Craft for improving dimensional stability of die castings

A technology for dimensional stability and die casting, which is applied in the technological field of improving the dimensional stability of die castings, can solve the problems of long processing time, energy waste, low efficiency, etc. black effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

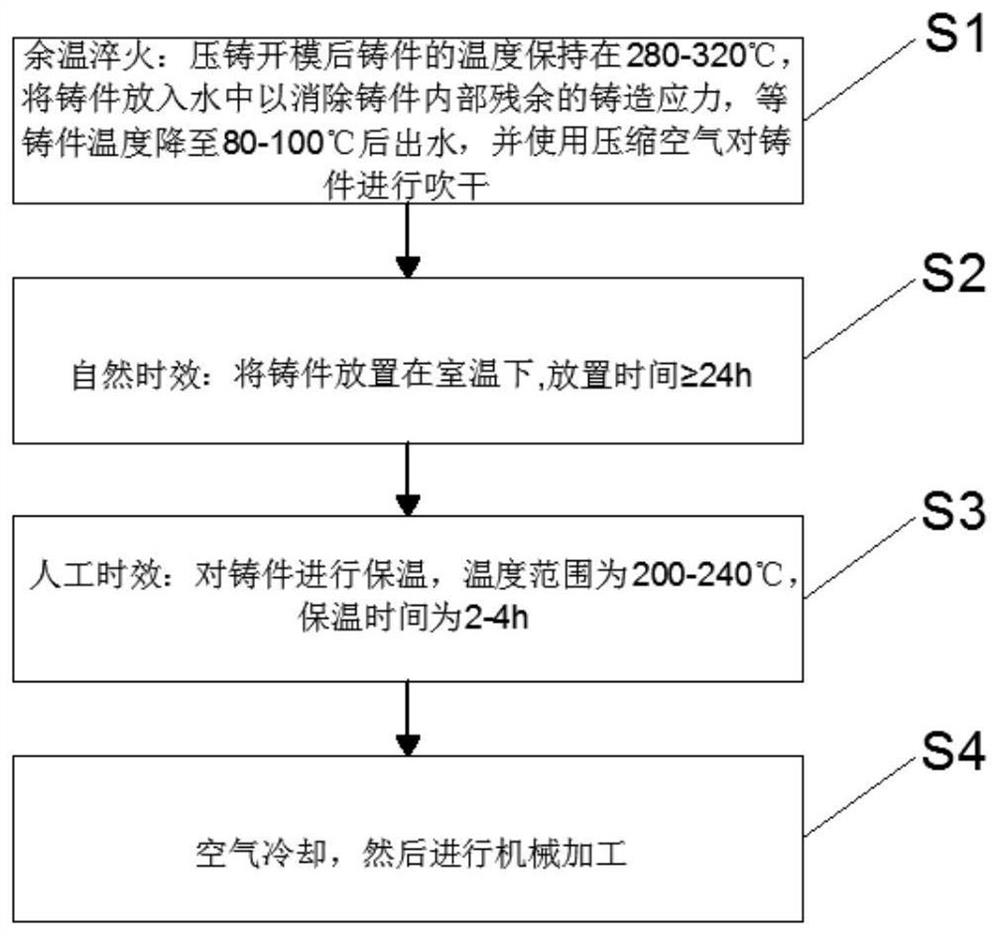

[0029] like figure 1 As shown, this embodiment discloses a process for improving the dimensional stability of die castings, comprising the following steps:

[0030] S1. Remaining temperature quenching: After the die-casting mold is opened, the temperature of the casting is kept at 280-320 ° C. Put the casting into water to eliminate the residual casting stress inside the casting. After the temperature of the casting drops to 80-100 ° C, the water is released and compressed air is used. Blow dry the casting;

[0031] S2. Natural aging: place the casting at room temperature for ≥24 hours;

[0032] S3. Artificial aging: keep the castings warm, the temperature range is 200-240°C, and the holding time is 2-4h;

[0033] S4, air cooling, and then machining.

[0034] Aging treatment, also known as low temperature tempering, includes natural aging and artificial aging. The traditional artificial aging heats the casting to 175-185°C, and the holding time is 5-24h. This process signi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com