Large-diameter low-deformation-resistance free cutting aluminum alloy ingot and preparation process thereof

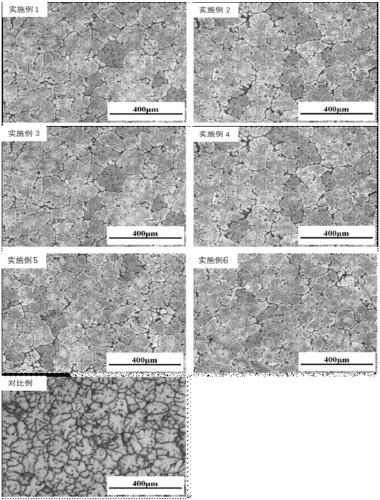

An aluminum alloy ingot, preparation process technology, applied in the field of aluminum alloy preparation, can solve the problems of large radial chemical composition difference, high casting stress, central cold crack or surface crack, etc., achieve small radial distribution difference, eliminate casting Stress, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

[0036] The difference between the present embodiment 4 and embodiment 2 is the casting step, specifically:

[0037] The casting process adopts oil-air lubricating tooling and pulse oil injection. The oil injection time in one cycle is 12s, and the oil injection time is 18s. The aluminum melt enters the vacuum online degassing box through the launder, and the air in the degassing box is extracted to form a negative pressure. The liquid level in the degassing box rises, and the bottom-mounted rotor rotates at a high speed and feeds argon with a purity of 99.999%. The gas is cut into countless fine bubbles, and the gas and impurities in the aluminum melt are adsorbed on the surface of the bubbles, and then float on the surface of the melt to achieve the purpose of degassing and impurity removal. The rotor speed is 450rpm. The melt flows to the crystallizer platform, and when the liquid level rises to 1 / 4 of the height of the insulation cap, the casting is started and the holding ...

Embodiment 5

[0039] The difference between this embodiment 5 and embodiment 2 is the casting step, specifically:

[0040] The casting process adopts oil-air lubricating tooling and pulse oil injection. The oil injection time in one cycle is 12s, and the oil injection time is 18s. The aluminum melt enters the vacuum online degassing box through the launder, and the air in the degassing box is extracted to form a negative pressure. The liquid level in the degassing box rises, and the bottom-mounted rotor rotates at a high speed and feeds argon with a purity of 99.999%. The gas is cut into countless tiny bubbles, and the gas and impurities in the aluminum melt are adsorbed on the surface of the bubbles, and then float on the surface of the melt to achieve the purpose of degassing and impurity removal, and the rotor speed is 500pm. The melt flows to the crystallizer platform, and when the liquid level rises to 1 / 4 of the height of the insulation cap, the casting is started and the holding time...

Embodiment 6

[0042] The difference between this embodiment 6 and embodiment 2 lies in the high temperature diffusion treatment step, specifically:

[0043] The heating process of high-temperature diffusion treatment is three-stage, the first stage is 50-60°C / h, from room temperature to 250°C; the second stage is 65-75°C / h, from 250°C to 400°C; the third stage is 50°C ~60°C / h, rising from 400°C to 500°C. The holding temperature is 500°C, and the holding time is 20h. The cooling process of high-temperature diffusion treatment is three-stage, including one stage cooling to 420°C at 15-20°C / h in the heat treatment furnace, the second stage cooling to 250°C at 20-30°C / h in the holding furnace, and the third stage Transfer out of the holding furnace to air cool. Among them, the holding furnace is a closed furnace body, and the furnace gas can realize internal circulation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com