Wax mold combination of four-connection hollow turbine guide vane and precision casting method of wax mold combination

A turbine guide vane, hollow technology, applied in the direction of casting mold, casting mold composition, casting molding equipment, etc., can solve the problems that cannot completely eliminate casting hot cracks and loose defects, uneven stress, high rejection rate, etc. Small casting stress, not easy to under-cast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

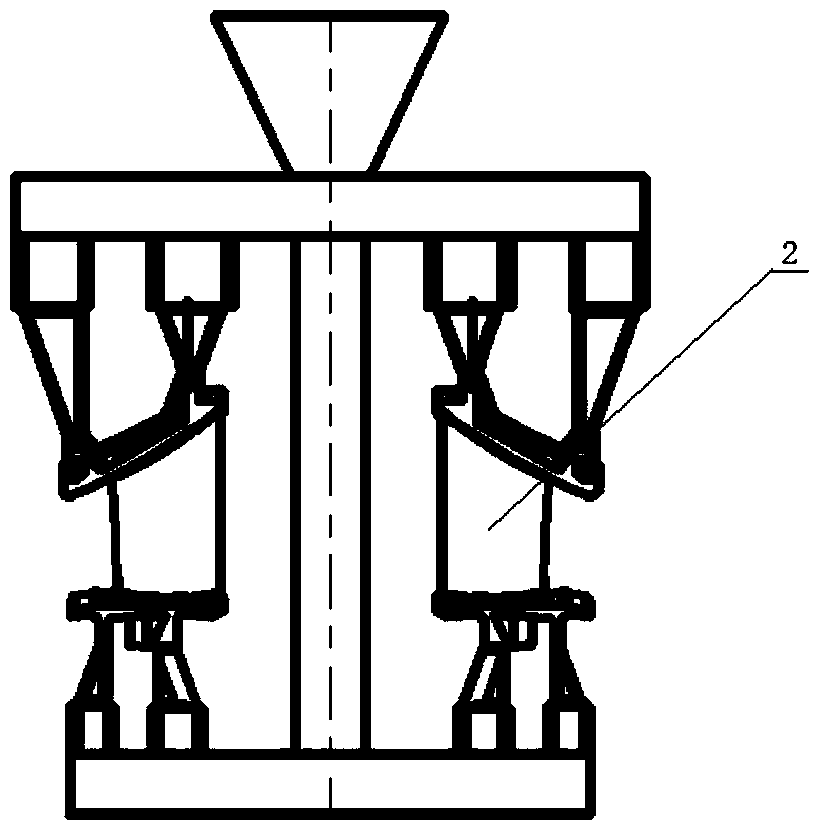

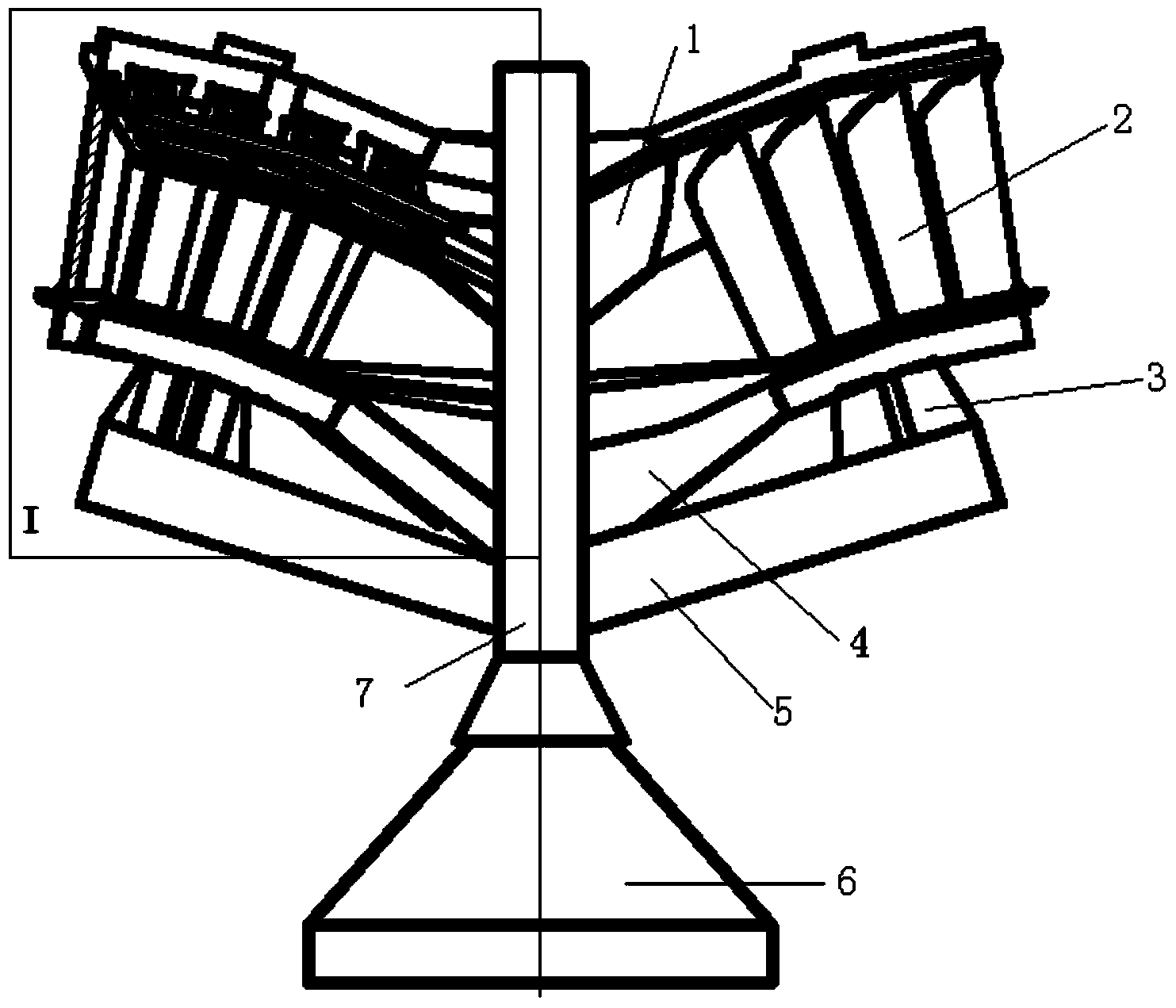

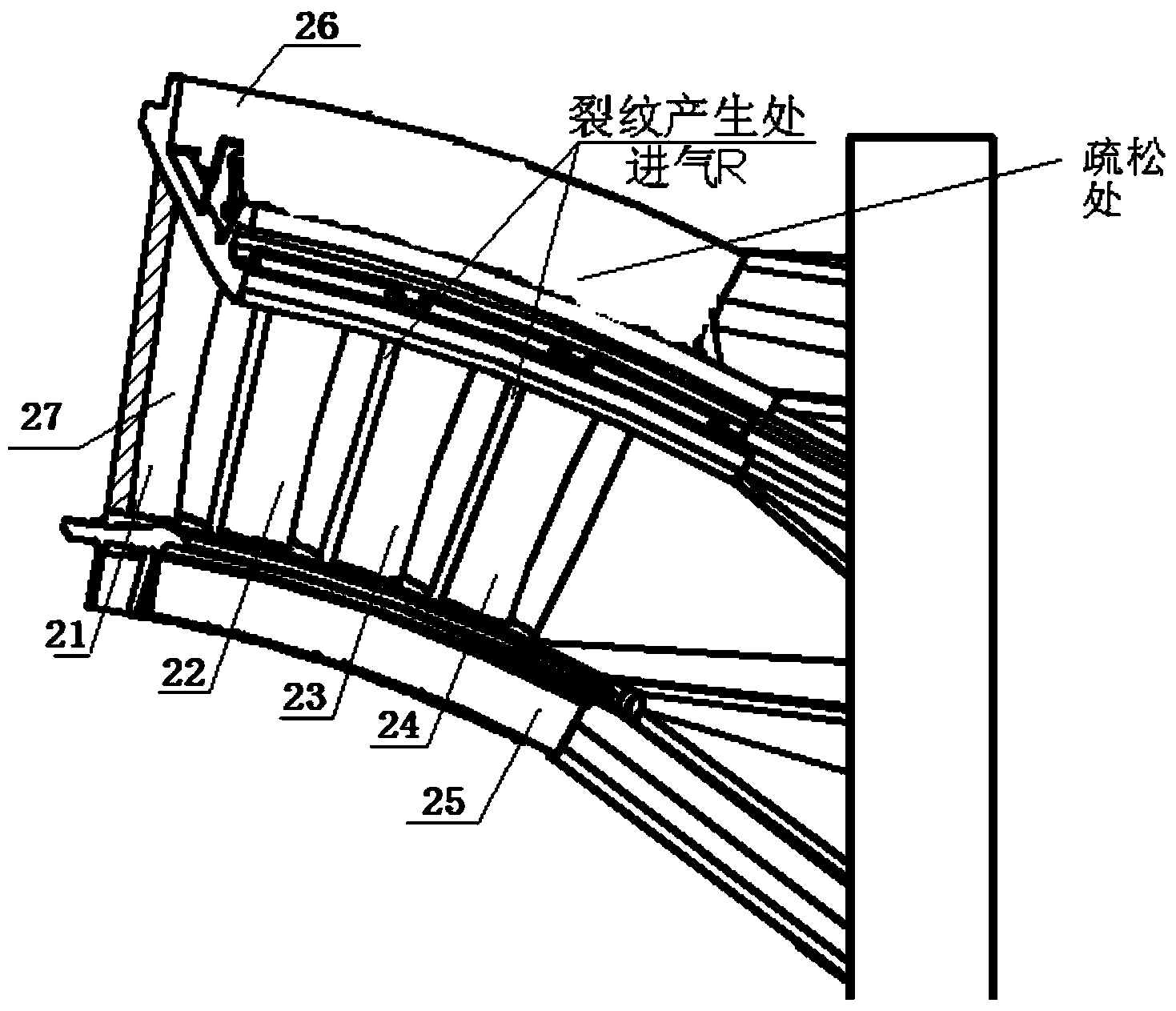

[0028] The wax pattern combination of a kind of quadruple hollow turbine guide vane of the present invention, as figure 2 As shown, it includes a sprue cup 6, and a sprue 7 connected to the outlet end of the sprue cup 6; an ingate assembly is arranged on the side wall of the sprue 7; each ingate assembly includes a blade lower edge plate The lower edge ingate 4 connected to one side of the cavity, and the upper edge ingate 1 connected to the cavity side of the upper edge plate of the blade; the lower edge ingate 4 and the upper edge ingate 1 follow the flow channel 7 in sequence flow direction settings. In this preferred example, two groups of ingate assemblies arranged symmetrically to the central axis are taken as an example for illustration, that is, a combination of two pieces is used; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com