Method for casting copper sleeve and piston into whole

A technology of copper sleeve and piston, which is applied in the field of mechanical casting, can solve the problems of accelerated wear, increased cost, and increased copper sleeve inner diameter out-of-roundness, and achieves the effects of increasing mechanical clamping force, reducing product cost, and increasing occlusal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

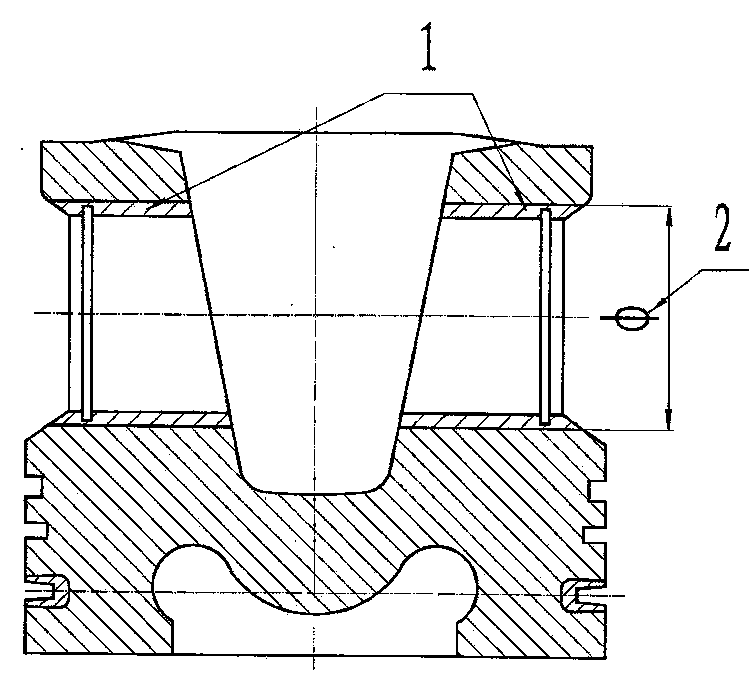

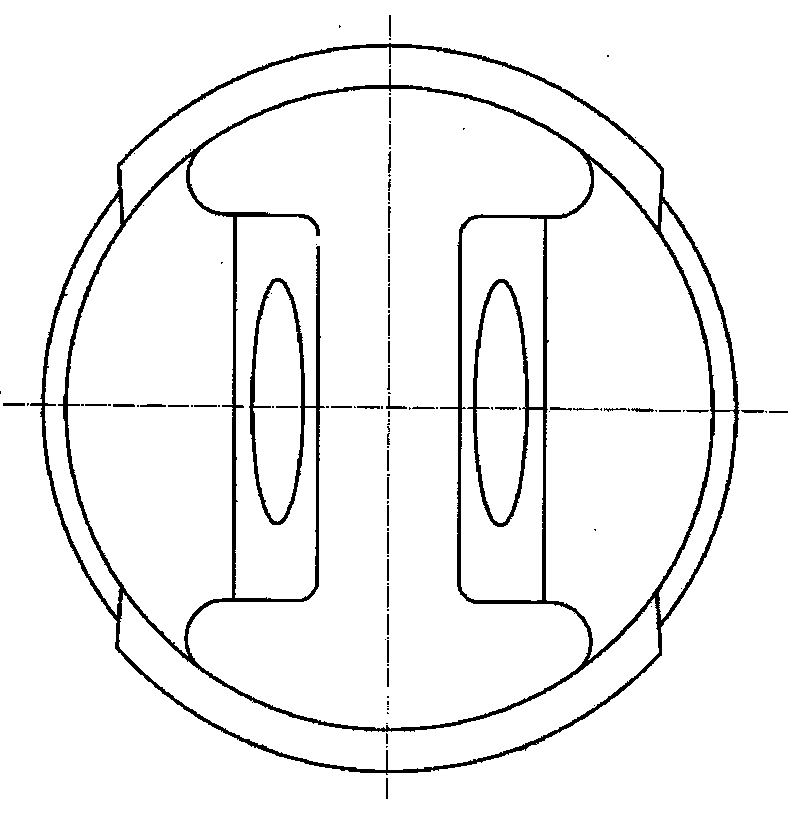

[0029] Example 1: A method of casting a copper sleeve and a piston into one body by squeeze casting, including the following steps: (1) First, process the piston according to the finished product drawing. Figure 5 , Image 6 with Figure 7 The semi-finished copper sleeve 8 is provided with an occlusal groove 3 on the outer circle of the semi-finished copper sleeve 8. The inner diameter of the semi-finished copper sleeve 8 is required to be φ1 = the inner diameter of the pin hole specified in the product drawing + cutting allowance, and it can match the pin hole axis of the model Fitting; the outer diameter of the semi-finished copper sleeve is required to be φ2 = the outer diameter of the copper sleeve specified in the product drawing;

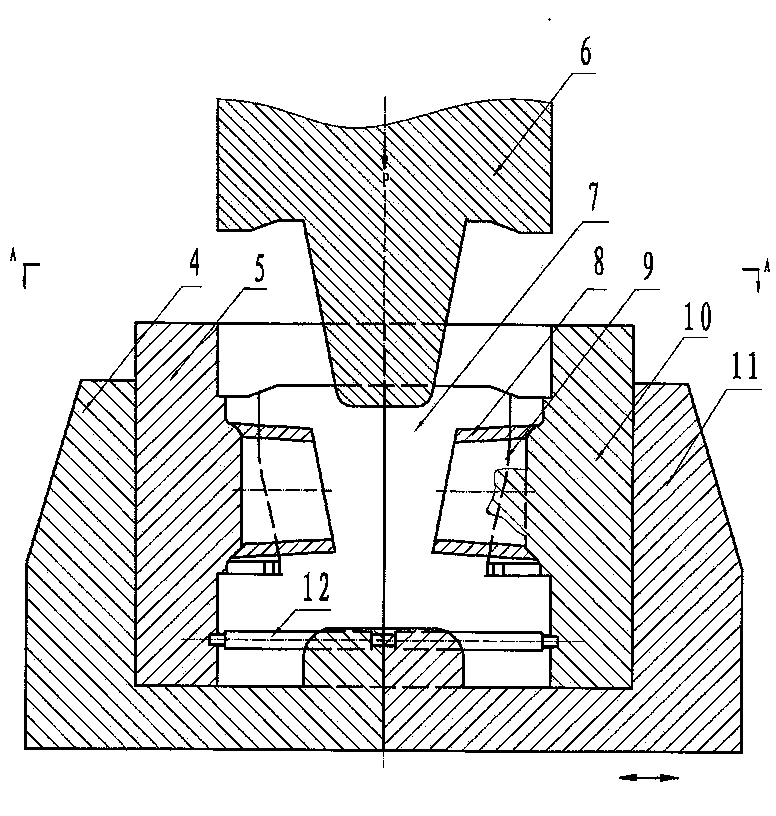

[0030] ⑵, produce such as image 3 with Figure 4 The piston extrusion mold consists of: fixed mold sleeve 4, fixed tire mold 5; wedge compression head 6, piston cavity 7, pin hole shaft 9, movable tire mold 10, movable mold sleeve 11 and wear-re...

Embodiment 2

[0035] Embodiment 2: The method of casting a copper sleeve and a piston into one body by squeeze casting includes the following steps:

[0036] ⑴, first process the piston according to the finished drawing as Figure 5 , Image 6 with Figure 7 The semi-finished copper sleeve 8 is uniformly provided with three occluding grooves 3 on the outer circle of the semi-finished copper sleeve 8. The inner diameter of the semi-finished copper sleeve 8 is required to be φ1 = the inner diameter of the pin hole specified in the product drawing + the machining allowance, and it can match the model Pin hole shaft assembly; the outer diameter of the semi-finished copper sleeve is required φ2 = the outer diameter of the copper sleeve specified in the product drawing;

[0037] ⑵, produce such as image 3 with Figure 4 The piston extrusion mold consists of: fixed mold sleeve 4, fixed tire mold 5; wedge compression head 6, piston cavity 7, pin hole shaft 9, movable tire mold 10, movable mold sleeve 1...

Embodiment 3

[0042] Embodiment 3: The method of casting a copper sleeve and a piston into one body by squeeze casting includes the following steps:

[0043] ⑴, first process the piston according to the finished drawing as Figure 5 , Image 6 with Figure 7 The semi-finished copper sleeve 8 is uniformly provided with three occluding grooves 3 on the outer circle of the semi-finished copper sleeve 8. The inner diameter of the semi-finished copper sleeve 8 is required to be φ1 = the inner diameter of the pin hole specified in the product drawing + the machining allowance, and it can match the model Pin hole shaft assembly; the outer diameter of the semi-finished copper sleeve is required φ2 = the outer diameter of the copper sleeve specified in the product drawing;

[0044] ⑵, produce such as image 3 with Figure 4 The piston extrusion mold consists of: fixed mold sleeve 4, fixed tire mold 5; wedge compression head 6, piston cavity 7, pin hole shaft 9, movable tire mold 10, movable mold sleeve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com