Cationic-anionic surfactant mixed system gel and preparation method thereof

A surfactant, anion and cation technology, applied in the field of anionic and cationic surfactant mixed system gel and its preparation, can solve the problem of few reports of fluorocarbon surfactant gel, achieve novel structure, high stability, The effect of enriching the field of study

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment prepares a kind of anion-cation surfactant mixed system gel, and concrete steps are:

[0032] The tetradecyltrimethylammonium chloride solution of the cationic hydrocarbon surfactant is passed through the anion exchange resin CG-400 to replace the chloride ions with hydroxide ions to obtain the tetradecyltrimethylammonium hydroxide solution, and use Standard HCl solution was used to calibrate its concentration, and then prepared to a concentration of 0.100mol L -1 The solution.

[0033] Weigh 0.1542g perfluorodecanoic acid (anionic fluorocarbon fatty acid surfactant), measure 2.0mL of 0.100mol L -1 Tetradecyltrimethylammonium hydroxide solution, adding triple distilled water to prepare the total concentration of the two surfactants is 0.100mol L -1 And the solution with a concentration ratio of 6:4 was heated to 60°C and slowly stirred until the perfluorodecanoic acid was completely dissolved, and reacted for 60 minutes.

[0034] Naturally cool the so...

Embodiment 2

[0038] This embodiment prepares a kind of anion-cation surfactant mixed system gel, and concrete steps are:

[0039] The tetradecyltrimethylammonium chloride solution of the cationic hydrocarbon surfactant is passed through the anion exchange resin CG-400 to replace the chloride ions with hydroxide ions to obtain the tetradecyltrimethylammonium hydroxide solution, and use Standard HCl solution was used to calibrate its concentration, and then prepared to a concentration of 0.100mol L -1 The solution.

[0040] Weigh 0.2255g perfluoroundecanoic acid (anionic fluorocarbon fatty acid surfactant), measure 0.100mol L of 1.00mL -1 Tetradecyltrimethylammonium hydroxide solution, adding triple distilled water to prepare the total concentration of the two surfactants is 0.100mol L -1And the solution with a concentration ratio of 8:2 was heated to 80°C and slowly stirred until the perfluoroundecanoic acid was completely dissolved, and reacted for 60 minutes.

[0041] Then the solution...

Embodiment 3

[0045] This embodiment prepares a kind of anion-cation surfactant mixed system gel, and concrete steps are:

[0046] The cationic hydrocarbon surfactant cetyltrimethylammonium chloride solution is passed through the anion exchange resin CG-400 hydroxide ion to replace the chloride ion to obtain the cetyltrimethylammonium hydroxide solution, and the standard HCl solution was used to calibrate its concentration, and then prepared to a concentration of 0.100mol L -1 The solution.

[0047] Weigh 0.1965g perfluorododecanoic acid (anionic fluorocarbon fatty acid surfactant), measure 1.80mL of 100mmol L -1 cetyltrimethylammonium hydroxide solution, adding triple distilled water to prepare the total concentration of the two surfactants is 0.100mol L -1 And the solution with a concentration ratio of 6.4:3.6 was heated to 80°C and stirred slowly until the perfluorododecanoic acid was completely dissolved, and reacted for 60 minutes.

[0048] Then the solution was naturally cooled to ...

PUM

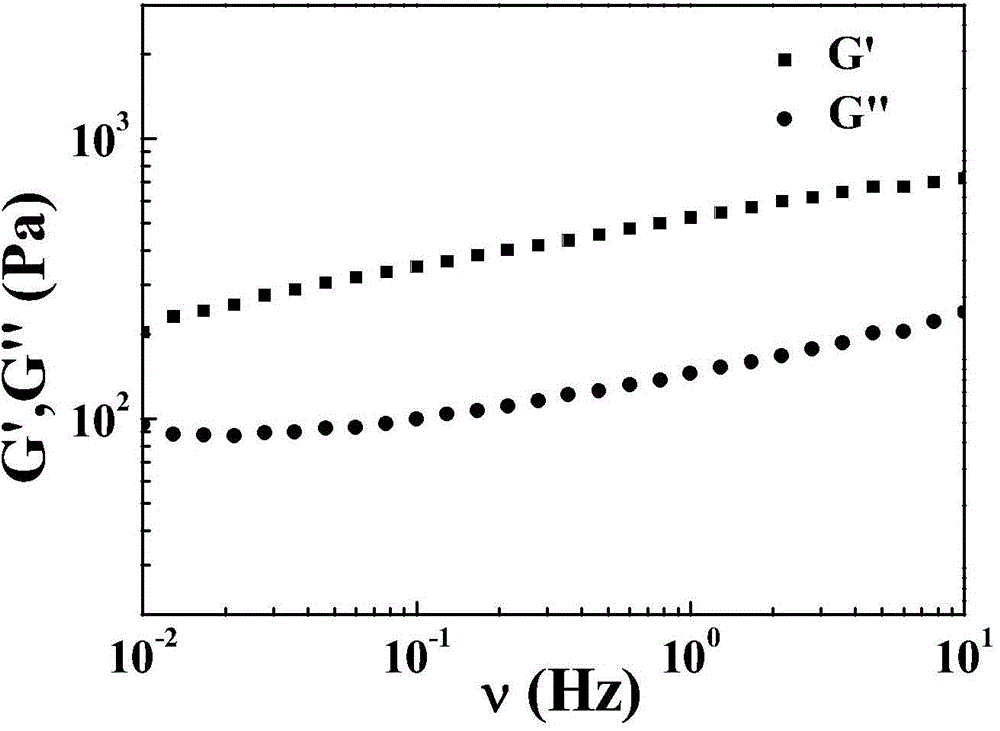

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Viscosity modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com