Use of an adaptive fiber for z-pinch filament array loading

An adaptive and fiber-based technology, applied in the direction of single-component polyurethane artificial filaments, etc., can solve the problems that the self-adaptive technology cannot complete the assembly process, and achieve the effects of high rebound rate, high dimensional stability and high resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

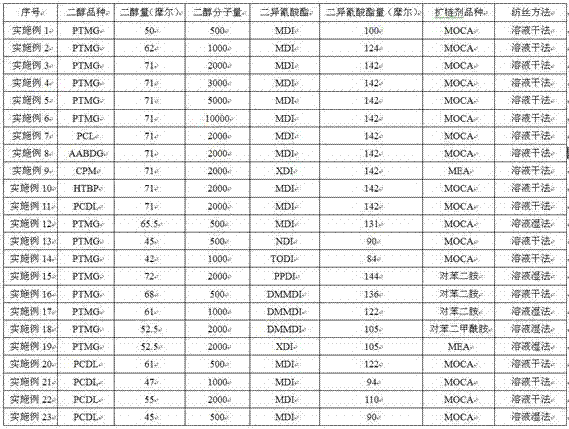

Examples

Embodiment 1

[0024] Add 50 moles of polytetrahydrofuran glycol (PTMG) with a molecular weight of 500 to a reactor equipped with a stirrer, a thermometer, a vacuum system and an electric heating mantle. The temperature is raised to 105°C and dehydrated under high vacuum for 2 hours until the water content is low At 0.05%, then cool to 60°C, release the vacuum, add 100 moles of diphenylmethane diisocyanate (MDI), maintain a constant temperature of 80°C, and keep the temperature for 2h. After deaeration, the prepolymer is obtained. Use 50 moles of 3,3ˊ-dichloro-4,4ˊdiaminodiphenylmethane (MOCA) to carry out chain extension reaction with the prepolymer, and then select the solution dry method for spinning forming.

Embodiment 2

[0026] Add 62 moles of polytetrahydrofuran glycol (PTMG) with a molecular weight of 1000 to a reactor equipped with a stirrer, a thermometer, a vacuum system and an electric heating mantle. The temperature is raised to 105°C and dehydrated under high vacuum for 2 hours until the water content is low At 0.05%, then cool to 60°C, release the vacuum, add 124 moles of diphenylmethane diisocyanate (MDI), and keep a constant temperature of 80°C for 2 hours. After deaeration, the prepolymer is obtained. Use 62 moles of chain extender 3,3ˊ-dichloro-4,4ˊdiaminodiphenylmethane (MOCA) for chain extension reaction with the prepolymer, and then select the solution dry method for spinning forming.

Embodiment 3

[0028] Add 71 moles of polytetrahydrofuran glycol (PTMG) with a molecular weight of 2000 to a reactor equipped with a stirrer, a thermometer, a vacuum system and an electric heating mantle. The temperature is raised to 105°C and dehydrated under high vacuum for 2 hours until the water content is low At 0.05%, then cool to 60°C, release the vacuum, add 142 moles of diphenylmethane diisocyanate (MDI), and keep a constant temperature of 80°C for 2 hours. After deaeration, the prepolymer is obtained. Use 71 moles of chain extender 3,3ˊ-dichloro-4,4ˊdiaminodiphenylmethane (MOCA) to carry out chain extension reaction with the prepolymer, and then select the solution dry method for spinning forming.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com