Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Reduce viscoelasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

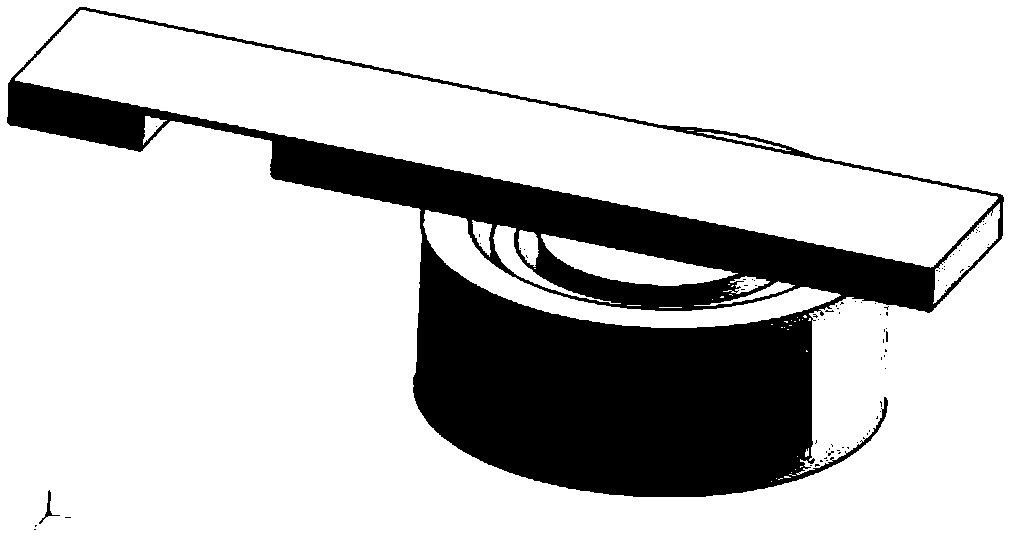

Permanent magnet torquer for accelerometer

ActiveCN109164273AGood spatial stabilityImproved scale factor stabilityAcceleration measurementAccelerometry techniqueSpatial stability

The invention belongs to the technical field of flexible pendulous accelerometers, and particularly relates to a permanent magnet torquer based on a silicon-based coil for an inertial navigation accelerometer. The permanent magnet torquer for the accelerometer provided by the invention comprises a yoke, a permanent magnet, a magnetic conducting sheet and the silicon-based coil, wherein the yoke islocated at the most bottom, the permanent magnet is fixed on the yoke, and the magnetic conducting sheet is fixed on an upper surface of the permanent magnet. A permanent magnet air gap is formed between the yoke and the magnetic conducting sheet, the silicon-based coil is located in the permanent magnet air gap, and when the permanent magnet torquer is at work, the silicon-based coil is fixed onan accelerometer pendulum sheet through a coil cushion block. According to the permanent magnet torquer provided by the invention, an enameled wire wound coil of the permanent magnet torquer of the accelerometer is replaced by the silicon-based coil, thereby effectively reducing the thermal stress between the accelerometer pendulum sheet and the coil of the permanent magnet torquer, and meanwhilereducing the viscoelasticity of the coil. The silicon-based coil has better spatial stability in a permanent magnet magnetic circuit and can significantly improve the scale factor stability of the accelerometer.

Owner:XIAN FLIGHT SELF CONTROL INST OF AVIC

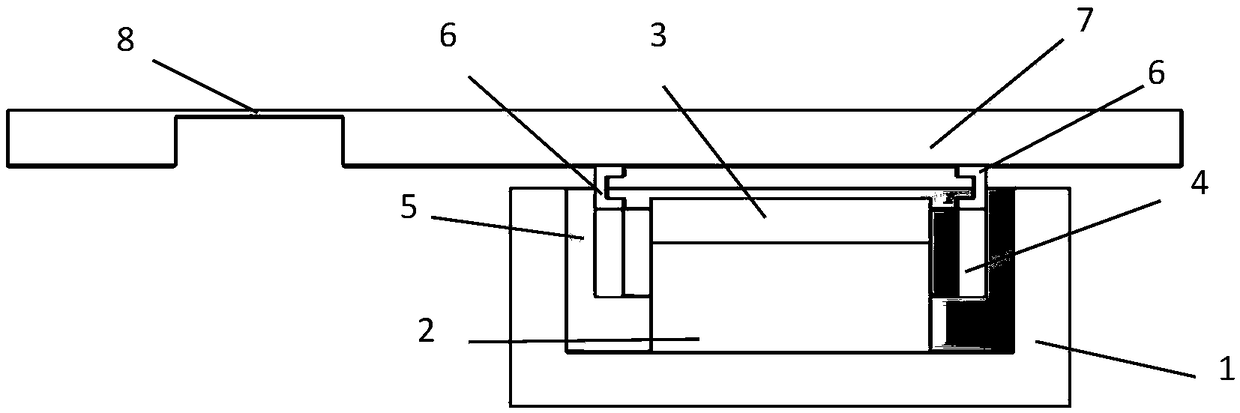

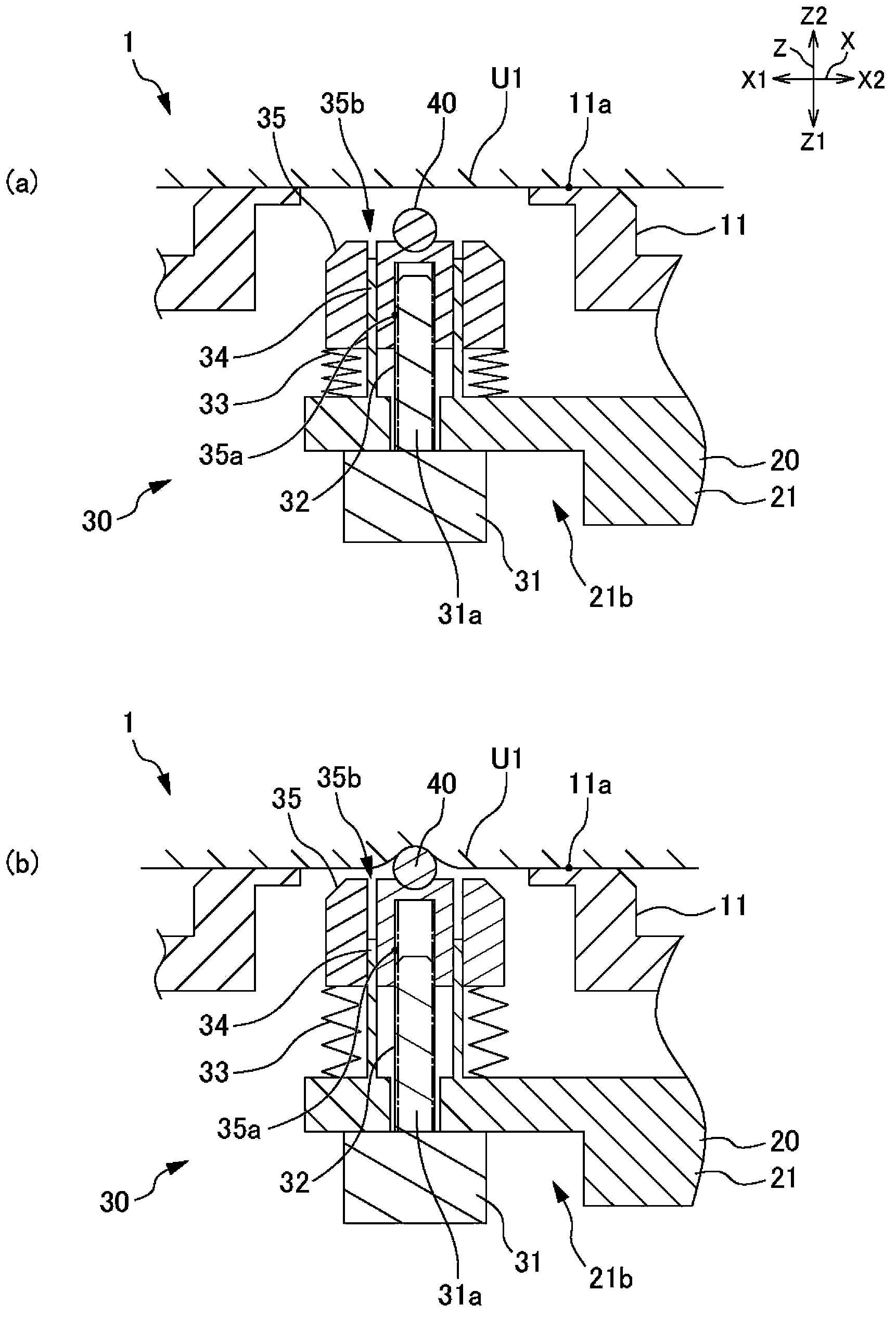

Viscoelasticity measuring apparatus

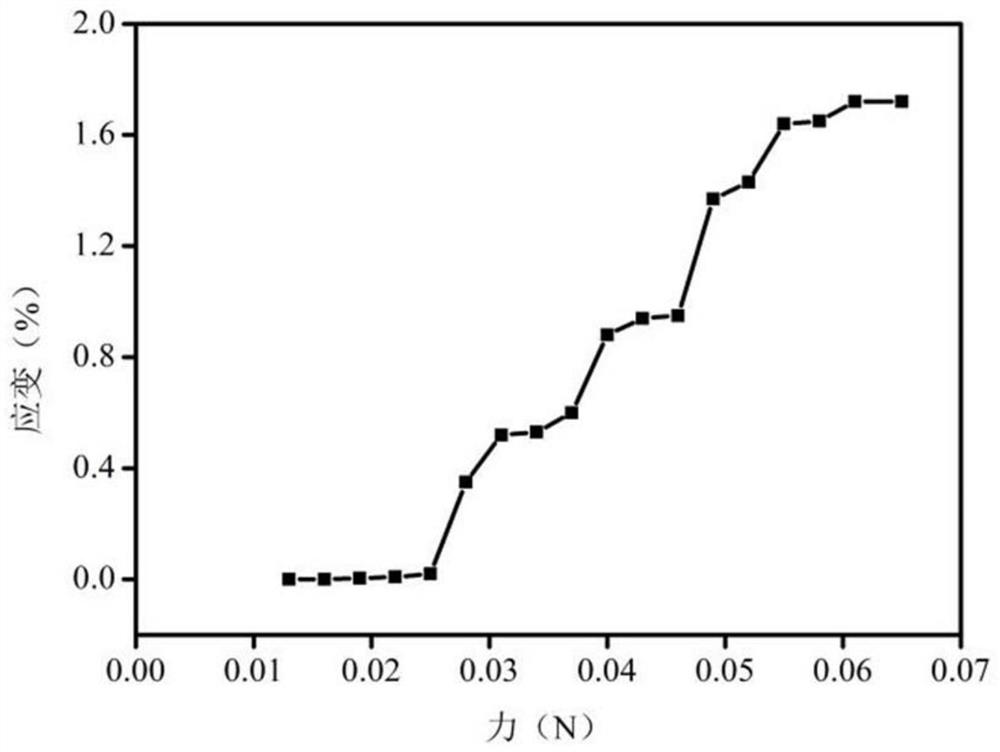

InactiveCN103565414ASmall driving forceReduce the effect of jitterDiagnostics using pressureForce measurementMeasurement deviceEngineering

A viscoelasticity measuring apparatus that measures viscoelasticity of a measurement target with high precision is provided. The measuring apparatus includes: a casing; a surface contact part provided in the casing and brought into surface contact with skin; a ball indenter that moves toward the skin more than the surface contact part and is pushed into the skin; a driving unit that supports the ball indenter and moves the ball indenter toward the skin; a load cell whose right end side is fixed to the casing and left end side supports the driving unit, the load cell detecting a pushing load that pushes the ball indenter into the skin; and a control unit that obtains displacement of the ball indenter.

Owner:TANITA CORP +1

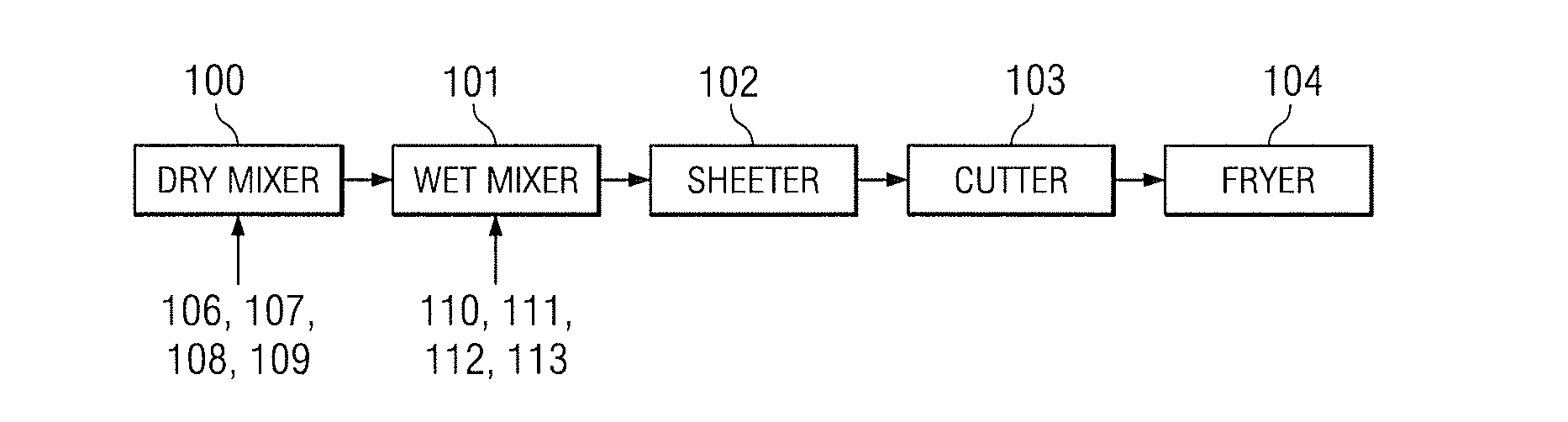

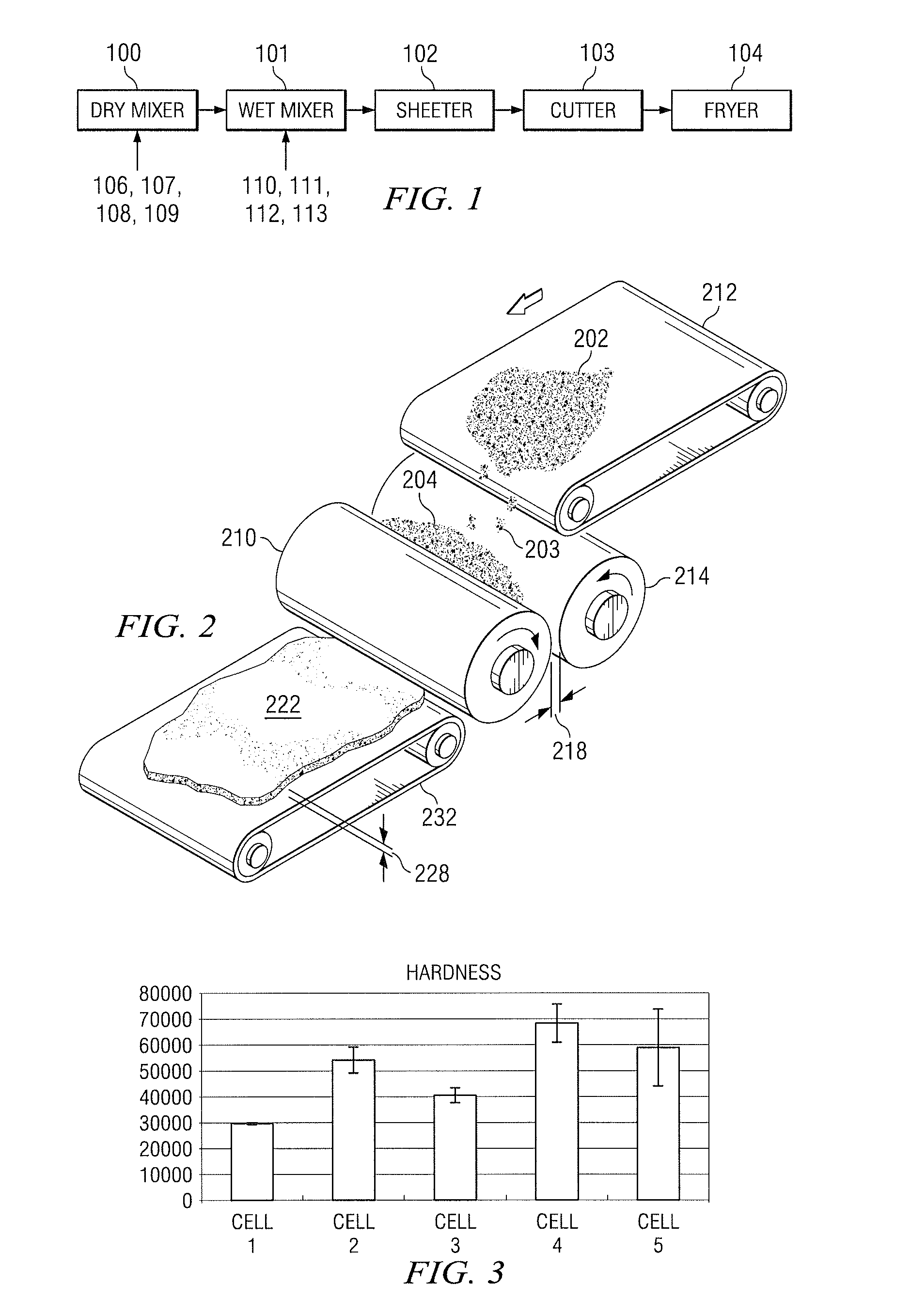

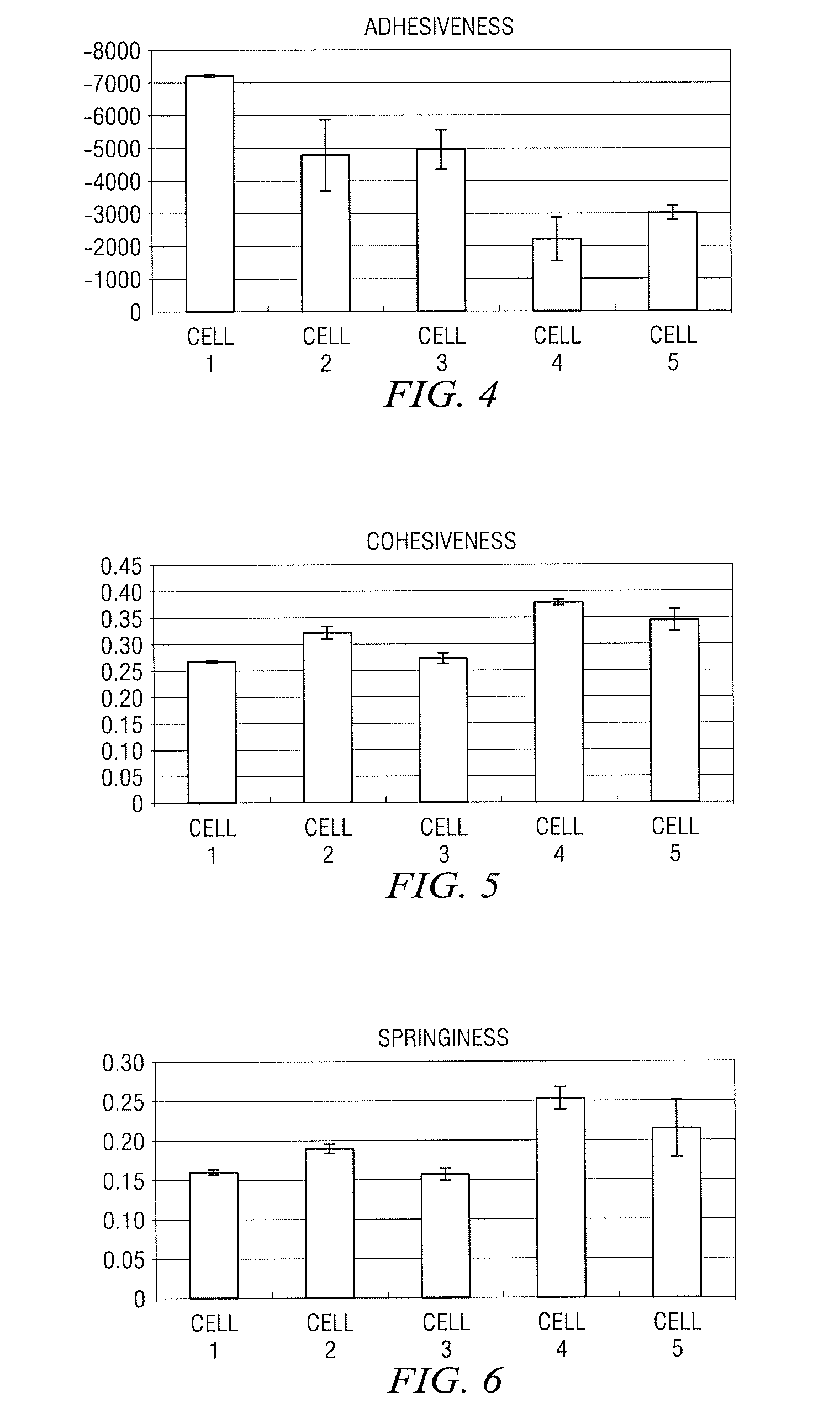

Rice snack chip with high rate of visual inclusions made on tortilla sheeting equipment

ActiveUS8080273B2Increase stickinessReduce viscoelasticityBakery productsFood preparationHigh rateInulin

A method and formulation are disclosed for using a mixture of inulin and surfactant to overcome adhesive and viscoelastic problems associated with using tortilla sheeters for processing rice-based dough to make rice crisps. The inulin decreases viscoelasticity whereas the surfactant decreases adhesiveness. The additive decouples the relationship between water content and the adhesiveness and viscoelasticity of the dough, allowing water content to be used to control other product variables such as product moisture content and oil take-up.

Owner:FRITO LAY NORTH AMERICA INC

Preparation of epoxide resin based foam material

The invention discloses a method for preparing an epoxide resin foaming material. The method comprises the following steps that: 1. according to the mass ratio, epoxide resins, foaming agents, foam stabilizing agents and addition agents are respectively picked up and evenly mixed with high-speed stirring; 2. the mixture obtained is put in an oven with a temperature of between 40 and 80 DEG C and pre-heated for 0.5 to 1 hour, and the mixture is taken out and cooled down to a temperature of between 25 and 35 DEG C; 3. The mixture is added with curing agents and evenly mixed; 4. the mixture is put in a stainless steel mold and heated at the temperature of between 40 to 80 DEG C for 0.5 to 2 hours, and the mixture is cooled down to the room temperature and taken out, and finally the finished products are obtained. By controlling reaction conditions, the invention realizes the association control of the chemical foaming and the curing molding of epoxy, and the foaming multiplying factor is as high as 2.7, and products prepared by the method are good in water resistance, chemical corrosion resistance and strength. The method of the invention has the advantages of easy buying of materials, simple operation and easy industrialization, and provides a new path for preparing thermosetting foaming materials.

Owner:SHANGHAI INST OF TECH +1

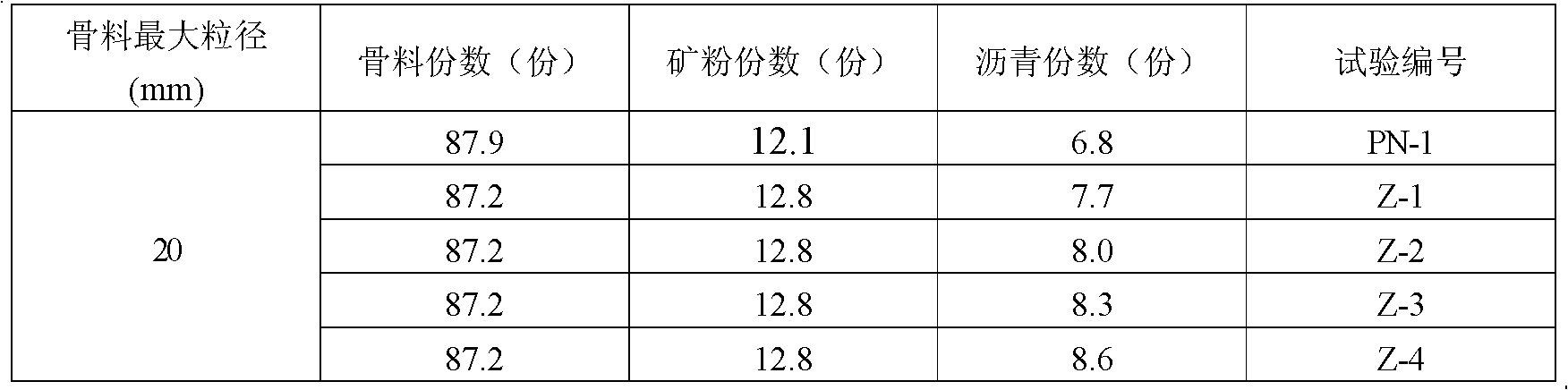

Insertion type vibration rolling construction method of asphalt concrete core of earth and rockfill dam

ActiveCN102493402AReduce viscoelasticityHigh viscoelasticityFoundation engineeringEarth-fill damsMixed materialsMaterials science

The invention relates to an insertion type vibration rolling construction method of an asphalt concrete core of an earth and rockfill dam, belonging to a construction method of an asphalt concrete watertight core of an earth and rockfill dam. The method comprises the steps of: paving an asphalt mixed material and a transition material, vibrating and compacting the asphalt mixed material, rolling the transition material and the asphalt mixed material, and preserving heat and maintaining. The construction method sufficiently utilizes the characteristic of high-temperature quick compaction of the vibration construction while considering the advantages of large scale and high mechanical degree of the rolling construction.

Owner:CHINA WATER NORTHEASTERN INVESTIGATION DESIGN & RES

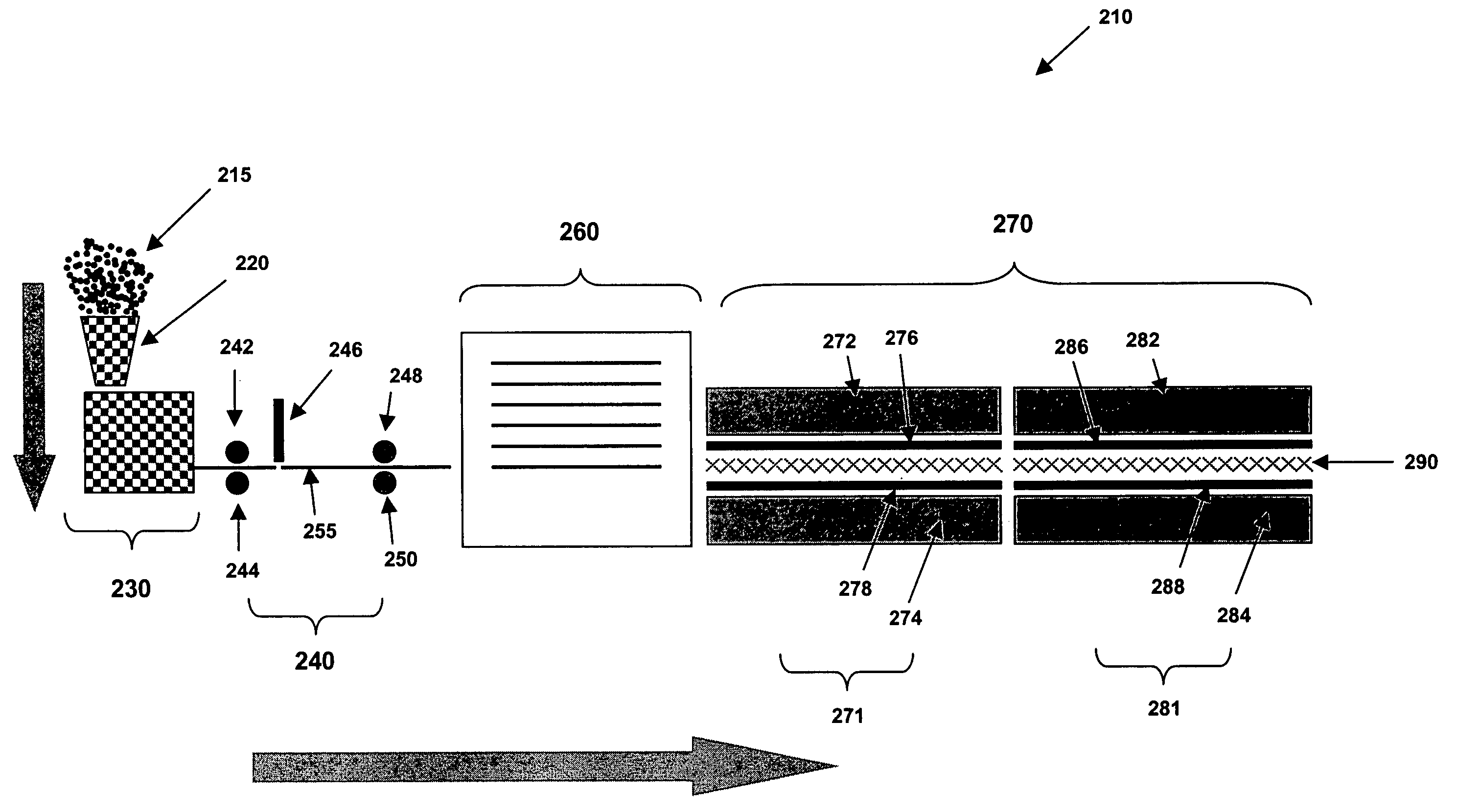

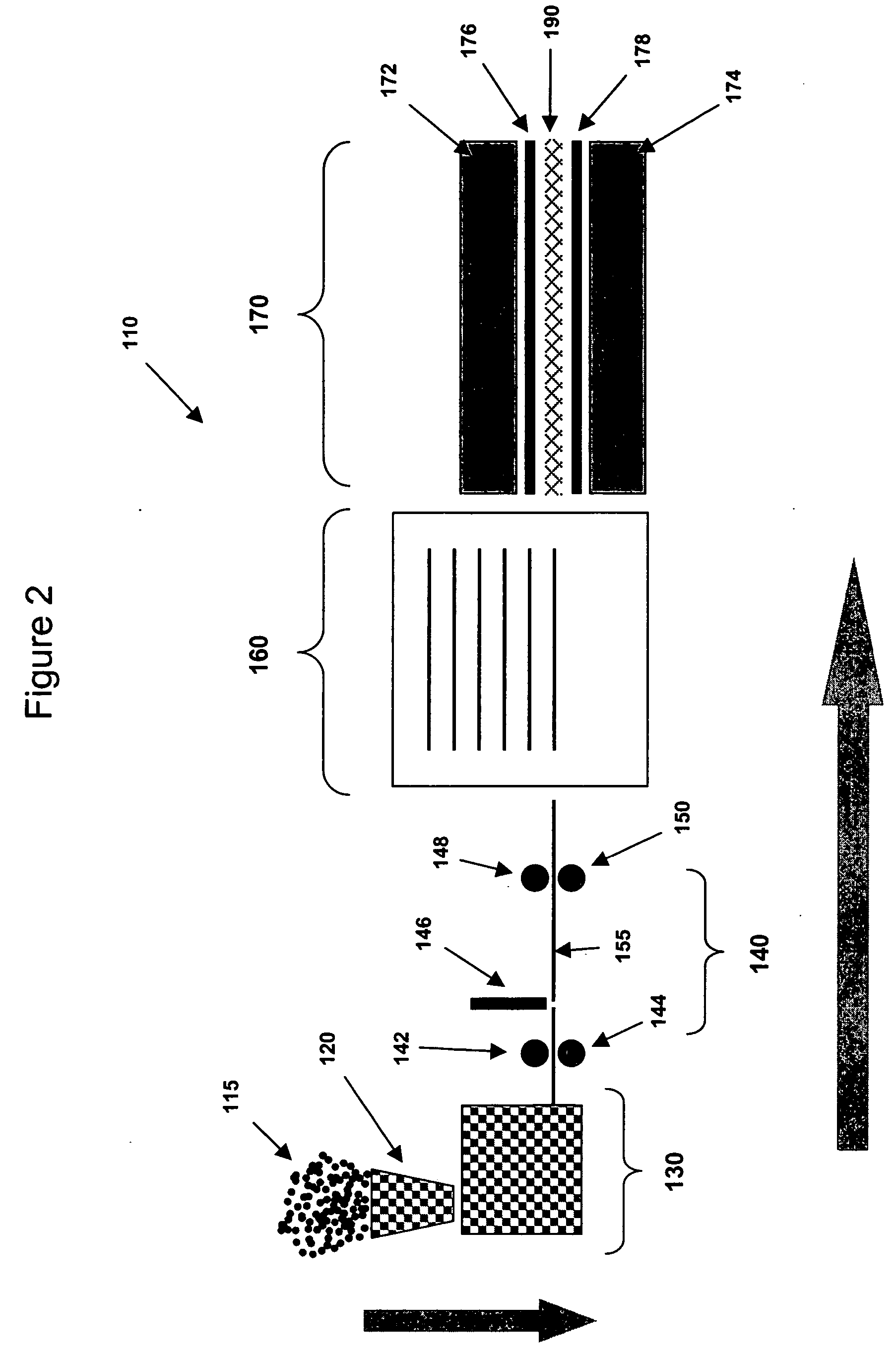

Method and apparatus for continuously producing discrete expanded thermoformable materials

InactiveUS20060157886A1Reduce viscoelasticityMaterial nanotechnologyArtifical filament manufactureContinuous productionMetallurgy

A method and apparatus for continuously and cost-effectively producing expanded thermoformable materials encompassing the steps of: providing raw thermoformable material into an extruder or mold; heating the material in the extruder or mold; extruding or co-extruding molding planar sheet material of suitable engineering performance parameters to a gauge and width; cutting or shearing the extruded or molded material while it is still hot to suitable lengths for expansion in a coreformer; conveying the hot thermoformable sheet material in between forming platens; heating the thermoformable material to a temperature at which the material adhesively bonds to the platens; expanding the cross-section of the thermoformable material; and then cooling the expanded thermoformable material by changing the temperature of the forming platens such that the thermoformable material can maintain its structural integrity and be released from the platens.

Owner:PANTERRA ENGINEERED PLASTICS

Preparation of epoxide resin based foam material

The invention discloses a method for preparing an epoxide resin foaming material. The method comprises the following steps that: 1. according to the mass ratio, epoxide resins, foaming agents, foam stabilizing agents and addition agents are respectively picked up and evenly mixed with high-speed stirring; 2. the mixture obtained is put in an oven with a temperature of between 40 and 80 DEG C and pre-heated for 0.5 to 1 hour, and the mixture is taken out and cooled down to a temperature of between 25 and 35 DEG C; 3. The mixture is added with curing agents and evenly mixed; 4. the mixture is put in a stainless steel mold and heated at the temperature of between 40 to 80 DEG C for 0.5 to 2 hours, and the mixture is cooled down to the room temperature and taken out, and finally the finished products are obtained. By controlling reaction conditions, the invention realizes the association control of the chemical foaming and the curing molding of epoxy, and the foaming multiplying factor isas high as 2.7, and products prepared by the method are good in water resistance, chemical corrosion resistance and strength. The method of the invention has the advantages of easy buying of materials, simple operation and easy industrialization, and provides a new path for preparing thermosetting foaming materials.

Owner:SHANGHAI INST OF TECH +1

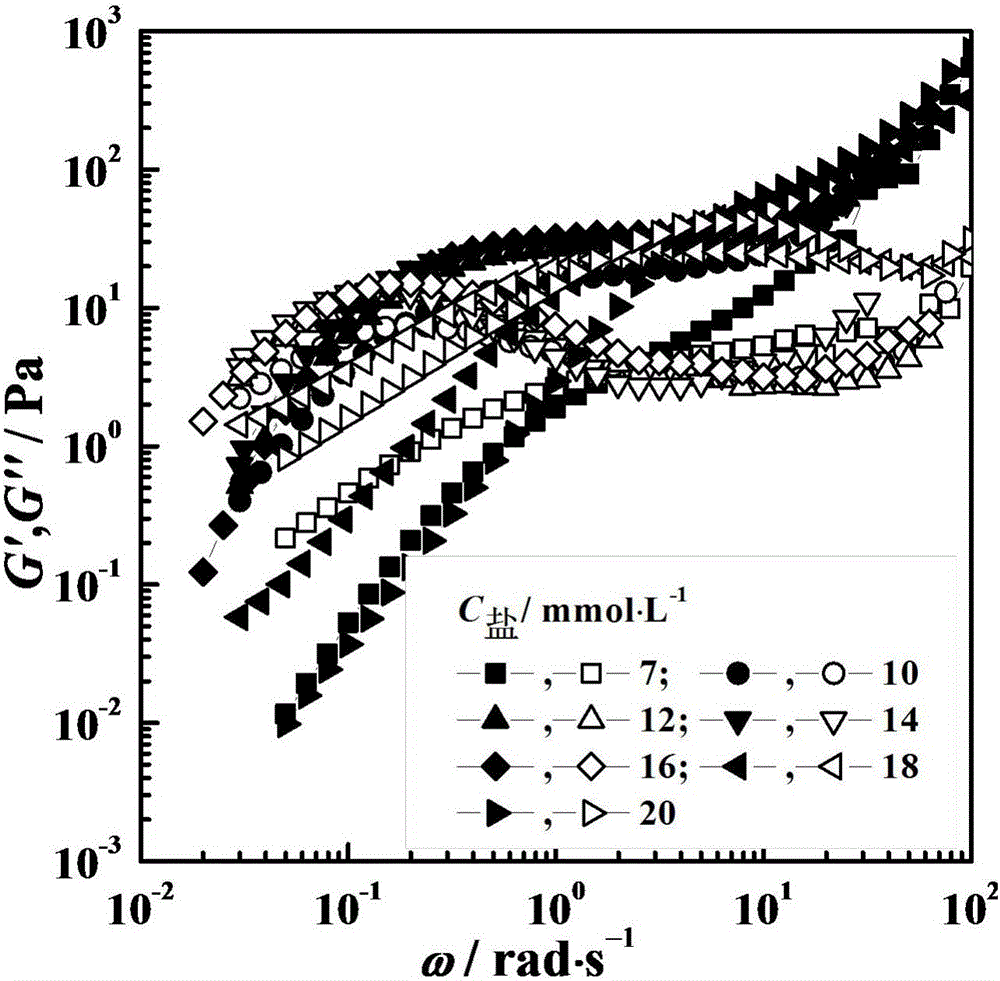

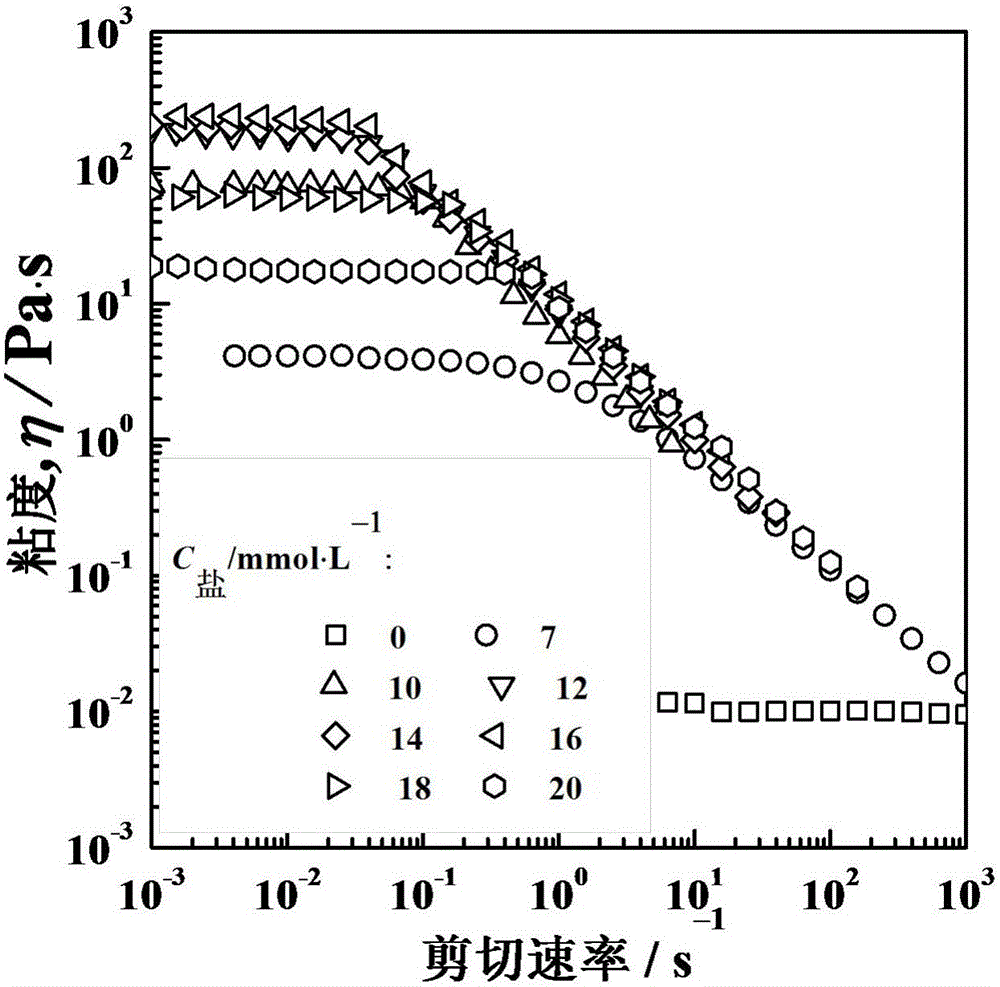

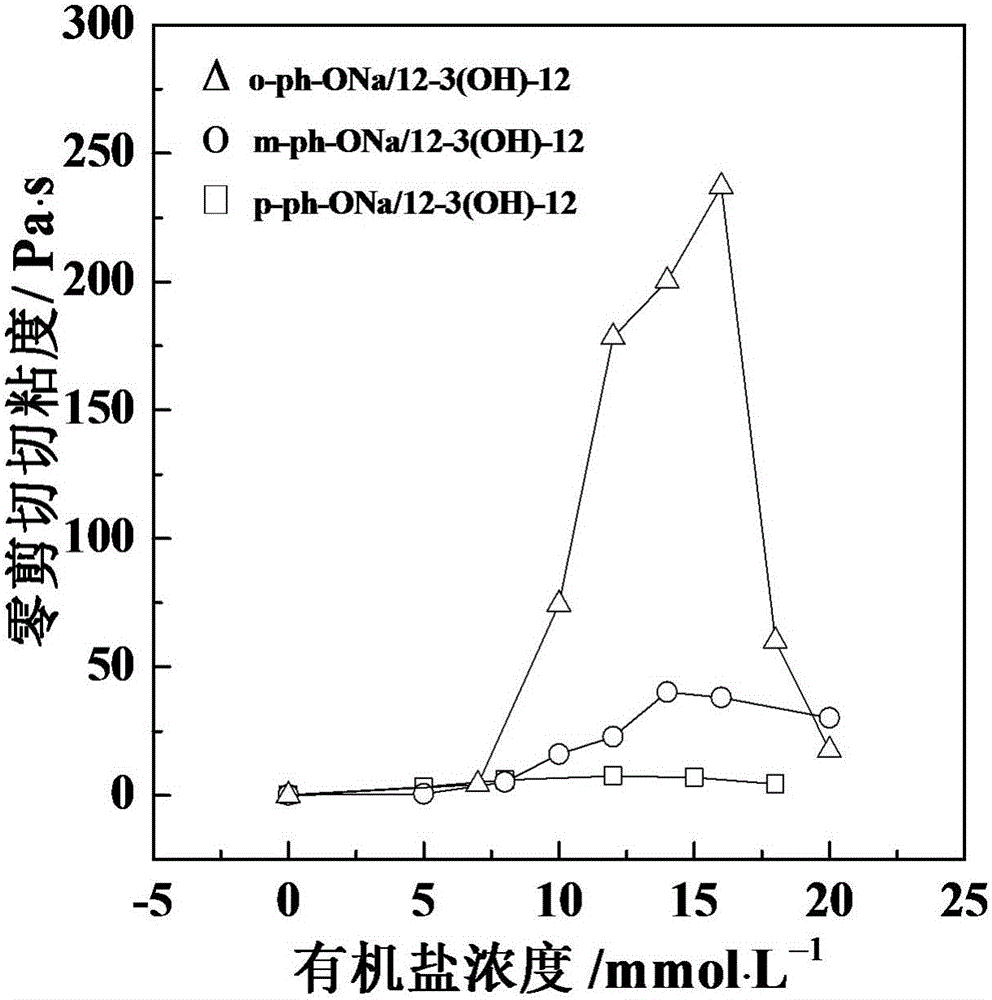

Viscoelastic system formed by functional Gemini surface active agent

InactiveCN106000217AAffect self-organizing behaviorRich in self-organizing behaviorTransportation and packagingMixingSurface-active agentsHydroxybenzoate

The invention discloses a viscoelastic system formed by a functional Gemini surface active agent and belongs to the technical field of a surface active agent. According to a preparation method of a viscoelastic surface active agent solution provided by the invention, organic salt comprises sodium o-hydroxybenzoate, 3-hydroxy-benzoic aci monosodium salt and sodium p-Hydroxybenzoate; Gemini surface active agent with hydroxyl group is taken as the main component and is compounded with few organic salts, and then the viscoelastic surface active agent solution is obtained; the preparation of the viscoelastic surface active agent solution comprises the two processes of compounding and testing viscoelastic property; Gemini cationic surface active agent is prepared into the solution in certain concentration and then is compounded with the salt at different ratio, thus, the viscoelastic surface active agent solution is acquired.

Owner:JIANGNAN UNIV

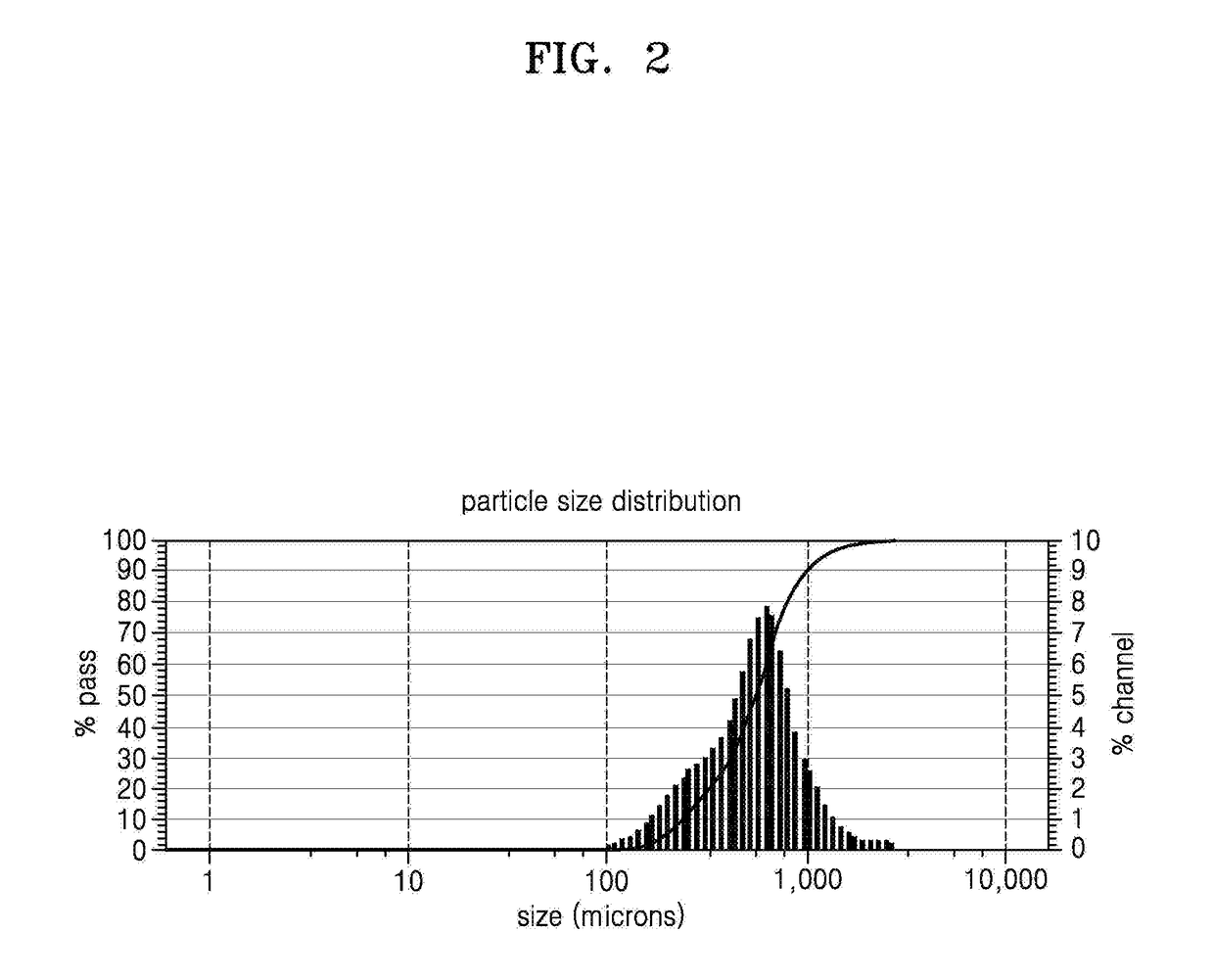

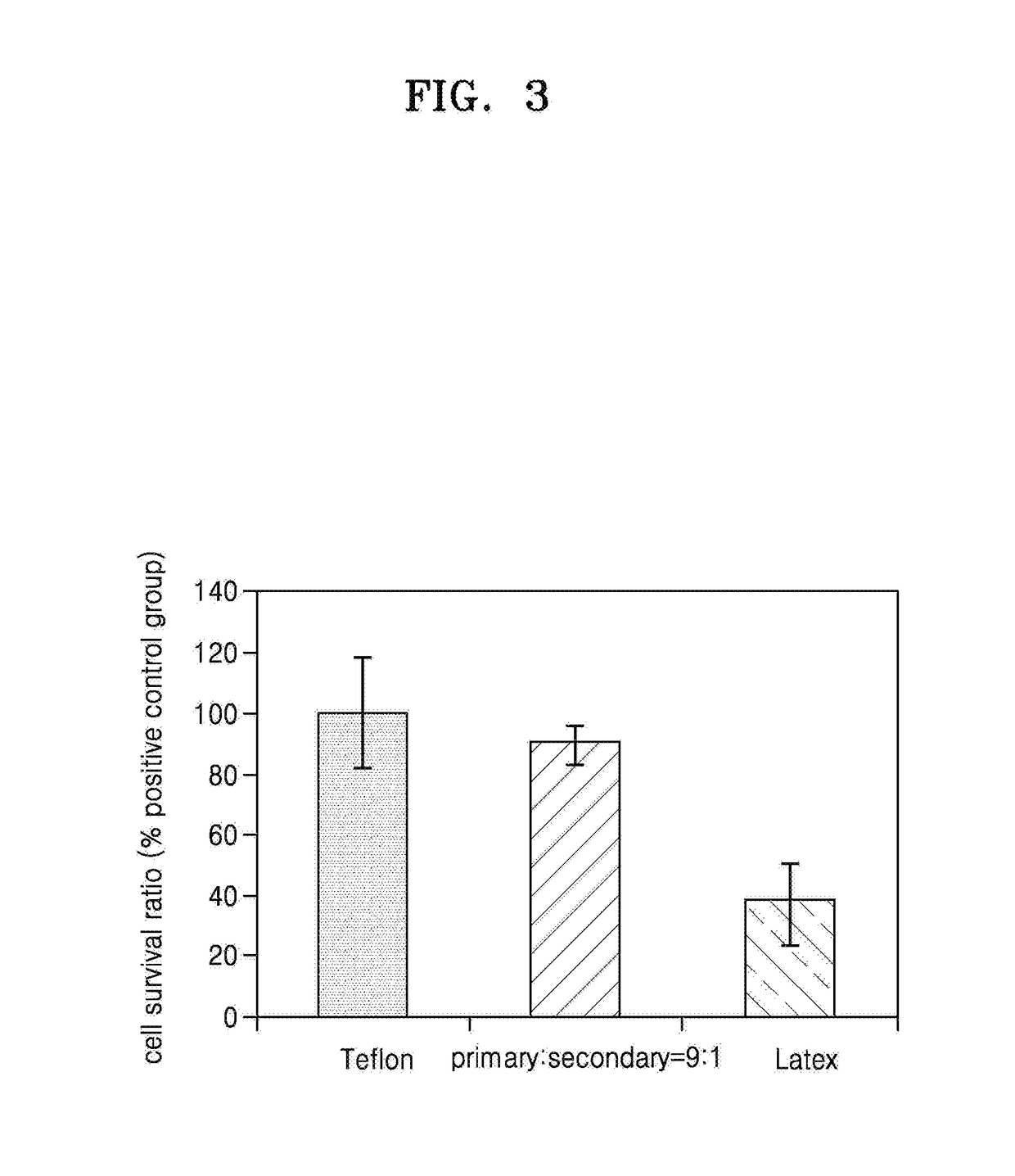

Powdery styrene-butadiene rubber preparation method

The invention belongs to the field of rubber synthesis, and particularly relates to a powdery styrene-butadiene rubber preparation method, which comprises: (1) sequentially adding water, styrene-butadiene latex and a reducing agent aqueous solution into a polymerization kettle, carrying out stirring heating, adding an oxidizing agent, and carrying out a cross-linking reaction to obtain surface-cross-linked styrene-butadiene latex; and (2) adding water and an anti-aging agent to the surface-cross-linked styrene-butadiene latex, then adding a primary agglomeration agent and a secondary agglomeration agent, carrying out agglomeration to obtain a powder polymer aqueous suspension, dewatering, washing, screening, and drying. According to the present invention, the chemical cross-linking is performed on the surface of the styrene-butadiene latex particles, such that the number of the rubber molecules active points on the surface of the particles is reduced, the plasticity of the surface of the particles is improved, the viscoelasticity of the surface is reduced, the deformation of the product is reduced, the long-lasting and stable chemical separation effect is generated between the rubber particles, the consumption of the inorganic separation agent is low, the influence on the performance of the rubber product is low, and the prepared powdery styrene-butadiene rubber has characteristics of uniform particles, good fluidity and good storage stability.

Owner:CHINA PETROLEUM & CHEM CORP

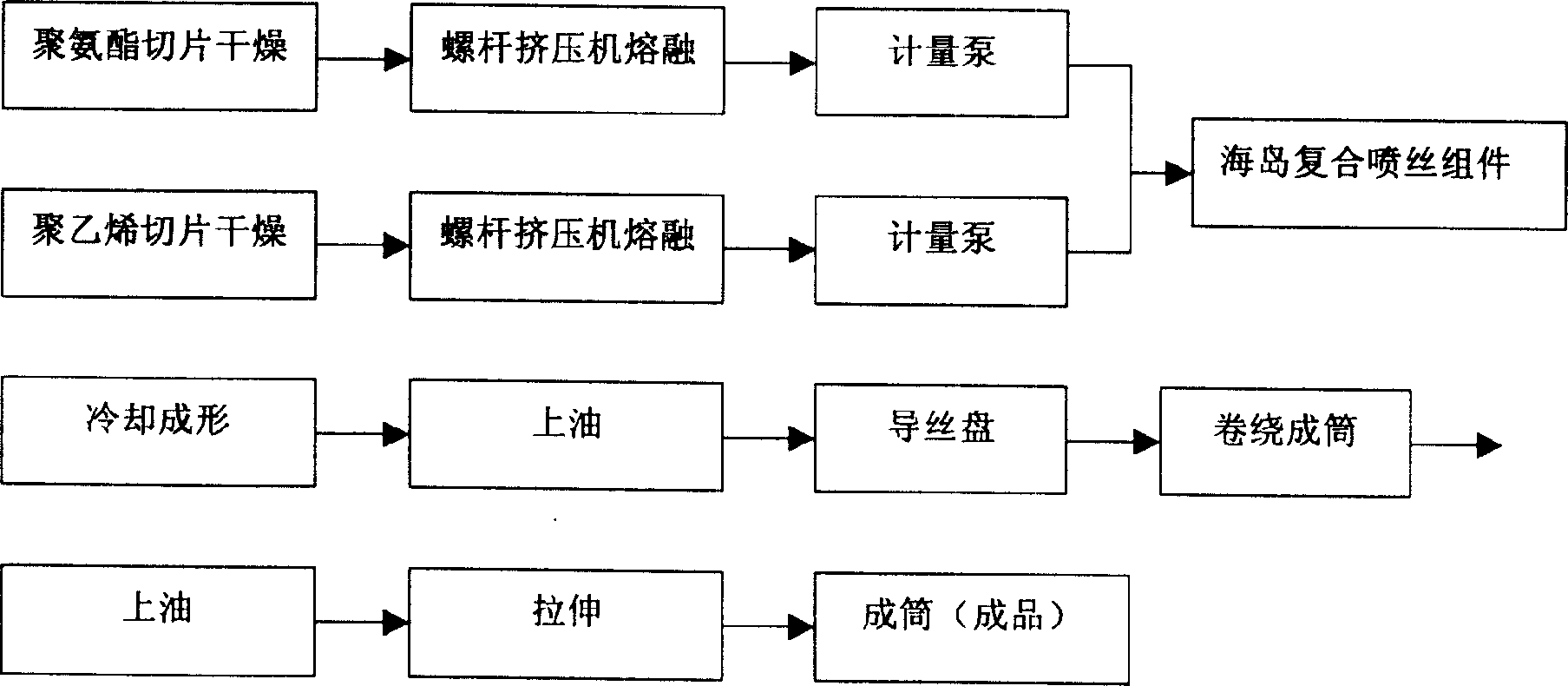

Ultra-fine denier polyurethane filament

InactiveCN1667167AEasy to stretchHigh strengthConjugated synthetic polymer artificial filamentsStretch-spinning methodsLow-density polyethyleneBreakdown strength

The invention relates to a superfine denier polyurethane filament and the method to manufacture. The filament is an island type superfine denier polyurethane filament that the low density polyethylene as see const and the polyurethane as the island const. And the weight ratio of polyethylene is from 0.4 to 1.5:1. The filament number after the island separated is from 0.08 to 0.3dtex. And the density of finished silk fiber product is 150-200dtex; breakdown strength of fiber is 1.9-2.1CN / dtex; the elongation at break is 100-150%. The invention is easy to be industrialization manufactured.

Owner:DONGHUA UNIV +1

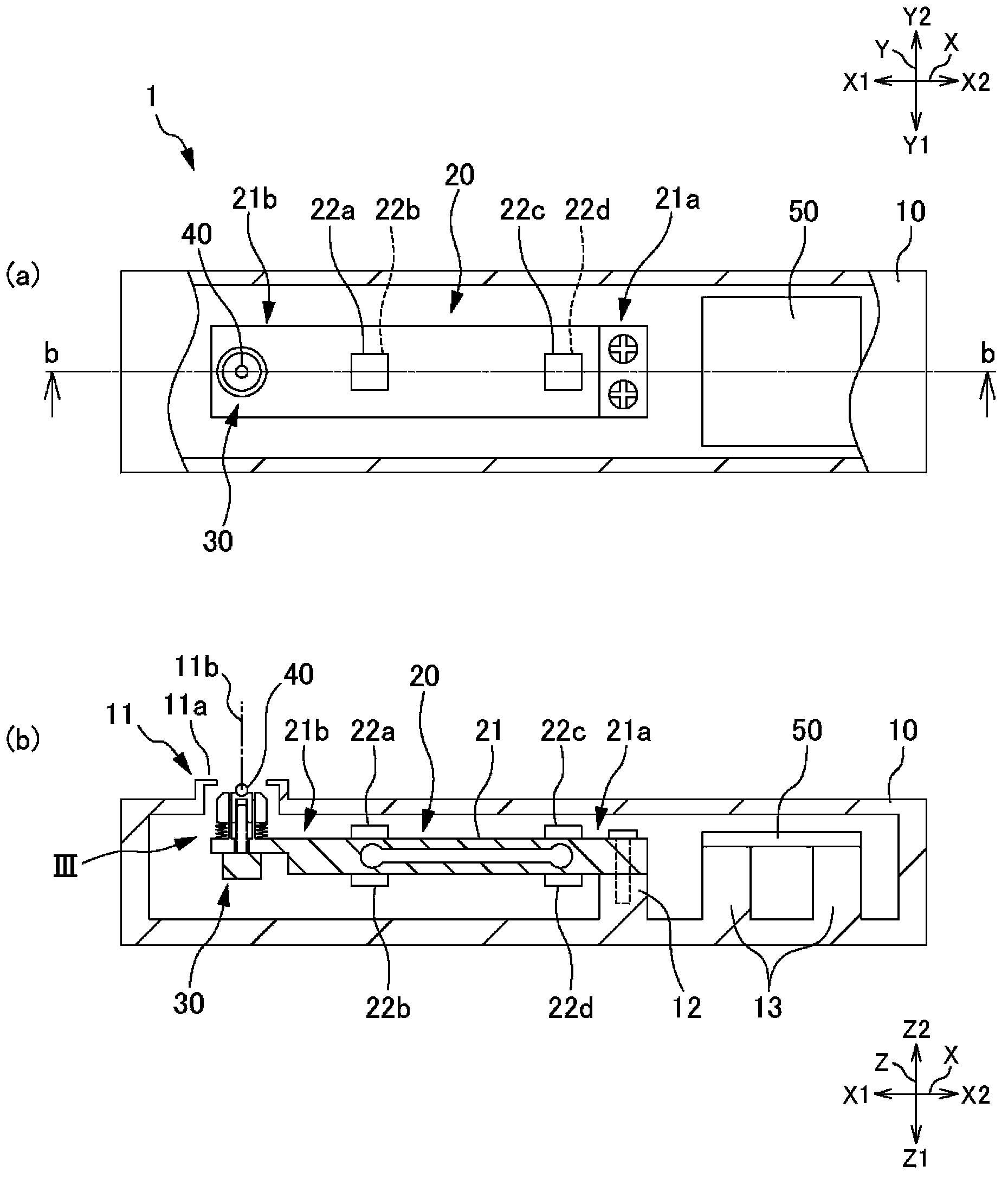

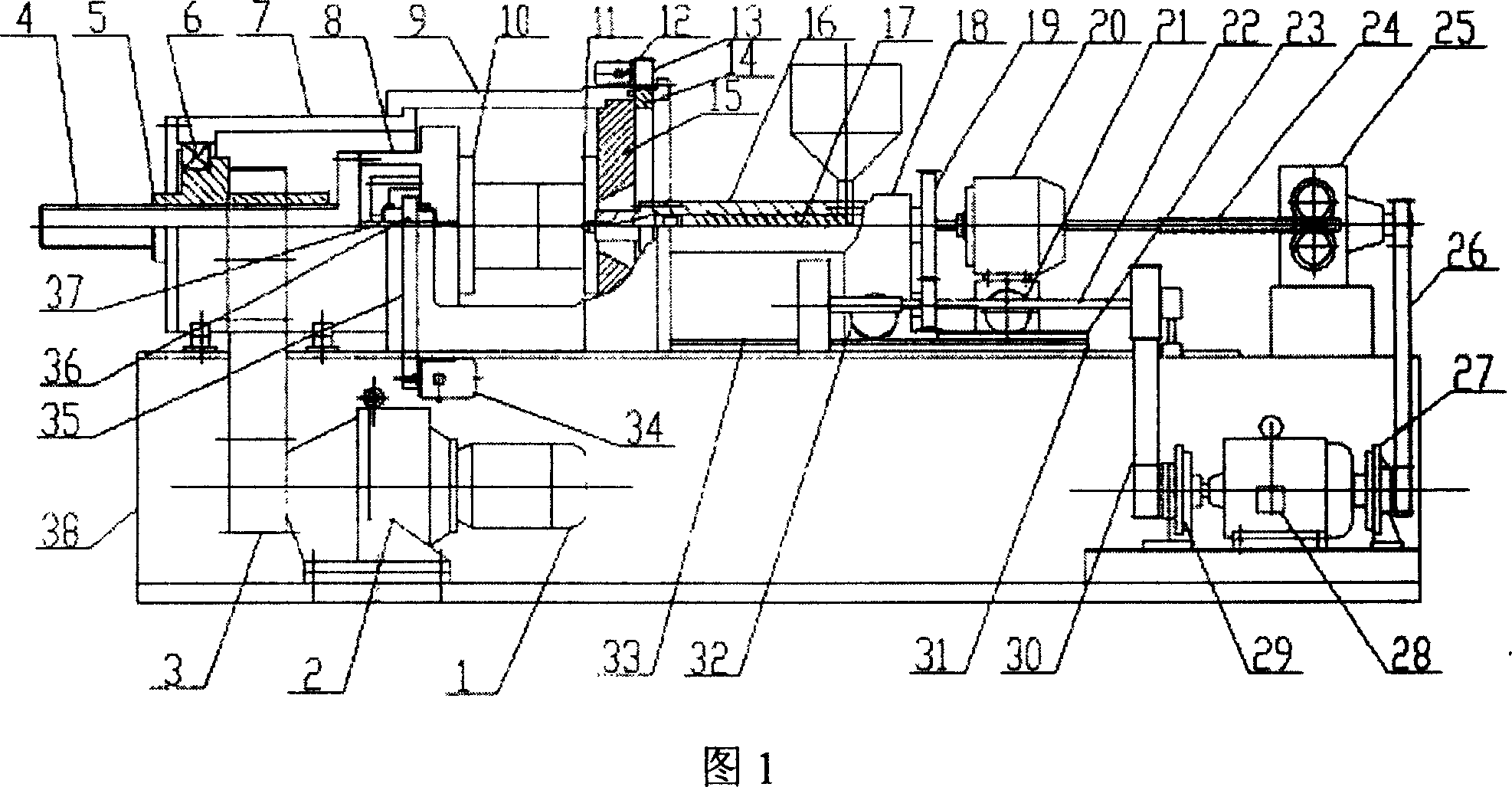

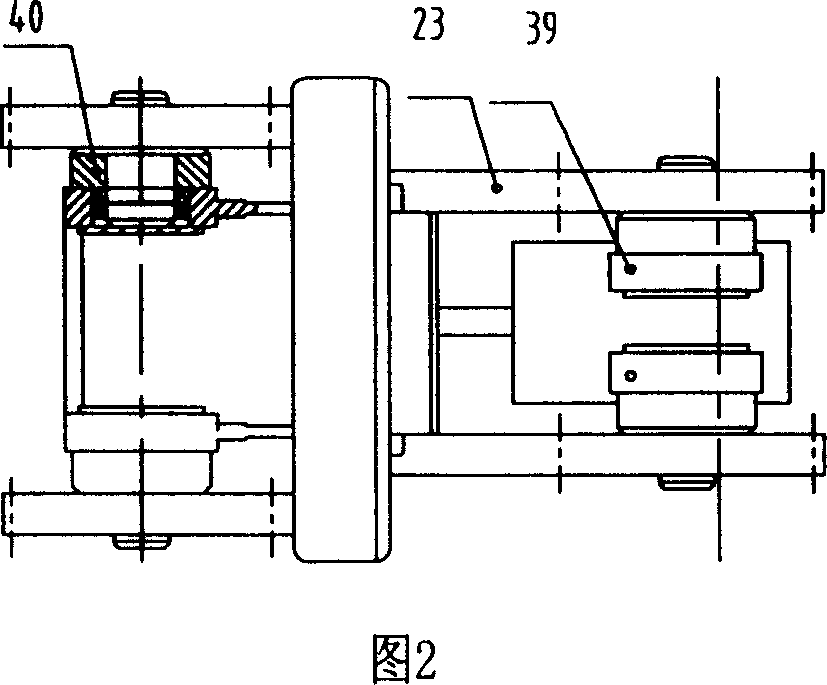

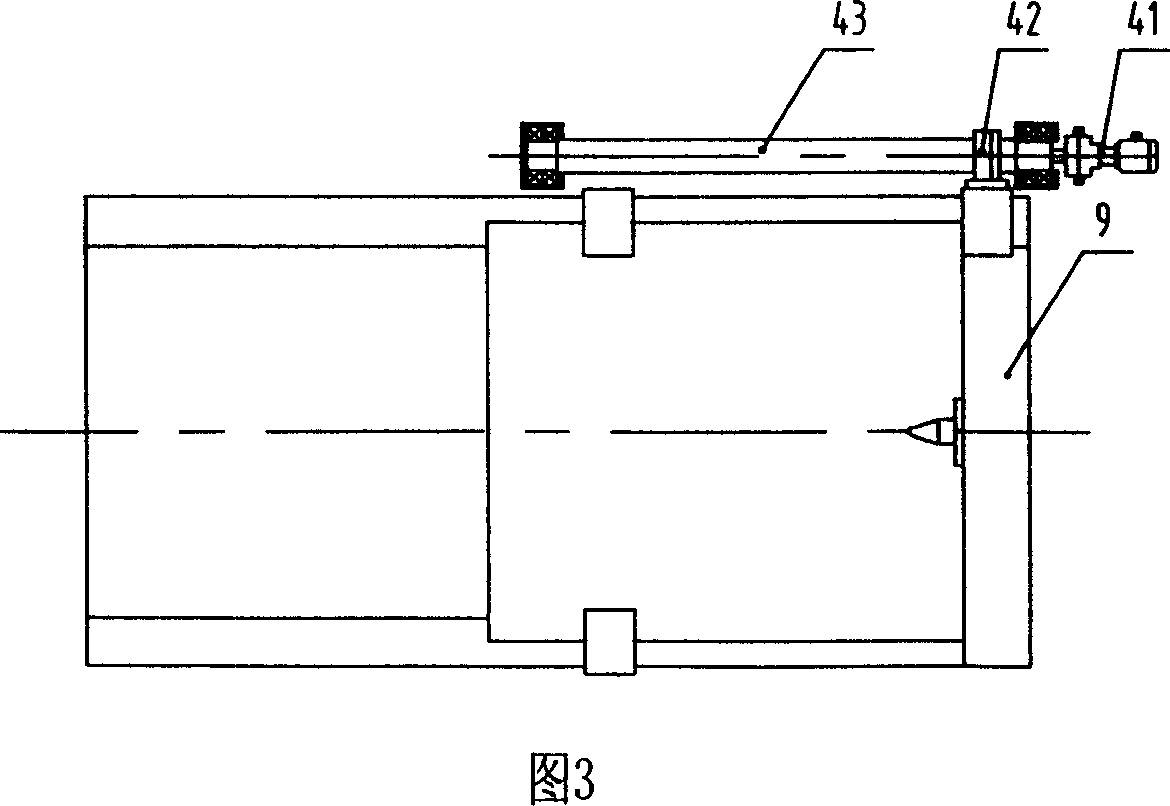

Electrically driven reverse mold moving and pulse pressure inducing injection molding process and apparatus

The present invention is electrically driven reverse mold moving and pulse pressure induced injection molding process and apparatus. During the injection molding, axial periodic vibration is superposed onto the rotating motion or linear motion of the injecting screw to result in pulsed displacement of the screw and the pulsed pressure consists of in the melt so as to realize the dynamic metering, the dynamic mold filling and dynamic pressure maintenance of polymer. By means of motor and lead screw driving device and reverse mold moving design, the process including electrically driven plasticizing, electrically driven injecting, electrically driven mold opening and closing, electrically driven mold regulation, electrically driven mold locking, etc is realized. The injection molding process and apparatus of the present invention is simple, reliable, low in power consumption, low in noise, high in product quality and environment friendship.

Owner:SOUTH CHINA UNIV OF TECH

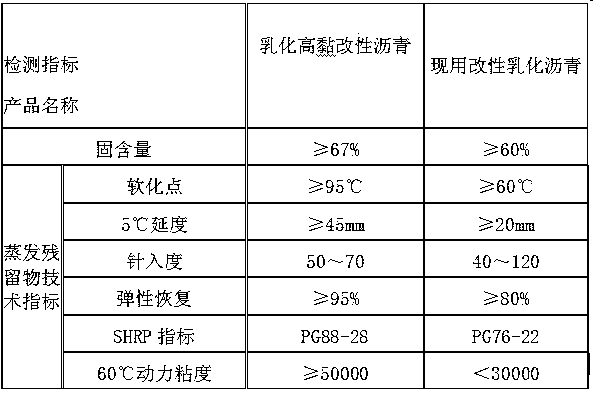

Factory-prefabricated self-adhesive pavement sticker and preparation and construction method thereof

InactiveCN109056453AReduce driving noiseHigh breaking strengthPaving detailsHighway maintenanceReflective crack

The invention discloses a factory-prefabricated self-adhesive pavement sticker, a preparation method and a construction method, belonging to the technical field of highway maintenance. The invention comprises an isolation paper layer, a self-adhesive adhesive layer, an anti-cracking cloth layer, a lower binder layer, an aggregate layer and an upper binder layer. 15 DEG C pull-out test>= 0. 5MPa;The binder completely covers the aggregate and forms a continuous bonding material layer to ensure that the water permeability coefficient is 0; Multi-texture surface structure and surface protectivefilm ensure the anti-slip coefficient BPN >= 55 and the driving noise is low; The longitudinal and transverse fracture strength is high, and the reflection crack is delayed. The pavement sticker of the invention is directly applied to the tortoise-shaped cracks of the local pavement network which needs to be repaired or the whole pavement is corrected and pre-cured, is convenient to use, can quickly open the traffic, has long service life, and has remarkable social and economic benefits.

Owner:SHANDONG DASHAN ROAD & BRIDGE ENG

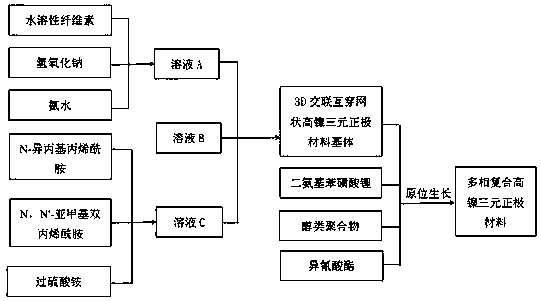

Multiphase composite high-nickel ternary positive electrode material and preparation method thereof

ActiveCN110350164AWith shuffling phenomenonReduce breakageCell electrodesSecondary cellsCross-linkElectrical conductor

The invention belongs to the field of batteries, and particularly relates to a multiphase composite high-nickel ternary positive electrode material and a preparation method thereof. The material is formed by bonding a 3D cross-linked interpenetrating netty high-nickel ternary positive electrode material matrix and a single-ion conductor polymer, and has a 3D cross-linked interpenetrating netty core-shell structure. The required preparation method comprises the following steps: 1) carrying out gradient temperature reaction on a solution A, a solution B and a solution C in a reaction kettle, andthen carrying out high-temperature treatment to obtain the 3D cross-linked interpenetrating netty high-nickel ternary positive electrode material matrix; and 2) carrying out in-situ growth on lithiumaminobenzenesulfonate, an alcohol polymer, isocyanate and the 3D cross-linked interpenetrating netty high-nickel ternary positive electrode material matrix in the reaction kettle, and carrying out annealing treatment to obtain the multi-phase composite high-nickel ternary positive electrode material. The multi-phase composite high-nickel ternary positive electrode material prepared by the preparation method is good in cycling performance, easy for size mixing of a lithium ion battery, excellent in rate performance and low-temperature performance, and stable in structure; and the process is simple and easy to operate, and is environment-friendly.

Owner:HUNAN ZHENGYUAN ENERGY STORAGE MATERIALS & DEVICE INST

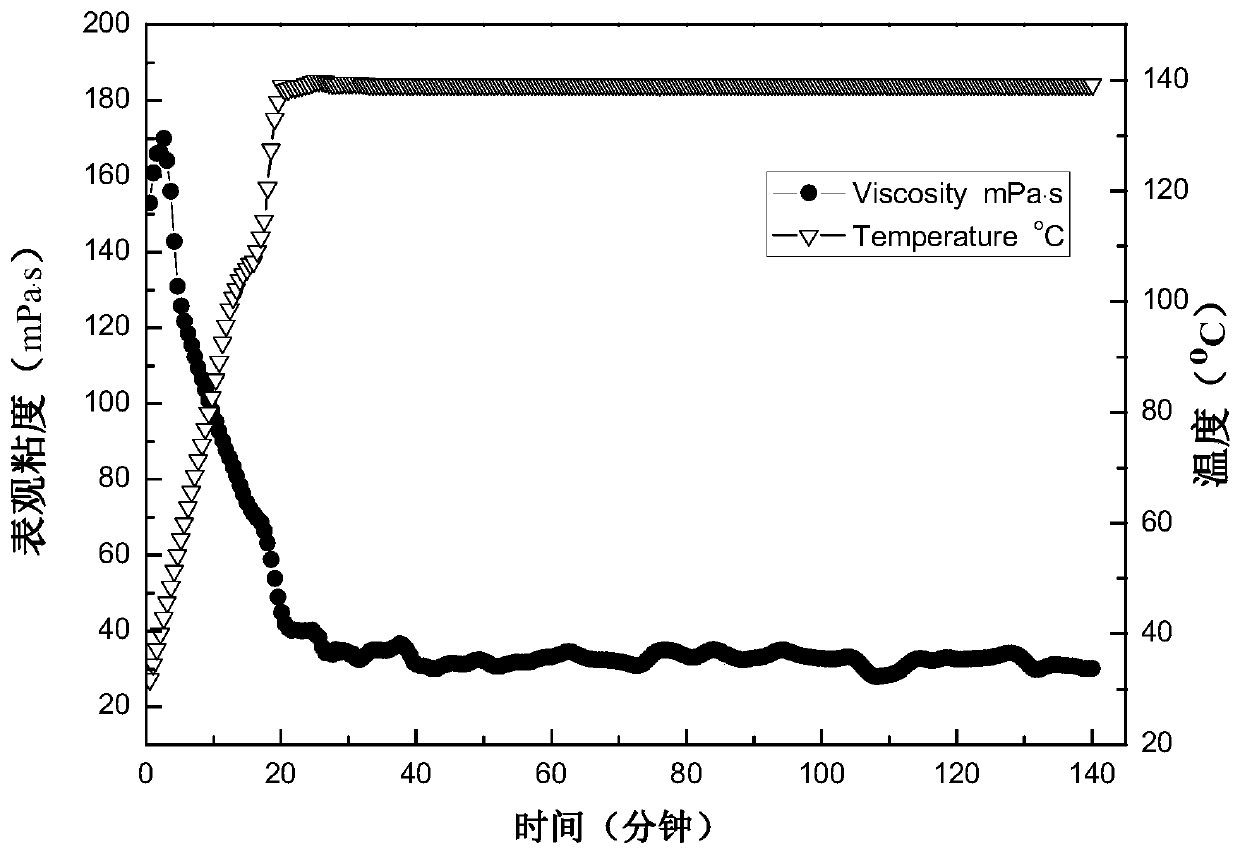

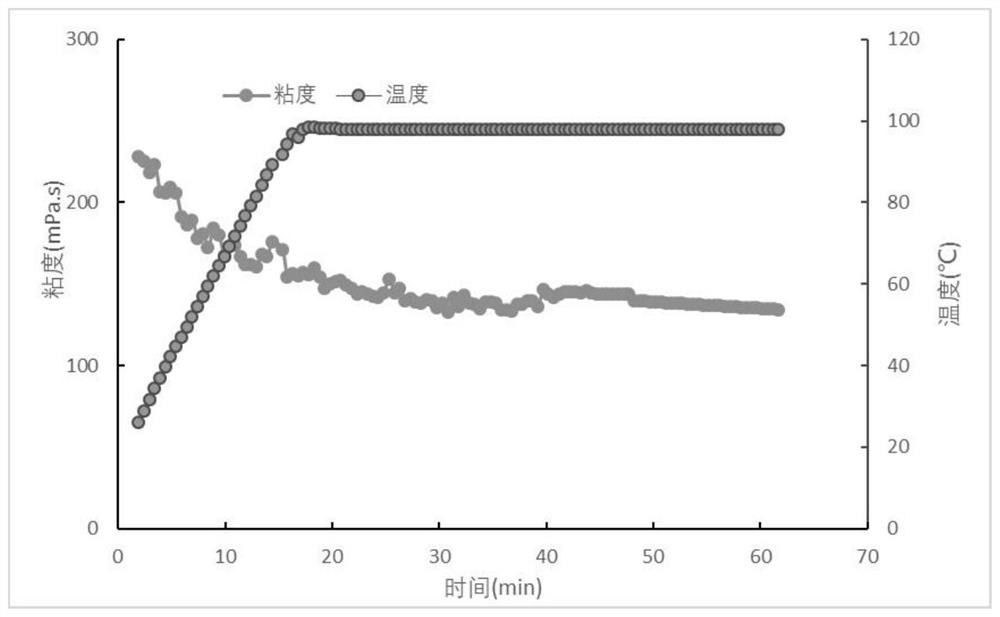

Temperature-resistant and salt-resistant viscoelastic surfactant, and preparation method and application thereof

InactiveCN111039819AImprove surface activityReduce the impactOrganic compound preparationCarboxylic acid amides preparationActive agentPhysical chemistry

The invention provides a temperature-resistant and salt-resistant viscoelastic surfactant, and a preparation method and an application thereof. The specific structural formula of the temperature-resistant and salt-resistant viscoelastic surfactant is shown, the preparation method of the temperature-resistant and salt-resistant viscoelastic surfactant, and the application of the temperature-resistant and salt-resistant viscoelastic surfactant in a foam fracturing fluid are provided. The temperature-resistant and salt-resistant viscoelastic surfactant disclosed by the invention has both a cationic group and an anionic group, can weaken the influence of counter ions on the area of a hydrophilic head group, reduces the utilization of freshwater resources, and effectively solves the problems ofpoor temperature resistance, poor salt resistance, insufficient fresh water resources, reservoir damage and the like.

Owner:SOUTHWEST PETROLEUM UNIV

Preparation method of high-viscoelasticity coupling material for non-fragrant soybean oil thermosetting web offset ink

The invention relates to a preparation method of high-viscoelasticity coupling material for non-fragrant soybean oil thermosetting web offset ink, comprising the following steps: in a standard normal-pressure kettle, adding 40+ / -1 parts of non-fragrant ink oil and 12+ / -0.5 parts of industrial soybean oil into the kettle according to parts by weight; adding 43+ / -1 parts of high-viscosity rosin modified phenolic resin while stirring for raising the temperature; keeping warm at the temperature of 180+ / -2 DEG C until resin is totally dissolved; stopping heating, and adding 4+ / -1 parts of non-fragrant ink oil; adjusting viscosity to 65000+ / -2000 MPa.s / 25 DEG C by the non-fragrant ink oil; adding 0.73+ / -0.01 part of gelling agent, and reacting at the temperature of 175+ / -2 DEG C; sampling and detecting per 0.5 hour; when viscosity is 500000+ / -50000 MPa.s / 25 DEG C, stopping temperature reduction reaction to obtain the product; and at the temperature of 135+ / -5 DEG C, filtering and packaging according to the normal ink coupling material production procedures. The high-viscoelasticity coupling material of the invention has favourable viscoelasticity and dissolubility in non-fragrant kerosene, has favourable performance in non-fragrant soybean oil thermosetting web offset ink and can satisfy high-speed and exquisite thermosetting web offset ink printing. The high-viscoelasticity coupling material has favourable dot reproduction, printability, simple technology and obvious effect.

Owner:TIANJIN TOYO INK

Wheat malt biscuit and making method thereof

PendingCN107637642AExpand the scope of processing applicationsLow costDough treatmentBakery productsDietary fiberVegetable oil

The invention relates to a wheat malt biscuit and a making method thereof. Part of wheat flour is replaced by whole wheat malt flour, and the wheat flour and the whole wheat malt flour serve as main materials to make wheat malt biscuit, and meanwhile syrup, vegetable oil, baked milk powder, a leavening agent, shortening, eggs, salt, water and the like are added to serve as auxiliary materials. Thesurface of the wheat malt biscuit is in a convex pattern shape, a cross section organization structure is porous, and the biscuit has puffy taste. The part of wheat flour is replaced by the whole wheat malt flour, the dough shortness can be improved, the crispness of the short biscuit can be improved, and the processing problem of insufficient weak strength flour raw materials is solved. In addition, the added whole wheat malt flour can also remarkably increase the content of dietary fiber in the short biscuit, and accordingly the nutrition and function characteristics of the wheat malt biscuit are improved.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

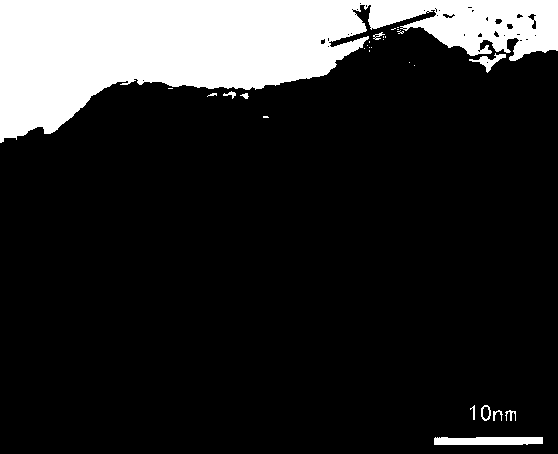

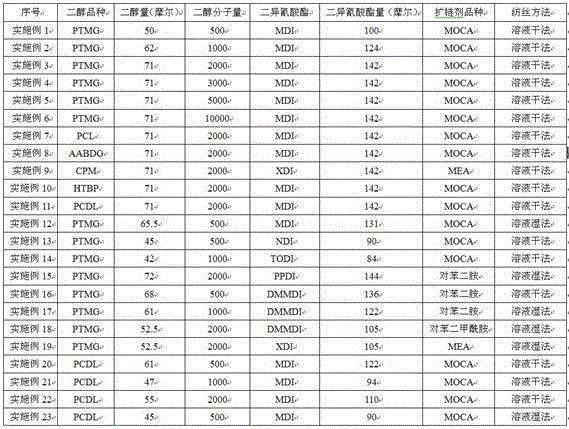

Self-adaptive fiber used in Z-pinch wire-array loads and preparing method thereof

InactiveCN105220261AIncrease elasticityHigh stress stabilityMonocomponent polyurethanes artificial filamentFiberOligomer

The invention provides a self-adaptive fiber used in Z-pinch wire-array loads and a preparing method thereof. The self-adaptive fiber is prepared from aliphatic series oligomer diol with the molecular weight of 500-10000, high-symmetry aromatic diisocyanate and a high-symmetry aromatic diamine compound. According to the preparing method of the self-adaptive fiber, at first, aliphatic series oligomer diol with a certain mole number and high-symmetry aromatic diisocyanate with the mole number being twice that of diol are adopted for carrying out prepolymerization, and high-symmetry aromatic diamine is used for carrying out chain extension so that a spinning solution can be prepared; finally, any one of a solution dry method and a solution wet method is adopted for carrying out spinning, forming and processing. In the self-adaptive fiber, cohesion energy density in a hard chain section is high, binding force of the hard chain section is large, dimensional stability is high, rebound resilience is good, and stress stability is high; according to the self-adaptive fiber, during the whole service period, obvious stress relaxation is avoided, and rebound stress can be kept unchanged for a long term.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS +1

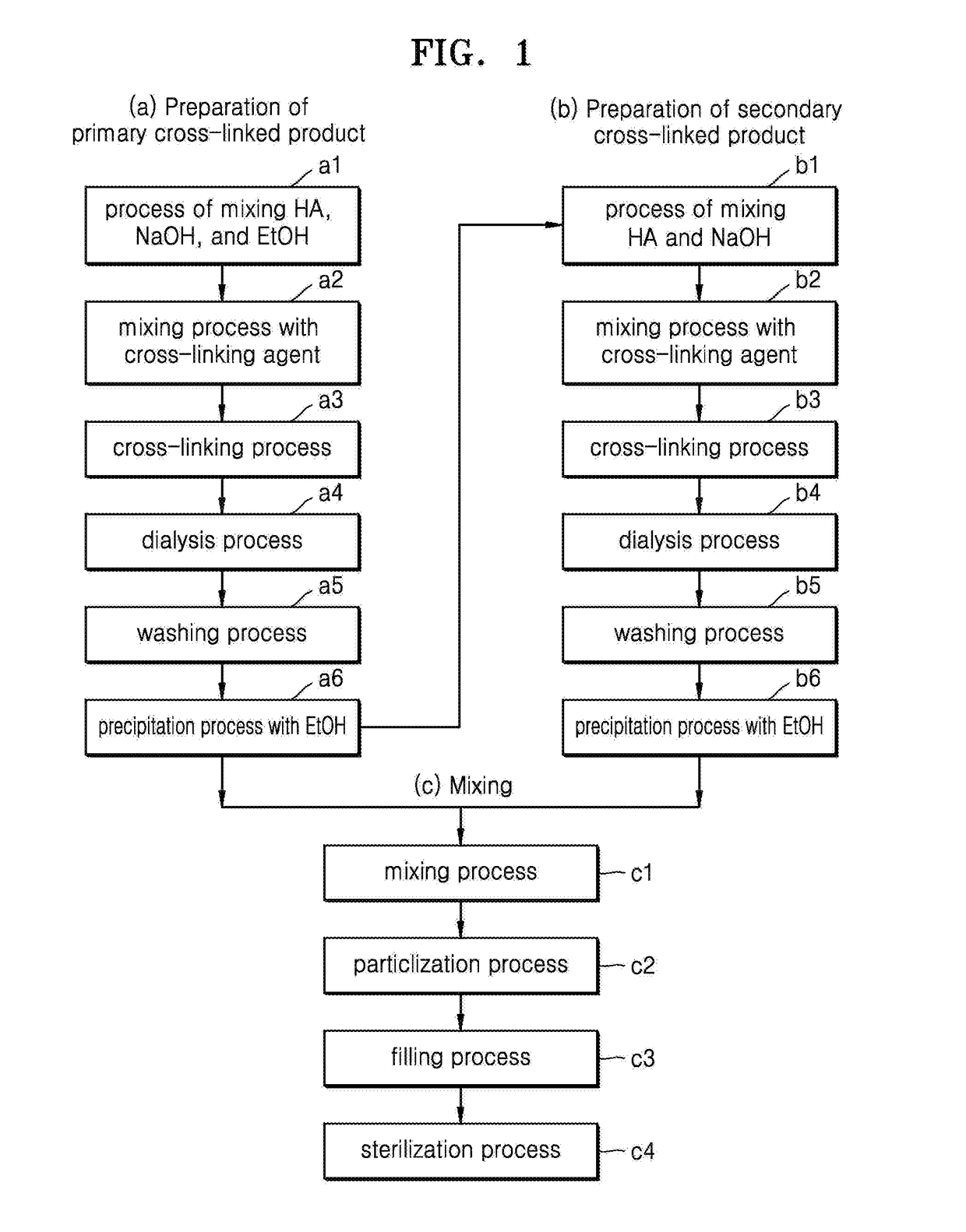

Combination of cross-linked hyaluronic acids and method of preparing the same

InactiveUS20180215840A1Reduce viscoelasticityEasy to useCosmetic preparationsToilet preparationsEpoxyCross-link

Provided are a method of preparing a cross-linked hyaluronic acid having an elasticity of about 50 to about 200 Pa and a viscosity of about 20 to about 100 Pa, including cross-linking hyaluronic acid with an epoxy-based cross-linking agent having at least two epoxy functional groups in an ethanol-containing aqueous alkaline; a method of preparing a cross-linked hyaluronic acid having an elasticity of about 400 to about 800 Pa and a viscosity of about 40 to about 100 Pa, including cross-linking the same cross-linked hyaluronic acid with the same epoxy-based cross-linking agent in an aqueous alkaline solution; and a combination of the cross-linked hyaluronic acids one having an elasticity of about 50 to about 200 Pa and a viscosity of about 20 to about 100 Pa and the other having an elasticity of about 400 to about 800 Pa and a viscosity of about 40 to about 100 Pa.

Owner:HANMI PHARMA

High-elasticity recovery spun-bonded non-woven fabric and preparation method thereof

PendingCN112281313AIncrease elasticityHigh mechanical strengthConjugated synthetic polymer artificial filamentsNon-woven fabricsElastomerPolymer science

The invention relates to the technical field of production of non-woven fabrics, in particular to a high-elasticity recovery spun-bonded non-woven fabric and a preparation method thereof. The non-woven fabric is prepared from the following raw materials in percentage by weight of 0-50% of polypropylene; 0-5% of a slipping agent; and the balance of thermoplastic elastomer. The preparation method comprises the steps of mixing the raw materials to form a mixture, and controlling the melt index of the mixture to be 55-100g / 10min, the gram weight of the non-woven fabric to be 10-200g / m <2>, the fiber diameter to be 10-30mu m, the elongation to be 80-1000% and the elastic recovery rate to be 55-95%. The invention further discloses a preparation method of the high-elasticity recovery spun-bondednon-woven fabric. The prepared non-woven fabric can be applied to the fields of medical treatment and public health and clothes, and the prepared non-woven fabric is good in elasticity, stability andbreathability, low in preparation cost, environmentally friendly and worthy of wide application and popularization.

Owner:QINGDAO UNIV

Low-density polyurethane gel composition

A low-density polyurethane gel composition used for reducing vibration and noise of underwater acoustic equipment is prepared from the organic chemical containing hydroxy group, the organic compound containing isocyanate group and diluent. Its advantages are high acoustic penetrability, low specific weight, not freezing at low temp and high viscoelasticity.

Owner:MARINE CHEM RES INST CO LTD

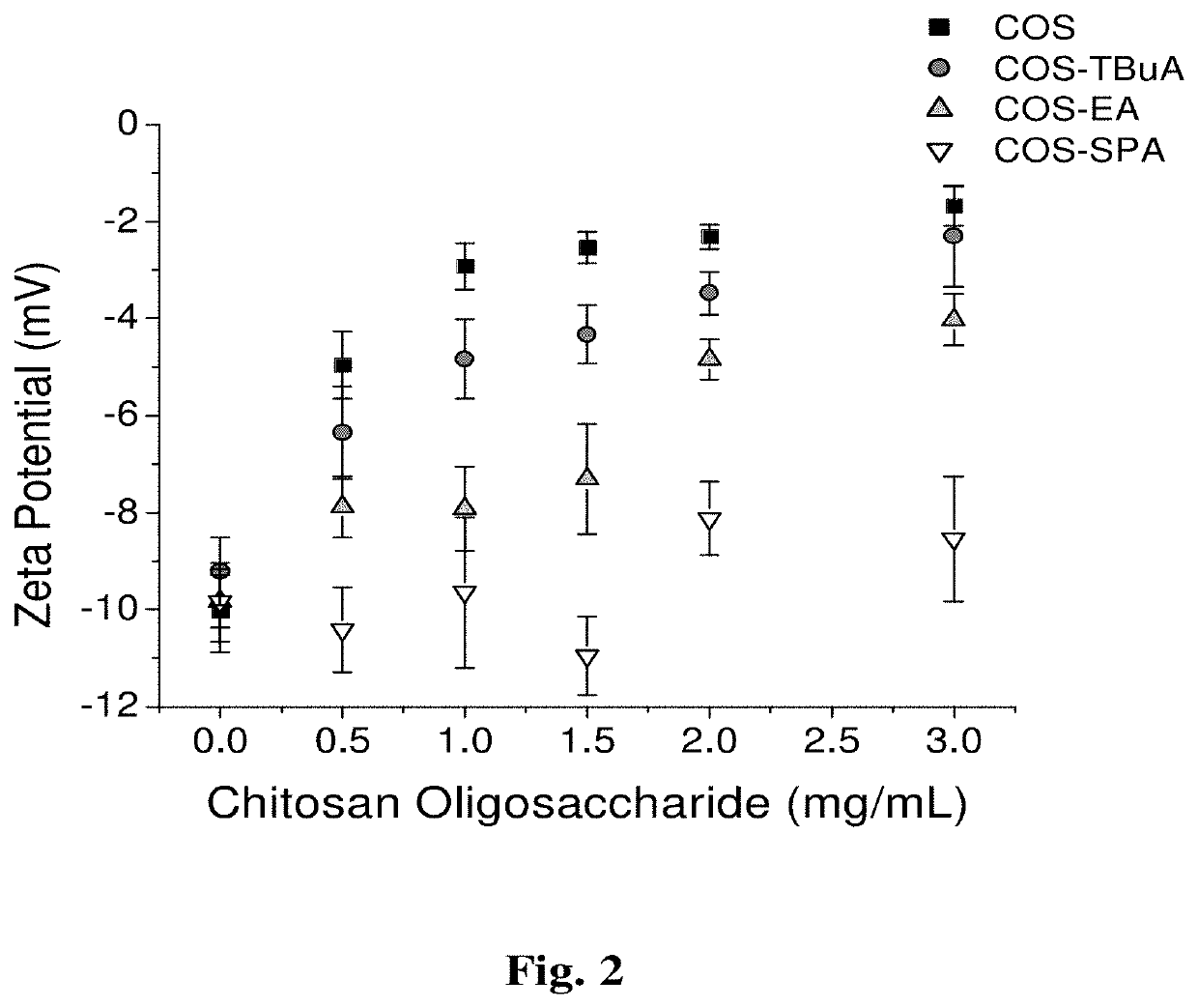

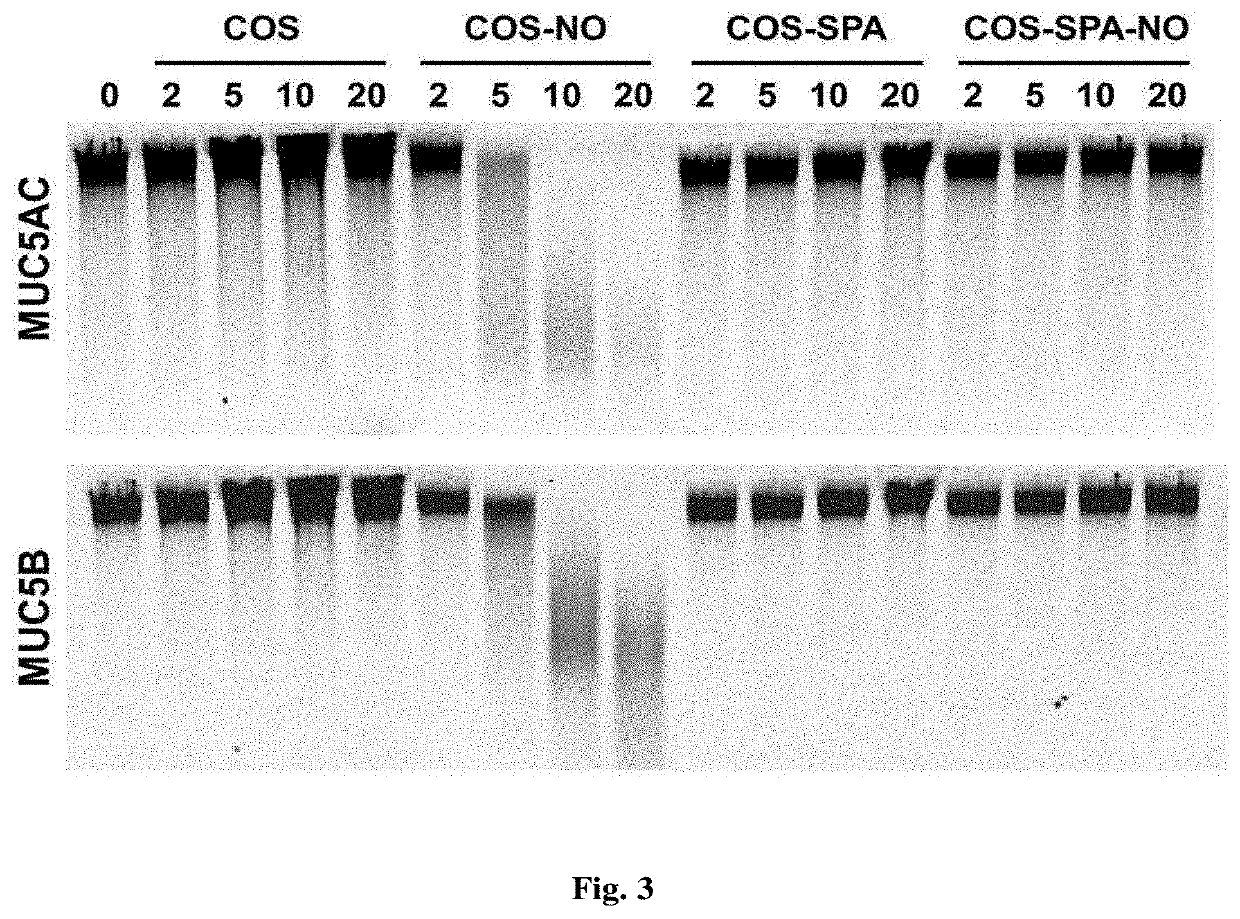

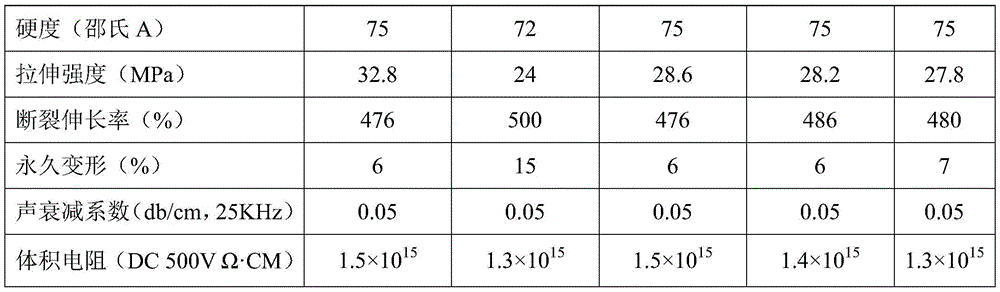

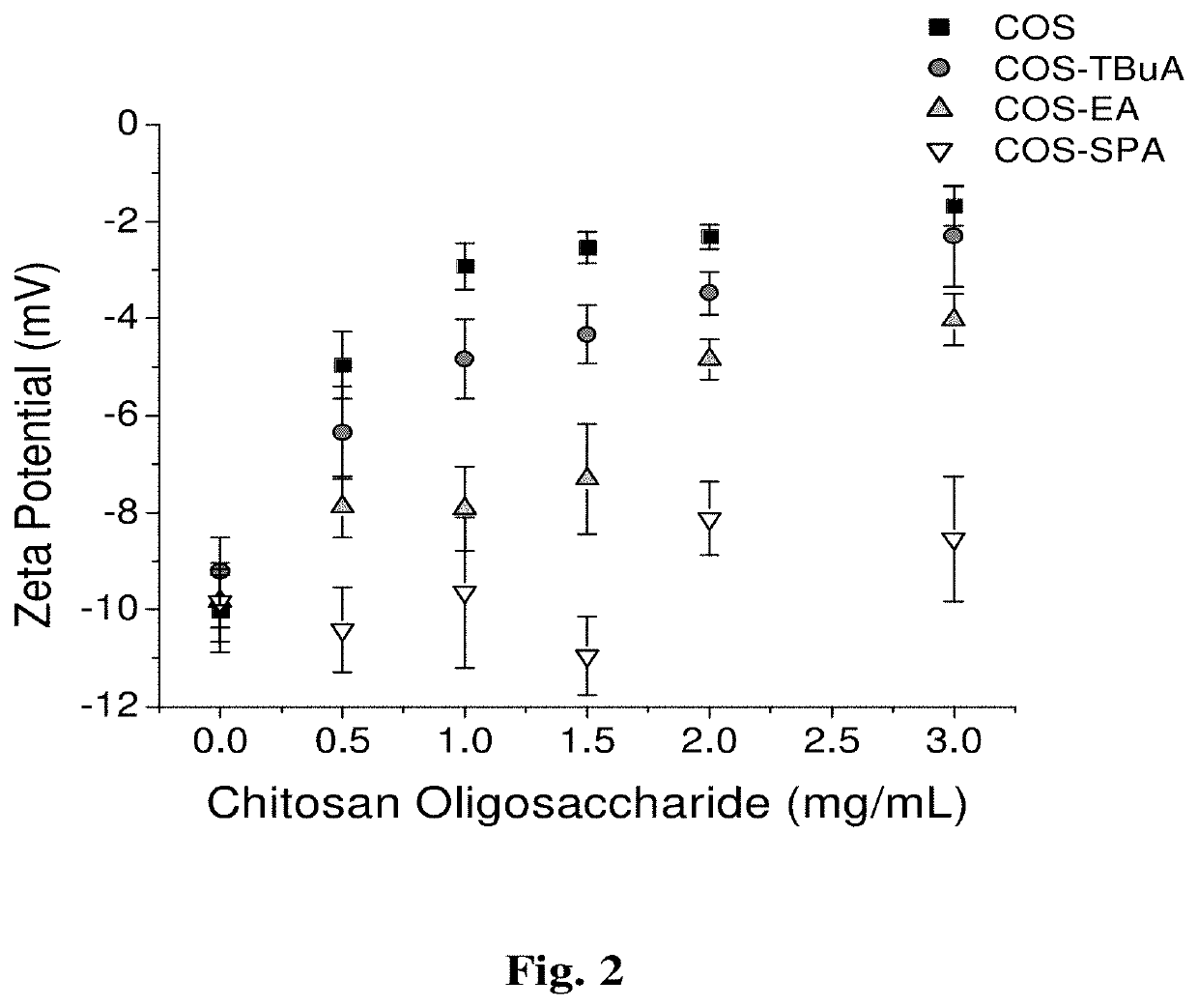

Compounds, compositions and methods for inhibiting a pathogen and/or modifying mucus

ActiveUS20200085858A1Decrease mucus viscoelasticityLow elastic modulusAntibacterial agentsOrganic active ingredientsNitric oxideChemical compound

Provided herein are compounds, compositions, and methods for modifying mucus, including modifying mucus using nitric oxide-releasing biopolymers (e.g., NO-releasing chitosan oligosaccharides). In some embodiments, a compound, composition, and / or method of the present invention modifies one or more properties of mucus to increase mucus clearance in a subject and / or prevents the growth or kills one or more pathogens present in mucus of a subject.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

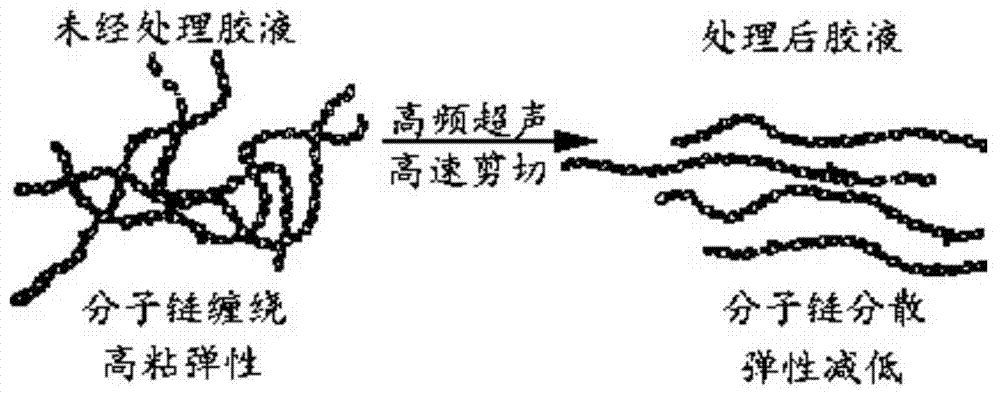

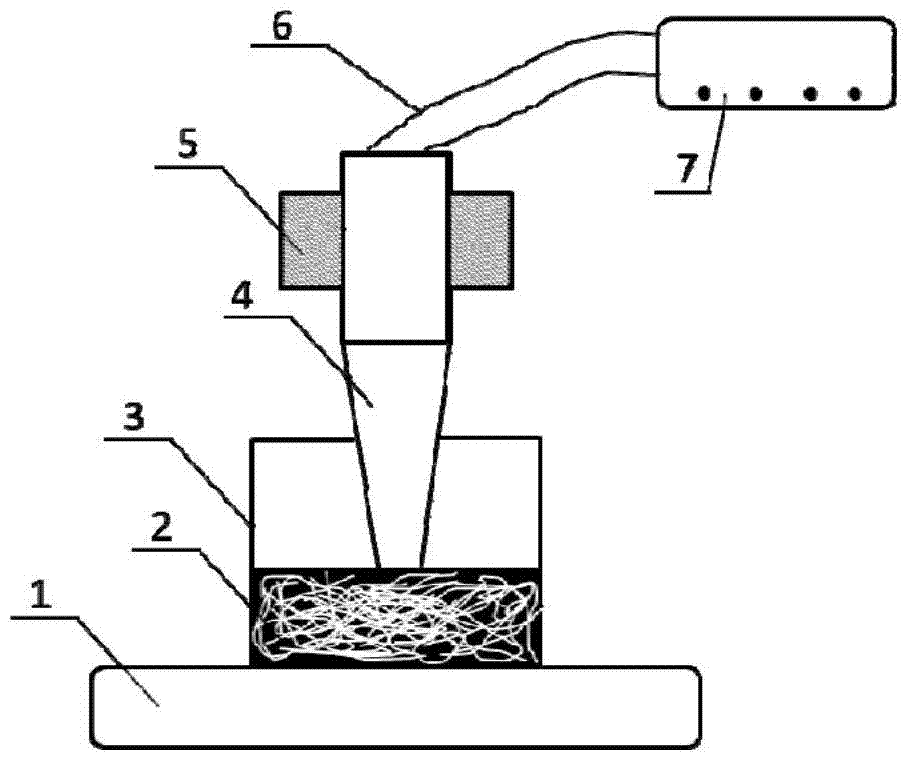

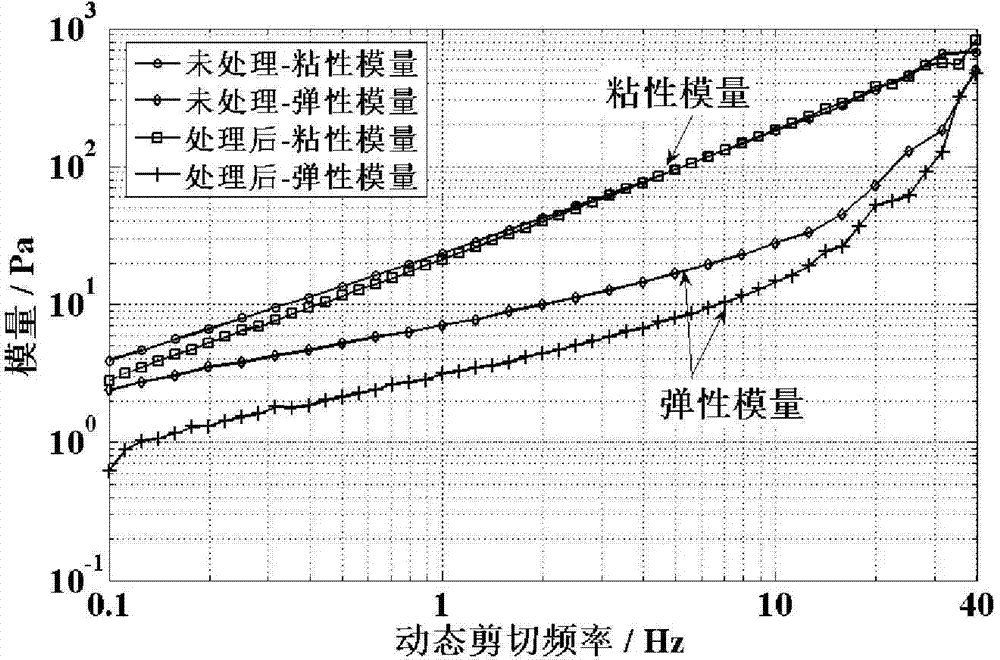

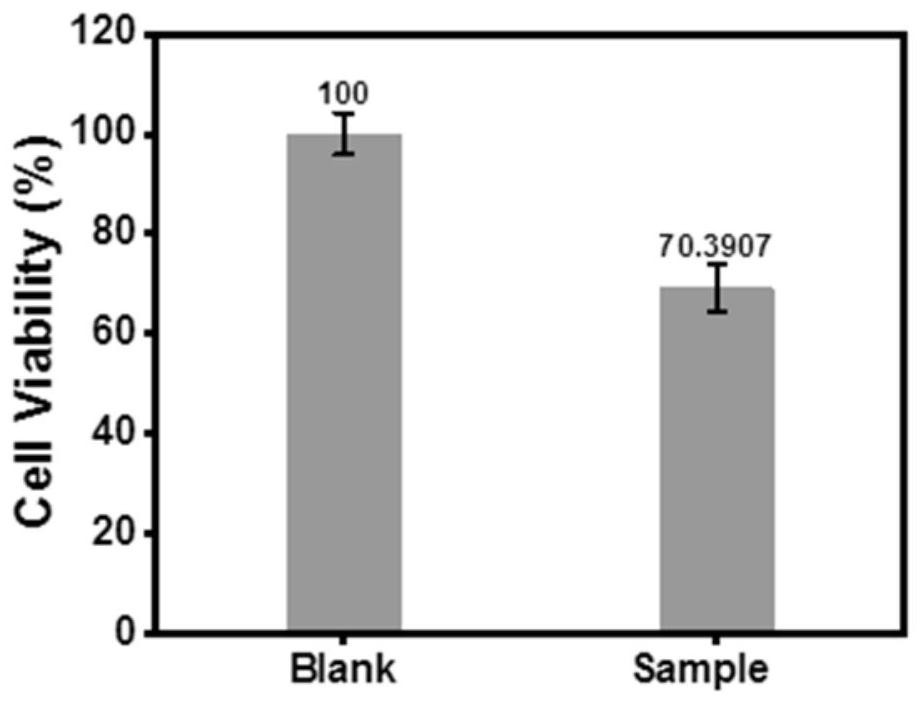

Method for improving liquidity of viscoelastic fluid via high frequency ultrasounds

InactiveCN104841322AReduce viscoelasticityWill not change natureShaking/oscillating/vibrating mixersSemiconductor/solid-state device manufacturingConductor CoilMechanics

The present invention discloses a method for improving the liquidity of a viscoelastic fluid via high frequency ultrasounds. High frequency ultrasonic waves are introduced into the viscoelastic fluid by utilizing an ultrasound amplitude-change pole supplied with power by an ultrasonic power supply to generate a large amount of bubbles, and the bubbles are detonated by shear movement generated by the ultrasonic amplitude-change pole, so that molecular chains wound together are scattered, the viscoelasticity of the viscoelastic fluid is lowered, and the fluidity of the viscoelastic fluid is improved. The method lowers the viscoelasticity of the fluid by way of scattering the molecular chains wound together, but does not change the molecular structure, therefore, the chemical property of the fluid is not changed; Scattered molecular chains can be recovered in the winding state along with Brownian motion step by step after being poured, so that the high viscoelasticity of the viscoelastic fluid can be recovered, and connected channels are better protected. The method lowers the viscoelasticity of the viscoelastic fluid on the basis of the high frequency ultrasonic shear movement without high temperature, as a result, extra thermal stress and transformation are not introduced into a chip in a pouring process.

Owner:GUANGDONG UNIV OF TECH

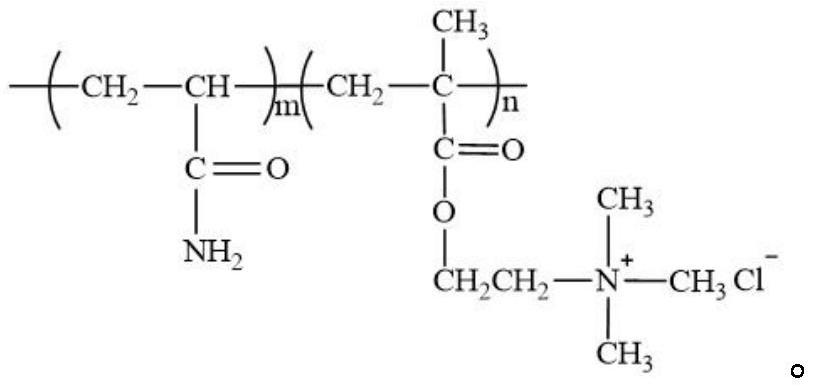

Ionized hydrogel-based artificial nervous tissue engineering material as well as preparation method and application thereof

ActiveCN112280060AImprove mechanical propertiesImprove toughnessNervous disorderAerosol deliveryNervous systemMeth-

The invention provides a preparation method of an ionic hydrogel-based artificial nervous tissue engineering material, which comprises the following steps: (1)preparation of a prepolymer solution: byusing acrylamide as a monomer and ammonium persulfate as an initiator, sequentially adding acrylamide, polylysine, N,N '-methylene bisacrylamide, ammonium persulfate and N, N, N ', N'-tetramethylethylenediamine to form the prepolymer solution; and (2)preparation of the hydrogel material: adding the prepolymer solution into a template, and reacting for 3-4 hours under ultraviolet irradiation to form the hydrogel material. The technical problem that in the prior art, a material capable of being effectively applied to nervous system injury reparation does not exist, and particularly a material capable of reconstructing neuroelectric signal conduction in the early stage is solved.

Owner:AIR FORCE MEDICAL CENT PLA

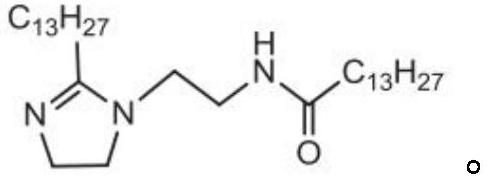

High-temperature-resistant clean acidic fracturing fluid and preparation method thereof

PendingCN112375556AHigh porosityImprove permeabilityDrilling compositionOXALIC ACID DIHYDRATEAcetic acid

The invention discloses a high-temperature-resistant clean acidic fracturing fluid and a preparation method thereof. The fracturing fluid comprises the following formula components: a viscoelastic surfactant ves-c, hydrochloric acid, acetic acid, citric acid, oxalic acid, an anti-swelling agent JSH and a corrosion inhibitor. According to the proportioning scheme, the high-temperature-resistant clean acidic fracturing fluid is prepared from the following components in parts by mass: 0.3-0.5 part of a viscoelastic surfactant ves-c; 3-4 parts of hydrochloric acid; 4-5 parts of acetic acid; 0.5-1part of citric acid; 0.5-1 part of oxalic acid; 1-1.5 parts of an anti-swelling agent JSH; and 0.3-0.5 part of a corrosion inhibitor . The fracturing fluid prepared by the preparation method disclosedby the invention is used for delaying the acid rock reaction rate, achieves deep acidification of a stratum without damage, and improves the fracturing effect of the acid fracturing fluid.

Owner:SHAANXI UNIV OF SCI & TECH

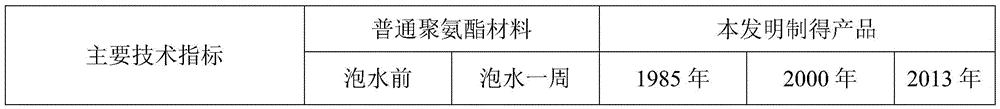

A kind of preparation method of waterproof potting material

The invention discloses a waterproof encapsulating material and preparation method thereof and relates to a plastic composition based on polyurethane and epoxy resin and a preparation method thereof. The invention aims to provide a waterproof encapsulating material which has high waterproofness, excellent electrical property and flexibly controlled mechanical property and a preparation method thereof. The waterproof encapsulating material comprises components A and B, wherein the component A is polyurethane prepolymer, or epoxy resin, or mixture of polyurethane prepolymer and epoxy resin; the polyurethane prepolymer comprises isocyanate and high-molecular-weight polyol; the component B comprises a curing agent, a reaction accelerant, an auxiliary and a silane coupling agent. The preparation method of the waterproof encapsulating material comprises the following steps: preparing the polyurethane prepolymer; preparing the component A; preparing the component B; mixing and pouring, and curing at room temperature. The waterproof encapsulating material prepared by the invention has corrosion resistance, high waterproofness, excellent electric property, strong tenacity, and flexibly controlled mechanical property. The waterproof encapsulating material is used for the encapsulating field of the underwater electric appliance.

Owner:李春梅

Compounds, compositions and methods for inhibiting a pathogen and/or modifying mucus

ActiveUS11324773B2Low elastic modulusLow viscosityAntibacterial agentsOrganic active ingredientsBiopolymerChemical compound

Provided herein are compounds, compositions, and methods for modifying mucus, including modifying mucus using nitric oxide-releasing biopolymers (e.g., NO-releasing chitosan oligosaccharides). In some embodiments, a compound, composition, and / or method of the present invention modifies one or more properties of mucus to increase mucus clearance in a subject and / or prevents the growth or kills one or more pathogens present in mucus of a subject.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

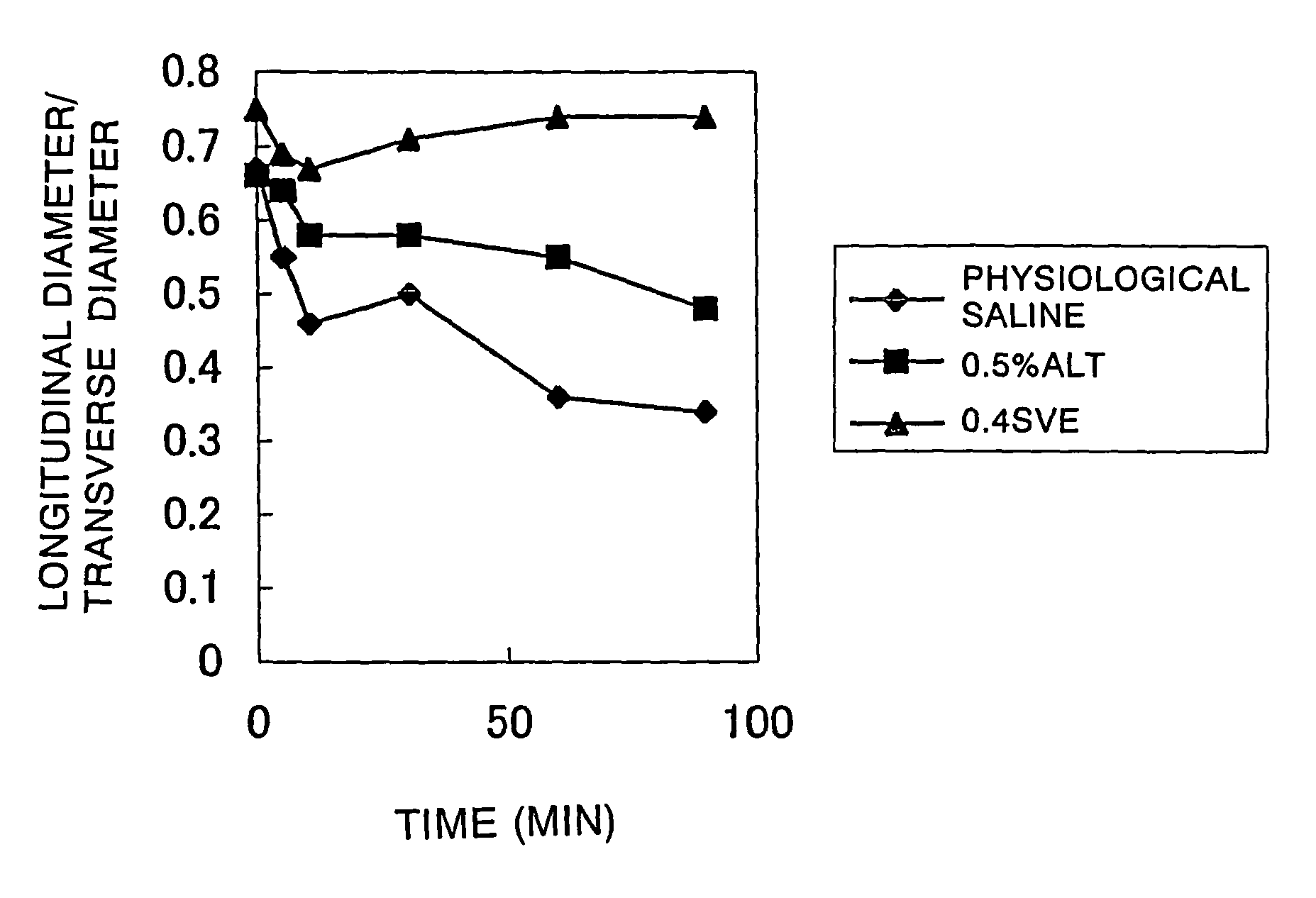

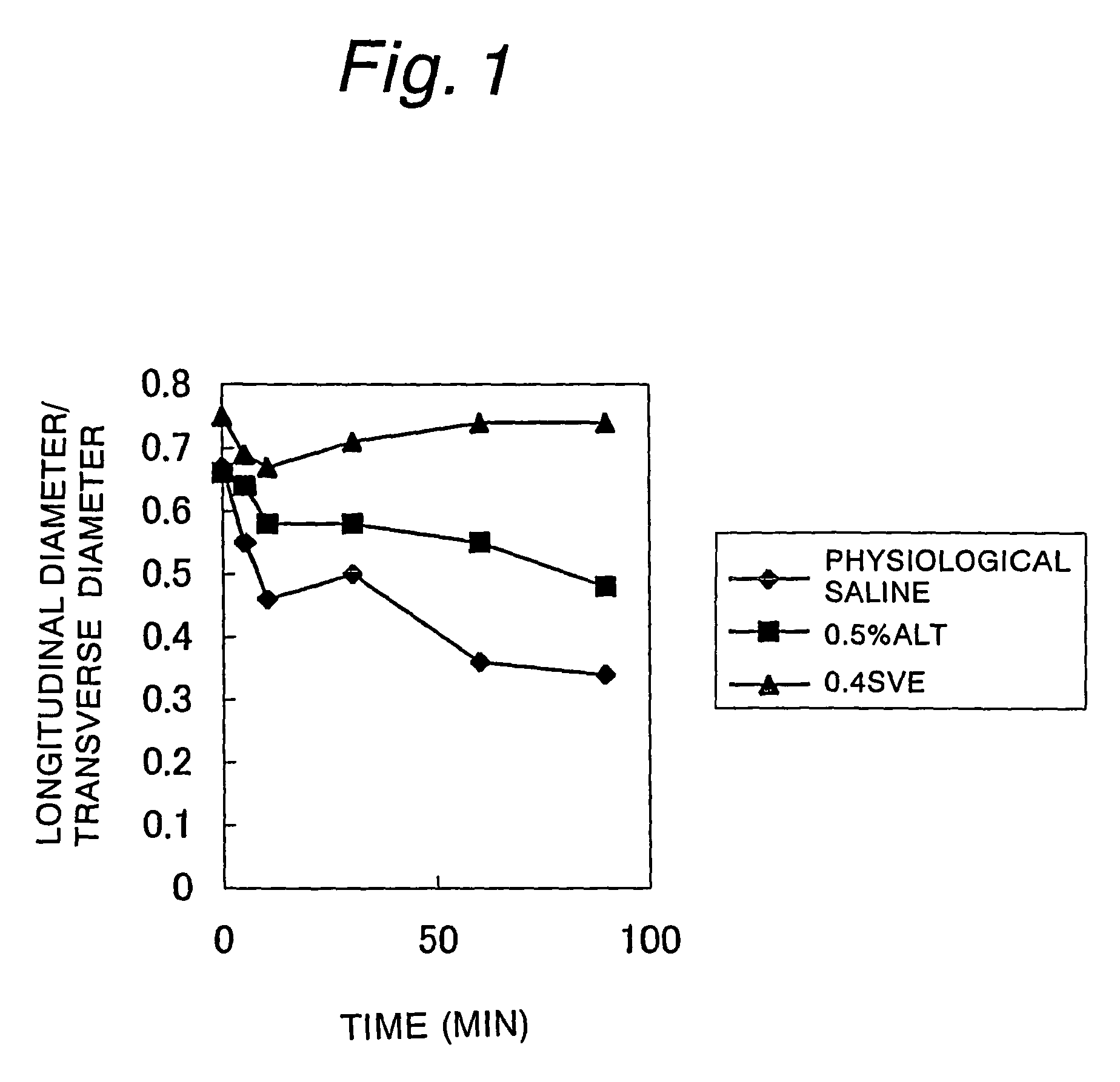

Endoscopic injectable preparation

ActiveUS7748388B2Prolong elevation timeReduce viscoelasticityOrganic active ingredientsDiagnosticsSurgical operationMucosal lesion

It is disclosed that a long elevation time is obtained and the efficiency of resection can be improved by providing an endoscopic injectable preparation using high molecular weight hyaluronic acid having an average molecular weight of 1,500,000 to 3,000,000 or its salt.In treating early cancer or other neoplastic mucosal lesion, the lesion is resected with handling of an endoscope (“endoscopic mucosal resection”) instead of performing a major surgical operation such as laparotomy, thoracotomy or organ excision. In performing endoscopic mucosal resection, physiological saline, or a solution of low molecular weight hyaluronic acid or its salt is injected into a stratum below the site of lesion scheduled for resection to elevate the site of lesion, thereby increasing the efficiency of resection. To raise the efficiency of endoscopic mucosal resection, however, the development of an injectable preparation presenting a longer elevation time and requiring a low injection pressure has been desired.

Owner:YAMAMOTO HIRONORI

Preparation method of high viscoelastic binder for non-aromatic soybean oil offset printing thermoset rotary ink

The invention relates to a preparation method of high-viscoelasticity coupling material for non-fragrant soybean oil thermosetting web offset ink, comprising the following steps: in a standard normal-pressure kettle, adding 40+ / -1 parts of non-fragrant ink oil and 12+ / -0.5 parts of industrial soybean oil into the kettle according to parts by weight; adding 43+ / -1 parts of high-viscosity rosin modified phenolic resin while stirring for raising the temperature; keeping warm at the temperature of 180+ / -2 DEG C until resin is totally dissolved; stopping heating, and adding 4+ / -1 parts of non-fragrant ink oil; adjusting viscosity to 65000+ / -2000 MPa.s / 25 DEG C by the non-fragrant ink oil; adding 0.73+ / -0.01 part of gelling agent, and reacting at the temperature of 175+ / -2 DEG C; sampling and detecting per 0.5 hour; when viscosity is 500000+ / -50000 MPa.s / 25 DEG C, stopping temperature reduction reaction to obtain the product; and at the temperature of 135+ / -5 DEG C, filtering and packaging according to the normal ink coupling material production procedures. The high-viscoelasticity coupling material of the invention has favourable viscoelasticity and dissolubility in non-fragrant kerosene, has favourable performance in non-fragrant soybean oil thermosetting web offset ink and can satisfy high-speed and exquisite thermosetting web offset ink printing. The high-viscoelasticity coupling material has favourable dot reproduction, printability, simple technology and obvious effect.

Owner:TIANJIN TOYO INK

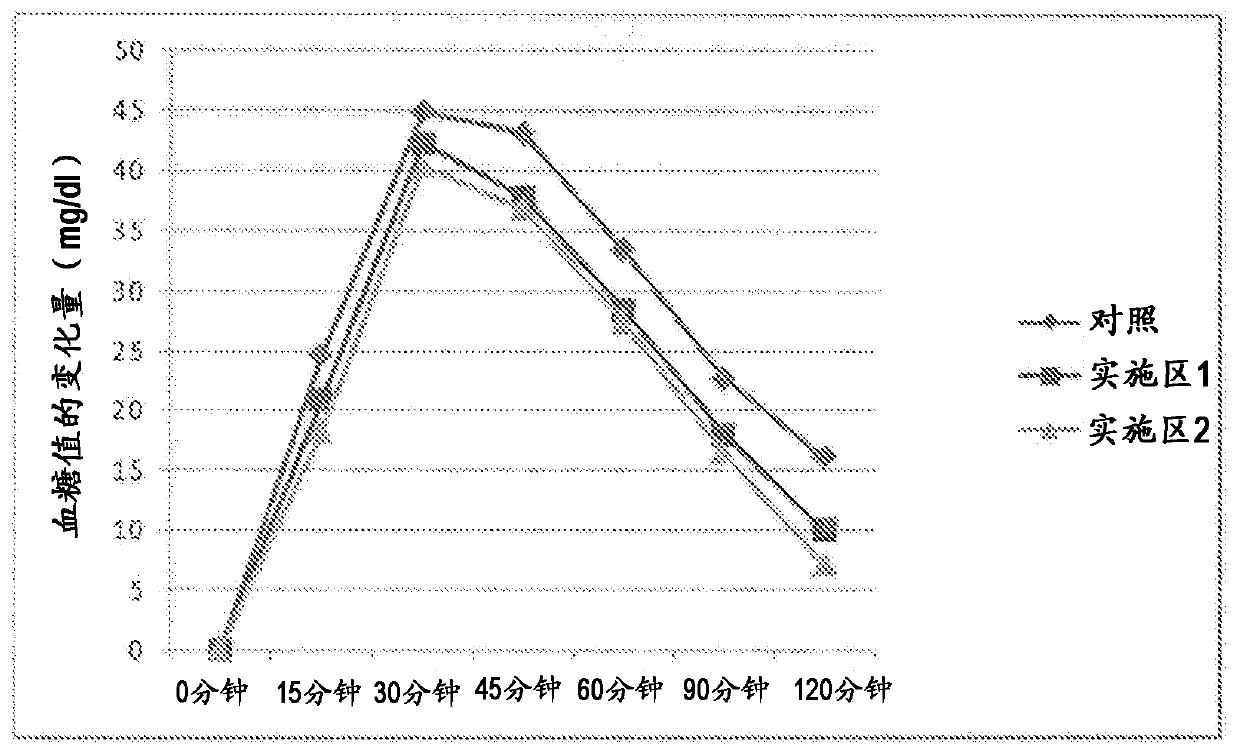

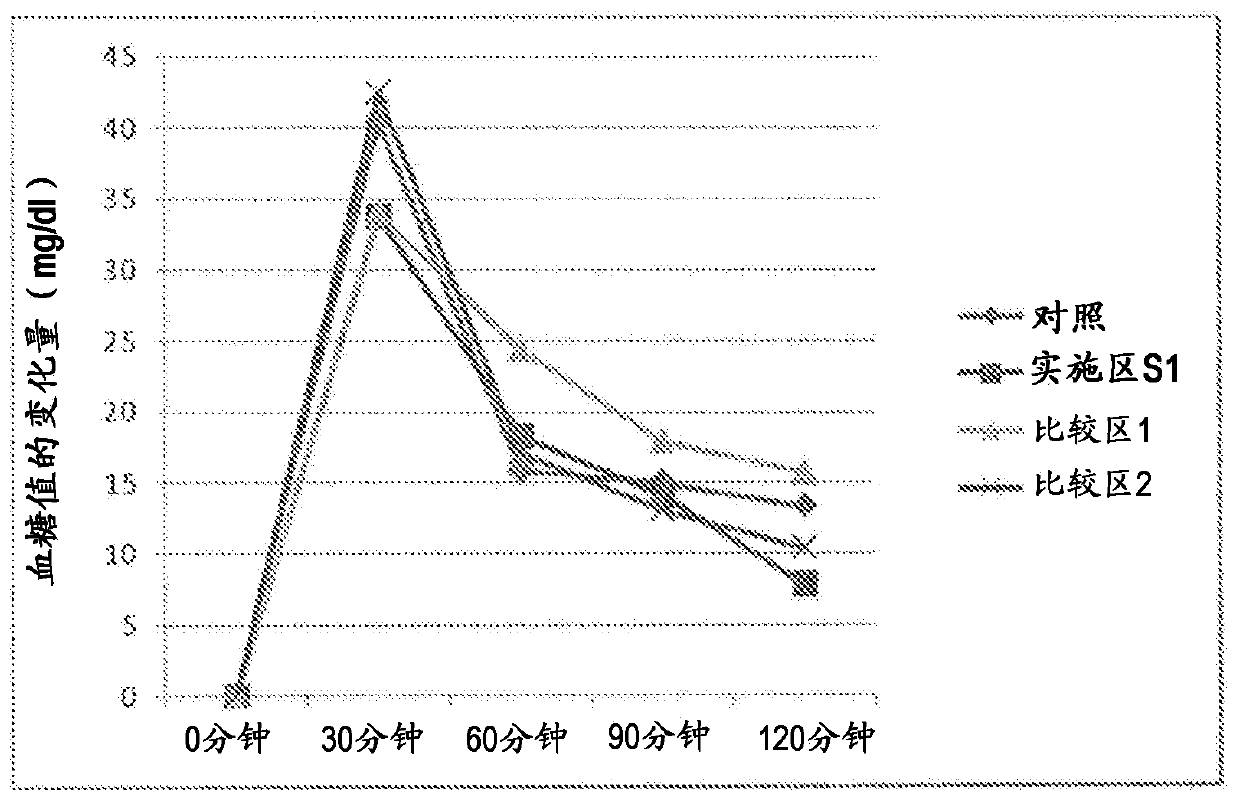

Good-texture healthy boiled noodle

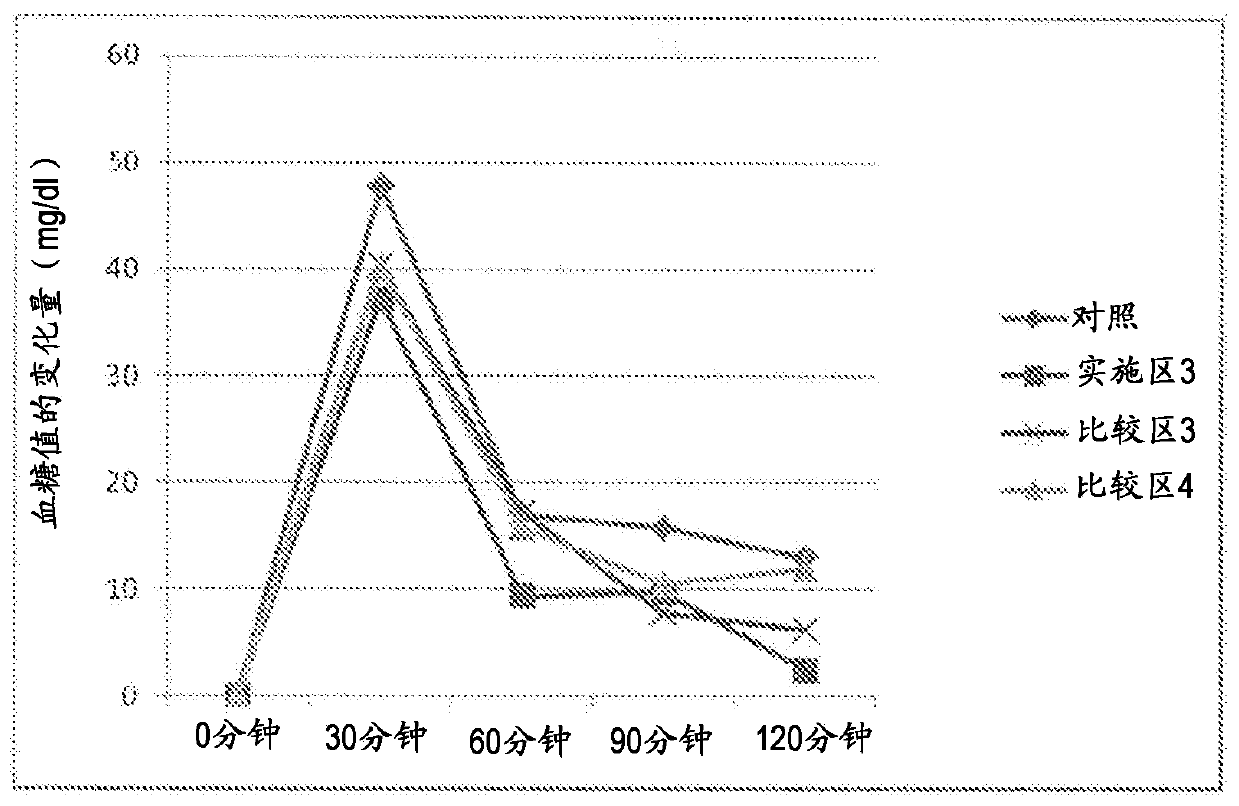

ActiveCN111447838ABlood sugar risesReduce tasteOrganic active ingredientsDough treatmentEngineeringProcess engineering

The present invention addresses the problem of providing a good-texture healthy boiled noodle and a good-texture healthy raw noodle in which the health effect of calcium alginate is given to the noodle, the original noodle texture is not lost, the effective health effect of calcium alginate and excellent texture are provided. In order to solve the problem, a method for manufacturing boiled noodlesor raw noodles, employs noodle manufacturing steps of the noodle manufacturing method, including: (A) a kneading step for adding kneading water to a noodles-manufacturing raw material powder obtainedby mixing a raw material containing wheat flour, so as to knead dough; and (B) a noodle manufacturing step for shaping the dough into noodle strings, wherein 270-mesh-pass finely ground calcium alginate powder is blended into the noodles-manufacturing powder in a proportion of 4-8 parts by mass with respect to 100 parts by mass of the noodles-manufacturing raw material powder. As a result, a healthy boiled noodle or a healthy raw noodle, in which the health function of calcium alginate and the high texture of the noodle are maintained, is manufactured. The present invention provides a good-texture healthy boiled noodle or a good-texture healthy raw noodle in which a health effect such as the effect of suppressing blood glucose level rise after eating is effectively maintained, and, in manufacturing of a noodle, the original noodle texture is maintained without causing a decrease of texture or a decrease of viscoelasticity and the like of a noodle structure that occurs when calcium alginate is added.

Owner:岛田屋公司

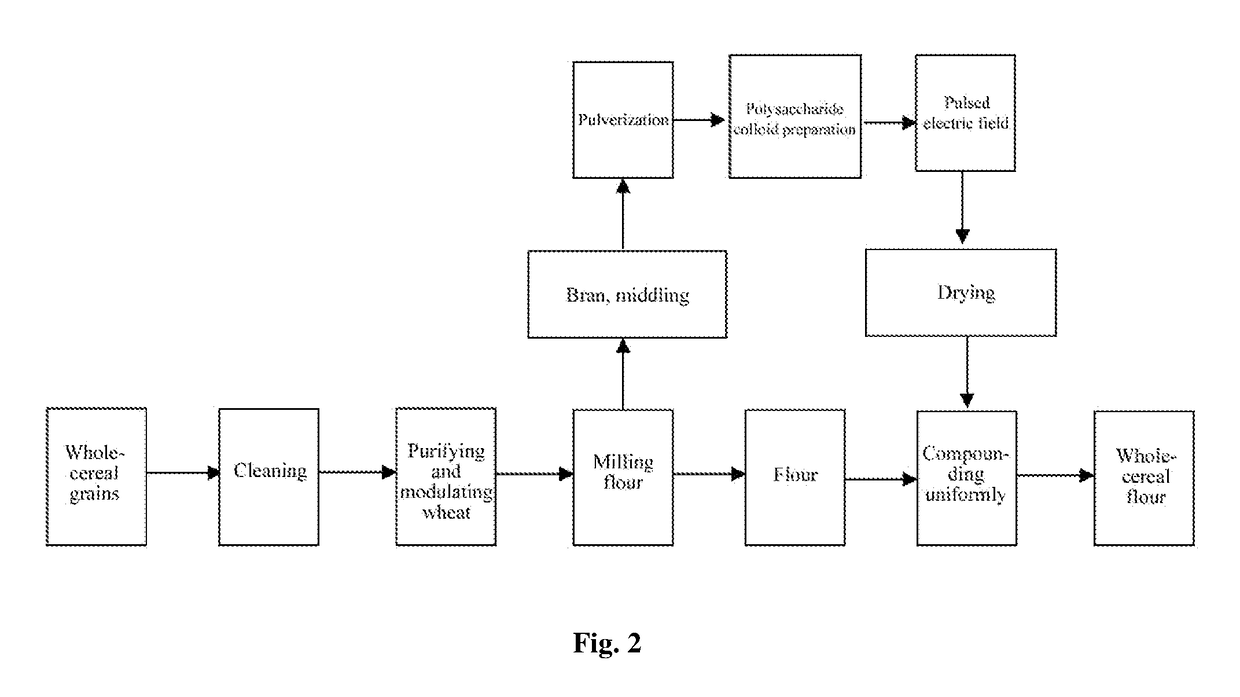

Method for Producing Intensified Whole-Cereal Flour by Means of Pulsed Electric Fields in Collaboration with Ultrafine Pulverization

ActiveUS20180242597A1Great tasteImprove shelf life stabilityBakery productsDough irradiationColloidHigh voltage pulse

A method is provided for producing intensified whole-cereal flour by means of pulsed electric fields in collaboration with ultrafine pulverization, which includes: (1) preparing bran, middling and flour by cleaning, modulating and milling cereal grains; (2) performing superfine pulverization on the bran and the middling and performing sieving; (3) preparing a suspension by using water and the sieved bran and middling, and stirring constantly; (4) adding polysaccharide colloids into the suspension, and adjusting the pH to 4.0; (5) performing high-voltage pulse treatment on the suspension to ensure stable flow of the suspension; (6) centrifuging the suspension to separate the supernatant, and drying the obtained precipitate and performing sieving to obtain the treated bran and middling; and (7) mixing the treated bran and middling with flour uniformly to obtain whole-cereal flour.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com