Oil-in-water type composition for whipped cream

A technology of oil-in-water whipping cream, which is applied in the fields of cream preparation, application, food science, etc. It can solve the problems of insufficient bubble stability and achieve good taste, good dehydration, good color and good drainage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

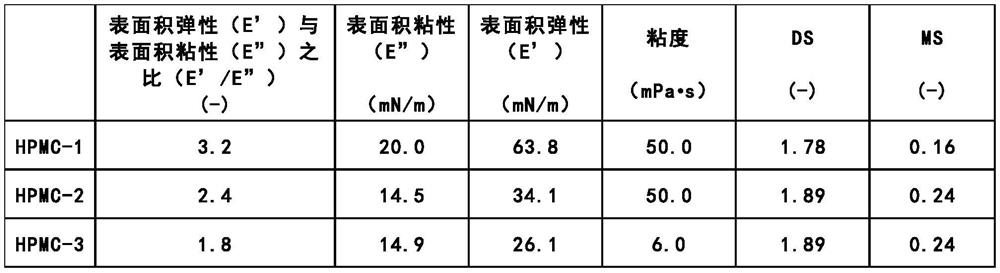

[0103] Hereinafter, the present invention will be described in more detail through synthesis examples, examples and comparative examples, but the present invention is not limited to the synthesis examples and examples.

[0104]

Synthetic example 1

[0105] Synthesis Example 1: Preparation of HPMC-1

[0106] While stirring in a reactor with an internal stirrer, 1.98 parts by mass of a 49% by mass aqueous sodium hydroxide solution was sprayed onto 1.00 parts by mass of wood pulp (solid content 97% by mass) to obtain alkali cellulose.

[0107] Next, while stirring at 70° C., air was blown into the reactor for 70 minutes, thereby allowing the alkali cellulose to react with oxygen in the air to depolymerize the alkali cellulose. At this time, the supply amount of oxygen was 2.5 g per 1 kg of solid content in the wood pulp.

[0108] After the inside of the reactor was evacuated to -95kPa, 1.60 parts by mass of methyl chloride for methoxy substitution and 0.21 parts by mass of propylene oxide for hydroxypropoxy substitution were added to the reactor, at 60°C The reaction was carried out at a temperature of ~90° C. for 2 hours to obtain a crude product of HPMC.

[0109] The crude product of HPMC was washed with hot water at 90°...

Synthetic example 2

[0113] Synthesis Example 2: Preparation of HPMC-2

[0114] In addition to using 2.83 mass parts of 49 mass % sodium hydroxide aqueous solution, alkali cellulose is not depolymerized, 2.13 mass parts of methyl chloride is used, 0.53 mass parts of propylene oxide is used, and 120 Except for the mixed gas of air and nitrogen at °C, preparation of alkali cellulose, etherification reaction, washing, pulverization and drying were carried out in the same manner as in Synthesis Example 1 to obtain powdered HPMC with a water content of 1.2% by mass. The powdery HPMC had a viscosity of 4000 mPa·s at 20° C. in a 2% by mass aqueous solution.

[0115] 12 mass % of hydrochloric acid was sprayed to the obtained powdery HPMC so that hydrogen chloride might be 0.3 mass parts with respect to 100 mass parts of HPMC. HPMC sprayed with hydrochloric acid was reacted for 10 minutes in a rotating glass reactor with a jacket temperature of 80° C. to perform depolymerization.

[0116] Hydrogen chlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com