A high temperature steam turbine blade and its production method

A steam turbine blade, high temperature technology, applied in the field of mechanical materials, can solve the problems of high temperature lasting low life, mixed crystal structure and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

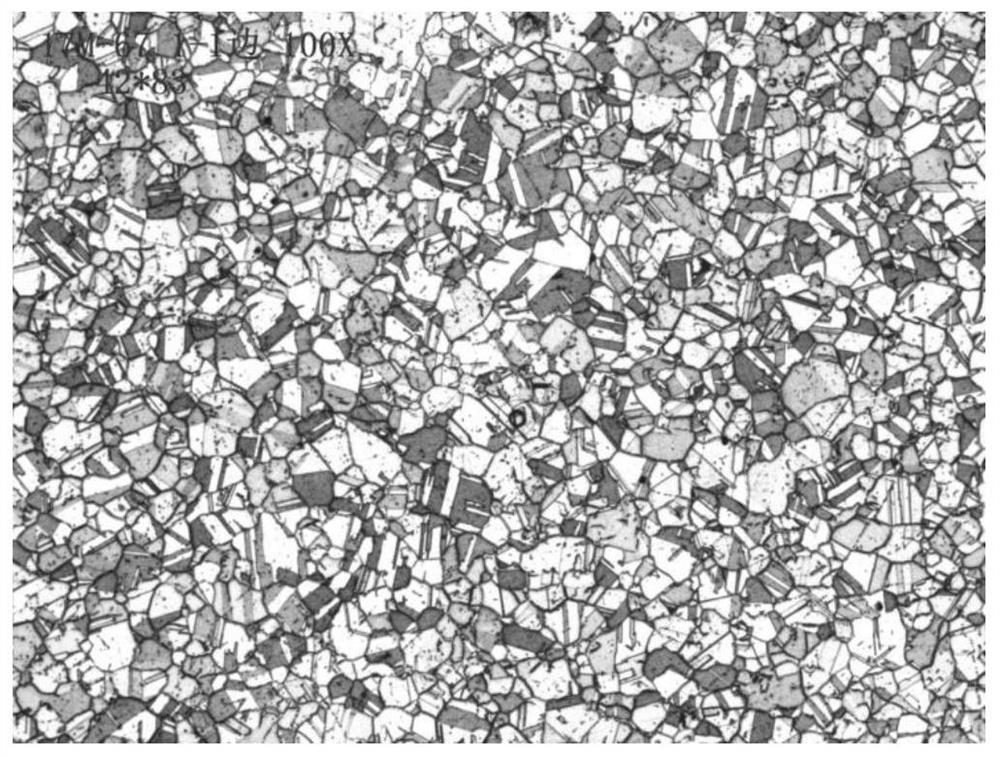

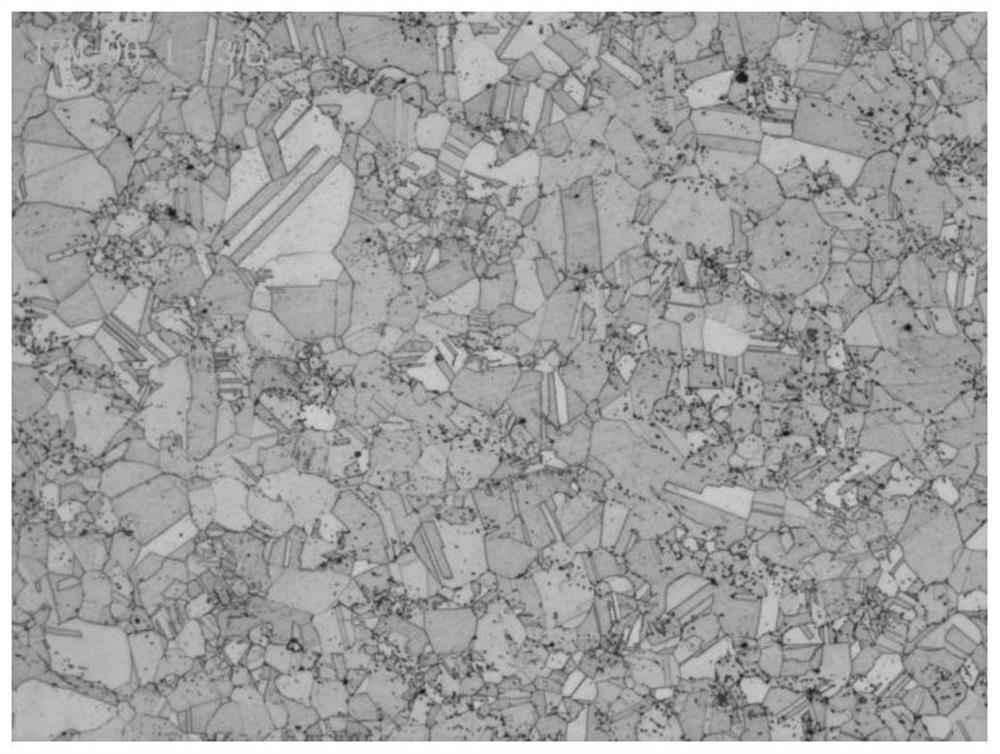

Image

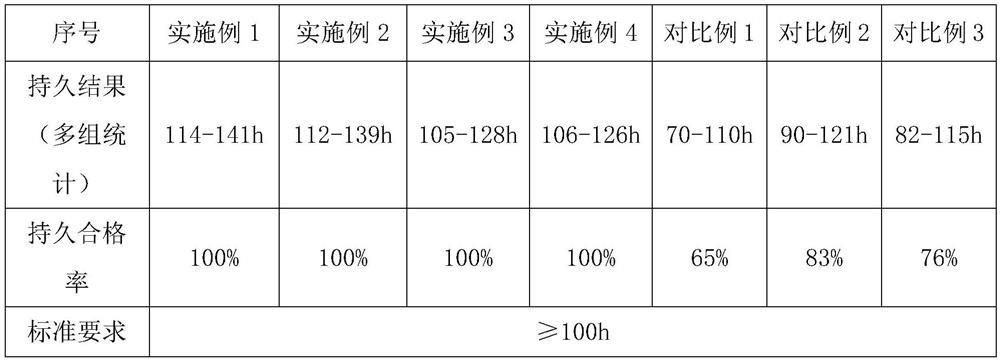

Examples

Embodiment 1

[0028] Prepare high-temperature steam turbine blades according to the following components and methods,

[0029] Step A, carry out vacuum induction smelting according to the composition ratio, in which C element is 0.06%, Cr element is 19.5%, Al element is 1.55%, Ti element is 2.60%, and Ni element balance is carried out at 1470-1500°C. It is 0.5pa, and the refining time is 60min.

[0030] Step B, electroslag remelting is carried out on the electrode rod obtained in step A, the electroslag remelting process controls the melting rate at 4.5kg / min, and the outlet water temperature is 46-52°C;

[0031] Step C, subjecting the steel ingot obtained in step B to high-temperature homogenization treatment, the homogenization treatment temperature is 1120°C, and the heat preservation is ≥ 20h,

[0032] In step D, the temperature of the steel ingot obtained in step C is lowered to 1130° C., and after being kept for 3 hours, cross forging is used at this temperature to form a material. ...

Embodiment 2

[0035] Prepare high-temperature steam turbine blades according to the following components and methods:

[0036] Step A, vacuum induction smelting is carried out according to the composition ratio, in which C element is 0.053%, Cr element is 20.5%, Al element is 1.58%, Ti element is 2.55%, and Ni element balance is carried out at 1470-1500°C for casting electrode rods; vacuum degree 0.5pa, refining time 60min;

[0037] Step B, electroslag remelting is carried out on the electrode rod obtained in step A, the electroslag remelting process controls the melting rate at 4.5kg / min, and the outlet water temperature is 46-52°C;

[0038] Step C, subjecting the steel ingot obtained in step B to high-temperature homogenization treatment, the homogenization treatment temperature is 1120°C, and the heat preservation is ≥ 20h;

[0039] In step D, the temperature of the steel ingot obtained in step C is lowered to 1130° C., and after being kept for 3 hours, the steel ingot obtained in step ...

Embodiment 3

[0042] Prepare high-temperature steam turbine blades according to the following components and methods:

[0043] Step A, vacuum induction smelting is carried out according to the composition ratio, wherein C element is 0.065%, Cr element is 19.5%, Al element is 1.65%, Ti element is 2.60%, and Ni element balance is carried out at 1470-1500°C. It is 0.7pa, and the refining time is 60min.

[0044] In step B, electroslag remelting is performed on the electrode rod obtained in step A, and the electroslag remelting process controls the melting rate at 4.0kg / min, and the outlet water temperature is 46-52°C;

[0045] Step C, subjecting the steel ingot obtained in step B to high-temperature homogenization treatment, the homogenization treatment temperature is 1190-1210°C, and the heat preservation is ≥ 20h;

[0046] In step D, the temperature of the steel ingot obtained in step C is lowered to 1130° C., and after being kept for 3 hours, the steel ingot obtained in step C is formed by cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com