepare suitable construction concrete;

[0021] (3) Concrete pouring from the plane direction, first pass through the construction joint position Line No. divides the whole construction area into 3 zones, among which, No. ①~⑧ is Zone 1, No. 8~⑨ is Zone 2, and No. It is zone 3, and follow the order of foundation floor in zone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com