Alloy material for casting and technology of casting large gearbox casting of offshore platform by using alloy material

A technology for offshore platforms and alloy materials, which is applied in the field of casting alloy materials and large gearbox castings for offshore platforms. It can solve the problems of poor filling of molten metal, uneven cooling, and low rate of genuine castings, and achieve the goal of finished products. High efficiency, good fluidity and reasonable formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

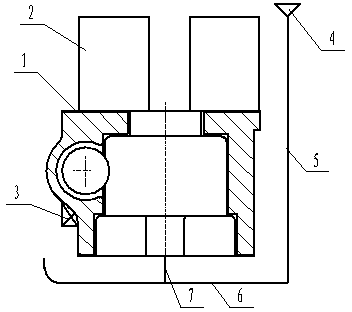

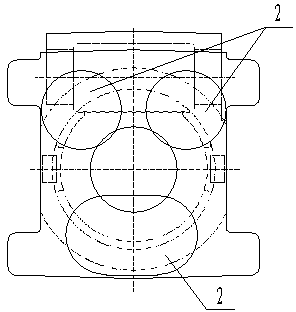

Image

Examples

Embodiment 1

[0035] The ZG32CrNiMo alloy material used for casting large gear box castings on offshore platforms is prepared, and its composition and mass ratio are: C: 0.26%, Si: 0.40%, Mn: 0.90%, Cr: 0.50%, Ni: 0.80%, Mo: 0.30%, P: 0.015%, S: 0.02%, Fe: 96.805%.

[0036] The ZG32CrNiMo alloy material prepared above is used to cast offshore platform large gearbox castings. The casting and heat treatment process includes the following steps:

[0037] A, the ZG32CrNiMo alloy material that above-mentioned preparation obtains is smelted into molten metal;

[0038] b. Carry out resin sand molding according to the above method, set up bottom pouring pouring system, open riser and forming cold iron, pour 1200kg of molten metal, and the pouring temperature is 1550°C. After pouring, the casting is kept in the sand mold for 48 hours, and then the sand is cleaned And gas-cut riser, the temperature of the gas-cut riser is 150 ℃, and the gross weight of the large gearbox casting of the offshore platfor...

Embodiment 2

[0042] The ZG32CrNiMo alloy material used for casting large gear box castings on offshore platforms is prepared, and its composition and mass ratio are: C: 0.35%, Si: 0.20%, Mn: 1.00%, Cr: 0.80%, Ni: 0.70%, Mo: 0.38%, P: 0.01%, S: 0.01%, Fe: 96.55%.

[0043] The ZG32CrNiMo alloy material prepared above is used to cast offshore platform large gearbox castings. The casting and heat treatment process includes the following steps:

[0044] A, the ZG32CrNiMo alloy material that above-mentioned preparation obtains is smelted into molten metal;

[0045] b. Carry out resin sand molding according to the above method, set up bottom pouring pouring system, open riser and forming cold iron, pour 1200kg of molten metal, and the pouring temperature is 1540°C. After pouring, the casting is kept in the sand mold for 48 hours, and then the sand is cleaned And gas-cut riser, the temperature of gas-cut riser is 160 ℃, and the gross weight of the large gearbox casting of offshore platform is 800...

Embodiment 3

[0049] The ZG32CrNiMo alloy material used for casting large gearboxes of offshore platforms is formulated, and its composition and mass ratio are: C: 0.32%, Si: 0.40%, Mn: 0.90%, Cr: 0.70%, Ni: 0.70%, Mo: 0.34%, P: 0.025%, S: 0.01%, Fe: 96.605%.

[0050] The ZG32CrNiMo alloy material prepared above is used to cast offshore platform large gearbox castings. The casting and heat treatment process includes the following steps:

[0051] A, the ZG32CrNiMo alloy material that above-mentioned preparation obtains is smelted into molten metal;

[0052] b. Carry out resin sand molding according to the above method, set up bottom pouring pouring system, open riser and forming cold iron, pour 1200kg of molten metal, and the pouring temperature is 1560°C. After pouring, the casting is kept in the sand mold for 48 hours, and then the sand is cleaned And gas-cut riser, the temperature of gas-cut riser is 160 ℃, and the gross weight of the large gearbox casting of offshore platform is 800kg; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com