Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Eliminate casting stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of 3003-brand cathode aluminum foil

InactiveCN101519760AEvenly distributedImprove plasticityElectrolytic capacitorsCapacitanceMetallurgy

The invention relates to a production method of 3003-brand cathode aluminum foil, which includes the following steps: a. raw materials are refined and rolled into a blank with the thickness of 6.5 mm to 8.5 mm; b. the blank obtained in step a is rolled into the blank with the thickness of 3.5 mm to 4.3 mm in a cooling mode to be uniformly annealed; c. the uniformly-annealed blank is rolled into the blank with the thickness of 0.3 mm to 0.5 mm in a cooling mode to be recrystallized and annealed; and d. the recrystallized-and-annealed blank is rolled into the 3003-brand cathode aluminum foil with the required thickness. The method of the invention enables the cost to be lower and the product quality to be better, the specific capacitance of the product is increased to be higher than 530 microfarads / cm<2>, and the highest specific capacitance can be 560 microfarads / cm<2>. The invention greatly improves the product competitive strength, reduces the disparity with abroad products, and makes a contribution for the trade progress.

Owner:登电集团铝加工有限公司

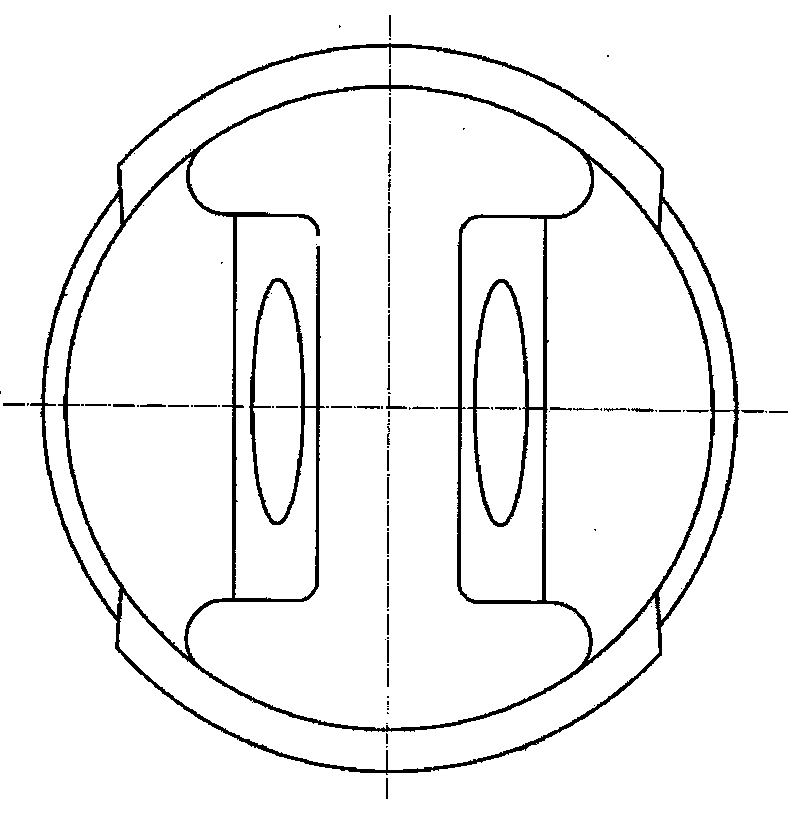

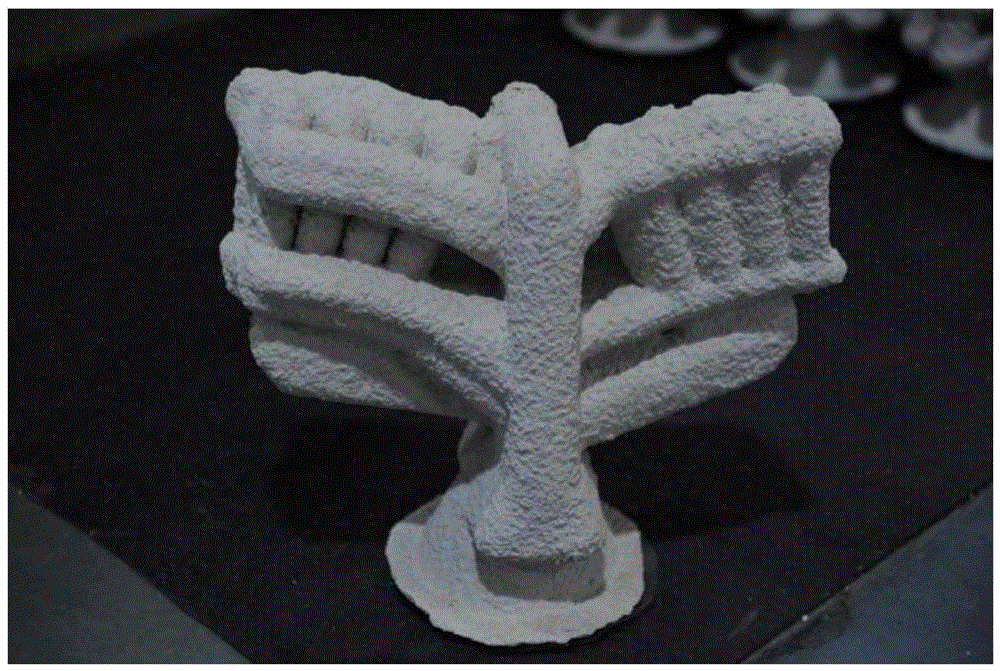

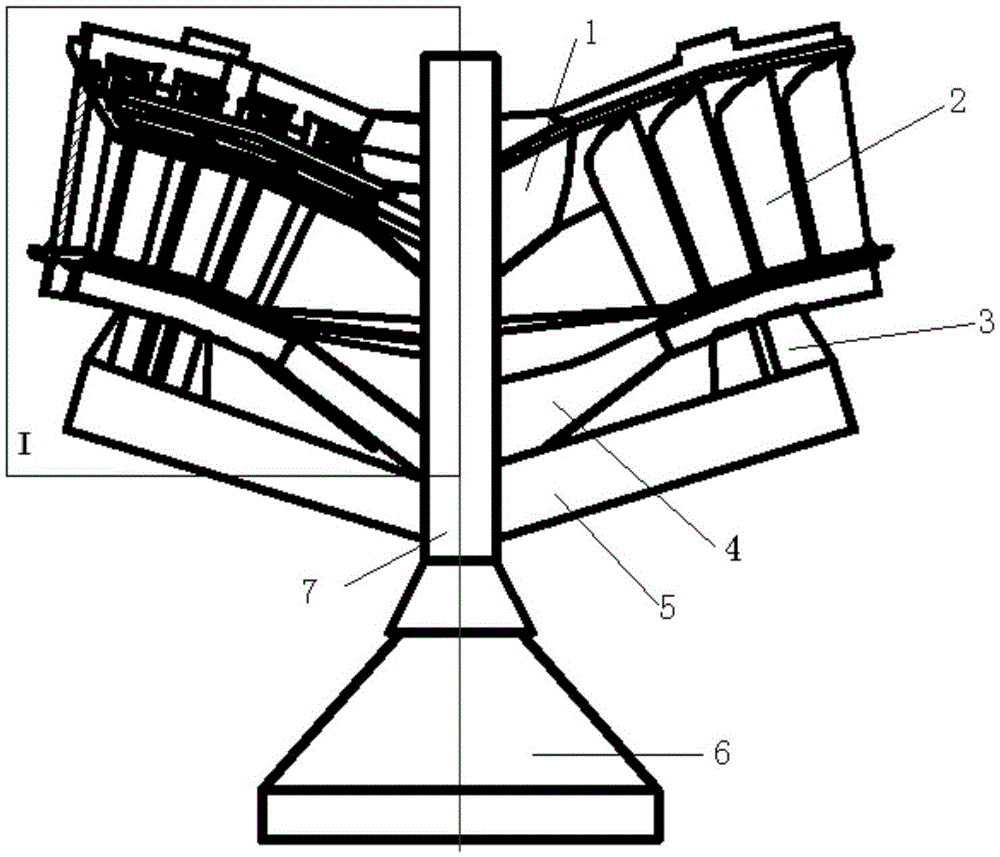

Wax mold combination of four-connection hollow turbine guide vane and precision casting method of wax mold combination

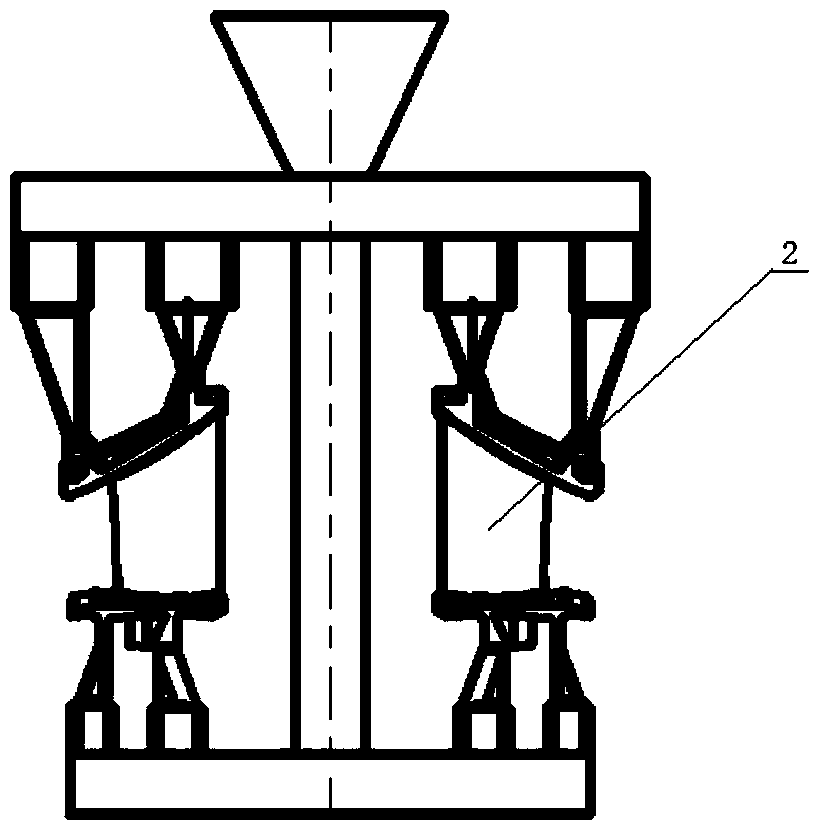

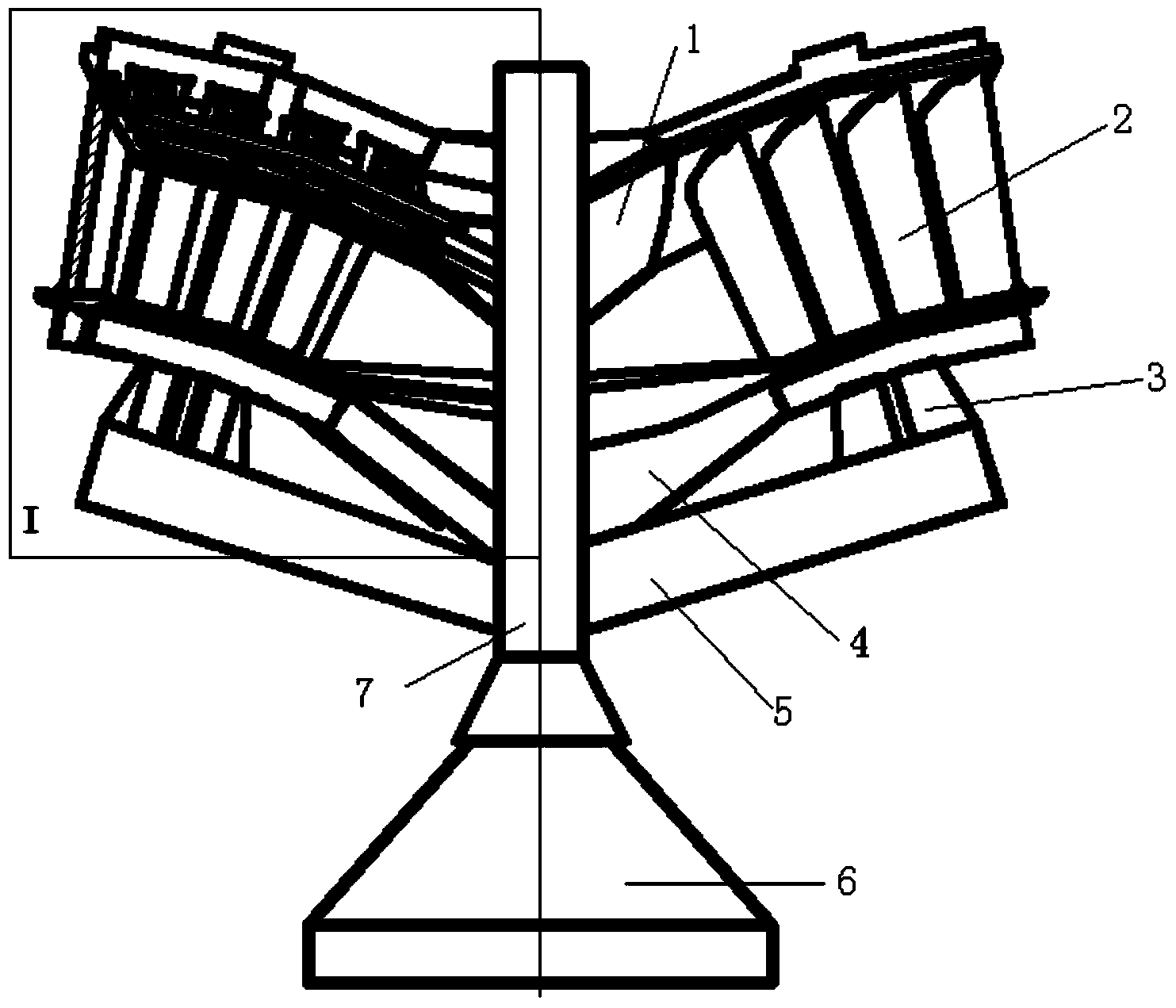

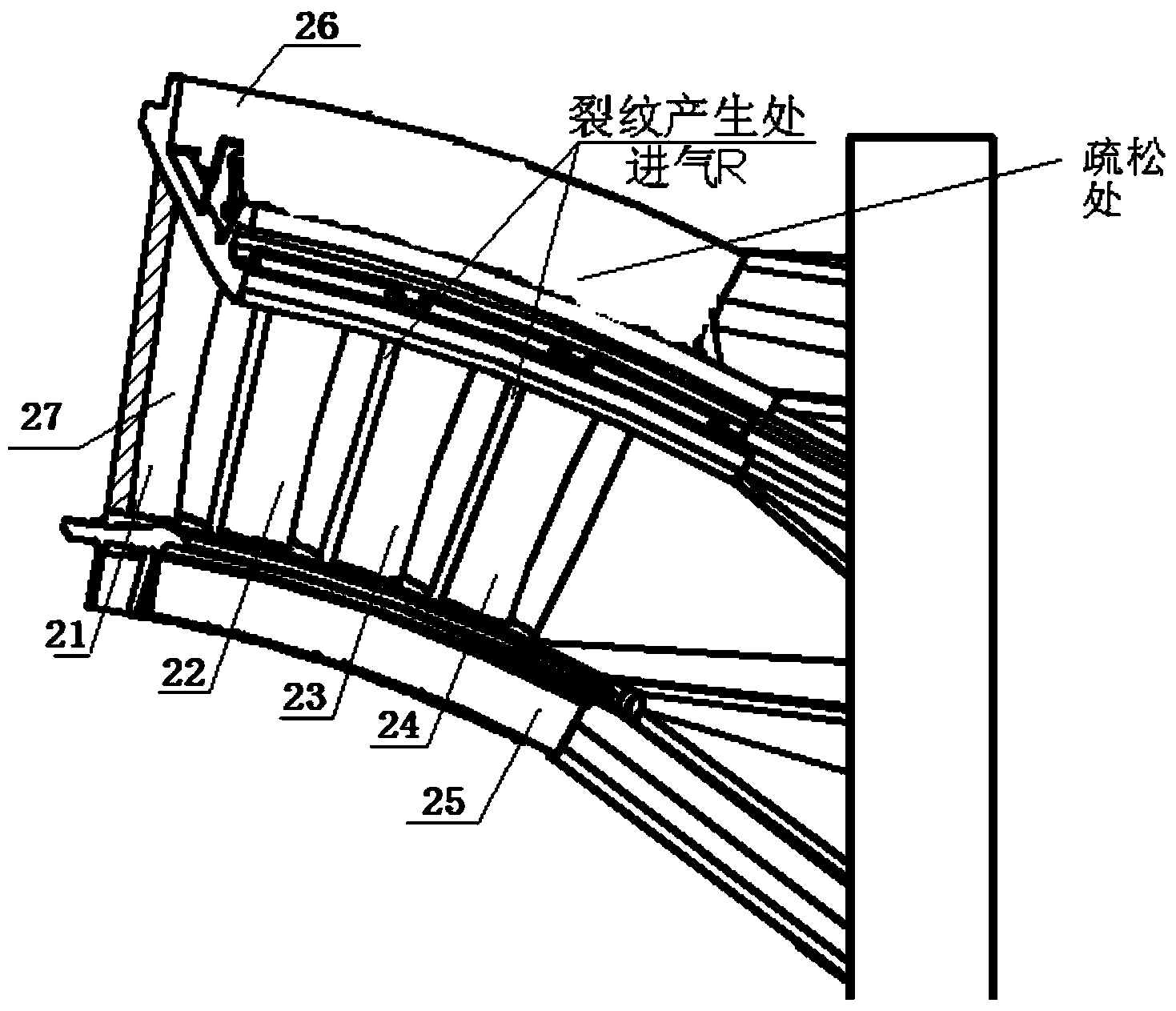

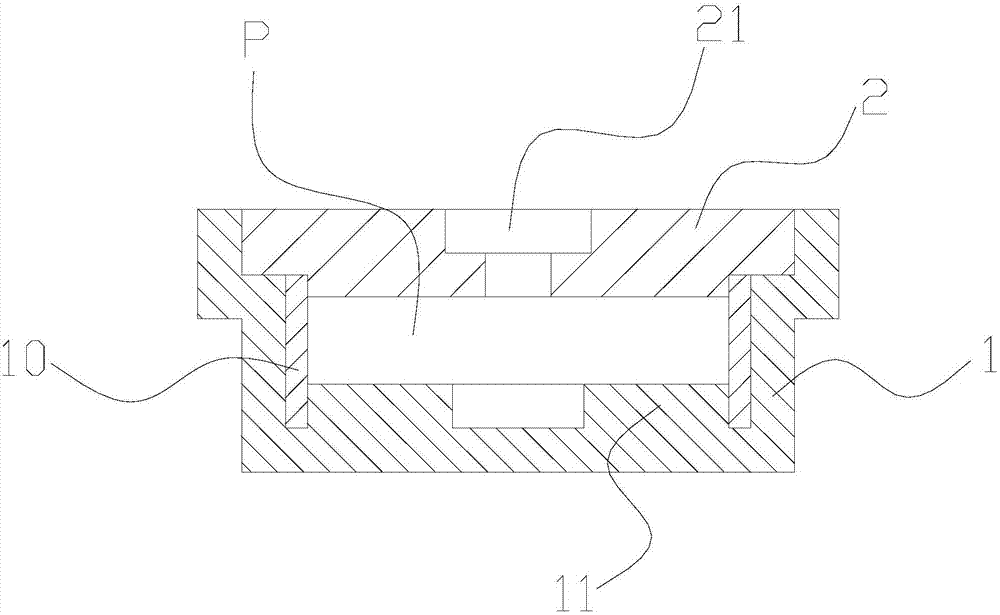

The invention provides a wax mold combination of a four-connection hollow turbine guide vane, which has high product quality and can completely solve the problems that a rotary connection R part of an edge plate and a vane body is hotly cracked and loosened, and a precision casting method of the wax mold combination. The wax mold combination comprises a sprue cup and a straight pouring gate which is communicated with an outlet end of the sprue cup, wherein inner sprue assemblies are arranged on the side wall of the straight pouring gate; each inner sprue assembly comprises a lower edge inner sprue communicated with one side of a vane lower edge plate cavity, and an upper edge inner sprue communicated with one side of a vane upper edge plate cavity; and each lower edge inner sprue and each upper edge inner sprue are sequentially arranged along the flow direction of the straight pouring gate. The precision casting method comprises the following steps: (1) manufacturing the wax mold combination; (2) carrying out shell making on the wax mold combination prepared in the step (1) to obtain a four-connection hollow turbine guide vane shell; and (3) covering one layer of ceramic heat-preservation cotton on a shell vane body part and covering two layers of ceramic cotton on the whole shell; and putting the treated shell into a roasting furnace for carrying out casting.

Owner:AECC AVIATION POWER CO LTD

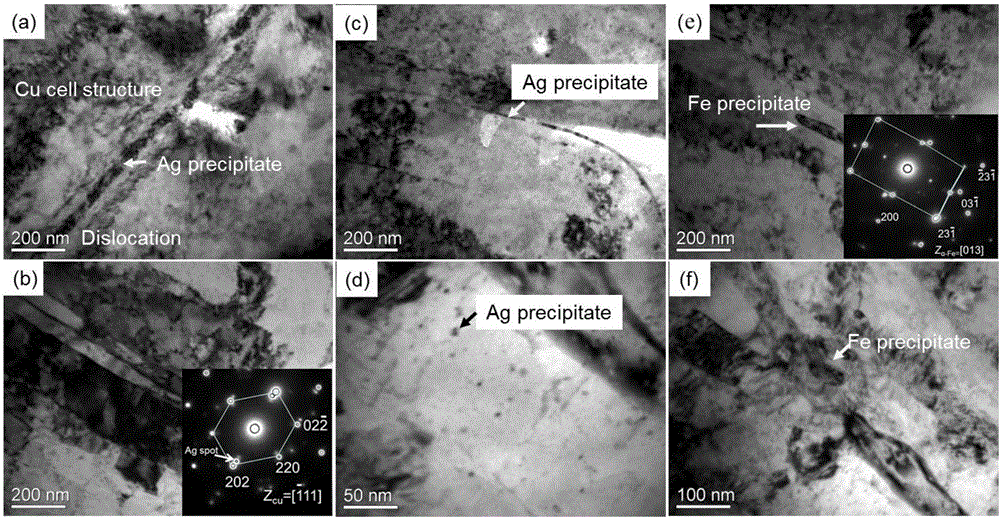

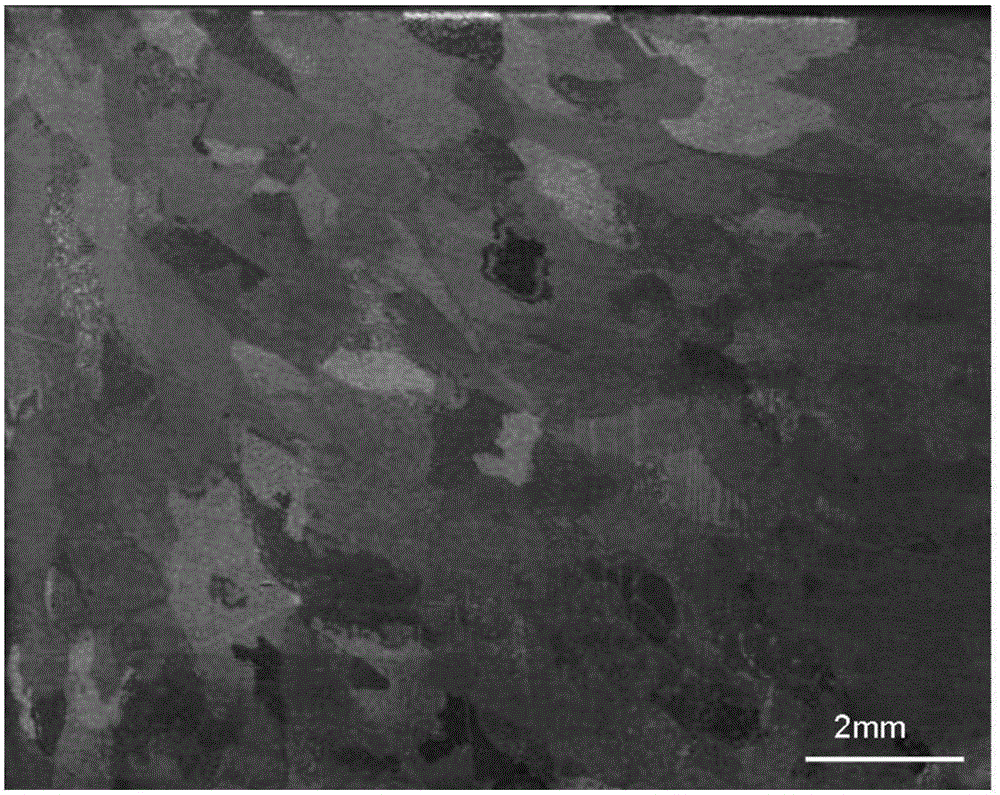

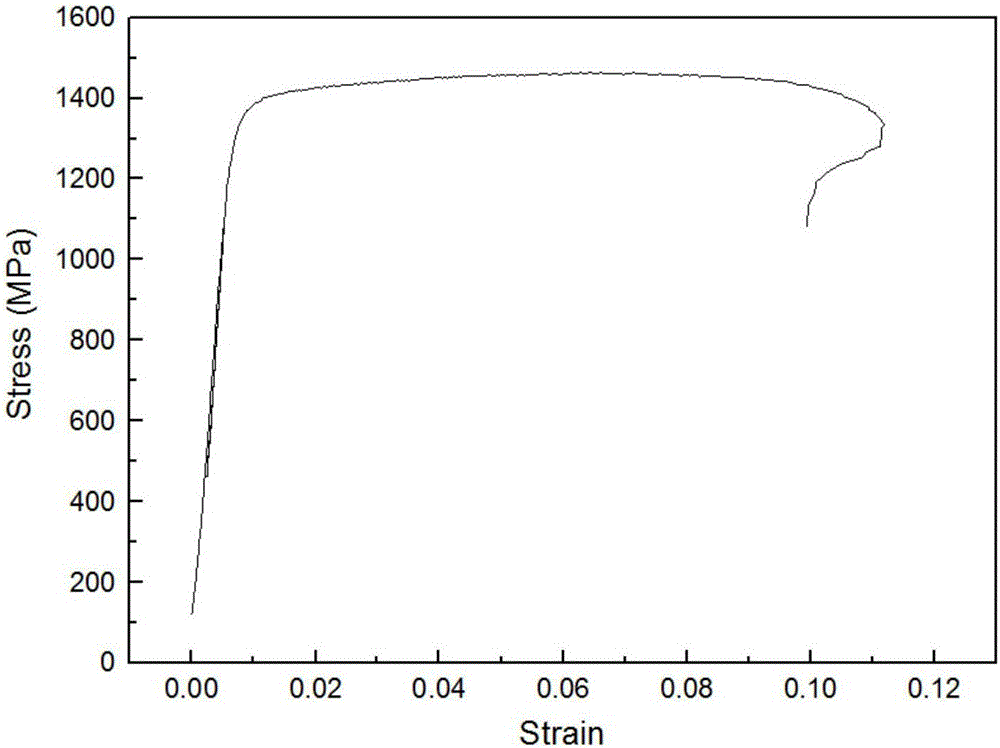

Preparation method for high-strength high-conductivity Cu-Ag-Fe alloy

The invention discloses a preparation method for a high-strength high-conductivity Cu-Ag-Fe alloy, belonging to the technical field of non-ferrous alloys. The preparation method comprises the following steps that raw materials of the Cu-Ag-Fe alloy are smelted according to proportions, and then are poured at 1000-1300 DEG C to form a cast-condition Cu-Ag-Fe mother alloy; the Cu-Ag-Fe alloy is solidified under the effect of a 0.1-1 T alternating magnetic field; the alloy is subjected to homogenization treatment under the effect of a 0.1-30 T steady-state magnetic field; and then the alloy is subjected to pre-deformation, intermediate annealing heat treatment and re-deformation, and finally is subjected to final annealing heat treatment under the effect of a 0.1-30 T steady-state magnetic field so as to obtain a high-strength high-conductivity Cu-Ag-Fe alloy wire / plate, of which the conductivity is 55-88% IACS and the extension strength is 750-1760 MPa. According to the method, the Cu-Ag-Fe alloy is prepared by utilizing the electromagnetic fields and deformation combined with heat treatment, so that the excellent conductivity of a Cu-Ag alloy is reserved, and the strength of the alloy is improved; and the raw material cost of the alloy is lowered.

Owner:NORTHEASTERN UNIV

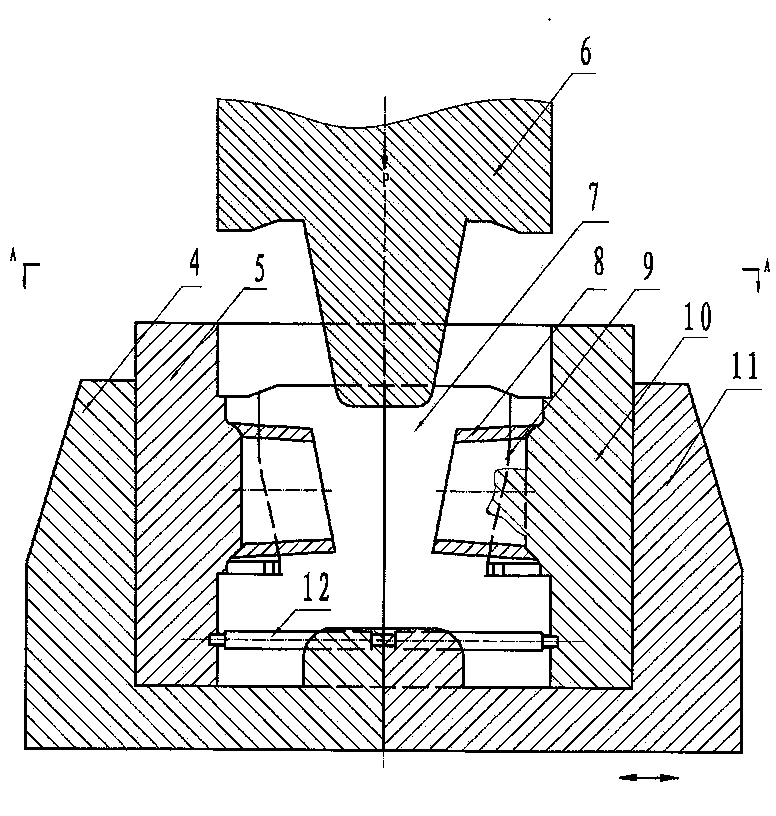

Pouring method of hollow turbine guide vane

ActiveCN104308082AUniform temperature fieldEliminate casting stressFoundry mouldsFoundry coresWaxTurbine

The invention provides a pouring method of a hollow turbine guide vane. The pouring method comprises the following steps: (1) manufacturing a wax mold combination; (2) carrying out shell making on the wax mold combination to obtain a hollow turbine guide vane shell; (3) covering one layer of ceramic heat-preservation cotton on a shell vane body part; covering two layers of ceramic cotton on the whole shell; and putting the treated shell into a roasting furnace and carrying out casting, wherein in a casting process, the temperature of casting the shell is 1065-1085 DEG C and the pouring temperature is 1460-1480 DEG C. According to the pouring method of the hollow turbine guide vane, a pouring system of the hollow turbine guide vane is not changed and the shell temperature and the pouring temperature are adjusted so that the casting temperature field is changed; the two layers of ceramic cotton on the whole body and one layer of the ceramic heat-preservation cotton on the vane body part are matched so that after the temperature of the whole shell is improved, the temperature field is uniform, the casting stress is eliminated and the casting temperature is reduced; and furthermore, the temperature field on a casting vane body and an edge plate keeps uniform, the shell is effectively insulated and the casting stress is eliminated.

Owner:AECC AVIATION POWER CO LTD

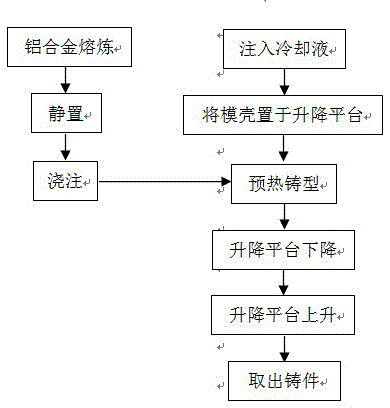

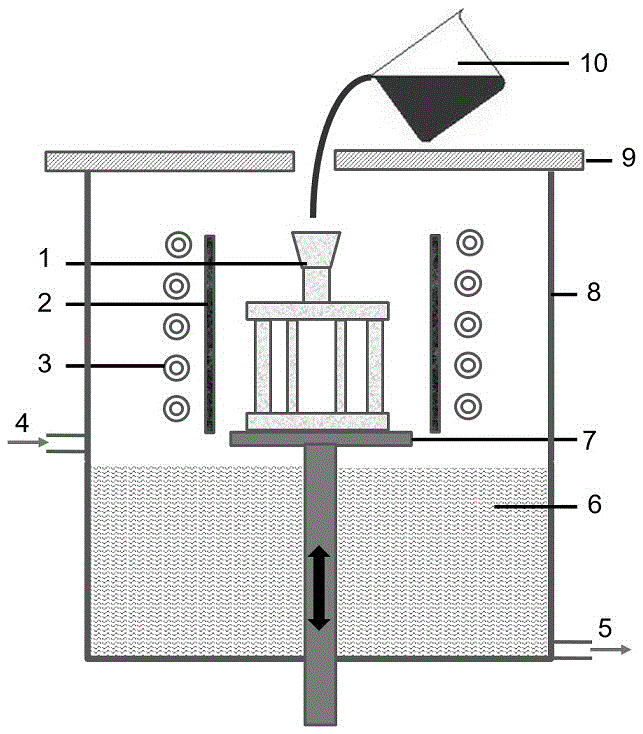

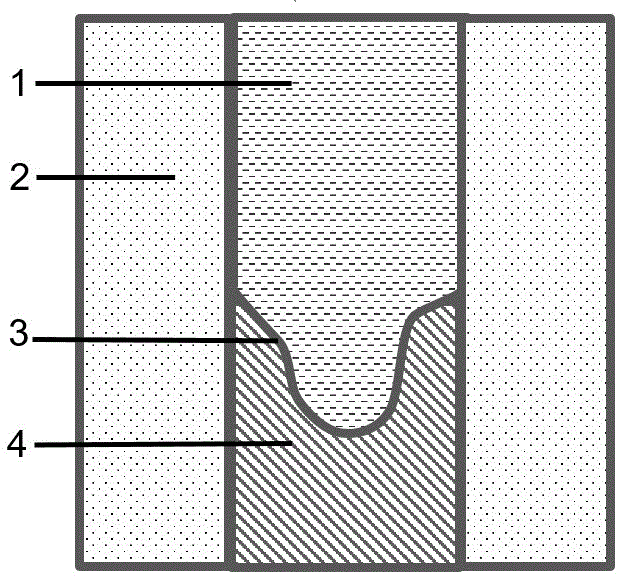

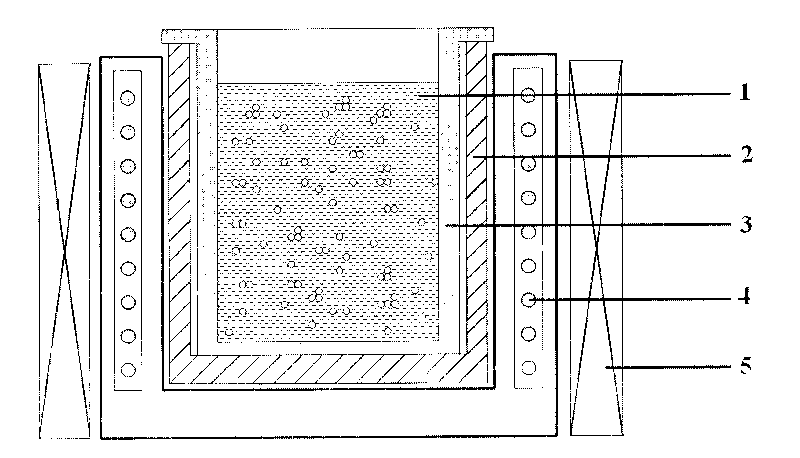

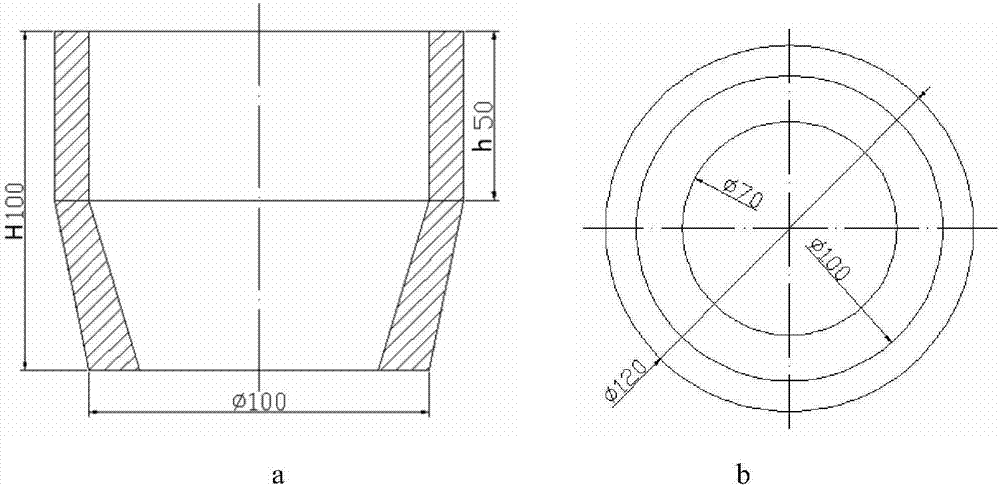

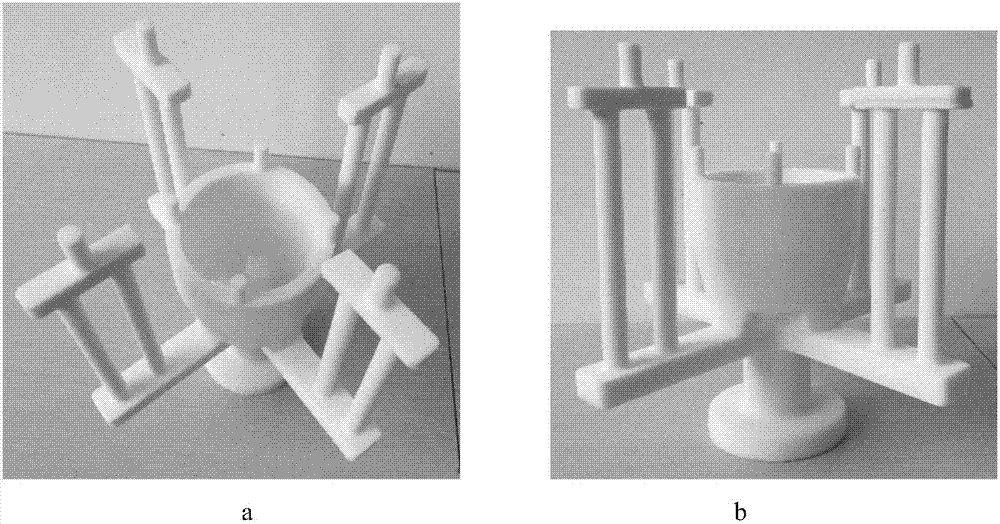

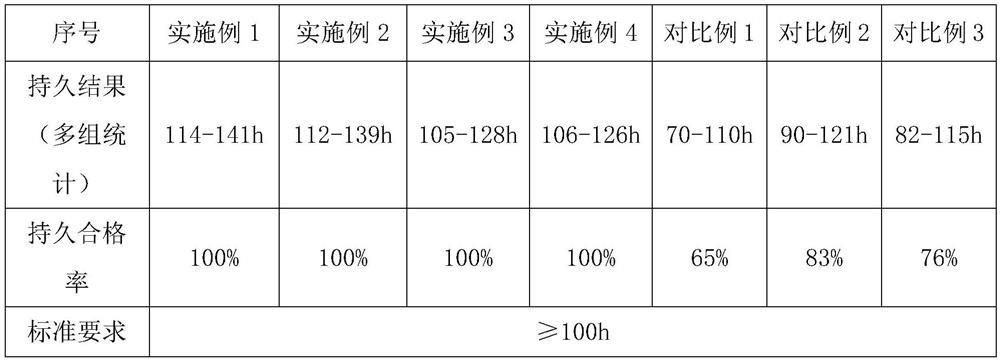

Aluminum alloy investment casting method and investment casting device adopting near liquidus pouring

InactiveCN105598372ADense structure of castingEliminate casting stressFoundry mouldsFoundry coresInvestment castingMelt temperature

The invention discloses an aluminum alloy investment casting method adopting near liquidus pouring. The method comprises the following steps: preheating a mould shell to be close to the liquidus, performing near liquidus temperature pouring, and meanwhile, reducing the pouring temperature, and pouring after the melt temperature is higher than the temperature of the liquidus; after finishing pouring, immersing the mould shell into the cooling liquid at a certain speed, thereby effectively and accurately controlling a solidification process of the casting; quickening the cooling of the casting, thereby acquiring the high-quality aluminum alloy casting with uniform structure and small grain. In the casting solidification process, the temperature gradient can be accurately controlled, the lower part of the casting is firstly soaked into the cooling liquid and the upper part is still in the heating atmosphere and under the molten state, so that the casting can be solidified from bottom to top, the solidified part is subjected to full liquid feeding, the casting is compact in structure, and meanwhile, the casting stress in the solidification process of each part of the casting is eliminated. The method provided by the invention is fit for common aluminum alloy casting and large-size, thin-wall and complex aluminum alloy investment casting.

Owner:NANCHANG HANGKONG UNIVERSITY

5A06H14 sheet metal with thickness of 8.5mm, and preparation method thereof

The invention relates to a 5A06H14 sheet metal with a thickness of 8.5mm, and a preparation method thereof. The invention relates to a sheet metal and a preparation method thereof. The invention aims at solving the problems of unstable alloy ingot strength, low yield strength, low tensile strength, and large unevenness of 8.5mm-thick 5A06H14 sheet metals produced with prior arts. The preparation method comprises the steps of: 1, material blending; 2, smelting; 3, casting; 4, homogenizing annealing; 5, sawing, edge planing and surface milling; 6, aluminum coating; 7, hot rolling; 8, cold rolling; 9, pre-stretching; and 10, sawing. With the steps, the 8.5mm-thick 5A06H14 sheet metal is obtained. With the method provided by the invention, the prepared 8.5mm-thick 5A06H14 sheet metal has a yield strength of 373-420MPa, a tensile strength of 285-330MPa, an elongation of 8% to 12%, an unevenness less than 8mm / m, and a same plate difference less than 0.25mm. The method provided by the invention is applied in industrialized productions of 5A06 sheet metals.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Alloy material for casting and technology of casting large gearbox casting of offshore platform by using alloy material

The invention discloses an alloy material for casting and a technology of casting a large gearbox casting of an offshore platform by using the alloy material. The alloy material is ZG32CrNiMo. The technology of casting the large gearbox casting of the offshore platform by using the ZG32CrNiMo comprises the following steps: a, resin sand modeling; b, gating system, riser and chill block arrangement; c, liquid metal gating; d, normalizing and tempering pretreatment; and e, quenching and tempering thermal treatment. Due to the adoption of the mode, the formula of the ZG32CrNiMo alloy material is reasonable; particularly, the smelted liquid metal has the characteristic of good mobility, so that the casting in a casting state has good tensile strength and good ductility; meanwhile, the technology of casting a casting of a large-size bearing shell by using the ZG32CrNiMo is reasonable; by reasonably arranging a bottom gating type gating system, a riser and a chill block, the gated casting does not have a crack and is high in the yield.

Owner:CHANGSHU HONGQIAO CAST STEEL CO LTD

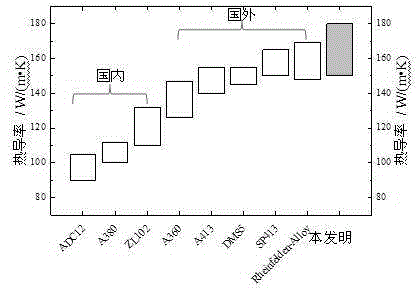

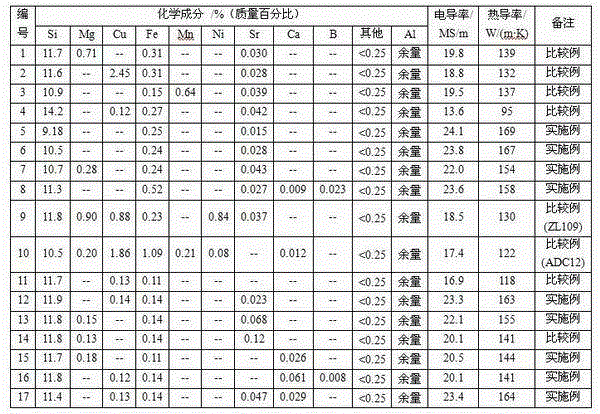

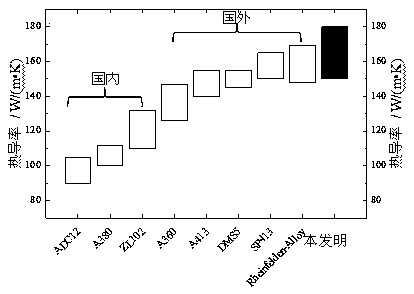

Near co-crystallizing type cast aluminum silicon alloy material with high heat conductivity and production method thereof

The invention relates to a near co-crystallizing type casting aluminum silicon alloy material with high heat conductivity and a production method thereof. The alloy comprises the main components including Al and Si, and is characterized by also comprising at least one of Sr, Ca and B. During casting production, the temperature of a melt is maintained within a range of 600-850 DEG C, and the alloy melt is cast into a casting mould so as to be cast into a casting; when the casting product is subjected to heat treatment, the temperature rising velocity of the heat treatment process is lower than 20 DEG C / min, and the temperature is maintained to be 100-450 DEG C and maintained for 0.5-10 hours, and then, the casting is cooled or air-cooled along with a furnace.

Owner:JIANGSU ZHONGSE RABILY IND CO LTD

High-wear-resistance long-life ductile iron and method of producing lower cylinder with ductile iron

ActiveCN106834901AImprove wear resistanceExtended service lifeFoundry mouldsFurnace typesHigh wear resistanceDuctile iron

The invention discloses high-wear-resistance long-life ductile iron, comprising, by weight, 3.80-3.88% of C, 2.20-2.30% of Si, 0.55-0.65% of Mn, < / =0.020% of P, < / =0.010% of S, 0.45-0.55% of Cu, 0.30-0.40% of Mo, 0.0040-0.0060% of La, 0.035-0.045% of Mg, and the balance of iron and unavoidable impurity. The invention is intended to provide the high-wear-resistance long-life ductile iron that has high rigidity and fatigue strength and has improved tensile strength and plasticity, and a method of producing a lower cylinder with the ductile iron.

Owner:GUANGDONG ZHONGTIAN CHUANGZHAN DUCTILE IRON CO LTD

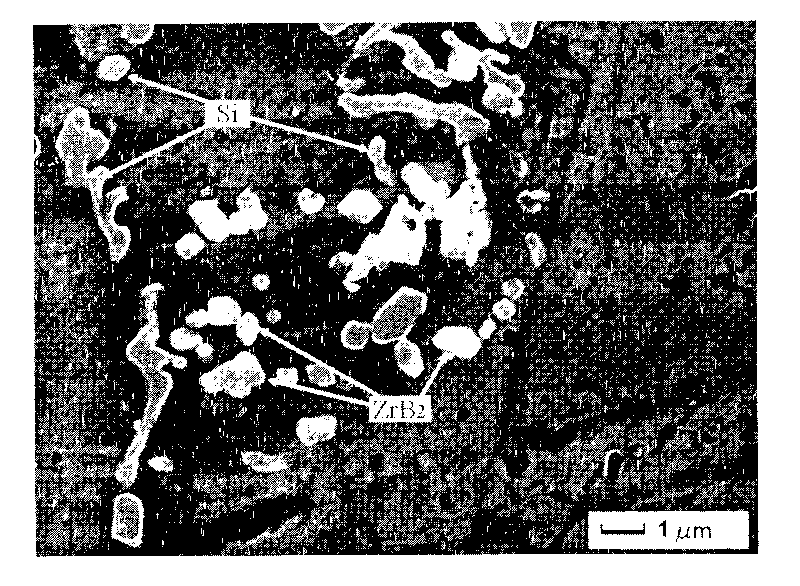

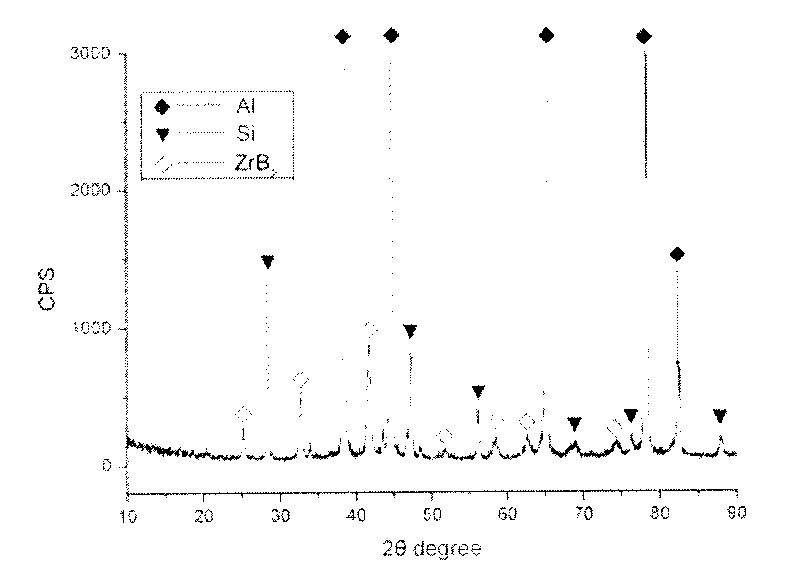

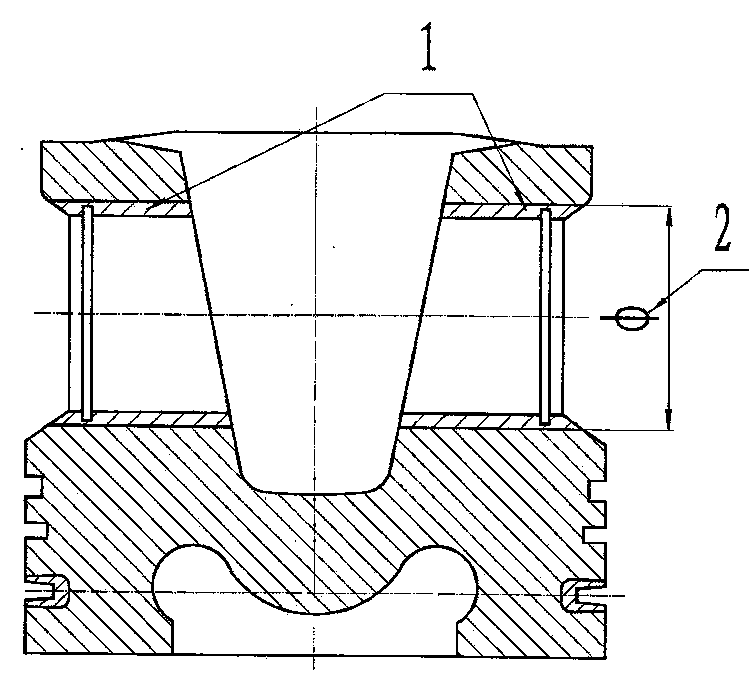

Energy-saving and short-flow manufacturing method of wheel hub with in situ particle reinforced A356 matrix composite material

The invention relates to an energy-saving and short-flow manufacturing method of a wheel hub with an in-situ particle reinforced A356 alloy. The main features of the method are as follows: (1) A356 alloy melt is prepared with pure metals Al and Mg as well as crystalline silicon through one-step melting, in-situ multi-phase reinforcing particles of ZrB2 (or TiB2), Al3Zr (or Al3Ti) and Al2O3 are synthesized through reactions synthesis of the melt in a pulsed magnetic field, the sizes of a majority of particles are at the sub-micron (0.1-1mum) level, and the sizes of a minority of particles are at the micron (1-4mum) level; and (2) a wheel hub is formed through low-pressure casting or metal gravity casting of the synthesized composite material melt, no solid solution is needed, and next procedure can be carried out after direct artificial aging treatment, thereby realizing the short-flow thermal treatment. The novel method for manufacturing of the A356 alloy wheel hub in the invention not only can effectively improve the mechanical property of the aluminum wheel hub and prolong the service life of the aluminum wheel hub, but also can significantly reduce the solid solution heat treatment procedure, thereby greatly reducing the energy consumption and improving the production efficiency.

Owner:JIANGSU UNIV

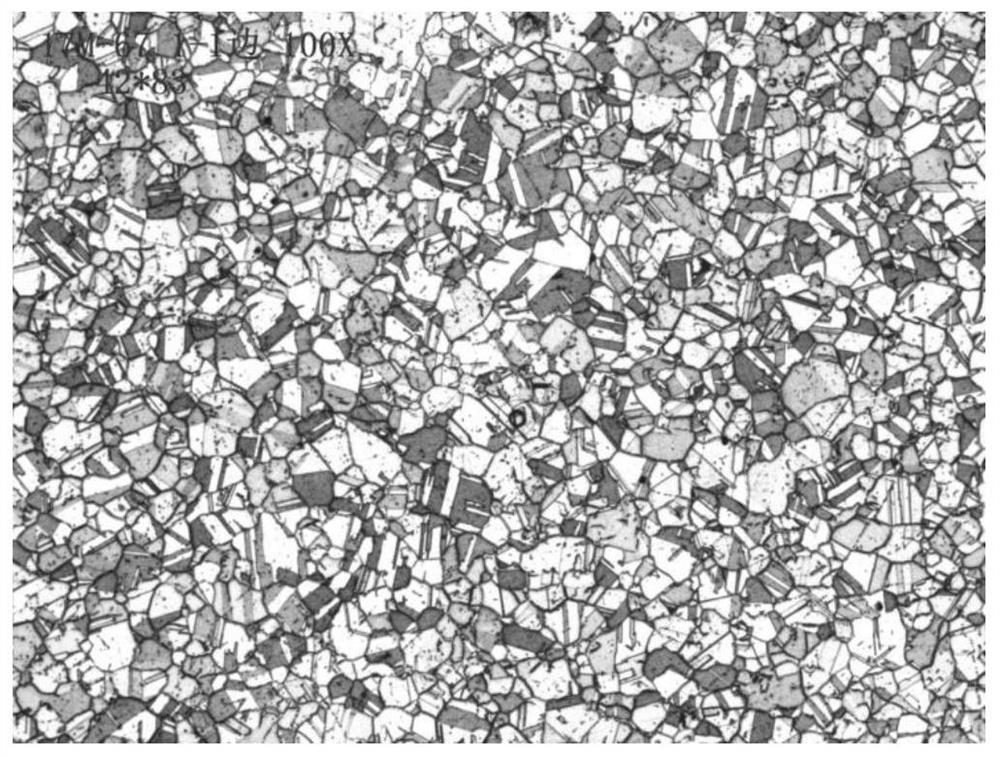

Preparation method of large-size 6061 aluminum alloy plate for semiconductor equipment

PendingCN112593100AImprove machining accuracyMeet the requirements of shape and position stabilityIngotStress relief

The invention discloses a preparation method of a large-size 6061 aluminum alloy plate for semiconductor equipment. The preparation method comprises the following steps of smelting and casting a proportioned aluminum alloy to obtain an aluminum alloy cast ingot; enabling the obtained aluminum alloy cast ingot to be subjected to homogenizing heat treatment, machining, preheating and hot rolling, and obtaining the large-specification aluminum alloy plate; and enabling the large-specification aluminum alloy plate obtained after the hot rolling to be pre-stretched, enabling the pre-stretched plateto be subjected to solution hardening, then conducting stretching and leveling, and conducting artificial aging. According to the preparation method, microstructure distortion energy segregation generated in the rolling process of the ultra-thick and ultra-wide 6061 plate can be eliminated or even, quenching internal stress generated by solid solution quenching is lower and more even, meanwhile,stress relief stretching after the quenching is combined, the residual internal stress is almost completely eliminated, the subsequent machining precision of the plate is remarkably improved, and therequirement of semiconductor equipment on high form and location stability of the aluminum plate is met.

Owner:广西南南铝加工有限公司

Rail transit derailment valve casting process

InactiveCN111230070AImprove performanceGuaranteed performanceMetal-working apparatusFurnace typesPunchingDerailment

The invention relates to the technical field of rail transit, and discloses a rail transit derailment valve casting process. The casting process comprises the following steps that raw materials are prepared, specifically, the raw materials conforming to national standards are purchased, impurity removing treatment is carried out on the purchased raw materials, impurities are removed, the raw materials are added into a melting device for melting treatment to form liquid metal, wherein the melting temperature is between 150 DEG C and 250 DEG C; and forging forming is conducted, specifically, theliquid metal is poured into corresponding forging dies, after the liquid metal is solidified and formed, preliminary parts in certain shapes are obtained, then the preliminary parts are punched and formed under a punching machine, special punching dies are adopted during punching, and after punching is completed, part blanks of all the parts of a derailment valve are obtained. According to the rail transit derailment valve casting process, casting stress can be effectively eliminated, the mechanical performance is improved, the cutting machinability is improved, the material performance can be effectively improved, and the quality of the parts is guaranteed.

Owner:SHIFANG YONGSEN MACHINERY

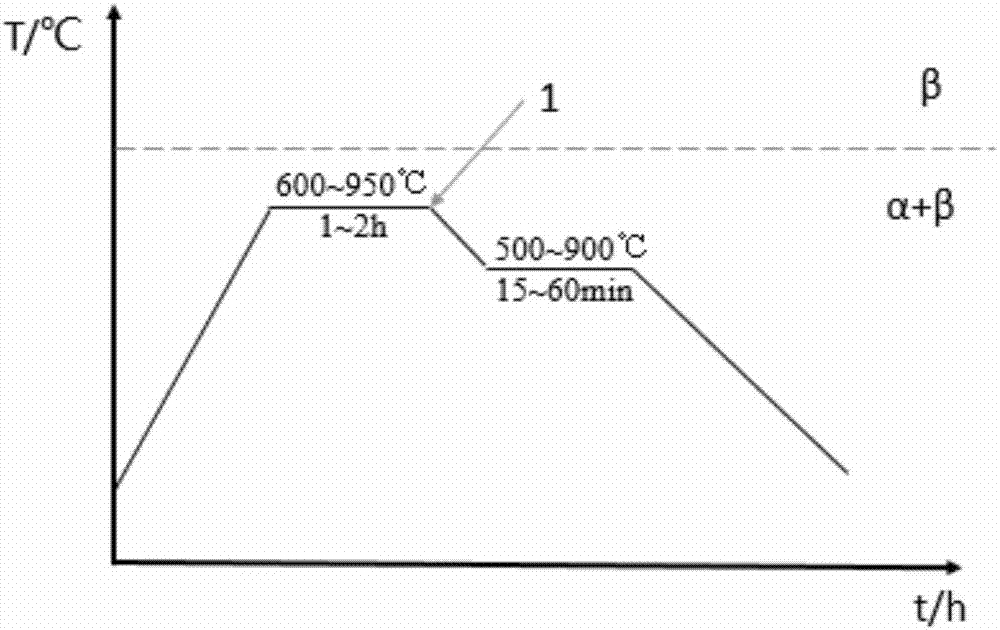

Temperature-control solidification method for Ti55 cast high-temperature titanium alloy

The invention discloses a temperature-control solidification method for Ti55 cast high-temperature titanium alloy. The method comprises the steps that a mould shell is heated in vacuum to 600-950 DEG C, the temperature is kept constant for 1-2 h, then, pouring is carried out, the metal liquid cooling speed is controlled in the solidification process, heat preservation is kept for 15-60 min at 500-900 DEG C, furnace cooling is carried out, and therefore the purpose of eliminating cracks in a casting process is achieved. Meanwhile, the obtained casting is better in surface smoothness, the mold filling performance and structure compactness of the titanium alloy casting are improved, and the cracking and deformation problems in the casting process are effectively eliminated.

Owner:重庆两航金属材料有限公司

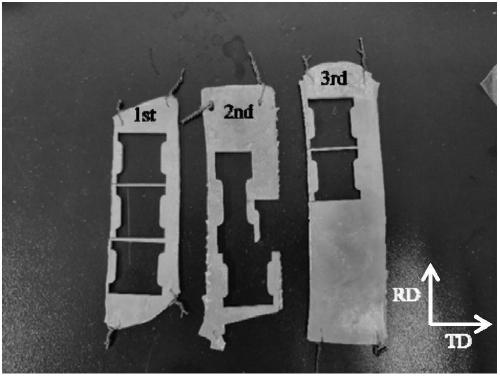

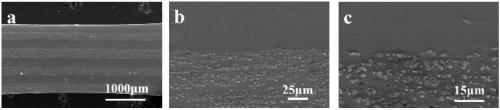

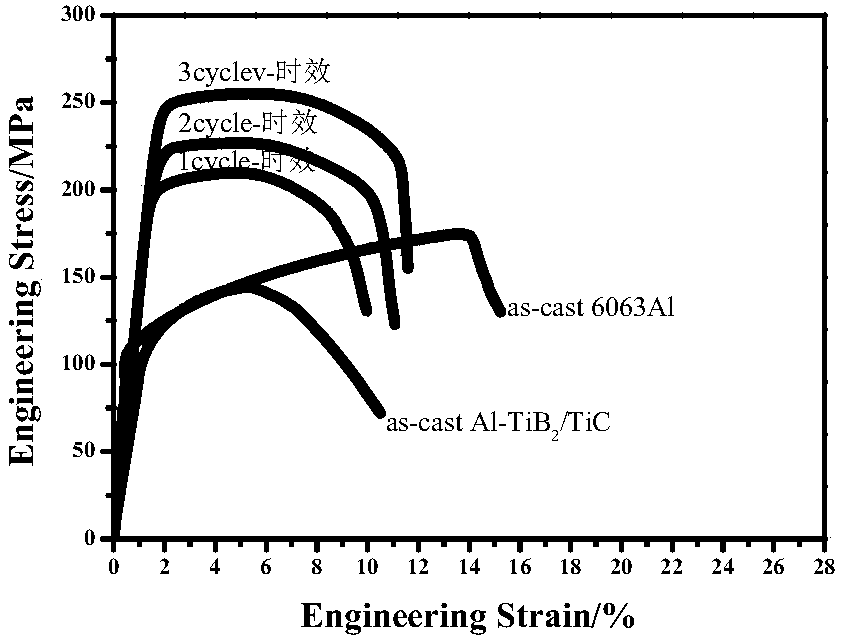

Preparation method of heterogeneous layered aluminum-based composite material

ActiveCN111376572AHigh strengthEnhanced interface bindingLamination ancillary operationsLaminationSolution treatmentSurface oxidation

The invention relates to a preparation method of a layered aluminum-based composite material. The method comprises the following steps: firstly, preparing Al-TiB2 / TiC and 6063Al plates with the same size; carrying out homogenization solution treatment on the two materials so as to deform in the pack rolling process; cleaning an oxide layer on the surface of the plate; stacking and fixing the treated materials, and carrying out multi-pass accumulative roll-bonding deformation treatment; and performing aging treatment on the material obtained after ply rolling, so that the overall strength of the plate is improved, thereby preparing the isomerous layered 6063Al / Al-TiB2 / TiC layered aluminum matrix composite. The preparation method is simple, low in cost, short in production period, green andnon-toxic; meanwhile, the material Al-TiB2 / TiC can integrate the strength of 6063Al while maintaining excellent characteristics such as wear resistance of the material Al-TiB2 / TiC, and an interface with tight combination is obtained.

Owner:NANJING UNIV OF SCI & TECH

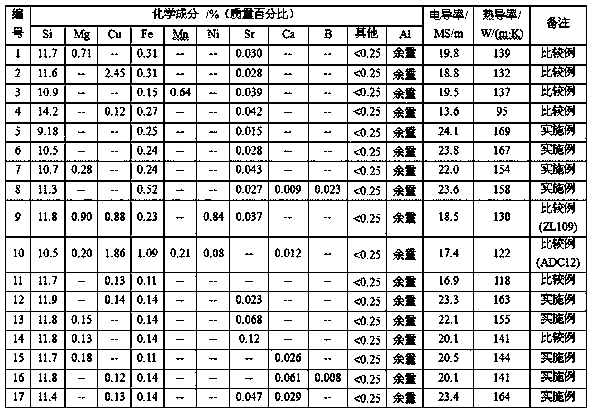

A kind of high thermal conductivity near-eutectic cast aluminum-silicon alloy material and production method

ActiveCN104674078BImprove thermal conductivityGood casting performanceSilicon alloyThermal conductivity

The invention relates to a near co-crystallizing type casting aluminum silicon alloy material with high heat conductivity and a production method thereof. The alloy comprises the main components including Al and Si, and is characterized by also comprising at least one of Sr, Ca and B. During casting production, the temperature of a melt is maintained within a range of 600-850 DEG C, and the alloy melt is cast into a casting mould so as to be cast into a casting; when the casting product is subjected to heat treatment, the temperature rising velocity of the heat treatment process is lower than 20 DEG C / min, and the temperature is maintained to be 100-450 DEG C and maintained for 0.5-10 hours, and then, the casting is cooled or air-cooled along with a furnace.

Owner:JIANGSU ZHONGSE RABILY IND CO LTD

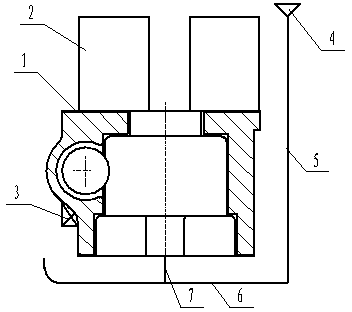

Method for casting copper sleeve and piston into whole

The invention discloses a method for casting a copper sleeve and a piston into a whole. The copper sleeve and the piston are cast into a whole by adopting an extrusion casting technology. Firstly, a mold is installed on an extruder in the extrusion process of the piston, the processed copper sleeve semi-finished product is arranged on a pin hole shaft of a piston extrusion model; aluminum melt is fully cast into a cavity, and extruded and cast, so that the copper sleeve semi-finished product and the piston are cast into a whole. The method comprises the following steps: 1, processing the copper sleeve semi-finished product according to a piston product drawing; 2, cleaning the copper sleeve semi-finished product, putting the cleaned copper sleeve semi-finished product into an electric furnace, preheating the copper sleeve semi-finished product, installing the copper sleeve semi-finished product on the pin hole shaft of a piston model, casting the aluminum melt into a piston cavity, and extruding and casting at the specific pressure of over 90Mpa; 3, carrying out heat treatment and machining on a piston product cast with the copper sleeve, and checking out to form the product. The piston produced by the method does not affect the matching precision of the piston and the cylinder due to the copper sleeve in operation of an engine, and the copper sleeve and a pin boss hole of the piston are tightly combined, and firm and reliable.

Owner:BINZHOU DONGHAILONG PISTON

A casting method for hollow turbine guide vanes

The invention provides a pouring method of a hollow turbine guide vane. The pouring method comprises the following steps: (1) manufacturing a wax mold combination; (2) carrying out shell making on the wax mold combination to obtain a hollow turbine guide vane shell; (3) covering one layer of ceramic heat-preservation cotton on a shell vane body part; covering two layers of ceramic cotton on the whole shell; and putting the treated shell into a roasting furnace and carrying out casting, wherein in a casting process, the temperature of casting the shell is 1065-1085 DEG C and the pouring temperature is 1460-1480 DEG C. According to the pouring method of the hollow turbine guide vane, a pouring system of the hollow turbine guide vane is not changed and the shell temperature and the pouring temperature are adjusted so that the casting temperature field is changed; the two layers of ceramic cotton on the whole body and one layer of the ceramic heat-preservation cotton on the vane body part are matched so that after the temperature of the whole shell is improved, the temperature field is uniform, the casting stress is eliminated and the casting temperature is reduced; and furthermore, the temperature field on a casting vane body and an edge plate keeps uniform, the shell is effectively insulated and the casting stress is eliminated.

Owner:AECC AVIATION POWER CO LTD

Thermal treatment process for alloy automobile hub casting

The invention discloses a thermal treatment process for an alloy automobile hub casting which is cast by adopting an aluminum-magnesium alloy liquid, wherein the aluminum-magnesium alloy liquid is prepared from the following components in proportion by mass: 2%-6% of magnesium, 0.5%-2.5% of silicon, 0.5%-0.8% of iron, 0.8%-1.2% of nickel, 0.2%-0.5% of chromium, 0.1%-0.5% of copper, 0.9%-1.5% of titanium, 0.1%-0.4% of zinc and the balance of aluminum. Thermal treatment for the alloy automobile hub casting comprises normalizing pretreatment and tempering treatment. In this way, the process is simple and easy to control; the automobile hub casting is cast by an aluminum-magnesium alloy with a reasonable formula; the casting is subjected to the normalizing pretreatment and the tempering treatment, so that casting stress is eliminated, thereby improving surface and inherent quality of the casting, and improving mechanical performance of the casting.

Owner:CHANGSHU HONGQIAO CAST STEEL CO LTD

Production method of 3003-brand cathode aluminum foil

InactiveCN101519760BEvenly distributedImprove plasticityElectrolytic capacitorsCapacitanceMetallurgy

The invention relates to a production method of 3003-brand cathode aluminum foil, which includes the following steps: a. raw materials are refined and rolled into a blank with the thickness of 6.5 mm The invention relates to a production method of 3003-brand cathode aluminum foil, which includes the following steps: a. raw materials are refined and rolled into a blank with the thickness of 6.5 mmts a contribution for the trade progress.es a contribution for the trade progress.o 8.5 mm; b. the blank obtained in step a is rolled into the blank with the thickness of 3.5 mm to 4.3 mm in a cooling mode to be uniformly annealed; c. the uniformly-annealed blank is rolled into thto 8.5 mm; b. the blank obtained in step a is rolled into the blank with the thickness of 3.5 mm to 4.3 mm in a cooling mode to be uniformly annealed; c. the uniformly-annealed blank is rolled into the blank with the thickness of 0.3 mm to 0.5 mm in a cooling mode to be recrystallized and annealed; and d. the recrystallized-and-annealed blank is rolled into the 3003-brand cathode aluminum foil wite blank with the thickness of 0.3 mm to 0.5 mm in a cooling mode to be recrystallized and annealed; and d. the recrystallized-and-annealed blank is rolled into the 3003-brand cathode aluminum foil with the required thickness. The method of the invention enables the cost to be lower and the product quality to be better, the specific capacitance of the product is increased to be higher than 530 micrh the required thickness. The method of the invention enables the cost to be lower and the product quality to be better, the specific capacitance of the product is increased to be higher than 530 microfarads / cm<2>, and the highest specific capacitance can be 560 microfarads / cm<2>. The invention greatly improves the product competitive strength, reduces the disparity with abroad products, and makofarads / cm<2>, and the highest specific capacitance can be 560 microfarads / cm<2>. The invention greatly improves the product competitive strength, reduces the disparity with abroad products, and make

Owner:登电集团铝加工有限公司

Large-diameter low-deformation-resistance free cutting aluminum alloy ingot and preparation process thereof

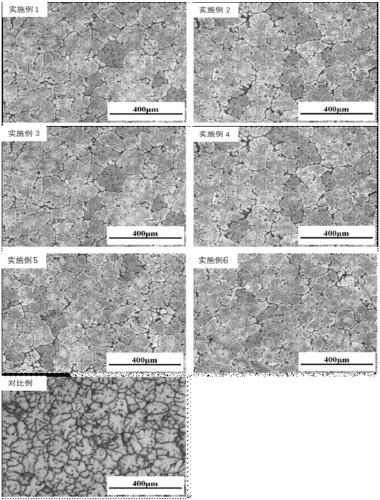

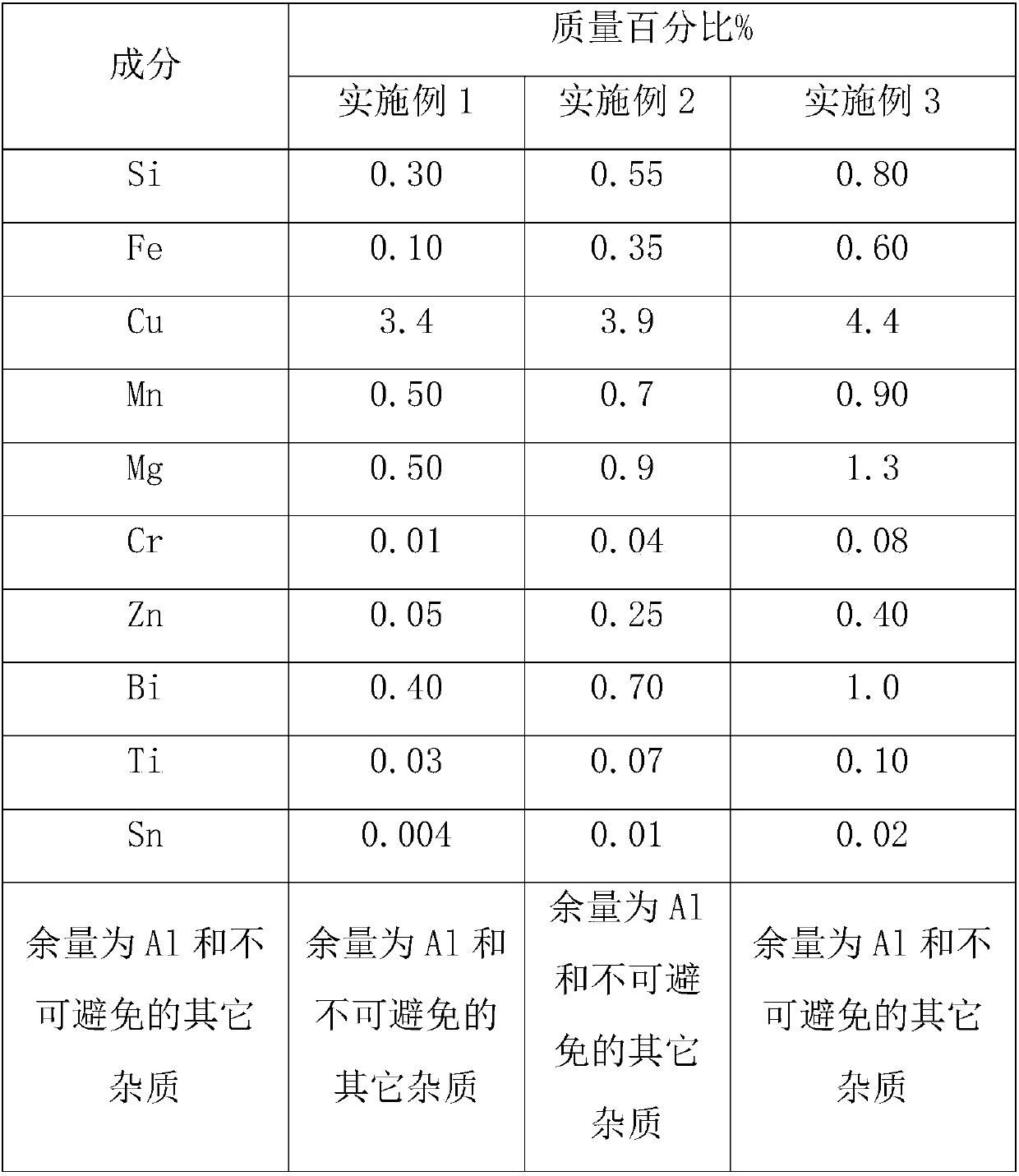

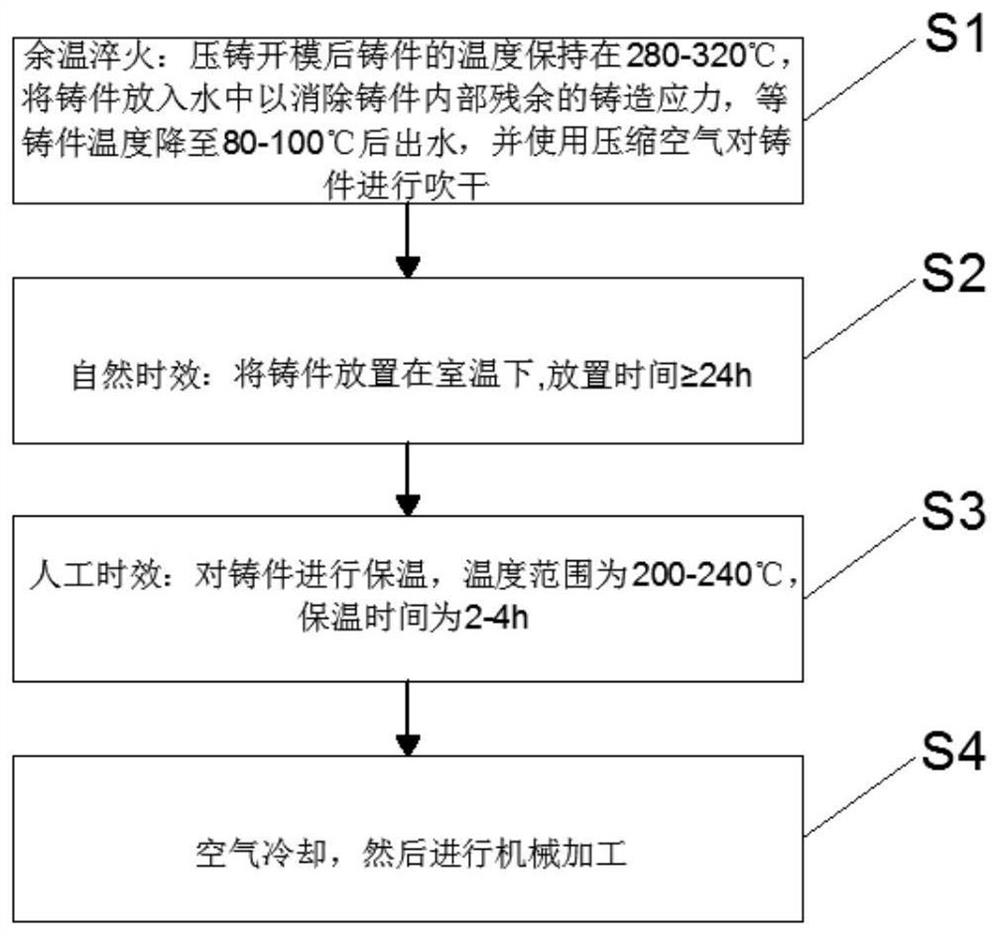

ActiveCN109666831AUniform compositionLittle difference in radial distributionChemical compositionIngot

The invention discloses a large-diameter low-deformation-resistance free cutting aluminum alloy ingot and a preparation process thereof. The aluminum alloy ingot comprises the following chemical components in percentage by mass: 0.30-0.80% of Si, 0.10-0.60% of Fe, 3.4-4.4% of Cu, 0.50-0.90% of Mn, 0.50-1.3% of Mg, 0.01-0.08% of Cr, 0.05-0.40% of Zn, 0.40-1.0% of Bi, 0.03-0.10% of Ti, Sn not more than 0.02%, and the balance of Al and inevitable other impurities; the single content of the inevitable other impurities is not more than 0.05%; and the total amount is not more than 0.15%. The invention aims to provide the preparation process of the large-diameter aluminum alloy ingot; the problems of thick segregation layers, easy generation of cracks and weak component uniformity in production of hard alloy ingots with diameters of more than 400 mm by a traditional process are overcome; and the high-temperature dispersion is performed before deformation machining to obtain high-quality ingots with uniform component distribution, compact structure dispersion and easy deformation machining.

Owner:广东精美特种型材有限公司

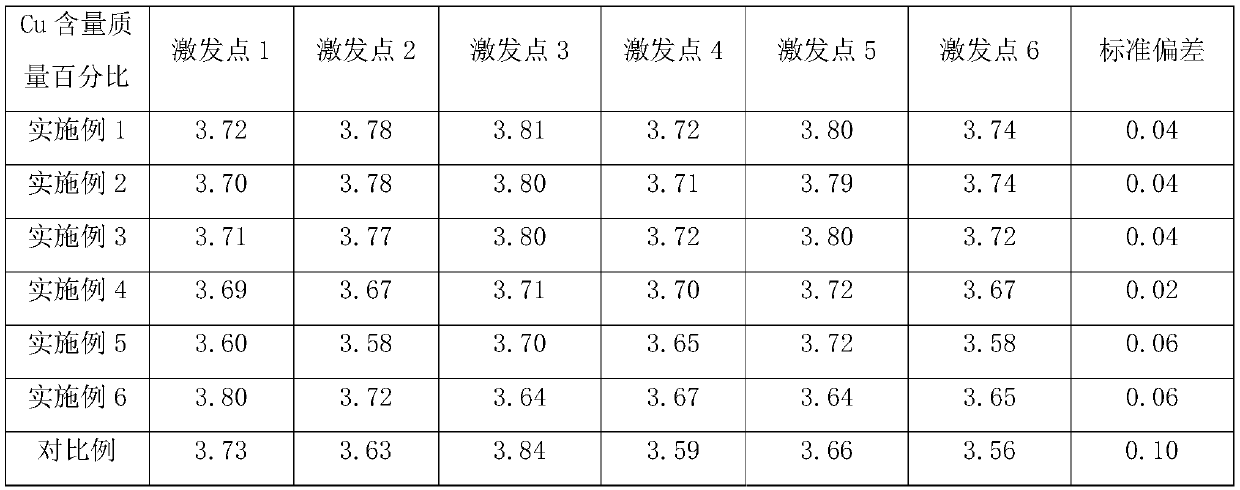

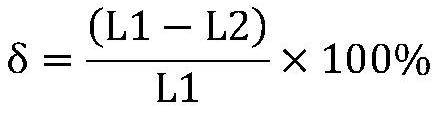

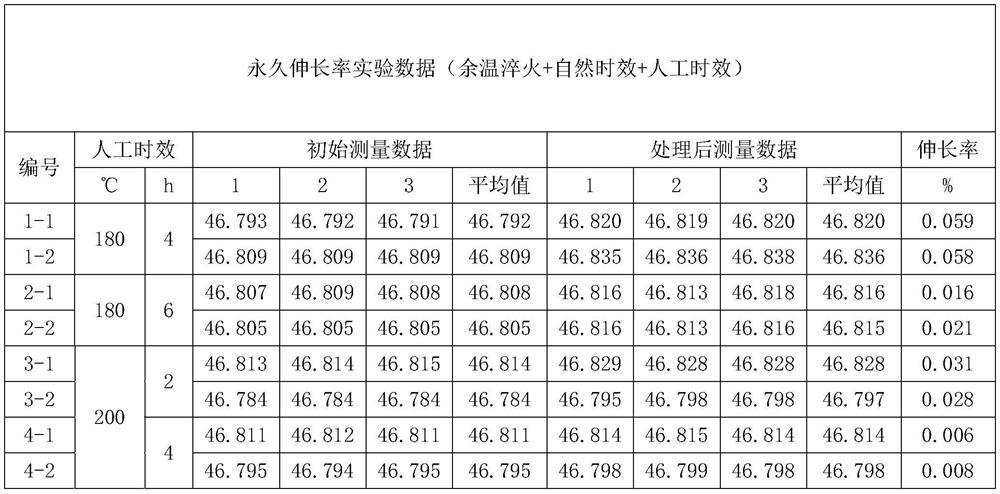

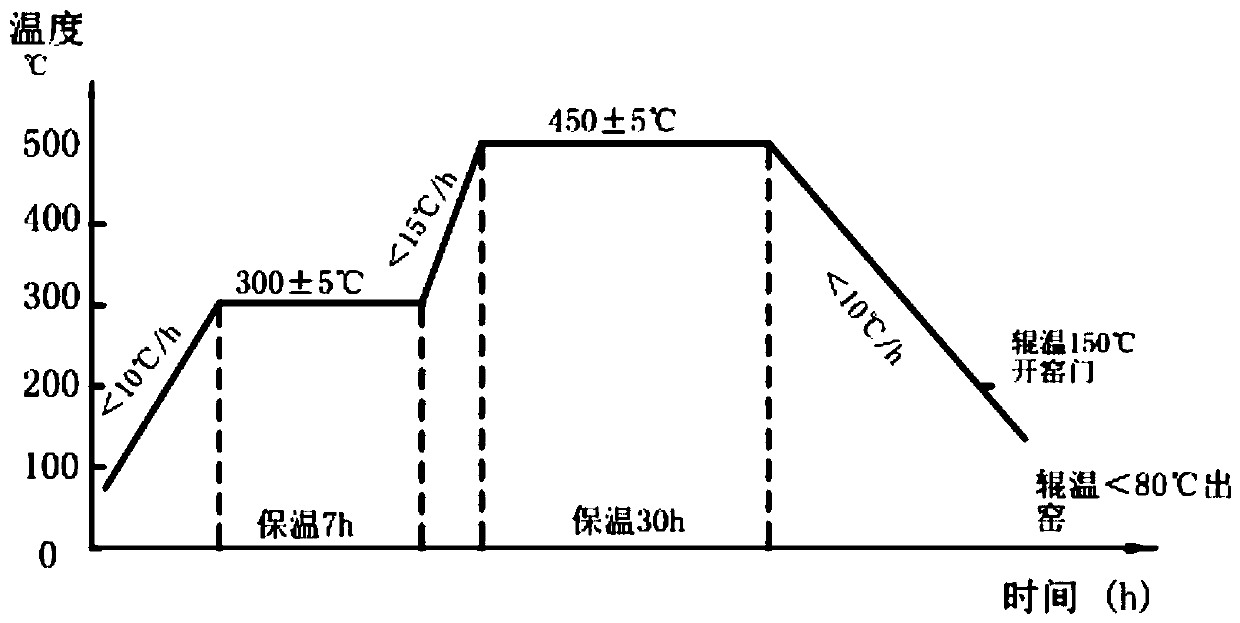

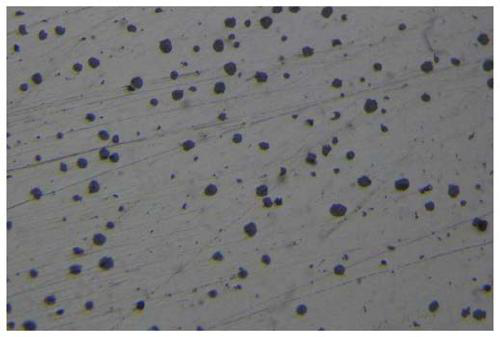

Craft for improving dimensional stability of die castings

The invention provides a craft for improving dimensional stability of die castings. The craft comprises the following steps of lingering warmth quenching: maintaining the temperature of castings from280 to 320 DEG C after die sinking, putting the castings in the water to remove the casting stress left inside the castings, taking the castings out of the water after the temperature of the castingsis reduced to 80 to 100 DEG C, and using compressed air to dry the castings; natural aging: placing the castings in the room temperature for greater than or equal to 24 hours; and artificial aging: keeping the temperature of the castings from 200-240 DEG C for 2-4 hours. The craft uses lingering warmth quenching to release the residual stress in the die castings, thereby improving the dimensionalstability of the die castings and obviously reducing the processing time of artificial aging.

Owner:DONGFENG SHIYAN NONFERROUS CASTING

Gray cast iron welding process

InactiveCN105983758AEasy to adjustMelting fastArc welding apparatusProcess specificationThermal treatment

The invention discloses a gray cast iron welding process. The gray cast iron welding process is characterized by including: (1), thermally treating before welding: charging a gray cast iron weldment into a furnace at low temperature, heating the gray cast iron weldment to specified temperature of 600-800 DEG C at a speed about 100 DEG C / h, holding temperature in the furnace for 2-4 h, and cooling the weldment to below 300 DEG C at a cooling speed of 20-50 DEG C / h; (2), drying a welding rod: adopting a Z308 nickel-based cast iron welding rod, drying the same at 150-400 DEG C, and holding the temperature for 1-2 h; (3), welding: adopting a CO2 gas protection welding method, wherein welding current is 50-100 A, electric arc voltage is 15-20 V, gas flow is 8-10 L / min, a welding material is H08Mn2SiA with diameter of 0.8-1 mm. The gray cast iron welding process has the advantages of strict and reasonable control on parameters at each stage and standard procedures, weldability of gray cast iron is improved, and cracks are reduced.

Owner:重庆沁煌实业有限公司

5A06H14 sheet metal with thickness of 8.5mm, and preparation method thereof

The invention relates to a preparation method of a 5A06H14 sheet metal with a thickness of 8.5mm. The invention relates to a sheet metal and a preparation method thereof. The invention aims at solving the problems of unstable alloy ingot strength, low yield strength, low tensile strength, and large unevenness of 8.5mm-thick 5A06H14 sheet metals produced with prior arts. The preparation method comprises the steps of: 1, material blending; 2, smelting; 3, casting; 4, homogenizing annealing; 5, sawing, edge planing and surface milling; 6, aluminum coating; 7, hot rolling; 8, cold rolling; 9, pre-stretching; and 10, sawing. With the steps, the 8.5mm-thick 5A06H14 sheet metal is obtained. With the method provided by the invention, the prepared 8.5mm-thick 5A06H14 sheet metal has a yield strength of 373-420MPa, a tensile strength of 285-330MPa, an elongation of 8% to 12%, an unevenness less than 8mm / m, and a same plate difference less than 0.25mm. The method provided by the invention is applied in industrialized productions of 5A06 sheet metals.

Owner:NORTHEAST LIGHT ALLOY CO LTD

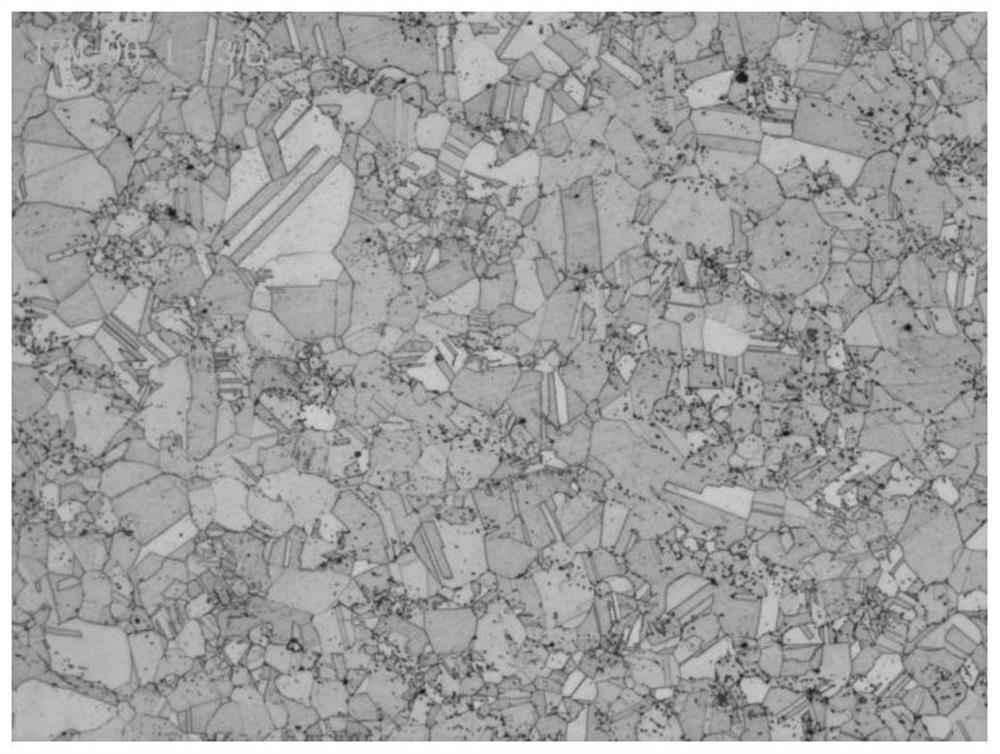

Casting method for improved infinite chilled alloy cast iron steel roll

ActiveCN111519089ASmall drop in hardnessImprove wear resistanceFurnace typesHeat treatment furnacesAlloyCast iron

The invention relates to a casting method for an improved infinite chilled alloy cast iron steel roll. The chemical components of the cast iron steel roll comprise, by weight percentage, 3.00%-3.50% of C, 1.05%-1.65% of Si, 0.40%-0.80% of Mn, being less than 0.10% of P, being less than 0.03% of S, 1.50-2.00% of Ni, 0.25%-0.65% of Cr, 0.25%-0.65% of Mo, and the balance Fe and inevitable impurities.Before pouring, primary nodularization and third inoculation treatment is carried out on molten iron, annealing treatment is carried out on castings after unpacking, and casting stress is eliminated.The cast iron steel roll has higher abrasion resistance and hot tearing resistance, thus the service life of the roll is effectively prolonged.

Owner:ANSTEEL HEAVY MACHINERY CO LTD

Heat treatment method for improving hardness of ZG270-500 eccentric body

ActiveCN101705346AUniform hardnessGuaranteed water cooling without crackingFurnace typesHeat treatment process controlRoom temperatureSharp angle

The invention discloses a heat treatment method for improving hardness of ZG270-500 eccentric body, comprising the following steps: placing the eccentric body in a heating furnace, heating till the temperature is higher than 650 DEG C, preserving the heat for more than 3 h, then placing in a heating furnace, heating till the temperature is higher than 850 DEG C, preserving the heat for more than 5 h, then taking out, and placing in the air to cool to room temperature; heating the cooled eccentric body in a heating furnace till the temperature is increased to 650 DEG C, and preserving the heat for more than 3 h; continuously heating the eccentric body till the temperature is higher than 850 DEG C, preserving the temperature for more than 5 h, then cooling in the air till the sharp angle part thereof becomes black and other parts thereof is 840 to 850 DEG C, then cooling the thickest part of the eccentric body with water, placing the whole eccentric body in the oil of 80 DEG C, and cooling for 50 to 60 min; finally, tempering. The thickest part of the eccentric body is cooled with water, and the whole eccentric body is cooled with oil, thus all parts of the eccentric body have uniform hardness, and the hardness is not less than 180 HB.

Owner:JIER MACHINE TOOL GROUP

Large-modulus and small-tooth-number gear machining method

The invention discloses a large-modulus and small-tooth-number gear machining method. The large-modulus and small-tooth-number gear machining method comprises piece forging, annealing treatment for casting stress removal, rough turning, semi finish turning, carburizing and quenching, finish turning, fine control shot blasting, flaw detection and final inspection. The large-modulus and small-tooth-number gear machining method has the advantages that large-modulus and small-tooth-number gear machining can be achieved, and the problems that machining is difficult and serious deformation is likelyto happen during machining are solved; and special design of a gear tool is not needed, complex tooth face rough and finish machining can be finished through a square shoulder disc milling tool bar tool, and machining is more simple and economical.

Owner:衡山同远机械有限公司

Method for preparing Cu-Fe alloy under action of magnetic field

Owner:NORTHEASTERN UNIV LIAONING

A kind of high toughness casting Fe-cr-mo base high damping alloy and its preparation method

The invention provides high-toughness casting Fe-Cr-Mo-based high-damping alloy. The alloy contains 0.05-0.8% of Zr in percentage by mass. Preferably, the alloy comprises the following components in percentage by mass: 13-17% of Cr, 1-4% of Mo, 0.3-1.5% of Si, 0.3-1.0% of Mn, 0-2.0% of Ni, 0.05-0.8% of Zr and the balance of Fe. The preparation method of the high-toughness casting Fe-Cr-Mo-based high-damping alloy comprises the following steps: weighing raw materials according to the components and the component ratio of the high-toughness casting Fe-Cr-Mo-based high-damping alloy; carrying out vacuum induction melting and pouring to obtain an alloy casting; and carrying out damping heat treatment on the alloy casting to obtain the high-toughness casting Fe-Cr-Mo-based high-damping alloy. During vacuum induction melting, a Zr source is added in the later stage of refining under the condition of vacuum. On the premise of not reducing damping property, the toughness of the Fe-Cr-Mo-based damping alloy can be greatly improved.

Owner:SICHUAN UNIV

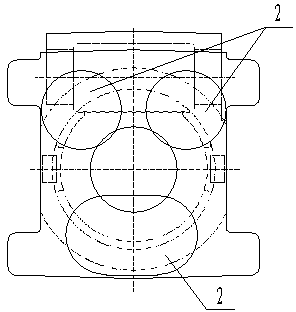

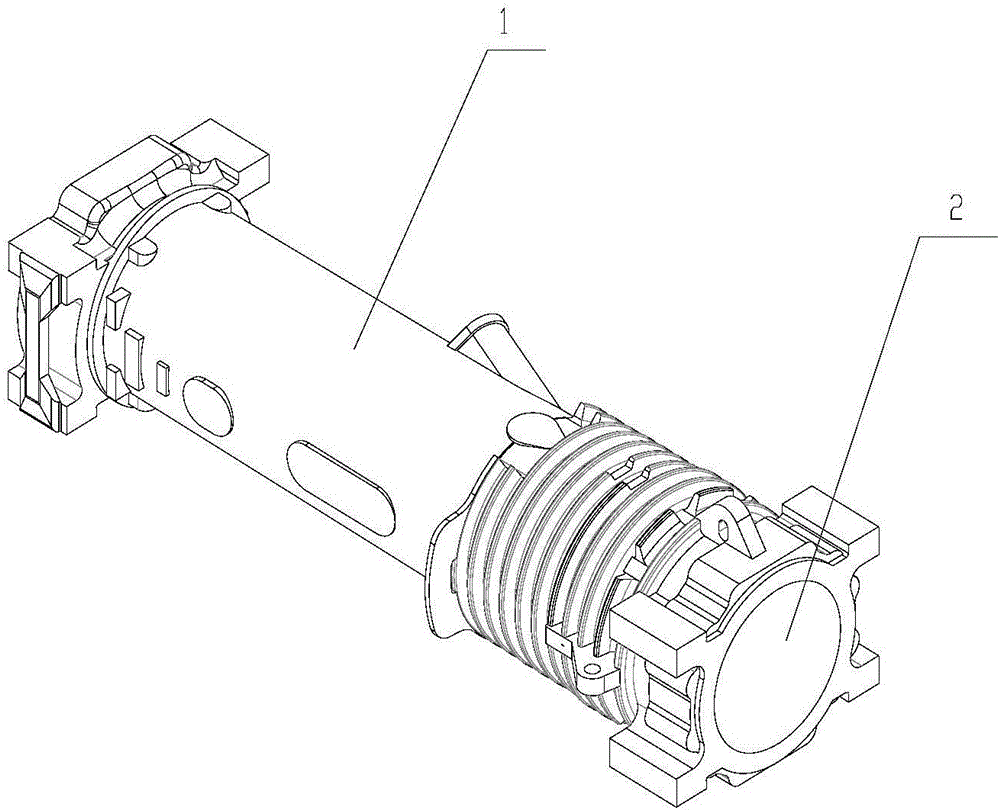

Gravity casting process

The invention relates to a gravity casting process for manufacturing an all-in-one rack of a compressor. The gravity casting process is characterized in that firstly, an upper cylinder head and the inner wall face of a housing of the compressor are simultaneously processed and cast, so that the coaxiality between the upper cylinder head and the housing is guaranteed, and noise and vibration of the compressor are reduced; secondly, the inventor creatively discovers that the gravity casting mode can enable the combination parts of the upper cylinder head and the housing which are made of two different metal materials to be fused to form a mutual fusion zone, the purpose of metallurgical bonding can be achieved after cooling, and favorable mechanical bonding property is achieved; and thirdly, the gravity casting process further comprises incomplete annealing heat treatment, so that the casting stress of the two combination parts of the all-in-one rack can be eliminated, the mechanical performance is better, and the formed all-in-one rack can be further machined.

Owner:SHANGHAI HITACHI ELECTRICAL APPLIANCES CO LTD

A high temperature steam turbine blade and its production method

ActiveCN109136472BIncrease contentIncrease the amount of forging deformationFurnace typesIncreasing energy efficiencySteam turbine bladeAlloy

The invention discloses a high-temperature turbine blade and a production method of the turbine blade. The turbine blade comprises the following chemical ingredients by mass percentage: 0.05-0.068% ofC, 19-21% of Cr, 1.50-1.65% of Al, 2.5-2.6% of Ti and the balance of Ni. The turbine blade is prepared by performing vacuum induction smelting and casting on the ingredients to form an electrode bar,and performing electroslag remelting, high temperature homogenization treatment and forging. According to the blade, contents of the preparation ingredients are optimized; on the premise of reducingthe content of C in the raw material ingredients, the segregation is reduced, and a crystallization direction can be effectively controlled at the same time by performing electroslag remelting treatment, selecting an appropriate electroslag remelting slag system and controlling electroslag remelting parameters; a crystallization structure in an alloy is improved by the homogenization treatment; casting stress is removed; the segregation is reduced; the uniformity of the structure can be further improved; and a forging deformation amount of a finished product is increased by cross forging.

Owner:SICHUAN JIANGYOU LIUHE STEAM TURBINE MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com