Method for determining gelling point of emulsified asphalt

A technology of emulsified asphalt and gel point, applied in the investigation phase/state change and other directions, can solve the problems of long time consumption, large human error, inability to identify the demulsification speed, etc., and achieve the effect of simple test method and accurate test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 【Test raw material】

[0027] Fresh cationic emulsified asphalt A.

[0028] 【Test steps】

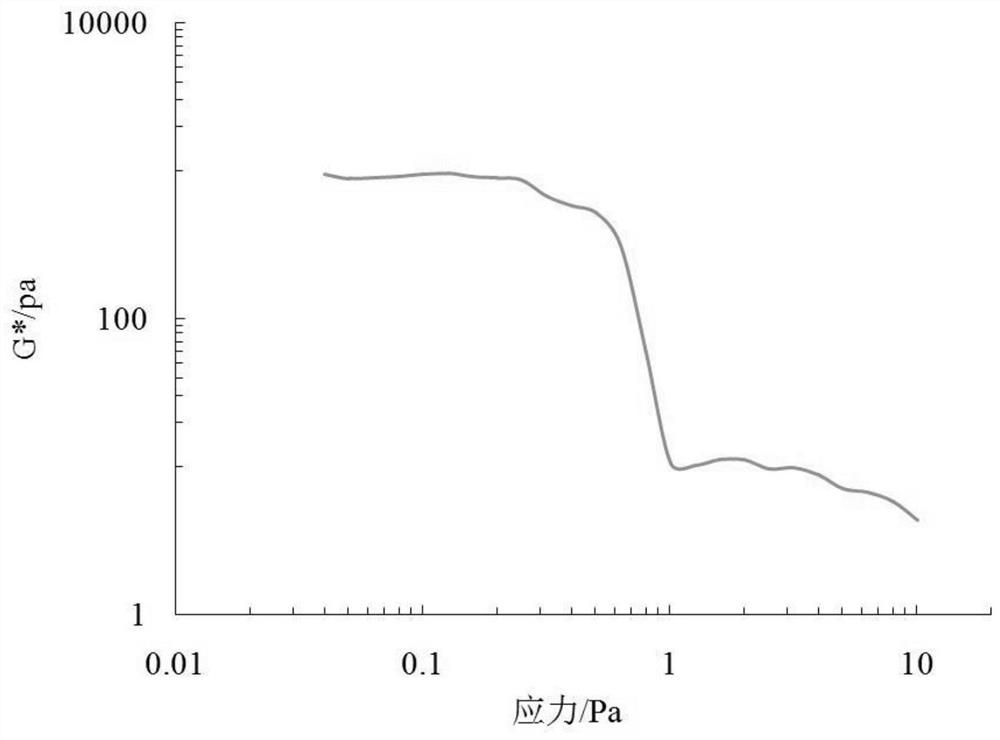

[0029] S1. A stress sweep test was performed on the emulsified asphalt sample A with a dynamic shear rheometer.

[0030] The stress scanning test uses a 25mm flat plate, the test temperature is 25°C, the frequency is 1HZ, and the stress variation range is 0.01-10Pa.

[0031] To draw a G*--stress diagram, see figure 1 , G* is reduced from the initial value to 90% of the original value, and the stress range interval is the linear viscoelastic region, that is, the vibration stress is in the range of 0.04-0.13Pa.

[0032] S2. According to the linear viscoelastic interval, select the stress value of the temperature scanning test as 0.1Pa. The emulsified asphalt sample A was subjected to a temperature sweep test with a dynamic shear rheometer.

[0033] In the temperature scanning test, a 25mm flat plate is used, the test frequency is 1HZ, the test temperature range is 25°C-60°C, the...

Embodiment 2

[0037] The test raw materials and test procedures are the same as those in Example 1, except that the stresses of the temperature scanning test selected in step S2 are 0.08Pa and 0.05Pa.

[0038] The gelation points of emulsified asphalt A obtained under different stresses are:

[0039] 0.1Pa 0.08Pa 0.05Pa gel point 30.5 30.3 30.3

[0040] It can be seen that the gel point of the emulsified asphalt A obtained under different temperature scanning stresses is basically the same, and the test method is stable and reliable.

Embodiment 3

[0042] 【Test raw material】

[0043] Fresh cationic emulsified bitumen B.

[0044] 【Test steps】

[0045] S1. A stress sweep test was performed on the emulsified asphalt sample B with a dynamic shear rheometer.

[0046] The stress scanning test uses a 25mm flat plate, the test temperature is 25°C, the frequency is 1HZ, and the stress variation range is 0.04-10Pa.

[0047] To draw a G*--stress diagram, see image 3 , G* is reduced from the initial value to 90% of the original value, and the stress range is the linear viscoelastic region, that is, the vibration stress is in the range of 0.04-0.17Pa.

[0048] S2. According to the linear viscoelastic interval, select the stress value of the temperature scanning test as 0.1Pa. The emulsified asphalt sample B was subjected to a temperature sweep test with a dynamic shear rheometer.

[0049] In the temperature scanning test, a 25mm flat plate is used, the test frequency is 1HZ, the test temperature range is 25°C-60°C, the heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com