Method of boring glass substrate and glass substrate for plasma display manufactured by the method

A plasma display and glass substrate technology, applied in the manufacture of discharge tubes/lamps, manufacturing tools, cold cathode manufacturing, etc., can solve problems such as failures, cracks, and rough surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

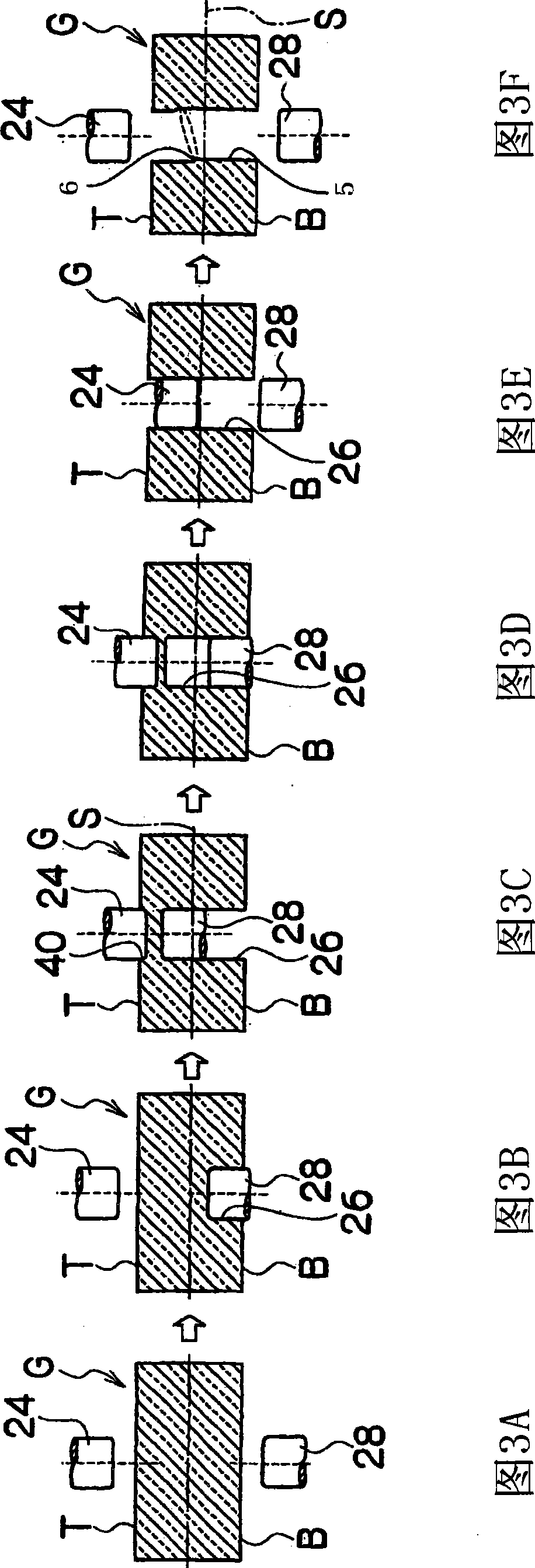

[0050] A total of 60 samples were prepared by opening through-holes having a diameter of 2 mm at positions 11.5 mm apart from respective two right-angled end faces of a substantially rectangular PDP glass substrate G measuring 150 mm by 150 mm and having a thickness of 1.8 mm, where the step 6 appearing on the through hole 5 is formed at a position separated from the bottom surface B of the glass substrate G by 1.7 mm. In seven of the above-mentioned samples, the steps 6 were formed at intervals of 0.1 mm from positions 1.7 mm to 1.0 mm from the bottom surface. In four samples of the above samples, the step 6 was formed at a position of 0.9 mm from the bottom surface B of the glass substrate G. As shown in FIG. For the above samples, the glass substrate G was heated for 10 minutes (approximately 280 degrees: where a temperature difference of approximately 170 degrees between the top and bottom surfaces was achieved), while the bottom surface B was placed in a heated On the de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com