Temperature-control solidification method for Ti55 cast high-temperature titanium alloy

A technology for high-temperature titanium alloy and alloy ingot, which is applied in the field of high-temperature titanium alloy casting melting and solidification, and the temperature-controlled solidification field of Ti55 casting high-temperature titanium alloy. Expansion, simple operation process, the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

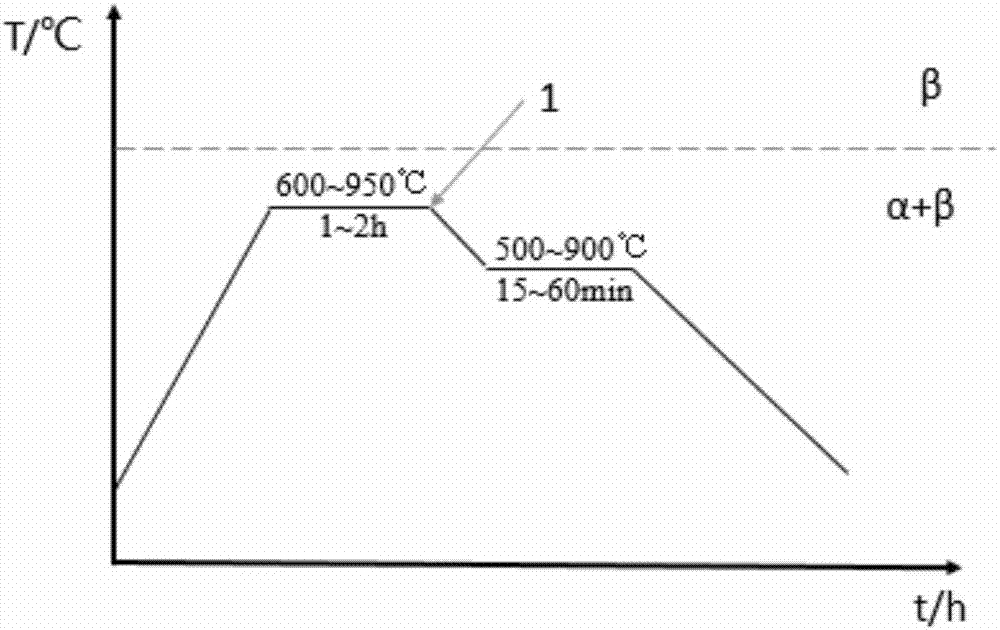

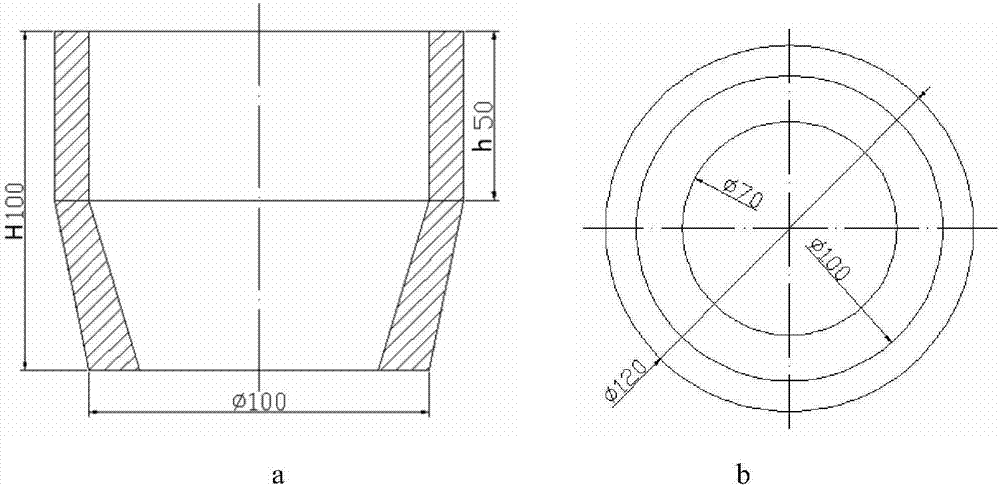

[0037] The concrete process of this embodiment is:

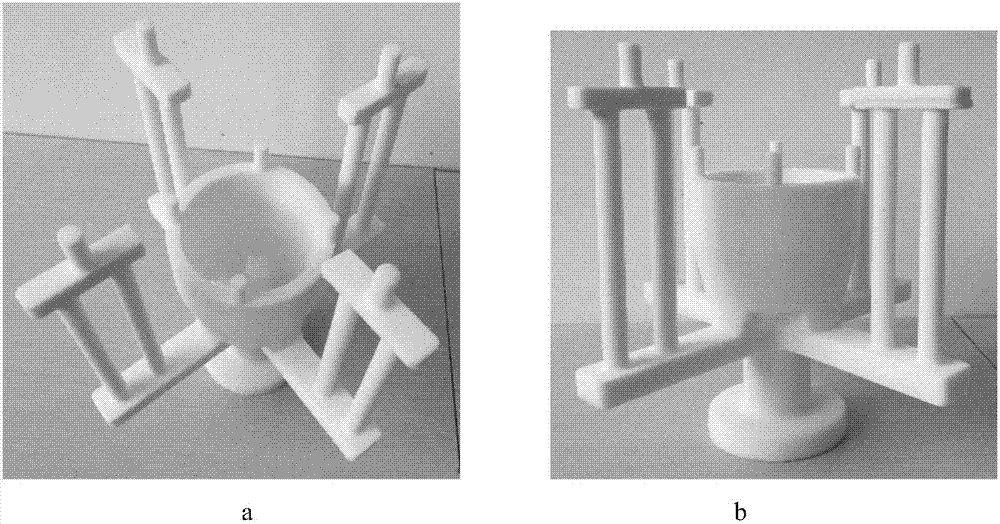

[0038] Step 1, coat and hang the mold. Print out the designed cracking cup mold with 3D, paint and hang the mold and let it dry. When coating and hanging, 2 layers, 2 layers, 3 layers, and 1 layer are respectively coated on the surface layer, transition layer, back layer, and sealing layer of the mold; the coating material of the fabric is pure yttrium oxide, and the coated mold is obtained.

[0039] Step 2, dewaxing and roasting. Put the dried mold in an electric blast drying oven for dewaxing treatment: raise the temperature of the electric blast drying oven to 150°C; put the dried mold in the electric blast drying oven for 2 hours; after the heat preservation, the The electric blast drying oven continues to heat up to 170 ° C for 2 hours to complete the dewaxing of the mold and obtain the mold shell. Roast the dewaxed formwork in a high-temperature box furnace, specifically: raise the temperature of the high-temperatur...

Embodiment 2

[0045] A temperature-controlled solidification method for casting a high-temperature titanium alloy according to the present embodiment is carried out in the following steps:

[0046] Step 1, coat and hang the mold. Print out the designed cracking cup mold with 3D, paint and hang the mold and let it dry. When coating and hanging, 2 layers, 2 layers, 3 layers, and 1 layer are respectively coated on the surface layer, transition layer, back layer, and sealing layer of the mold; the coating material of the fabric is pure yttrium oxide, and the coated mold is obtained.

[0047] Step 2, dewaxing and roasting. Put the dried mold in an electric blast drying oven for dewaxing treatment: raise the temperature of the electric blast drying oven to 150°C; put the dried mold in the electric blast drying oven for 2 hours; after the heat preservation, the The electric blast drying oven continues to heat up to 170 ° C for 2 hours to complete the dewaxing of the mold and obtain the mold shel...

Embodiment 3

[0053] A temperature-controlled solidification method for casting a high-temperature titanium alloy according to the present embodiment is carried out in the following steps:

[0054] Step 1, coat and hang the mold. Print out the designed cracking cup mold with 3D, paint and hang the mold and let it dry. When coating and hanging, 2 layers, 2 layers, 3 layers, and 1 layer are respectively coated on the surface layer, transition layer, back layer, and sealing layer of the mold; the coating material of the fabric is pure yttrium oxide, and the coated mold is obtained.

[0055] Step 2, dewaxing and roasting. Put the dried mold in an electric blast drying oven for dewaxing treatment: raise the temperature of the electric blast drying oven to 150°C; put the dried mold in the electric blast drying oven for 2 hours; after the heat preservation, the The electric blast drying oven continues to heat up to 170 ° C for 2 hours to complete the dewaxing of the mold and obtain the mold shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com