Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39 results about "Viscous modulus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The loss modulus represents the viscous part or the amount of energy dissipated in the sample. The ‘sum’ of loss and storage modulus is the so-called complex modulus G*. Viscosity h*. The complex viscosity h* is a most usual parameter and can be calculated directly from the complex modulus.

Low application temperature hot melt adhesive

InactiveUS20070088116A1High bond strength levelSame level of performanceAbsorbent padsAdhesivesElastomerCardboard

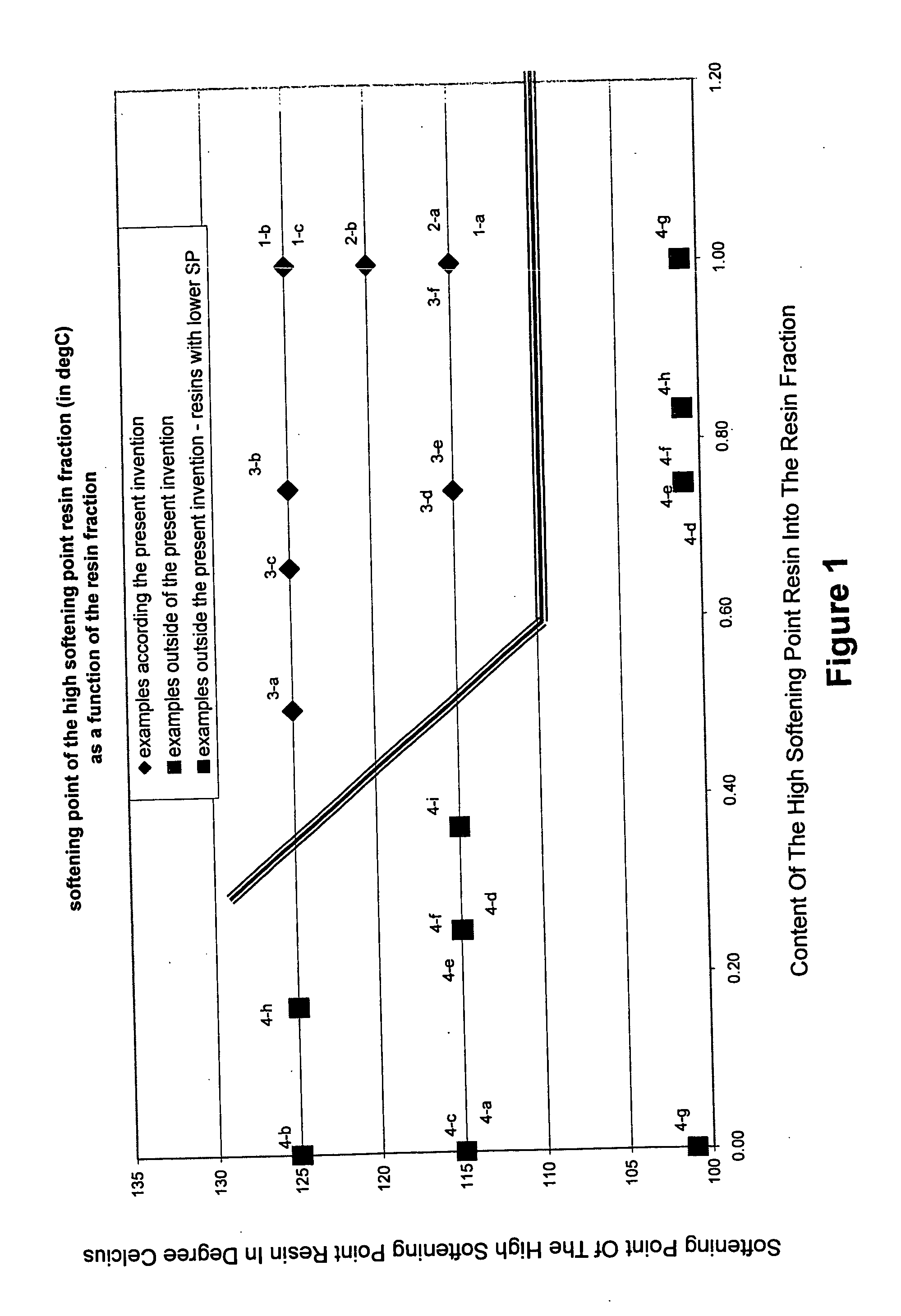

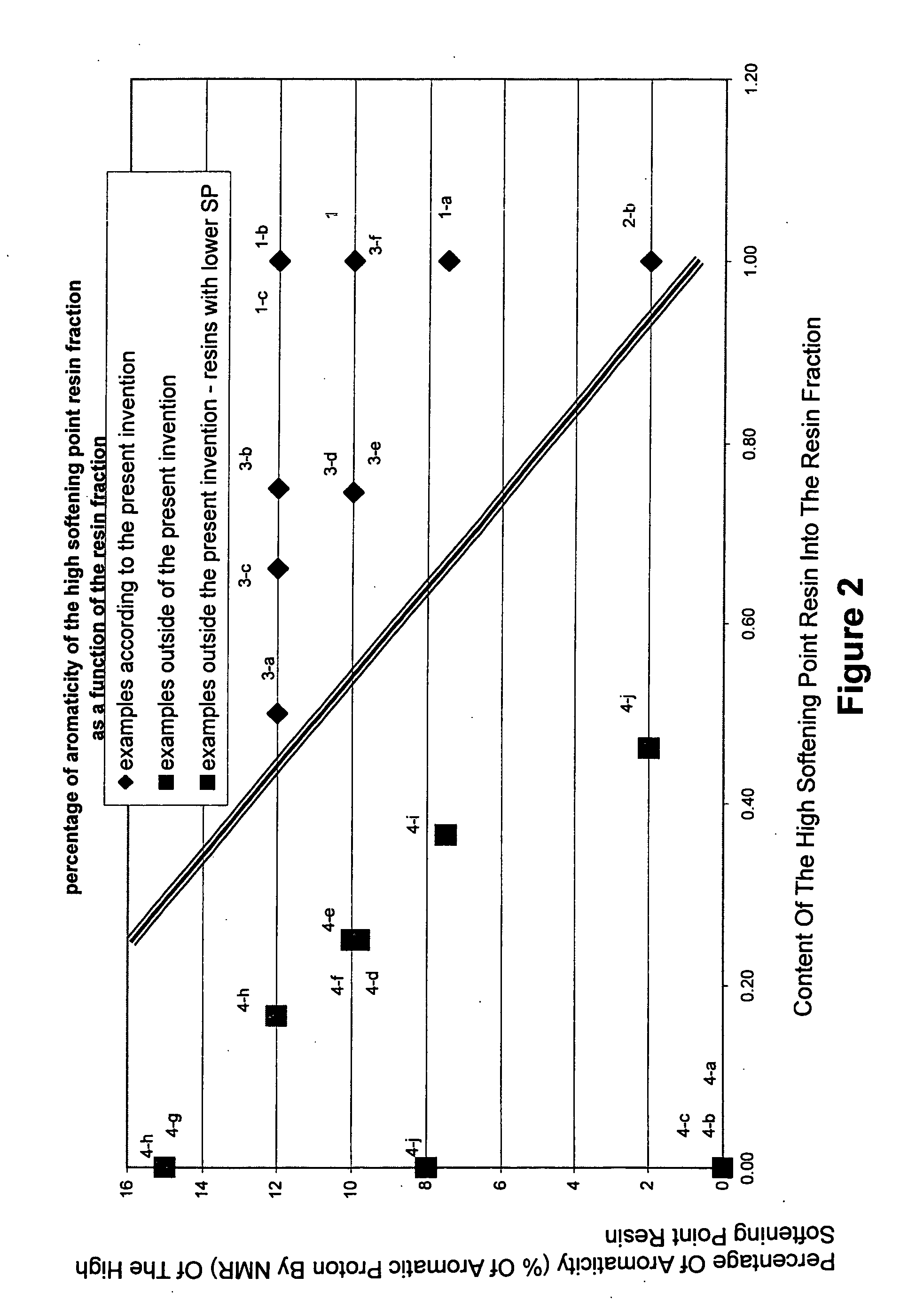

A hot melt adhesive composition, comprising a blend of components including about 10% to about 40% by weight of an elastomeric block copolymer, preferably styrene-isoprene-styrene (SIS) or styrene-butadiene-styrene (SBS), about 15% to about 70% by weight of a first midblock tackifying resin having a softening point of at least about 110° C. and having an aromatic content of at least about 1.5% by weight; about 0 to 55% of second midblock tackifying resin, about 5% to about 35% by weight of a plasticizer; and about 0% to about 20% by weight of an end block resin having a softening point lower than 125° C.; wherein the components total 100% by weight of the composition, the viscosity of the composition is equal to or less than about 20,000 mPa.s at 120° C., and is applied at a temperature lower that 150° C. and initial bond retention of the composition on elastic strands is at least about 60%. Also, the elastic modulus G′ of the composition is higher than about 5000 Pa, the vicous modules G″ is higher than about 50 Pa, and the tan delta value is between about 0.5 and about 60. Laminates, especially those used in disposable soft goods, and methods of making such laminates are also described. The adhesive composition and / or laminate may be used in making a variety of end products such as a disposable diaper, a sanitary napkin, a bed pad, a bandage, a surgical drape, a tape, a label, a plastic sheet, a nonwoven sheet, a paper sheet, a cardboard, a book, a filter, or a package.

Owner:BOSTIK INC

Flooring material

The invention relates to a wood based flooring material having an upper surface and a backing surface, the wood based flooring material comprising one or more layers, wherein the backing surface has a coating of a thermoplastic composition, wherein the thermoplastic composition has a ratio elastic modulus G′ to viscous modulus G″, G′ / G″, of less than or equal to about 5 at 0.001 Hz and 25° C. The invention also relates to a method of producing the flooring material.

Owner:AKZO NOBEL COATINGS INT BV

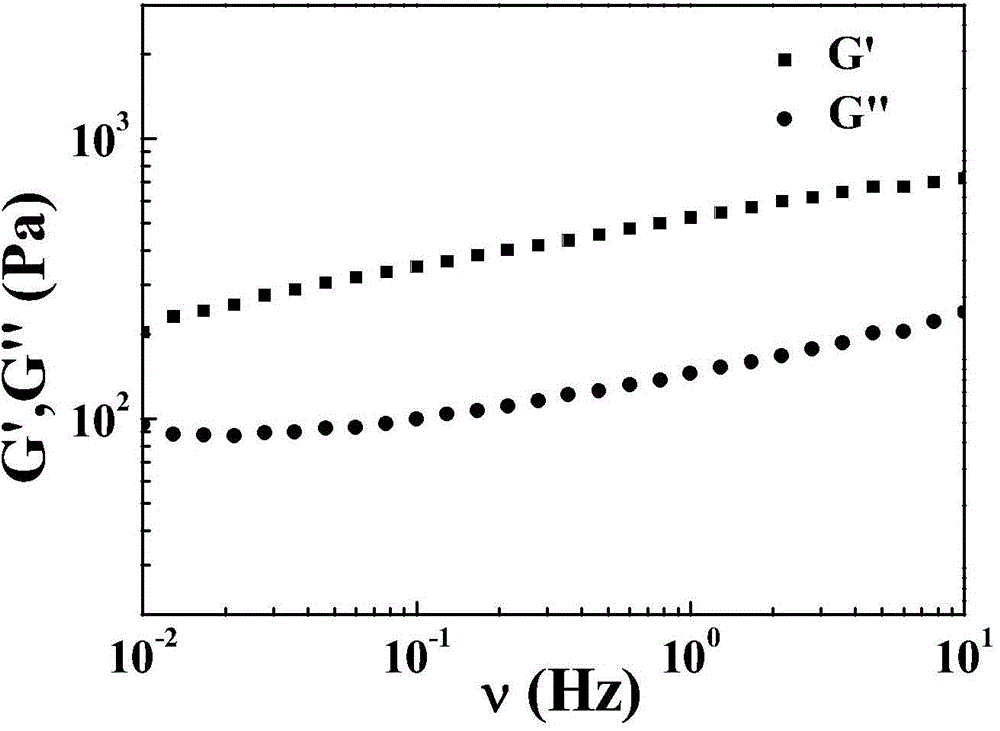

Gel prepared from chitosan or chitosan derivatives by multi-crosslinking and preparation method

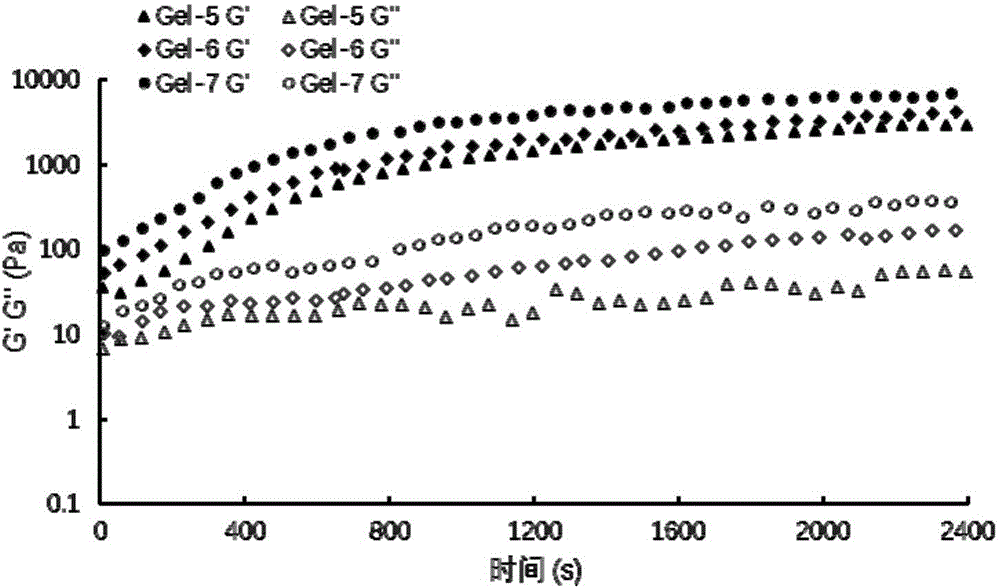

ActiveCN107325306AHigh modulus of elasticityIncreased viscous modulusSurgeryProsthesisViscous modulusBiological glue

The invention relates to gel prepared from chitosan or chitosan derivatives by multi-crosslinking and a preparation method. By multi-crosslinking chitosan or the chitosan derivatives, the elasticity modulus and the viscous modulus of the gel are increased and the swelling degree of the gel is reduced under the condition that the crosslinking degree of the gel is not increased. The elasticity modulus and the viscous modulus of the chitosan gel can be further increased each time one crosslinking is increased in the multi-crosslinking process, and the viscoelastic modulus of the gel can be increased by multi-crosslinking under the condition of equal crosslinking degree. The crosslinking times of the chitosan gel are selected according to characteristics of the viscoelastic modulus of different tissue parts, so that the viscoelastic modulus of the chitosan gel is matched with the related tissue, the histocompatibility of the gel in the tissue can be improved, and the use quantity of a crosslinking agent which is irritant or toxic to a human body can be reduced. The gel is applied to the field of soft tissue in tissue engineering such as tissue filling and repair, joint viscoelasticity replenishers, biological scaffolds, anti-cicatricial, anti-adhesion and biological glue and the like.

Owner:IMEIK TECH DEV CO LTD

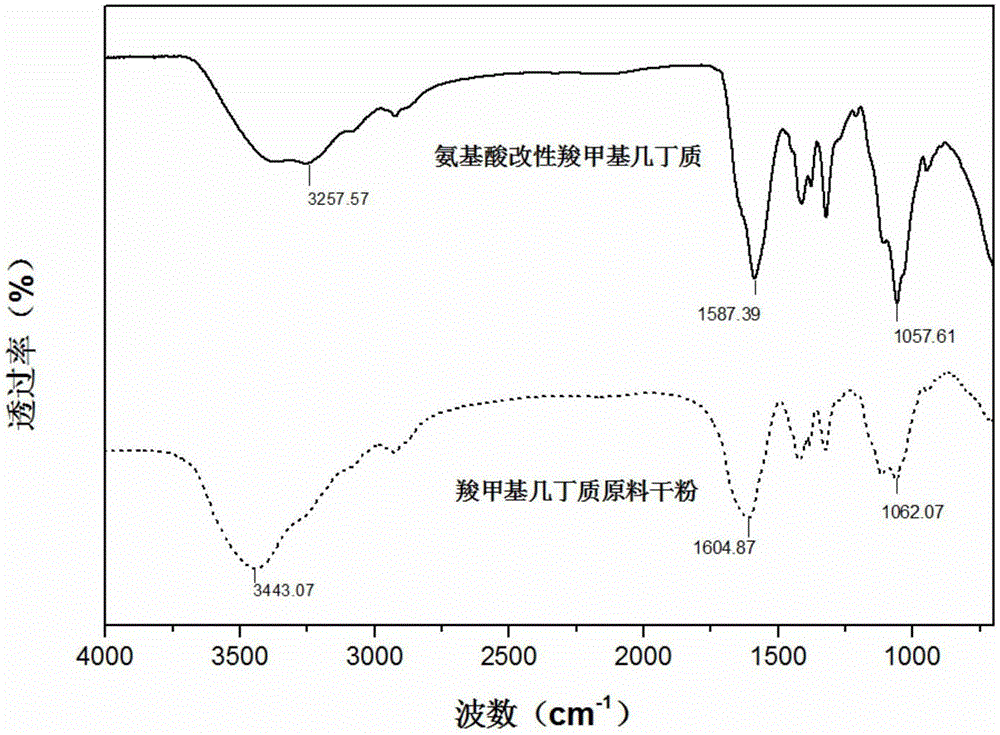

Preparation method of carboxymethyl chitin critical hydrogel

ActiveCN106474569AStay stickyStay flexibleSurgeryPharmaceutical delivery mechanismViscous modulusBiocompatibility Testing

The invention provides a preparation method of a completely new gel form, namely a critical gel, wherein with carboxymethyl chitin as a raw material and natural and non-toxic amino acid, namely lysine, as a modifying substance, the critical gel is prepared under the catalytic action of a coupling reagent, namely 4-(4,6-dimethoxytriazin-2-yl)-4-methyl morpholine hydrochloride (DMTMM). The gel has the main characteristic that the gel can constantly keep viscous modulus and elasticity modulus equal, which is to say the gel possesses two properties, namely high viscosity and high elasticity. The modified gel, which is under a 'critical state', can achieve terminal sterilization, prolong an in vivo residue time and achieve single-dose injection; with the application of the non-toxic amino acid modifying substance, the intrinsic biocompatibility and bio-activity of the carboxymethyl chitin are reserved, and all potential risks are avoided; since the viscous modulus and the elasticity modulus are simultaneously increased and are constantly kept equal, the viscoelasticity of the carboxymethyl chitin is enhanced; and meanwhile, the original liquid state of the carboxymethyl chitin is kept, so that pain in injection can be relieved easily.

Owner:SHANGHAI QISHENG BIOLOGICAL PREPARATION CO LTD

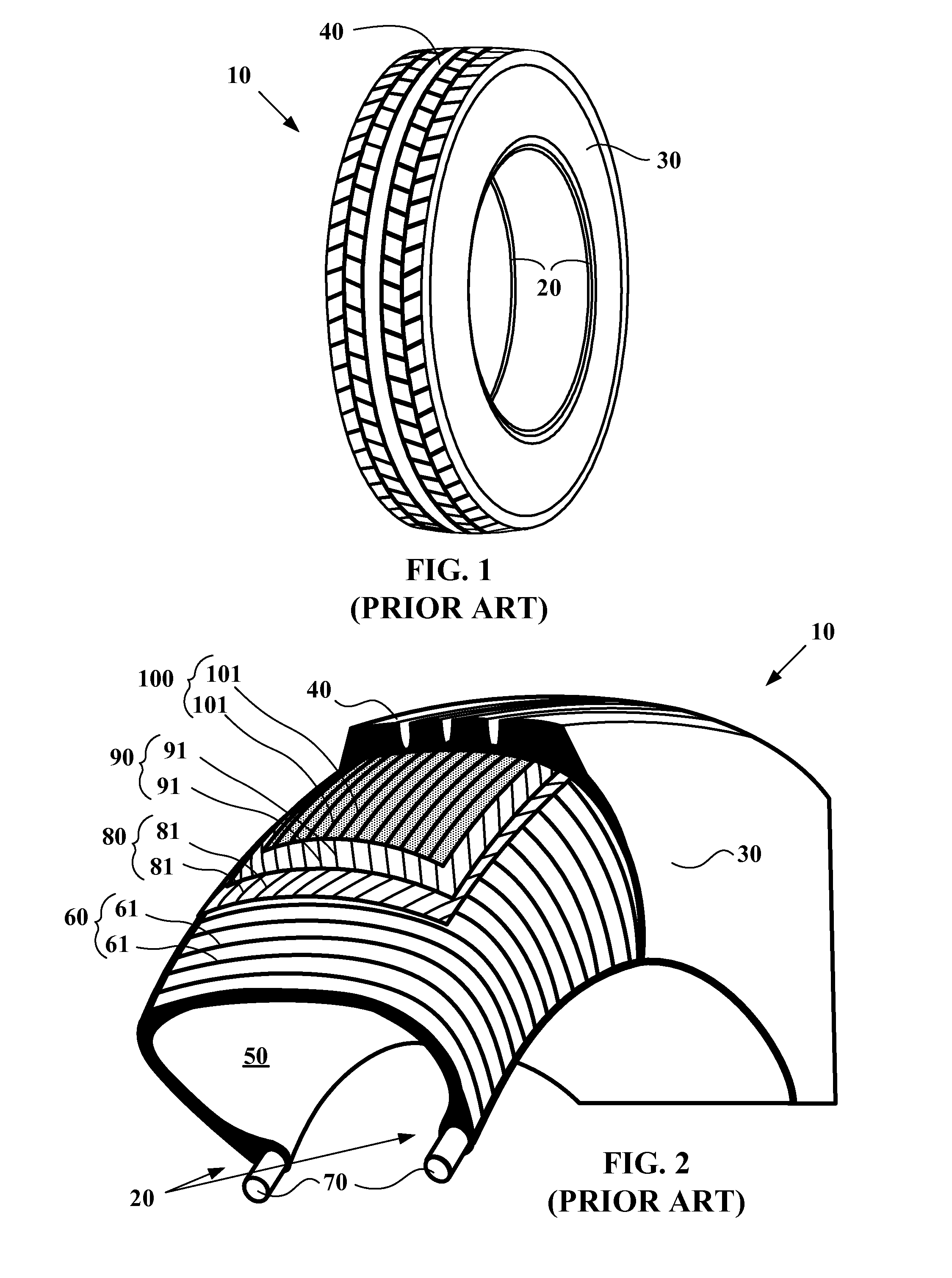

Motor vehicle tire with low rolling resistance

InactiveUS7150301B2RSs is decreasedWithout separate inflatable insertsSpecial tyresViscous modulusRolling resistance

A tire for a motor vehicle includes at least one carcass ply, a belt structure radially external to the at least one carcass ply, a tread band radially external to the belt structure, a pair of sidewalls axially-external to the at least one carcass ply, and a pair of beads. The beads include bead wires or circumferentially-inextensible annular inserts. Opposite lateral edges of the at least one carcass ply are associated with respective beads. The at least one carcass ply includes a first composition having an elastic modulus at 70° C. less than or equal to 5.0 MPa and a viscous modulus at 70° C. less than or equal to 0.50 MPa. The sidewalls include a second composition having an elastic modulus at 70° C. greater than or equal to 3.5 MPa and a viscous modulus at 70° C. less than or equal to 0.50 MPa.

Owner:PIRELLI TYRE SPA

Ultrasonic tissue mimicking phantom as well as preparation method and application thereof

ActiveCN107446293AEasy to operateProcess conditions are easy to controlInfrasonic diagnosticsSonic diagnosticsCross-linkViscous modulus

The invention provides an ultrasonic tissue mimicking phantom as well as a preparation method and application thereof. The ultrasonic tissue mimicking phantom is prepared by performing a cross-linking reaction on a mixed liquid of a polyacrylamide mixture, water, scatters and glycerinum. By controlling the components of the polyacrylamide mixture, the elasticity modulus of the ultrasonic tissue mimicking phantom is adjusted and controlled, and by adding glycerinum, the viscous modulus of the ultrasonic tissue mimicking phantom is adjusted and controlled, so that adjustability of the elasticity modulus and the viscous modulus of the ultrasonic tissue mimicking phantom is achieved, and relatively rich possibility of the ultrasonic tissue mimicking phantom in inspection and calibration of ultrasonic imaging instruments is provided.

Owner:海斯凯尔(山东)医学科技有限公司

Preparation method of laser transparent ceramic optical fiber with waveguide structure based on Isobam gel-state dip-coating technology

ActiveCN112341184AAchieve preparationEffective bondingCladded optical fibreOptical waveguide light guideViscous modulusCore (optical fiber)

The invention discloses a preparation method of a laser transparent ceramic optical fiber with a waveguide structure based on an Isobam gel-state dip-coating technology. The preparation method comprises the following steps: preparing a core layer of an Nd: YAG transparent ceramic optical fiber by using a gel forming technology; conducting coating of cladding YAG transparent gel slurry in a core gel state (at an intersection point of an elastic modulus and a viscous modulus) by using the gel state dip-coating technology, thereby achieving effective adhesion of a core layer and the cladding, wherein coating thickness is adjusted through time; and finally, conducting warm isostatic pressing and vacuum sintering to prepare the laser transparent ceramic optical fiber with the waveguide structure. By accurately controlling a gel point in the gel state, effective bonding of the core layer and a cladding ceramic material is realized, an interface is clear, and the method is simple and efficient in process and capable of realizing batch and industrial production.

Owner:XINYI XIYI ADVANCED MATERIALS RES INST OF IND TECH CO LTD

Cross-linked hyaluronic acid gel

The invention relates to a cross-linked hyaluronic acid gel. The gel has an elastic modulus of from about 10 Pa to about 1000 Pa at 1 Hz, the viscous modulus of the gel is from about 10 Pa to about 500 Pa at 1 Hz, the ratio tandelta value of the viscous modulus to the elastic modulus of the gel is about 0.4 to about 1.5 at 1 Hz, and the cohesive force is from about 2N to about 10 N. The invention also relates to a preparation method and application of the cross-linked hyaluronic acid gel.

Owner:烟台德胜海洋生物科技有限公司

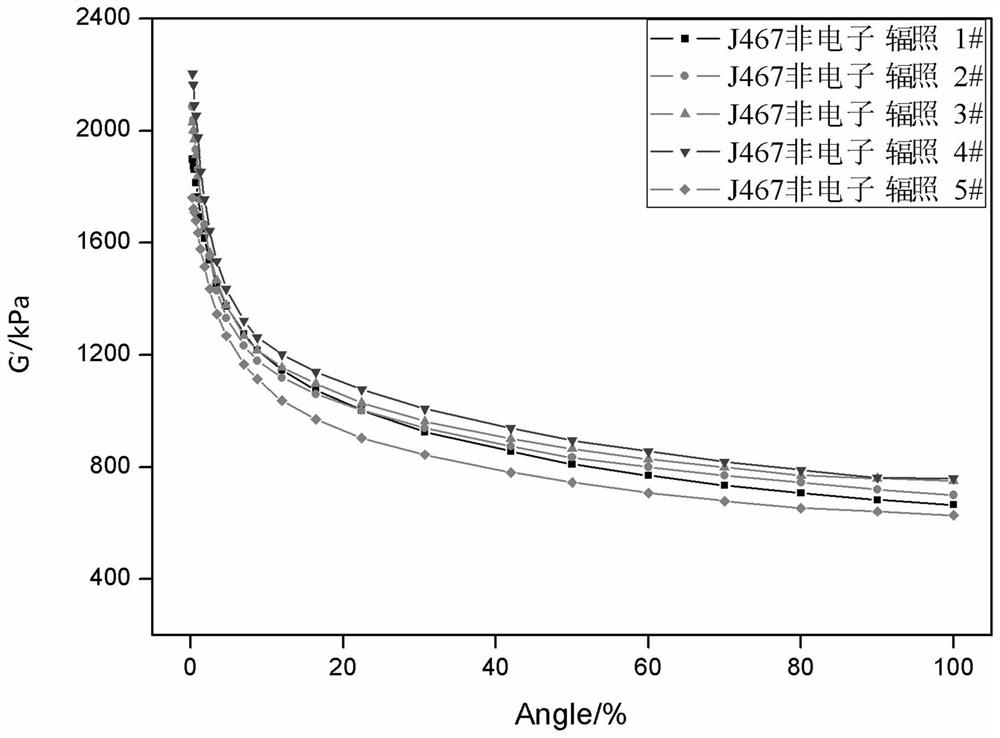

Evaluation method and device for pre-crosslinking of carcass ply rubber compound and computer readable carrier medium

ActiveCN114235607AStructural influenceNo pollution in the processFlow propertiesMaterial strength using repeated/pulsating forcesPolymer scienceViscous modulus

The invention belongs to the technical field of rubber detection, and particularly relates to an evaluation method and device for pre-crosslinking of a carcass ply rubber compound and a computer readable carrier medium. According to the evaluation method for pre-crosslinking of the carcass ply rubber compound, the elastic modulus and the viscous modulus obtained through strain scanning of a rubber processing analyzer are used for drawing corresponding to strain changes, a curve not only can reflect the modulus, but also can visually distinguish the elastic modulus and the viscous modulus of the rubber compound, and therefore the pre-crosslinking of the carcass ply rubber compound is evaluated. And deducing the pre-crosslinking rate of the carcass ply after electron irradiation according to the curve area. The method provided by the invention is simple to operate, high in sensitivity, accurate and reliable in test result and free of environmental pollution.

Owner:ZHONGCE RUBBER GRP CO LTD

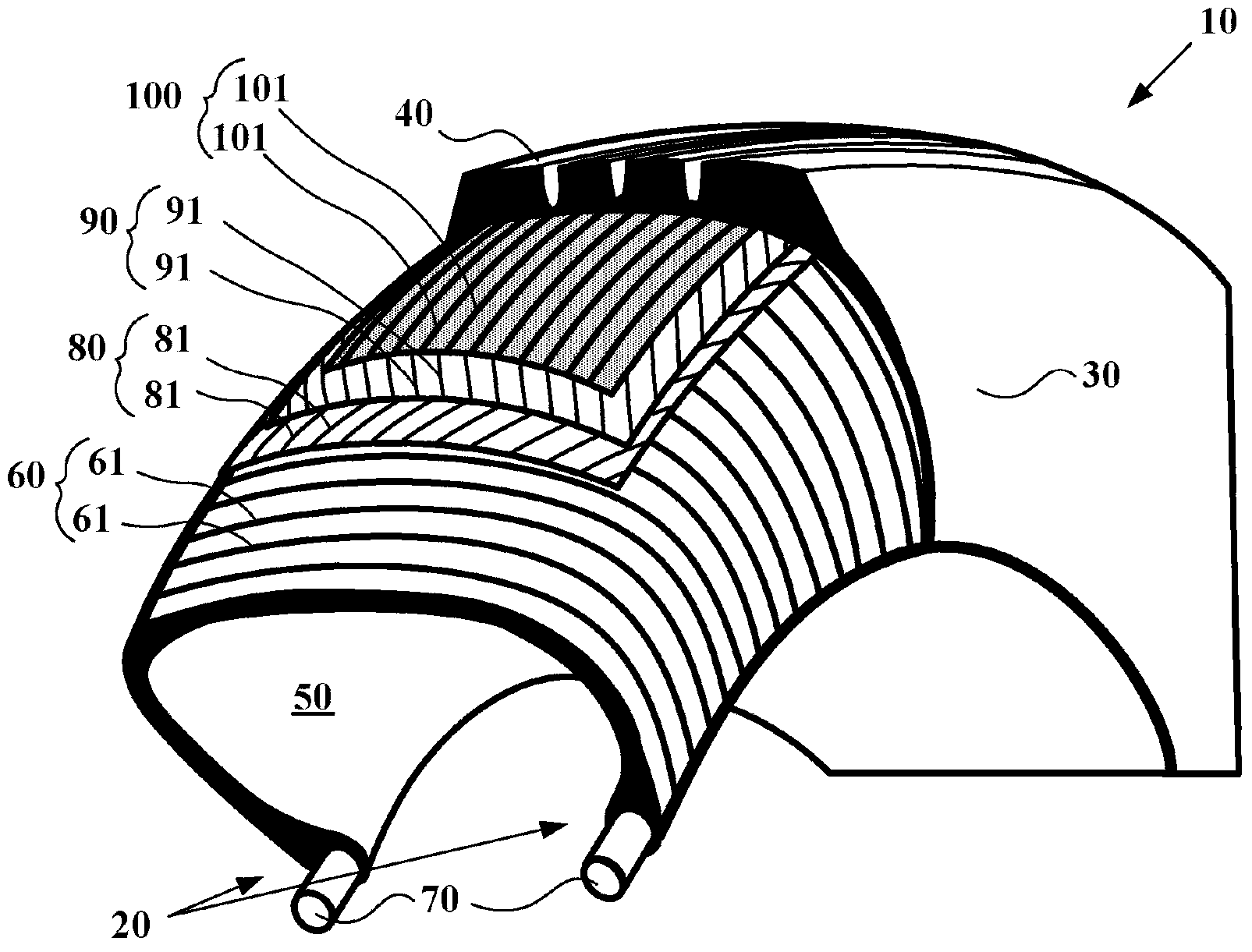

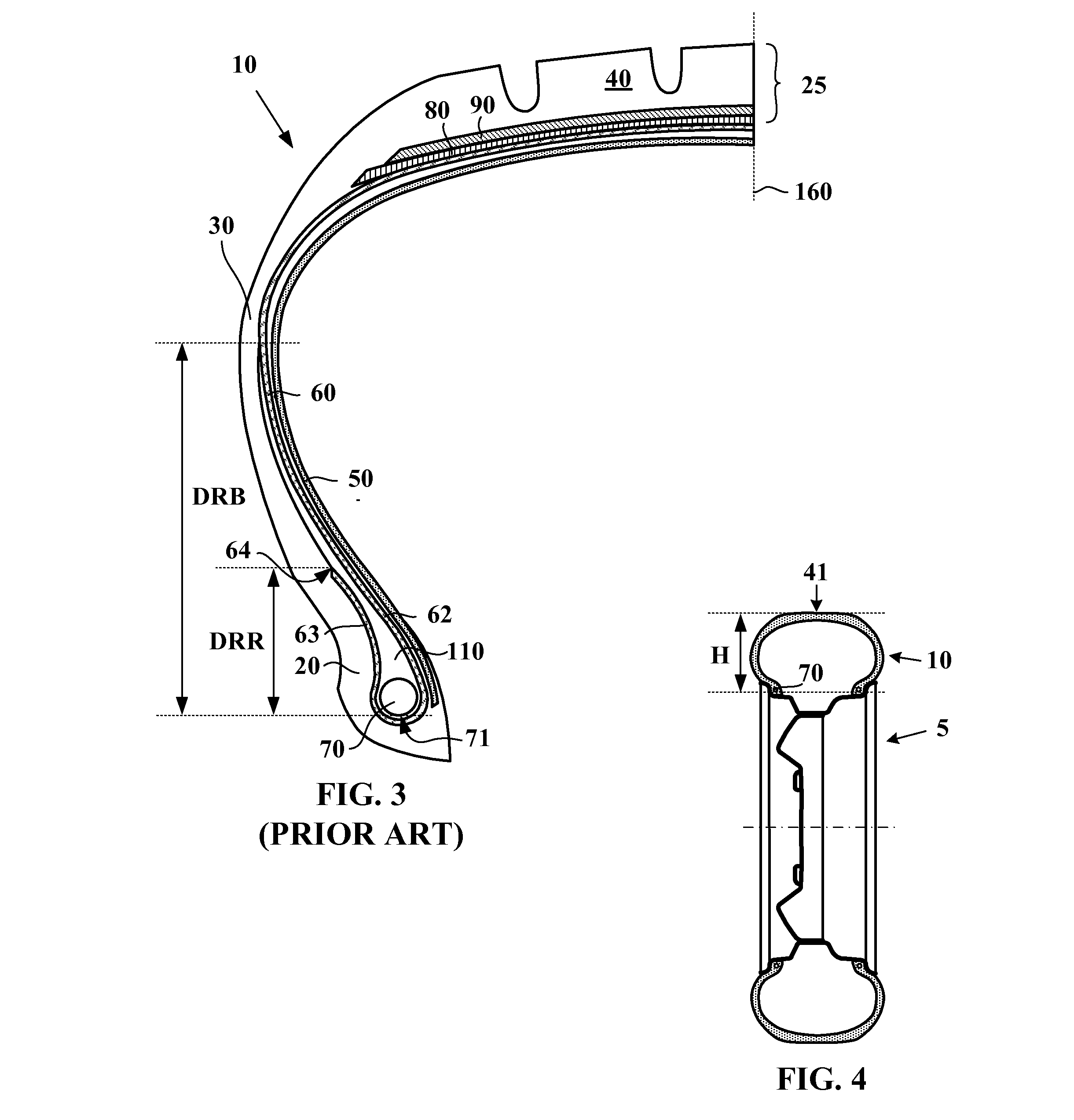

Tire with improved beads

ActiveUS20140360647A1Reduce rolling resistanceImprove cornering stiffnessSpecial tyresTyre beadsViscous modulusEngineering

Tire having two beads each comprising an annular reinforcing structure and a carcass reinforcement which is anchored in the two beads by being wrapped around the annular reinforcing structure so as to form, in each bead, a main portion and a wrapped-around portion, wherein each bead comprises an apex situated between the main portion and the wrapped-around portion of the carcass reinforcement, and an outer strip positioned axially on the outside of the carcass reinforcement and of the apex, the apex and the outer strip being made of a rubber compound that has an elastic modulus G′ less than or equal to 15 MPa and a viscous modulus G″ such that: G″ [MPa]≦0.2·G′ [MPa]−0.2 MPa, the elastic and viscous moduli being measured at 23° C.; wherein the entity formed by the apex and the outer strip has a thickness E(r), the thickness E(r) varying such that, in the range of distances r comprised between 25 and 45% of the height H of the tire, the variation in thickness∂E(r)∂ris less than or equal to −0.25 mm / mm over at least 4% of the height H of the tire, that, in the range of distances r comprised between 15 and 35% of the height H, the variation in thickness∂E(r)∂ris greater than or equal to 0.20 mm / mm over at least 2% of the height H of the tire, and that, in the range of distances r comprised between 10 and 20% of the height H of the tire, the variation in thickness∂E(r)∂ris greater than or equal to −0.10 mm / mm and less than or equal to 0.0 mm / mm over at least 5% of the height H of the tire.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

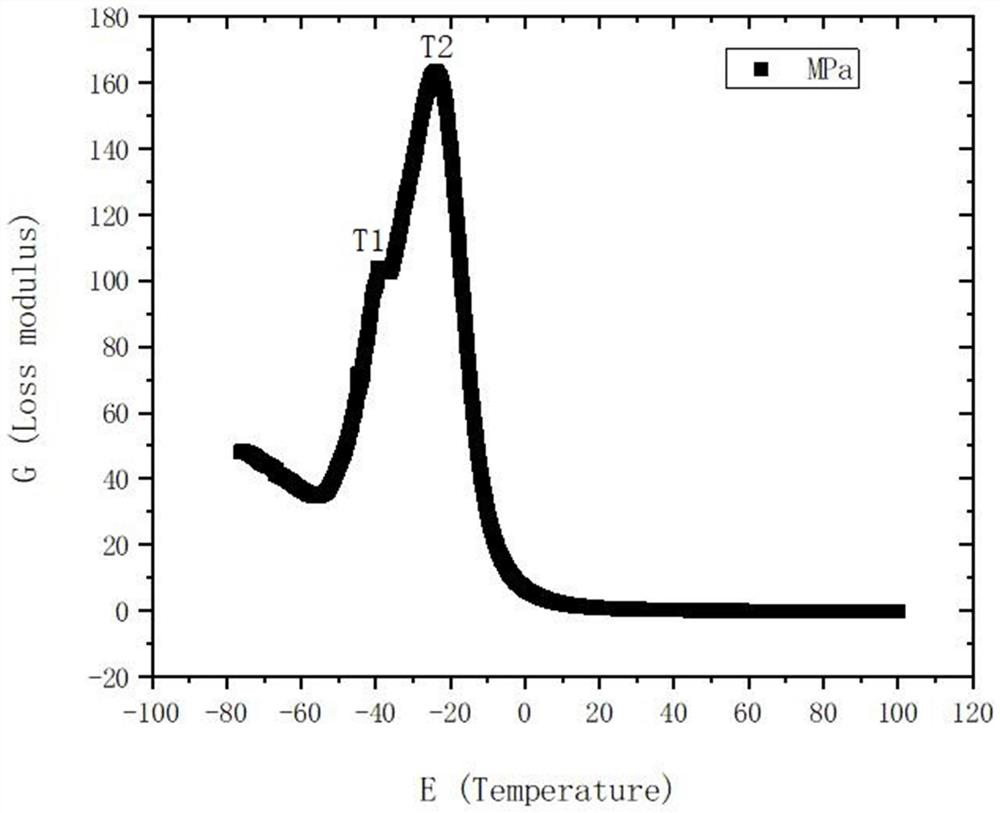

Rubber composition, screening method thereof and tire adopting composition

The invention relates to the field of tire production and manufacturing, in particular to a rubber composition with ultralow abrasion and ultralow rolling resistance for production, a screening method of the rubber composition and a tire adopting the composition. The rubber composition comprises two rubber components and a filler comprising at least white carbon black, wherein the rubber components are microscopically phase-separated into two phases in a rubber compound, and the two rubber components exhibits different peak temperatures in a temperature scanning curve of a viscous modulus G''. The rubber composition is ulcanized to obtain a G'' value and the peak temperature of a temperature scanning curve of T1 and T2, the temperature corresponding to the peak with a low temperature is recorded as T1, and the temperature corresponding to the peak with a high temperature is recorded as T2, wherein the relationship between T1 and T2 needs to meet the condition that T2-T1 is more than 0 DEG C and less than 20 DEG C. According to the invention, G'' is used for characterizing Tg, polymers with different Tg are not used for obtaining a partial microcosmic phase separation effect, and finally the tire tread rubber composition with good rolling resistance and abrasion balance is obtained.

Owner:ZHONGCE RUBBER GRP CO LTD

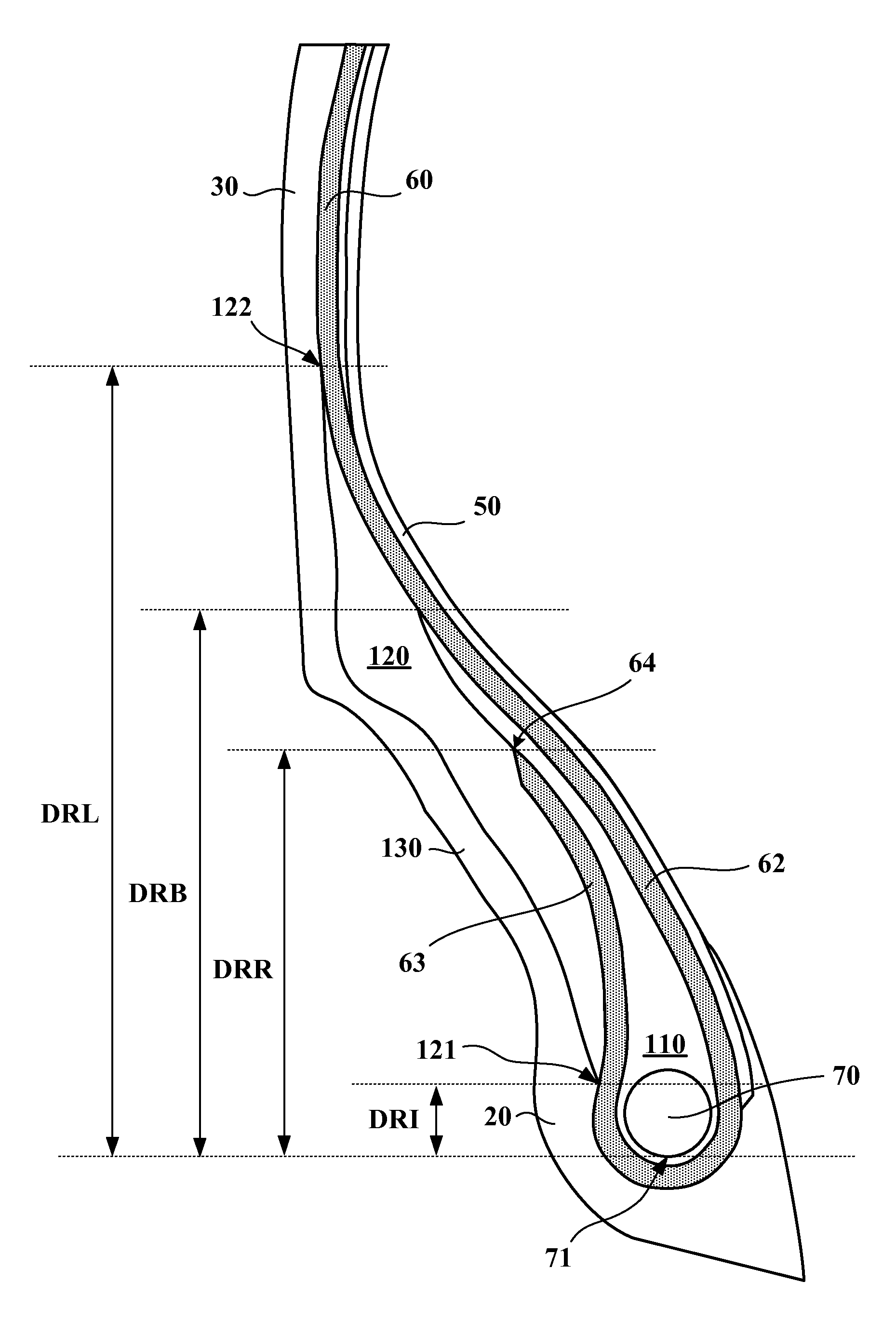

Tyre with improved beads

Tyre comprising two beads (20), two sidewalls (30) joining in a crown, and at least one carcass reinforcement (60) extending from the beads through the sidewalls to the crown, the carcass reinforcement being anchored in the two beads by a turn-up around an annular reinforcing structure (70) in such a way as to form in each bead an incoming portion (61 ) and a wrapped-around portion (62), wherein each bead comprises a bead filler (1 10) and an outer band (120), the latter being placed axially outside of both the carcass reinforcement and the bead filler, wherein the outer band (120) is made of a rubber compound having an elastic modulus G' less than or equal to 15 MPa and a viscous modulus G" such that: G" [MPa] = 0.2G' [MPa] - 0.2 MPa, the elastic and viscous moduli being measured at 23 DEG C.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

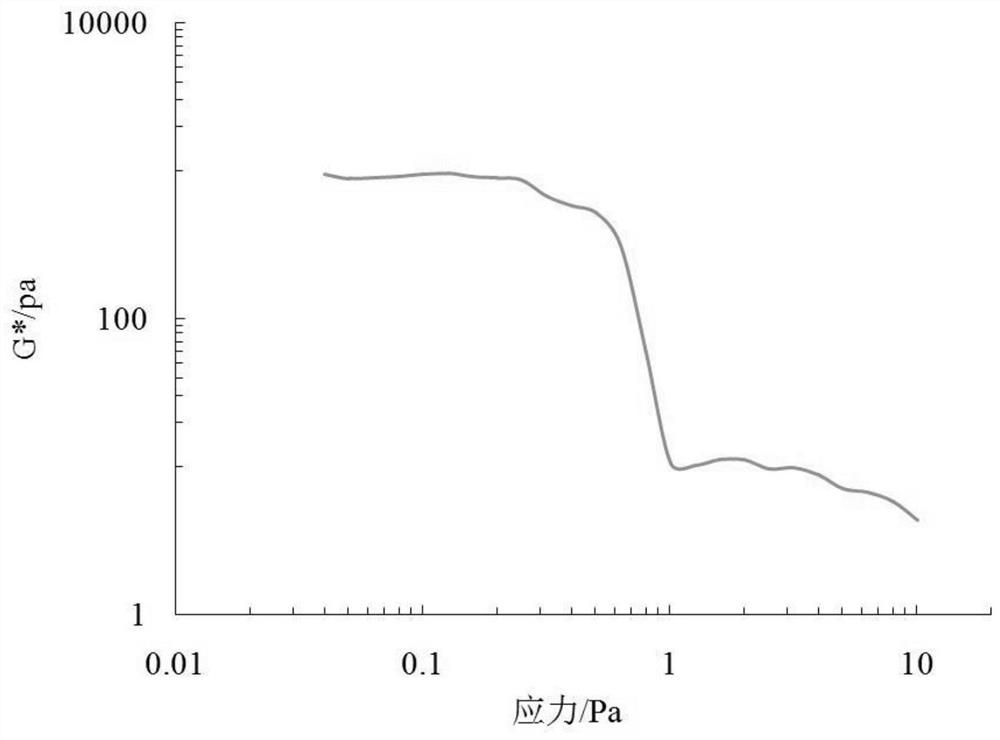

Cationic-anionic surfactant mixed system gel and preparation method thereof

ActiveCN104549077AHigh viscoelasticitySimple processDrilling compositionGel preparationViscous modulusFatty acid

The invention provides cationic-anionic surfactant mixed system gel and a preparation method thereof. The preparation method for the gel comprises the following steps: exchanging a halide ion in a cationic hydrocarbon surfactant solution into a hydroxyl ion through an anionic exchanger to obtain a solution A, and calibrating concentration of the solution A through a standard HCl solution; adding an anionic fluorocarbon fatty acid surfactant and the solution A into tri-distilled water, wherein the sum of concentration of anionic fluorocarbon fatty acid surfactant and solute in the solution A is 0.050-0.130mol.L<-1>, and a molar ratio of the anionic fluorocarbon fatty acid surfactant to the solute in the solution A is (8:2)-(1:1); heating until the hydrocarbon surfactant is completely dissolved, and reacting for 30-60 minutes; cooling the solution to the room temperature and keeping the temperature for 4-8 weeks at 25-50 DEG C after centrifuging and removing foams, so as to obtain the gel. The gel has high elasticity modulus and high viscous modulus, the elasticity is far higher than the viscidity, the gel is formed by closely packing polyhedral vesicles and novel in structure.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Tyre with improved beads

Tyre comprising two beads (20) comprising an annular reinforcing structure (70) and a carcass reinforcement (60) which is anchored in the two beads by being wrapped around the annular reinforcing structure so as to form, in each bead, a main portion (62) and a wrapped-around portion (63), in which each bead comprises a bead filler (110) situated between the main portion and the wrapped-around portion of the carcass reinforcement, and an outer strip (120) positioned axially on the outside of the carcass reinforcement and of the bead filler, the bead filler (110) and the outer strip (120) being made of a rubber compound that has an elastic modulus G' less than or equal to 15 MPa and a viscous modulus G" such that: G"[MPa] <= 0.2 G' [MPa] - 0.2 MPa, the elastic and viscous moduli being measured at 23 DEG C; in which the entity formed by the bead filler (110) and the outer strip (120) has a thickness E(r), the thickness E(r) changes as a function of the distance r such that, in the range of distances r comprised between 25 and 45 % of the height H of the tyre, the variation in thickness (X) is less than or equal to - 0.25 mm / mm over at least 4 % of the height H of the tyre, and in which the annular reinforcing structure has a maximum axial width DE such that the ratio (Y), where E(r)max is the maximum value of the thickness E(r), is less than or equal to 10%.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Reduction of misting in high speed offset printing

An ink or coating composition is rheologically tested at three or more temperatures which substantially cover the anticipated range of printing operation temperatures expected to be encountered during printing to determine the value of the rheological parameters viscous modulus, phase angle and phase-angle slope, and to identify values of these parameters encountered during printing around which the structural behavior of the ink or coating changes. An ink composition that has a phase angle of at least 55°, a viscous modulus of at least 150 Pa, and a phase-angle slope of at least −0.5° / ° C. exhibits low misting when employed in high speed printing apparatus.

Owner:SUN CHEM CORP

A kind of anion-cation surfactant mixed system gel and preparation method thereof

ActiveCN104549077BNovel structureRich research fieldsDrilling compositionGel preparationViscous modulusFatty acid

The invention provides cationic-anionic surfactant mixed system gel and a preparation method thereof. The preparation method for the gel comprises the following steps: exchanging a halide ion in a cationic hydrocarbon surfactant solution into a hydroxyl ion through an anionic exchanger to obtain a solution A, and calibrating concentration of the solution A through a standard HCl solution; adding an anionic fluorocarbon fatty acid surfactant and the solution A into tri-distilled water, wherein the sum of concentration of anionic fluorocarbon fatty acid surfactant and solute in the solution A is 0.050-0.130mol.L<-1>, and a molar ratio of the anionic fluorocarbon fatty acid surfactant to the solute in the solution A is (8:2)-(1:1); heating until the hydrocarbon surfactant is completely dissolved, and reacting for 30-60 minutes; cooling the solution to the room temperature and keeping the temperature for 4-8 weeks at 25-50 DEG C after centrifuging and removing foams, so as to obtain the gel. The gel has high elasticity modulus and high viscous modulus, the elasticity is far higher than the viscidity, the gel is formed by closely packing polyhedral vesicles and novel in structure.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Low residue antiperspirant gel-solid stick compositions containing select gellants

Anhydrous antiperspirant gel-solid stick compositions are disclosed comprising a particulate antiperspirant active, a solid non-polymeric gelling agent selected from the group consisting of 12-hydroxystearic acid, 12-hydroxystearic acid, esters, amides of 12-hydroxystearic acid, and combinations thereof; and an anhydrous liquid carrier, the average solubility parameter ((cal / cm 3 ) 0.5 ) is about 3-13; wherein the visible residue index of the composition is about 11-30 L-value, the product hardness is about 500-5000 g·force, elastic modulus (G′) and viscous modulus (G″) The ratio is about 0.1-100.The refractive indices of the particulate antiperspirant active, the solid non-polymeric gelling agent and the anhydrous liquid carrier need not be matched. The solid non-polymeric gelling agent preferably has an average particle size of less than about 1 micron and / or crystalline particles in the form of elongated particles having an aspect ratio greater than about 2. These antiperspirant gel-solid stick compositions provide improved low residue performance, efficacy and aesthetics.

Owner:THE PROCTER & GAMBLE COMPANY

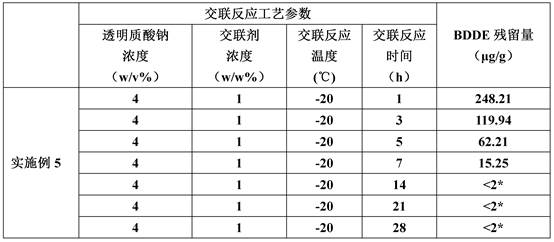

Emulsified cross-linked sodium hyaluronate gel microspheres for injection and preparation method thereof

ActiveCN111686664AIncrease acquisition rateReduce surface tensionMicroballoon preparationProsthesisViscous modulusAlcohol

The invention provides a preparation method of emulsified cross-linked sodium hyaluronate gel microspheres for injection. The preparation method comprises the following steps: firstly, preparing an emulsion of sodium hyaluronate microsphere particles; adding a cross-linking agent into the emulsion according to a certain mass ratio of the cross-linking agent to the sodium hyaluronate;, stirring anduniformly mixing the components in an ice bath, then stirring the mixture at room temperature to carry out primary reaction; and finally stirring the reactant in a water bath at 35-42 DEG C to reactto obtain a microsphere emulsion; cleaning the reaction product with n-hexane, ethyl acetate and absolute ethyl alcohol in sequence. According to the preparation method, uniform and ordered cross-linking reaction in a single sodium hyaluronate colloidal particle is ensured, so that proper viscous modulus, elastic modulus and pushing force are obtained, cross-linking reaction among the particles isavoided, and the yield of qualified gel microspheres is increased. The gel microsphere is suitable for injection and has a wide application prospect.

Owner:HANGZHOU SINGCLEAN MEDICAL PROD

Tomato peel soluble dietary fiber interpenetrating colloid and preparation method thereof

ActiveCN106729934ALow priceImprove securitySurgical adhesivesFood ingredientsViscous modulusAdditive ingredient

The invention provides tomato peel soluble dietary fiber interpenetrating colloid and a preparation method thereof. Concretely, the interpenetrating colloid provided by the invention has excellent elastic modulus, viscous modulus and hardness, and also has the characteristics of low cost, environment-friendly effect, high safety coefficient and natural ingredients.

Owner:SHANGHAI JIAO TONG UNIV

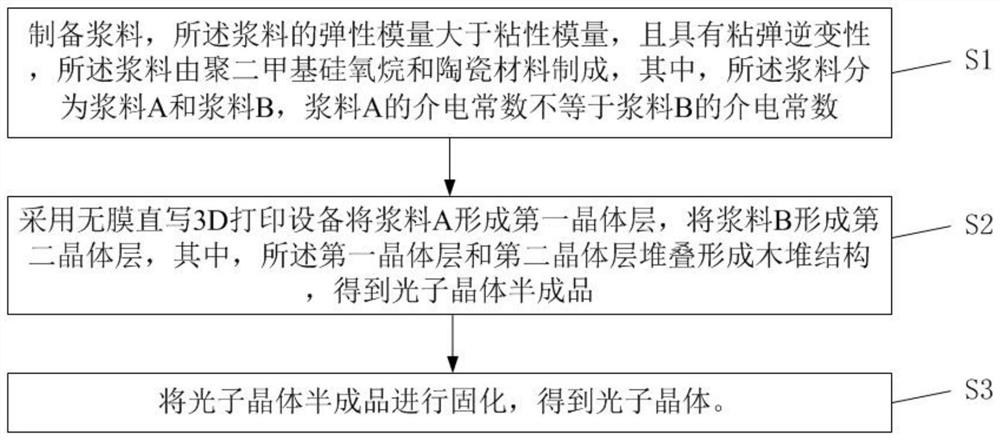

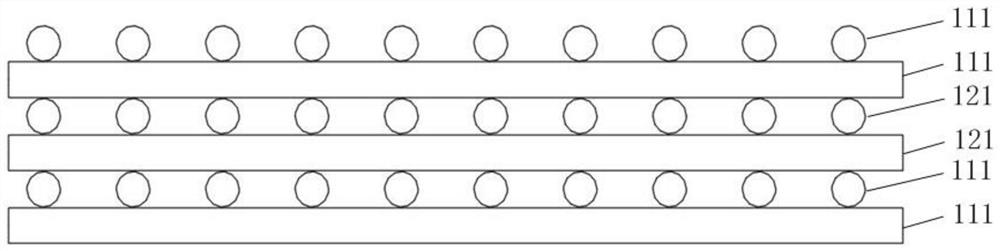

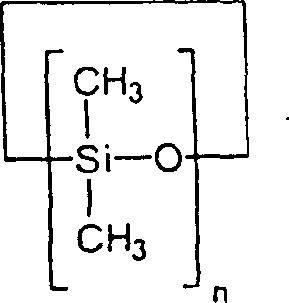

Preparation method of photonic crystal based on 3D printing and photonic crystal

PendingCN113650290AImprove flexibilityImprove ductilityAdditive manufacturing apparatus3D object support structuresViscous modulusPhotonic crystal

The invention discloses a photonic crystal based on 3D printing and a preparation method thereof. The preparation method comprises the following steps that S1, slurry is prepared, the elasticity modulus of the slurry is larger than the viscous modulus, the slurry has viscoelastic inversion performance, the slurry is prepared from polydimethylsiloxane and a ceramic material, the slurry is divided into slurry A and slurry B; the dielectric constant of the slurry A is not equal to that of the slurry B; S2, a first crystal layer is formed from the slurry A and forming a second crystal layer from the slurry B by film-free direct-writing 3D printing equipment, and the first crystal layer and the second crystal layer are stacked to form a wood pile structure to obtain a photonic crystal semi-finished product; and S3, the photonic crystal semi-finished product is cured to obtain the photonic crystal. According to the preparation method, the process is simple, the prepared photonic crystal is high in precision, the stealth of terahertz waves with different frequency bands can be realized, and the applied wave band can be in a range of 10 GHz-10 THz.

Owner:佛山(华南)新材料研究院

Methods of making low residue antiperspirant gel-solid stick compositions

Disclosed are methods of making anhydrous antiperspirant gel-solid stick compositions comprising a particulate antiperspirant active; a solid non-polymeric gellant that is substantially free of dibenzylidene alditol, n-acyl amino acid derivatives, organic polymeric gellants, and inorganic thickening agents; and an anhydrous liquid carrier having an average solubility parameter of from about 3 to about 13 (cal / cm<3>)<0.5>, wherein the composition has a visible residue index of from about 11 to about 30 L-value, a product hardness of from about 500 gram.force to about 5,000 gram.force, a rheology profile defined by a ratio of an elastic modulus (G') to a viscous modulus (G'') of from about 0.1 to about 100. The refractive indices of the particulate antiperspirant active, solid non-polymeric gellant, and anhydrous liquid carrier are not matched. The solid non-polymeric gellant is preferably a crystalline material having an average particle size of less than about 1 mu m, and / or has an elongated particle morphology having an aspect ratio of greater than about 2. These antiperspirant gel-solid stick compositions made in accordance with the methods herein provide improved low residue performance, efficacy and aesthetics.

Owner:THE PROCTER & GAMBLE COMPANY

Reduction of misting in high speed offset printing

Owner:SUN CHEM CORP

Antiperspirant gel-solid stick composition

InactiveCN1245420AImproved low residue performanceHigh hardnessCosmetic preparationsToilet preparationsParticulatesSolubility

Disclosed are anhydrous antiperspirant gel-solid stick compositions which comprise a particulate antiperspirant active; a solid non-polymeric gellant that is substantially free of dibenzylidene alditol, n-acyl amino acid derivatives, organic polymeric gellants, and inorganic thickening agents; and an anhydrous liquid carrier having an average solubility parameter of from about 3 to about 13 (cal / cm<3>)<0.5>, wherein the composition has a visible residue index of from about 11 to about 30 L-value, a product hardness of from about 500 gram.force to about 5,000 gram.force, a rheology profile defined by a ratio of an elastic modulus (G') to a viscous modulus (G'') of from about 0.1 to about 100. The refractive indices of the particulate antiperspirant active, solid non-polymeric gellant, and anhydrous liquid carrier are not matched. The solid non-polymeric gellant is preferably a crystalline material having an average particle size of less than about 1 mu m, and / or has an elongated particle morphology having an aspect ratio of greater than about 2. These antiperspirant gel-solid stick compositions provide improved low residue performance, antiperspirant and aesthetics.

Owner:THE PROCTER & GAMBLE COMPANY

Tire with improved beads

ActiveUS9499014B2Impairing industrial robustnessReduce rolling resistanceSpecial tyresTyre beadsViscous modulusEngineering

Tire having two beads each comprising an annular reinforcing structure and a carcass reinforcement which is anchored in the two beads by being wrapped around the annular reinforcing structure so as to form, in each bead, a main portion and a wrapped-around portion, wherein each bead comprises an apex situated between the main portion and the wrapped-around portion of the carcass reinforcement, and an outer strip positioned axially on the outside of the carcass reinforcement and of the apex, the apex and the outer strip being made of a rubber compound that has an elastic modulus G′ less than or equal to 15 MPa and a viscous modulus G″ such that: G″[MPa]≦0.2·G′[MPa]−0.2 MPa, the elastic and viscous moduli being measured at 23° C.; wherein the entity formed by the apex and the outer strip has a thickness E(r), the thickness E(r) varying such that, in the range of distances r comprised between 25 and 45% of the height H of the tire, the variation in thickness∂E(r)∂ris less than or equal to −0.25 mm / mm over at least 4% of the height H of the tire, that, in the range of distances r comprised between 15 and 35% of the height H, the variation in thickness∂E(r)∂ris greater than or equal to 0.20 mm / mm over at least 2% of the height H of the tire, and that, in the range of distances r comprised between 10 and 20% of the height H of the tire, the variation in thickness∂E(r)∂ris greater than or equal to −0.10 mm / mm and less than or equal to 0.0 mm / mm over at least 5% of the height H of the tire.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

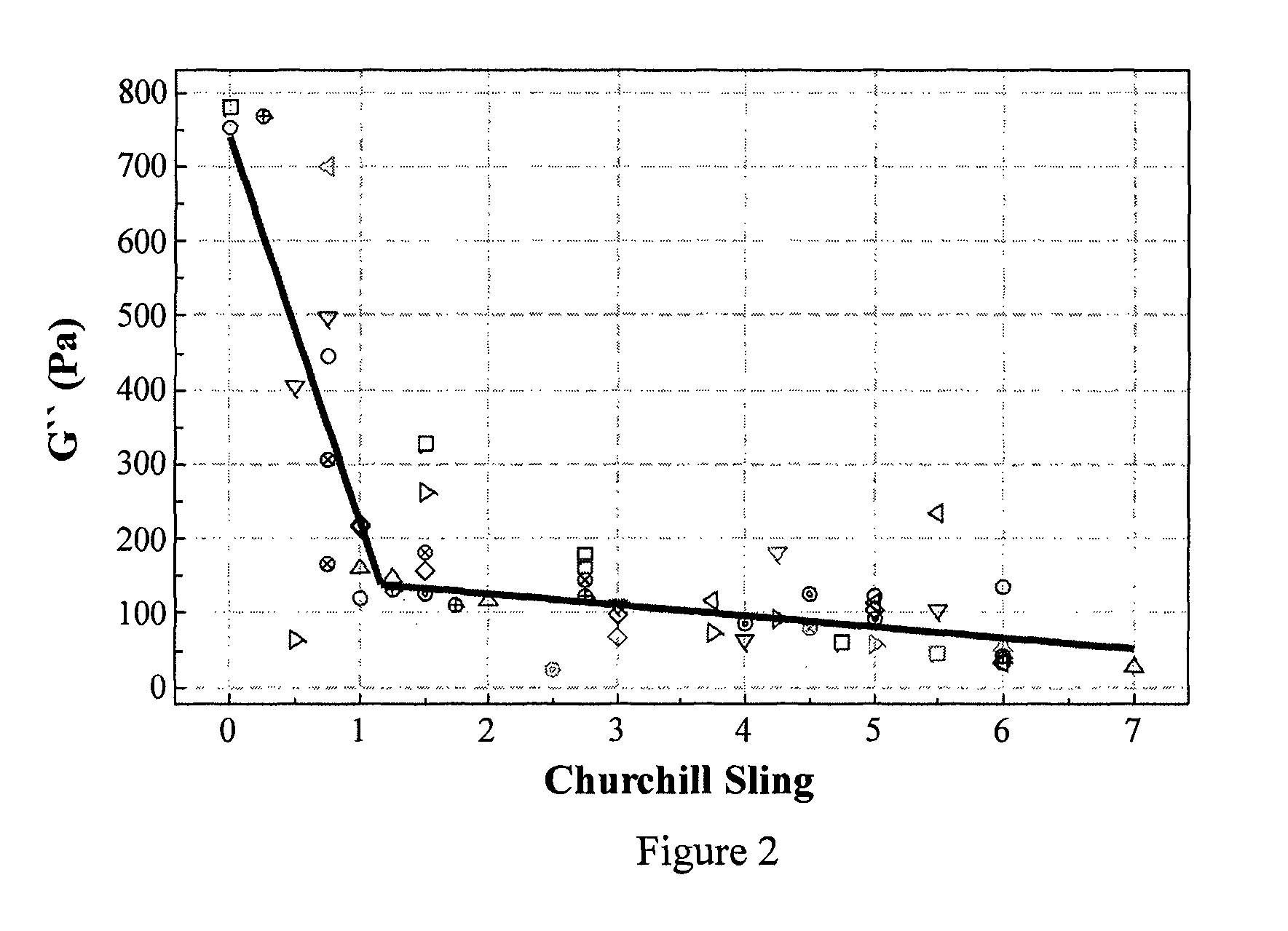

Method for testing suitability of microneedle material suitable for manufacture employing elongation process, and microneedle manufacturing method comprising same

PendingCN113226390AQuality improvementEffective discriminationSurgeryMicroneedlesViscous modulusShear rate

A microneedle manufacturing method according to one embodiment of the present invention comprises the steps: selecting and providing a microneedle material, wherein a value of the viscosity / elasticity coefficient of the microneedle material, measured for each shear rate by a viscoelasticity measurement apparatus, belongs to a scope between pre-arranged upper and lower limits; and manufacturing the microneedle material having been selected and provided in the previous step into a microneedle by means of an elongation method.

Owner:RAPHAS

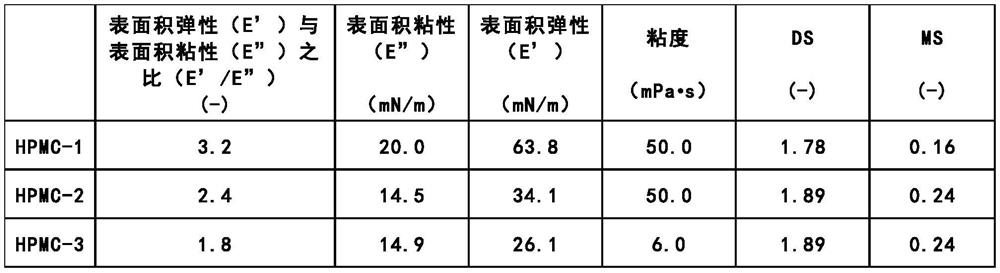

Oil-in-water type composition for whipped cream

PendingCN112335743AEasy to dehydrateModerate pass rateEdible oils/fats ingredientsOther dairy technologyViscous modulusAqueous solution

The objective of the present invention is to provide a composition used for producing a whipped cream which can have improved water separation while maintaining moderate overrun, and which further canstably retain a state of cream. The objective is achieved by an oil-in-water type composition for whipped cream, comprising hydroxypropyl methylcellulose, an oil, a non-fat milk solid and water, wherein a ratio of interfacial elastic modulus to interfacial viscous modulus of the hydroxypropyl methylcellulose is equal to or higher than 2.0 when measured with a tensiometer at 25 DEG C using a 0.2%by mass aqueous solution; and the like.

Owner:SHIN ETSU CHEM IND CO LTD

Method for determining gelling point of emulsified asphalt

PendingCN112067650ASolve the problem that emulsified asphalt cannot be correctly selected according to the technical characteristics of different road surface disposalSimple test methodInvestigating phase/state changeViscous modulusRoad engineering

The invention discloses a method for measuring the gelling point of emulsified asphalt, and belongs to the field of road engineering. The method is characterized in that the temperature correspondingto the condition that the elastic modulus of the emulsified asphalt is equal to the viscous modulus or the temperature when the tangent value of the phase angle is equal to 1 is taken as the gelling point. Compared with the prior art, the method has the advantages that the storage stability and demulsification speed of different emulsified asphalt can be conveniently and quickly identified by calculating the gelling point, and the method has good popularization and application values.

Owner:SHANDONG TRANSPORTATION INST

Chitosan or its derivative multiple cross-linked gel and preparation method

ActiveCN107325306BHigh modulus of elasticityIncreased viscous modulusSurgeryTissue regenerationViscous modulusBiological glue

The invention relates to gel prepared from chitosan or chitosan derivatives by multi-crosslinking and a preparation method. By multi-crosslinking chitosan or the chitosan derivatives, the elasticity modulus and the viscous modulus of the gel are increased and the swelling degree of the gel is reduced under the condition that the crosslinking degree of the gel is not increased. The elasticity modulus and the viscous modulus of the chitosan gel can be further increased each time one crosslinking is increased in the multi-crosslinking process, and the viscoelastic modulus of the gel can be increased by multi-crosslinking under the condition of equal crosslinking degree. The crosslinking times of the chitosan gel are selected according to characteristics of the viscoelastic modulus of different tissue parts, so that the viscoelastic modulus of the chitosan gel is matched with the related tissue, the histocompatibility of the gel in the tissue can be improved, and the use quantity of a crosslinking agent which is irritant or toxic to a human body can be reduced. The gel is applied to the field of soft tissue in tissue engineering such as tissue filling and repair, joint viscoelasticity replenishers, biological scaffolds, anti-cicatricial, anti-adhesion and biological glue and the like.

Owner:IMEIK TECH DEV CO LTD

Antiperspirant gel-solid stick composition

InactiveCN1269541CImproved low residue performanceHigh hardnessCosmetic preparationsToilet preparationsSolubilityParticulates

Disclosed are anhydrous antiperspirant gel-solid stick compositions which comprise a particulate antiperspirant active; a solid non-polymeric gellant that is substantially free of dibenzylidene alditol, n-acyl amino acid derivatives, organic polymeric gellants, and inorganic thickening agents; and an anhydrous liquid carrier having an average solubility parameter of from about 3 to about 13 (cal / cm<3>)<0.5>, wherein the composition has a visible residue index of from about 11 to about 30 L-value, a product hardness of from about 500 gram.force to about 5,000 gram.force, a rheology profile defined by a ratio of an elastic modulus (G') to a viscous modulus (G'') of from about 0.1 to about 100. The refractive indices of the particulate antiperspirant active, solid non-polymeric gellant, and anhydrous liquid carrier are not matched. The solid non-polymeric gellant is preferably a crystalline material having an average particle size of less than about 1 mu m, and / or has an elongated particle morphology having an aspect ratio of greater than about 2. These antiperspirant gel-solid stick compositions provide improved low residue performance, antiperspirant and aesthetics.

Owner:THE PROCTER & GAMBLE COMPANY

Coating with high speed and solid content

The invention discloses a coating with high speed and solid content, comprising heavy calcium carbonate, light calcium carbonate, kaolin pigment, polyvinyl alcohol, latex and thickening agents, wherein the solid content is in the range of 69-71 percent, and the PH value is 8.5-10; the coating includes the following components according to the parts by weight: 65-100 of heavy calcium carbonate, 5-100 of light calcium carbonate, 0-15 of kaolin pigment, 0.1-0.6 of polyvinyl alcohol, 9-11.5 of latex and 0.1-0.55 of thickening agents. The invention effectively reduces the high shearing resistance of the coating with high solid content and can satisfy higher coating speed and relatively lower coating quantity by a scraper. The coating integrally uses the theories of surface chemistry and hydromechanics of coating, the particle encapsulation of coating suspension, and the like, and has a certain performance-required rheological property and viscous modulus. The invention is applied to coating machines, obviously reduces the cost of paper per ton and greatly improves the quality of finished paper.

Owner:GOLD EAST PAPER JIANGSU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com