Electromagnetic flexible composite deposition direct preparation forming method of multifunctional gradient component

A multi-functional, component technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of high cost, complex manufacturing process, long manufacturing process and cycle, etc., achieve low pollution, avoid equipment volume and cost, improve formability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The method-based devices include MOTOMAN mechanical cantilever, Huazhong CNC three-axis CNC milling machine, FLIR camera equipment, SAF MIG welding machine, etc. The substrate material is Q235 stainless steel, the surface of the substrate is machined and cleaned with acetone to completely remove oil, dust, etc., and the welding wire material is CHW-50C6 low-alloy welding wire. The substrate fixed on the cooling pad is placed on the working platform, and the working platform remains stationary, while the mechanical cantilever can move along the three directions of X, Y, and Z and rotate around the X, Y, and Z axes, driving the cantilever fixed together The welding torch can also move along the X, Y, and Z directions and rotate around the X, Y, and Z axes.

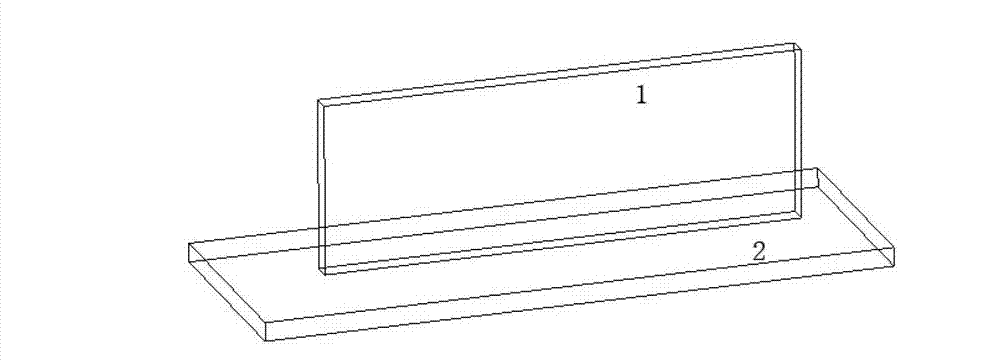

[0032] (1) Modeling and layering processing steps: first use the PROE 3D modeling software to model the parts, such as figure 1 , and then perform layered slice processing on the built model to obtain layered slice d...

Embodiment 2

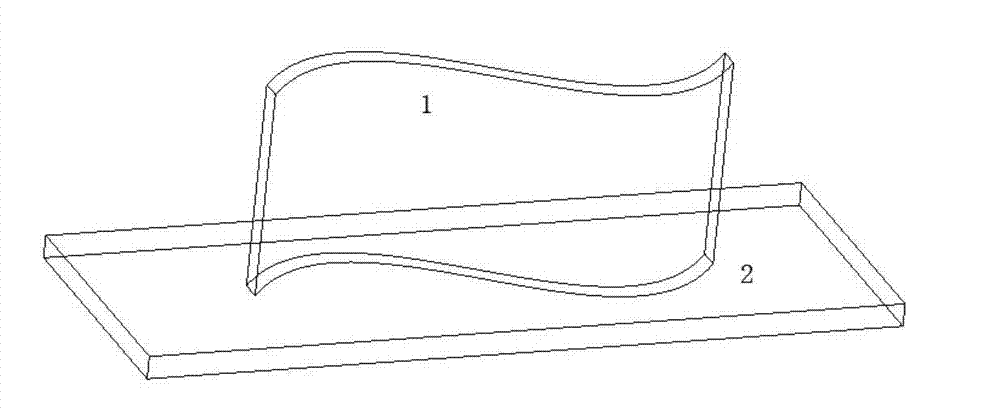

[0037] Using laser welding as the heat source, the 3D model such as figure 2 , fixed Y30 ferrite permanent magnets on the MOTOMAN machine cantilever to generate a static magnetic field, the others are the same as in Example 1, and the mechanical properties of the obtained parts are shown in Table 2.

Embodiment 3

[0039] Ar gas shielded MIG welding is used as the heat source, and the high-frequency alternating coil and Y30 ferrite permanent magnet are fixed on the MOTOMAN at the same time. The frequency of the alternating coil is 250KHz, the number of turns of the coil is 5, and the current is 90A. Others are the same as in Example 1, and the mechanical properties of the obtained parts are shown in Table 2.

[0040] Table 2

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com