An Electromagnetic Loading Device Used in Concrete Durability Test

A durability test and loading device technology, which is applied in the field of cement and concrete basic research, can solve the problems of spring effective area reduction, loading device failure, stress relaxation, etc., to avoid stress changes, simple force application method, and small occupied volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

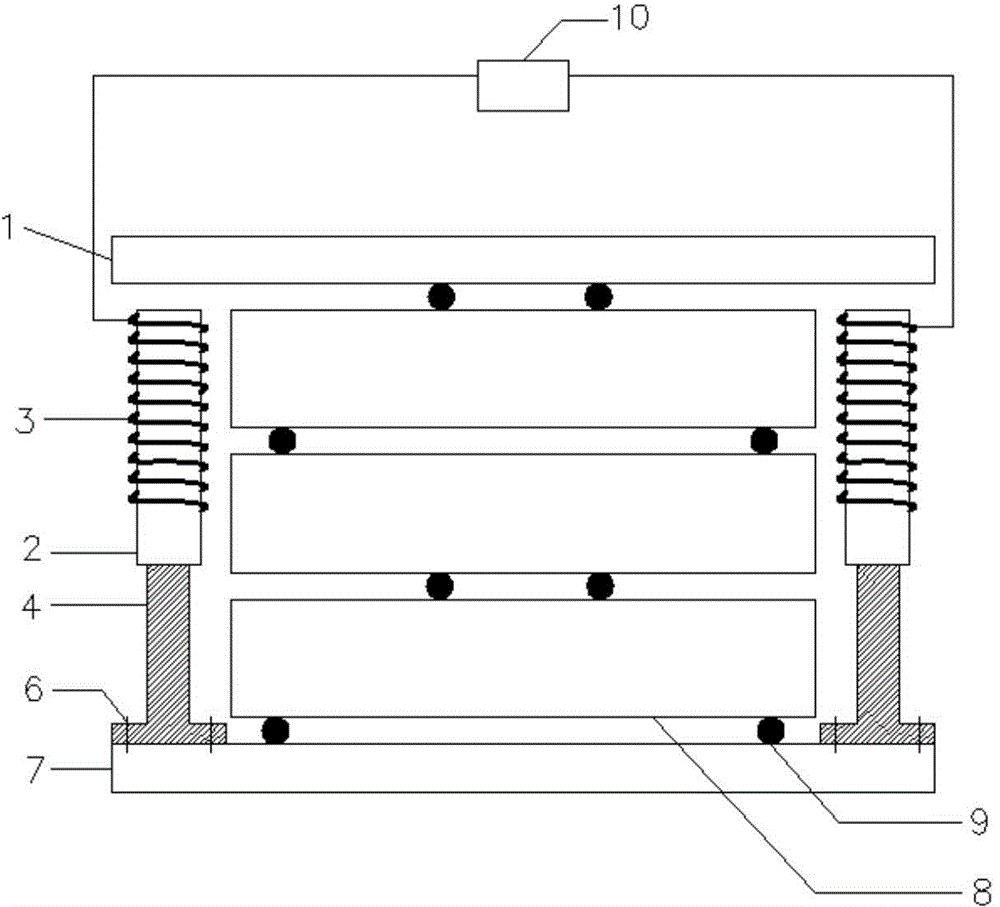

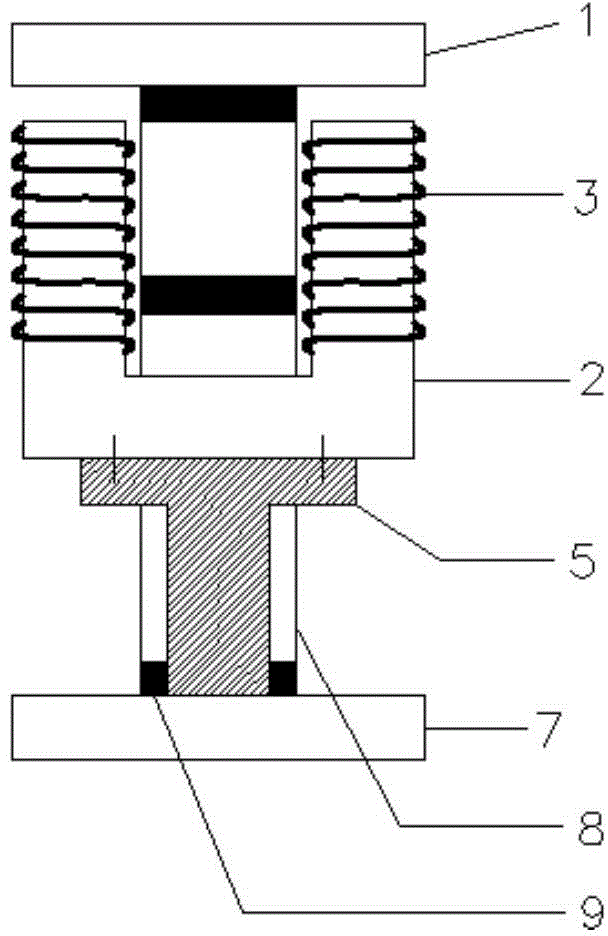

[0024] Such as figure 1 and figure 2 As shown, the core component of the electromagnetic loading device is an electromagnet device, and the electromagnet is composed of an upper platen 1 , a DC coil 3 , an iron core 2 , and an iron core support 4 . Wherein, the upper pressing plate 1 plays the role of the armature in the electromagnet, and the upper pressing plate 1 is made of steel plate. The iron core 4 is made of iron core laminations and a stainless steel iron core shell. The iron core lamination is made of U-shaped silicon steel sheets bent at 90 degrees, and the rigidity is small. In order to increase the overall rigidity of the electromagnet and prevent corrosion, a stainless steel core shell is wrapped around the iron core lamination. The iron core casing is a welded structure, fixed with the iron core laminations by bolts, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com