Rubber composition, screening method thereof and tire adopting composition

A rubber composition, rubber technology, applied in special tires, tire parts, transportation and packaging, etc., can solve problems such as inaccuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

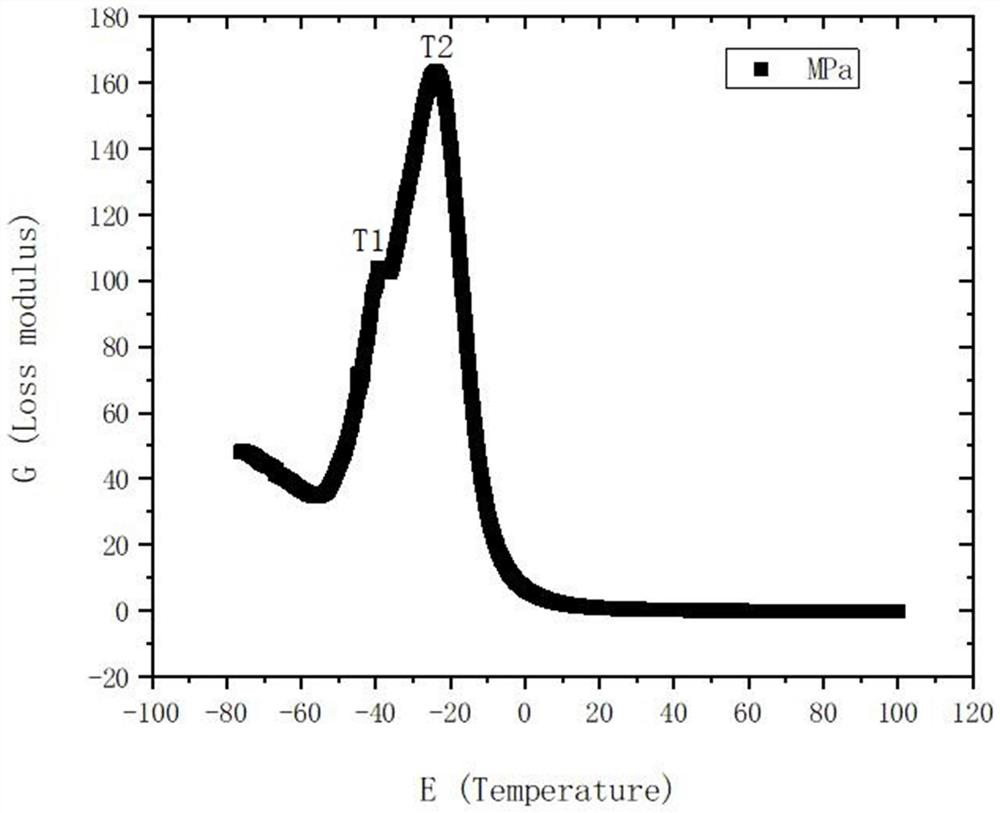

Image

Examples

Embodiment Construction

[0028] The present invention is further illustrated by the following examples, but the scope of the present invention is not limited to these examples.

[0029] Embodiments 1 to 5 and comparative example 1 and comparative example 2 are according to each component in the formula (parts by weight) shown in table 1, raw rubber except vulcanization accelerator and sulfur and compounding ingredients and banburying with 1.7 liters After 5 minutes of machine mixing, the sheet was released, and after standing for 24 hours, the vulcanization accelerator and sulfur were mixed in the mixture for 4 minutes with an 8 inch to obtain a rubber composition.

[0030] These rubber compositions were press-vulcanized at 160° C. for 20 minutes to prepare required abrasion samples and subjected to Akron abrasion tests. For the rolling resistance of tires, different tread compositions are used to make tires, and the composition and structure of other components of the tires are the same.

[0031] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com