Viscoelastic system formed by functional Gemini surface active agent

A surfactant and solution technology, applied in the field of viscoelastic systems, can solve the problems of insufficient viscoelasticity, poor stability, and easy turbidity of worm-like micelles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation of embodiment 1:12-3 (OH)-12

[0027] Add 1,3-dibromo-2-propanol (10.0g, 0.046mol), N,N-dimethyldodecylamine (21.6g, 0.102mol) and 100mL of absolute ethanol to the reaction equipped with a reflux condenser In a container, heat to reflux and stir for 48 hours. After the reaction, the ethanol is removed by rotary evaporation to obtain a yellow viscous liquid. Four equal parts of the obtained crude product are transferred to four 50mL centrifuge tubes, and 30mL anhydrous ether is added to wash three times, centrifuged, poured Remove the supernatant. Then recrystallize five times in the centrifuge tube with ethanol / ether, put the centrifuge tube into a vacuum drying oven and dry for 48 hours to obtain 10.8 g of white solid product with a yield of 65%.

Embodiment 2

[0029] Preparation of Viscoelastic Surfactant Solutions. Prepare 80mmol / L of Gemini cationic surfactant solution and 100mmol / L of salt solution, wherein each surfactant solution takes 1.25mL, and then add appropriate amount of sodium o-hydroxybenzoate, sodium m-hydroxybenzoate and sodium p-hydroxybenzoate salt solution, so that the molar ratio of salt to Gemini cationic surfactant reaches 2:25, 4:25, 5:25, 6:25, 7:25, 8:25, 9:25, 10:25, and then Add ultrapure water so that the total volume of the mixed solution is 2 mL, and after mixing evenly, a series of viscoelastic surfactant solutions are obtained.

Embodiment 3

[0031] The viscoelasticity measurement of the viscoelastic surfactant solution obtained by compounding salt and cationic surfactant solution in Example 2.

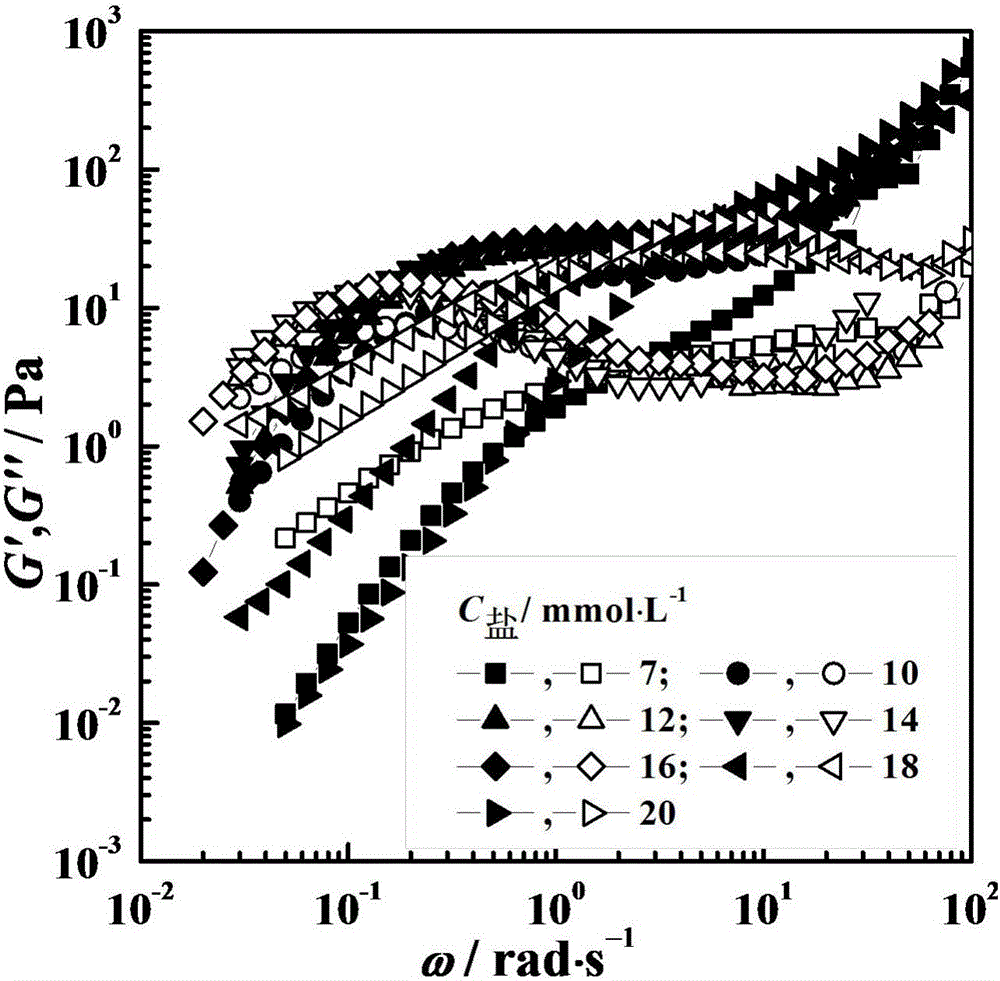

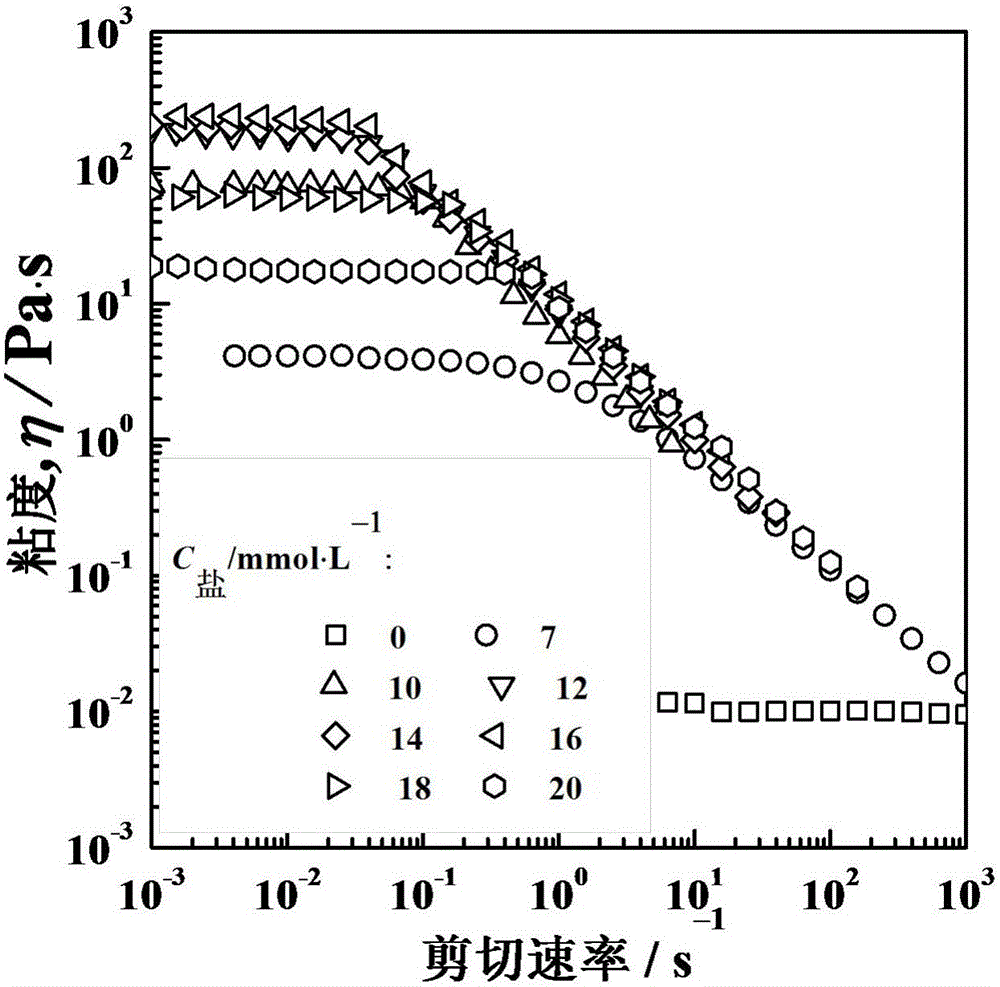

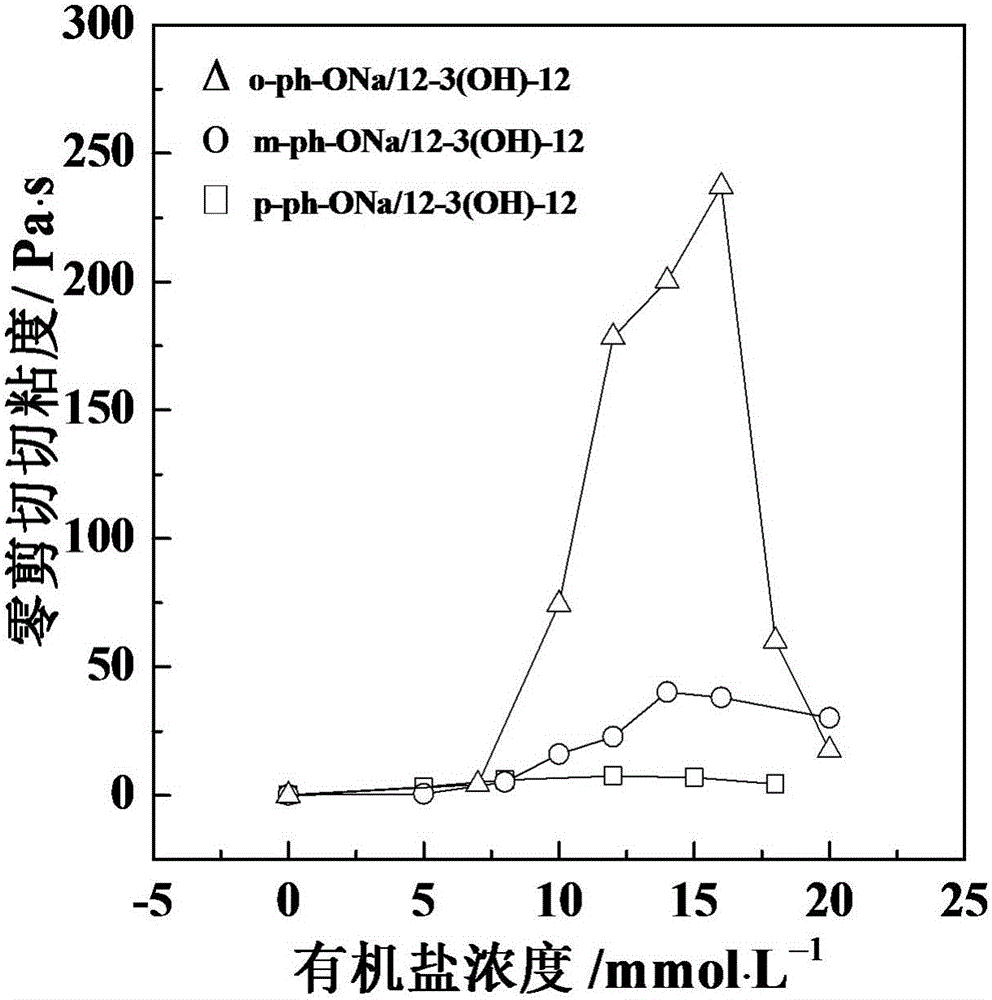

[0032] The resulting viscoelastic surfactant solution was left to stand at 25°C for 48 hours, and the rheological properties were tested at 25°C. Before the dynamic scanning, the stress scanning is carried out to determine the linear viscoelastic region of the test sample, and the tests of the samples are all carried out in the linear viscoelastic region. For specific data, see figure 1 , figure 2 with image 3 :

[0033] figure 1 It is a dynamic shear diagram of sodium o-hydroxybenzoate / 50mM 12-3(OH)-12. It can be seen that in the frequency range tested, the elastic modulus of the sample is always greater than the viscous modulus, indicating that the sample has good elasticity .

[0034] figure 2 is the steady-state shear diagram of the sample. With the increase of salt concentration, the zero-shear viscosity of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Zero shear viscosity | aaaaa | aaaaa |

| Zero shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com