Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Realize green and sustainable development" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

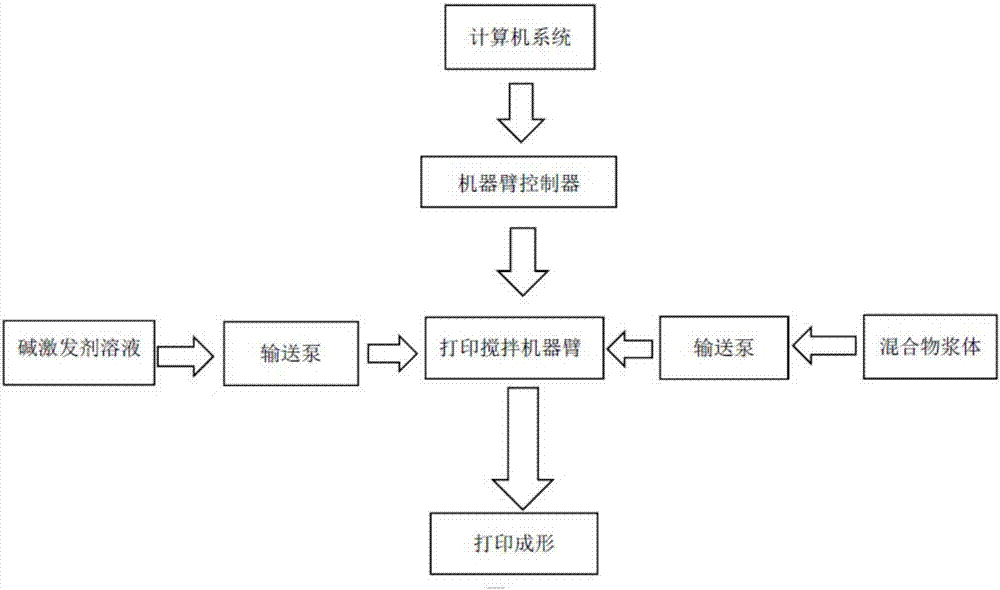

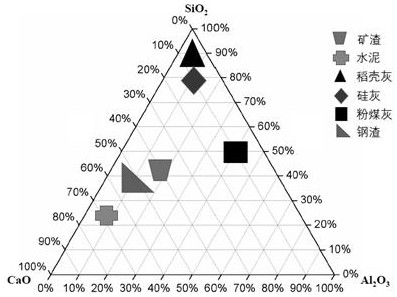

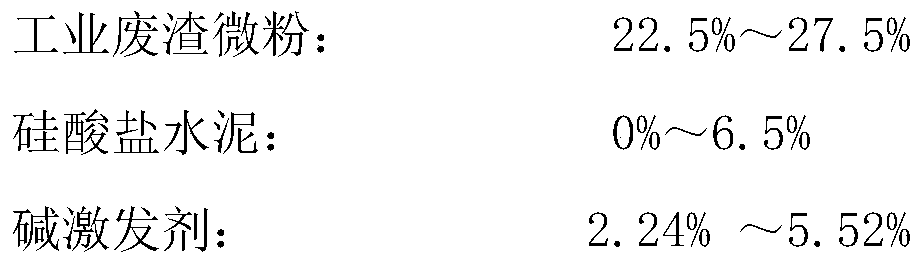

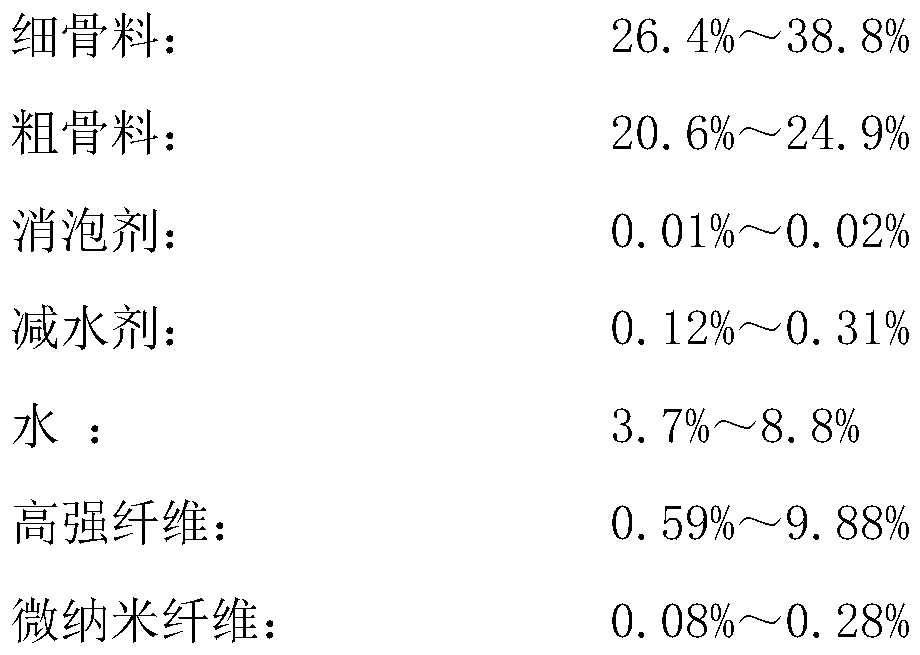

Alkali-activated cementing material for 3D printing and printing method of alkali-activated cementing material

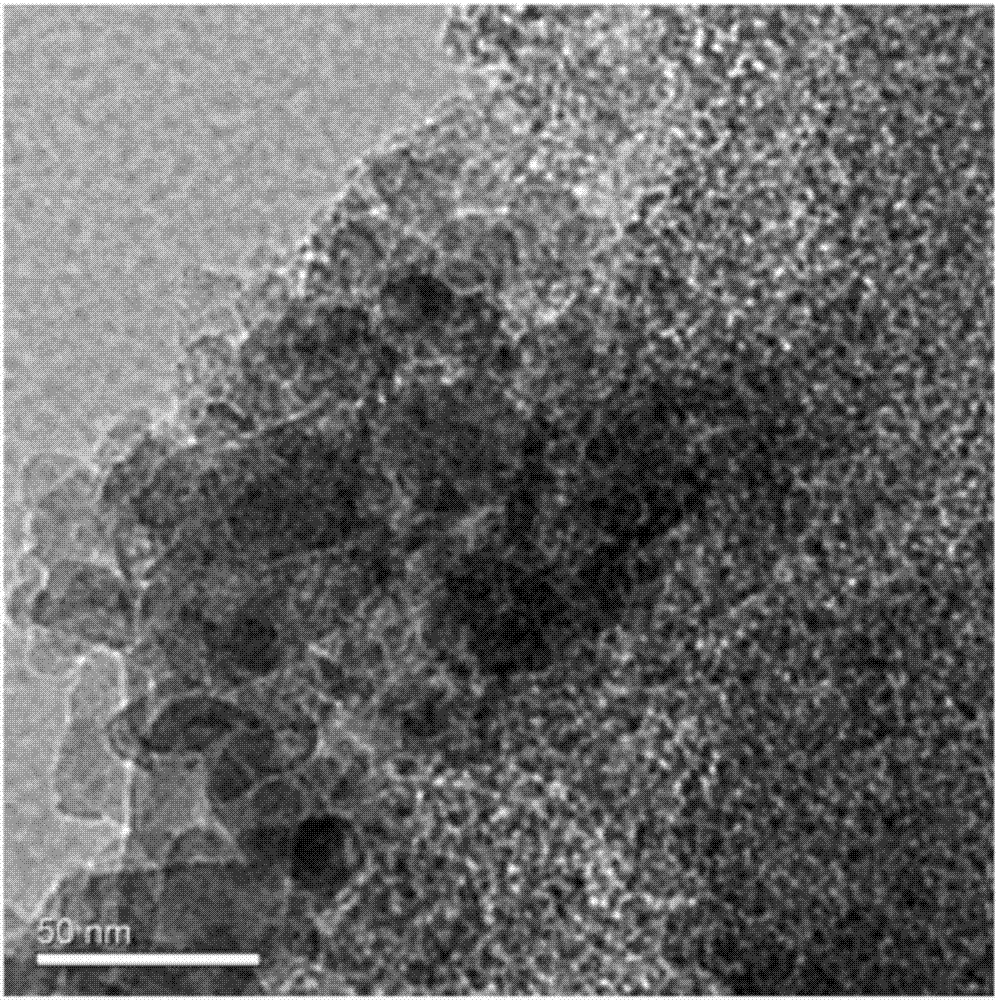

ActiveCN107298546AProtect the environmentReduce dosageAdditive manufacturing apparatusMicro nanoIndustrial waste

The invention discloses an alkali-activated cementing material for 3D printing and a printing method of the alkali-activated cementing material. The alkali-activated cementing material consists of the following raw materials: industrial wastes, an alkali activating agent, fine aggregates, a defoaming agent, a water reduction agent, water, coarse aggregates, high-strength fiber and a micro nano material. A prepared slurry mixture is fed by two pumps and is printed and molded in a 3D printing mode. The problem that 3D printing concrete is low in early strength is solved, and the slurry properties of the alkali-activated cementing material are effectively improved; as the slurry is fed by two pumps, the problems that the alkali-activated cementing material is high in condensation rate and not applicable to 3D printing are solved; and due to doping of various fibers, final pressure and bending resistance of printed concrete is greatly improved.

Owner:NANJING UNIV OF SCI & TECH +2

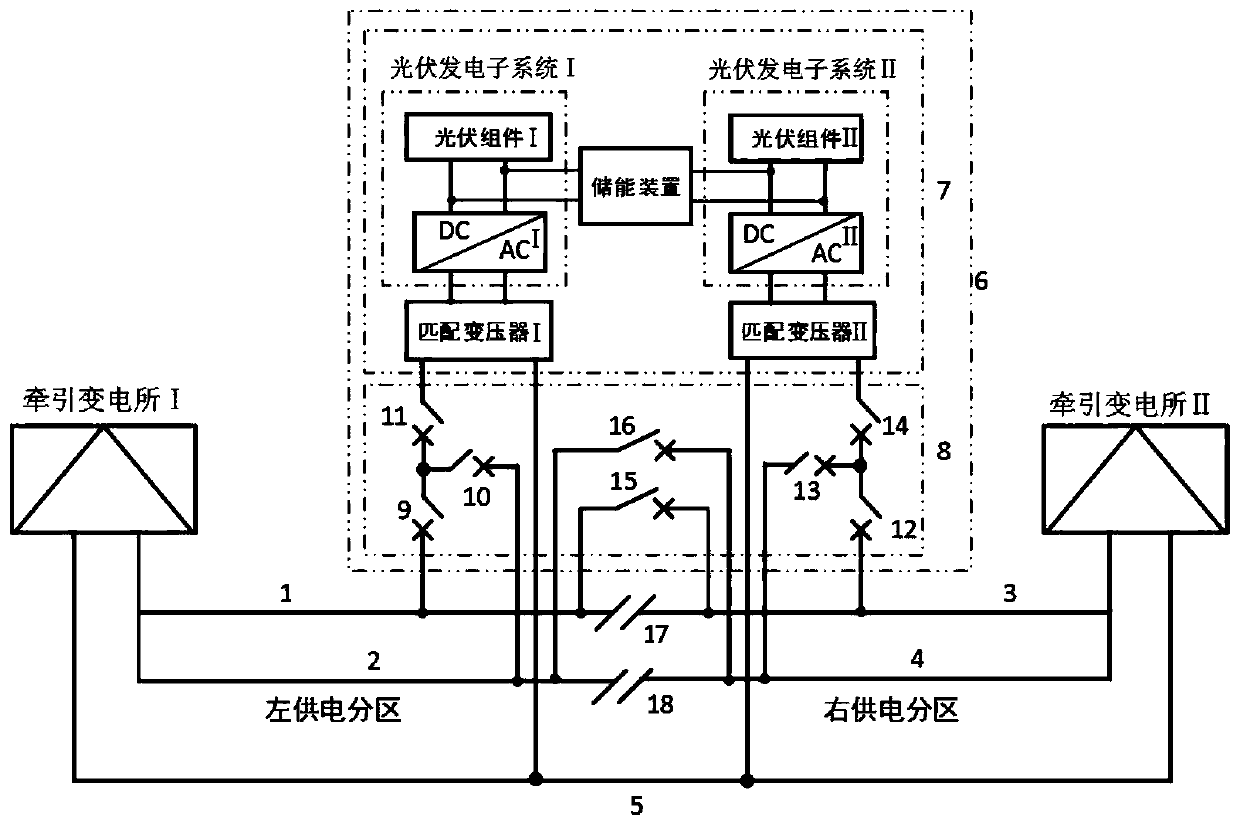

Photovoltaic power storage distributed power generation alternating current traction power supply system and method

ActiveCN110040039AImprove voltage qualityRaise the voltage levelSingle network parallel feeding arrangementsEnergy storageAlternating currentElectric power

The invention discloses a photovoltaic power storage distributed power generation alternating current traction power supply system and method. Anexistingout-phase power supply traction power supply system partition station is used foraccessing a photovoltaic power generation and storage system to the tail ends of traction networks of the left side and right side power supply partitions, bilateralpower supply is realized in each independent power supply partition through the distributed photovoltaic power generation and storage system, and double-end power source bilateral power supply of a traction power substation and a partition station photovoltaic power generation and storage systemis formed. According to the photovoltaic power storage distributed power generation alternating currenttraction power supply system and method,when the traction network is normal, the bilateral power supply of the traction power substation and the partition station photovoltaic power storage is enabledin the independent power supply partition, when the traction power substation malfunctions, cross-regional power supply by multiple power sources is realized by the adjacent traction substation and the partition station photovoltaic power storage, the voltage level of the traction network is improved, the power supply capacity is improved, and power is uninterruptedlysupplied for electric locomotives or electric motor train units; and at the same time power storage recycles locomotive regenerative feedback energy, the problem of high voltage level at the head end of the traction network caused by foldbackis avoided, and the stability and reliability of traction power supply is improved.

Owner:SOUTHWEST JIAOTONG UNIV

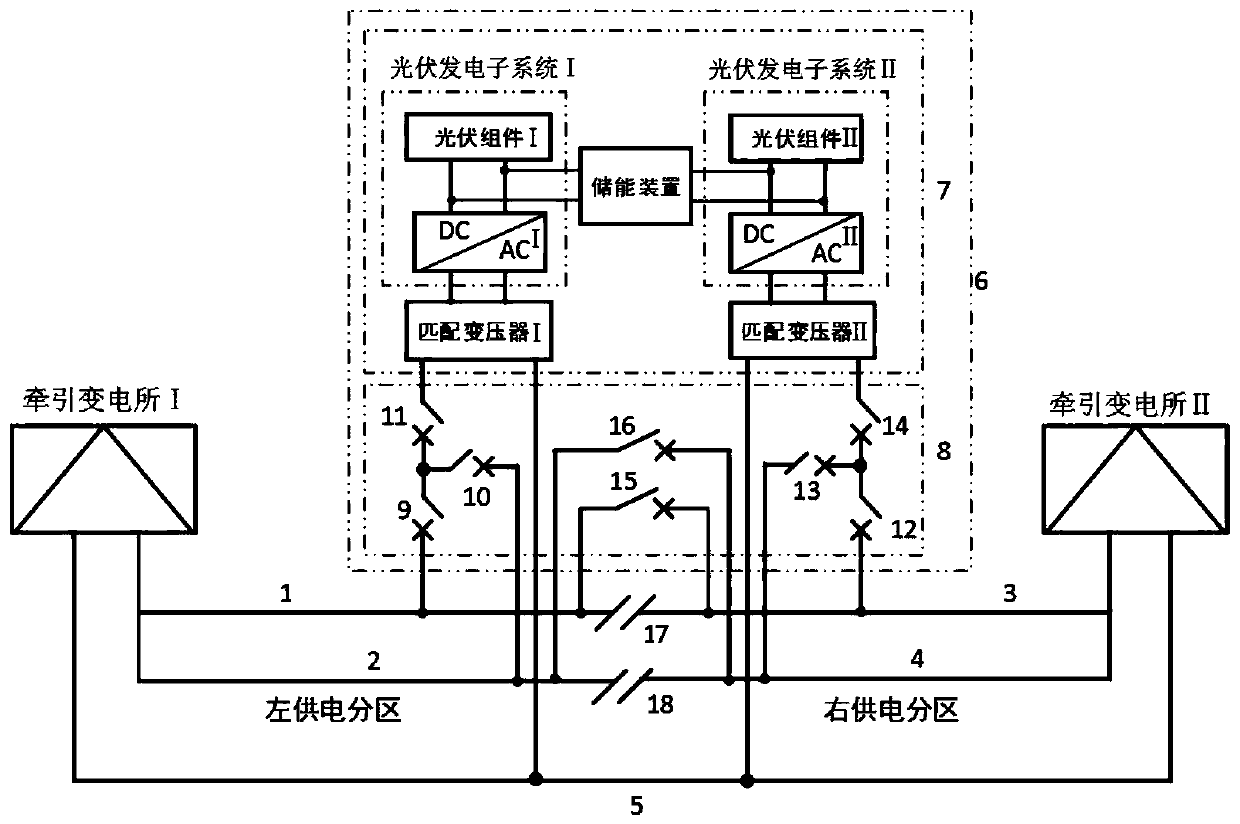

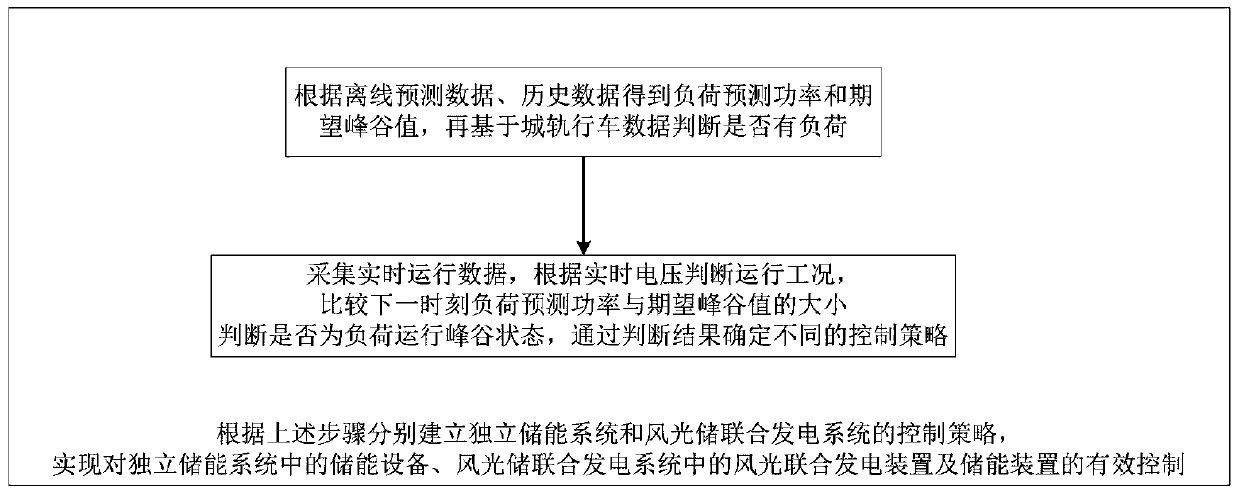

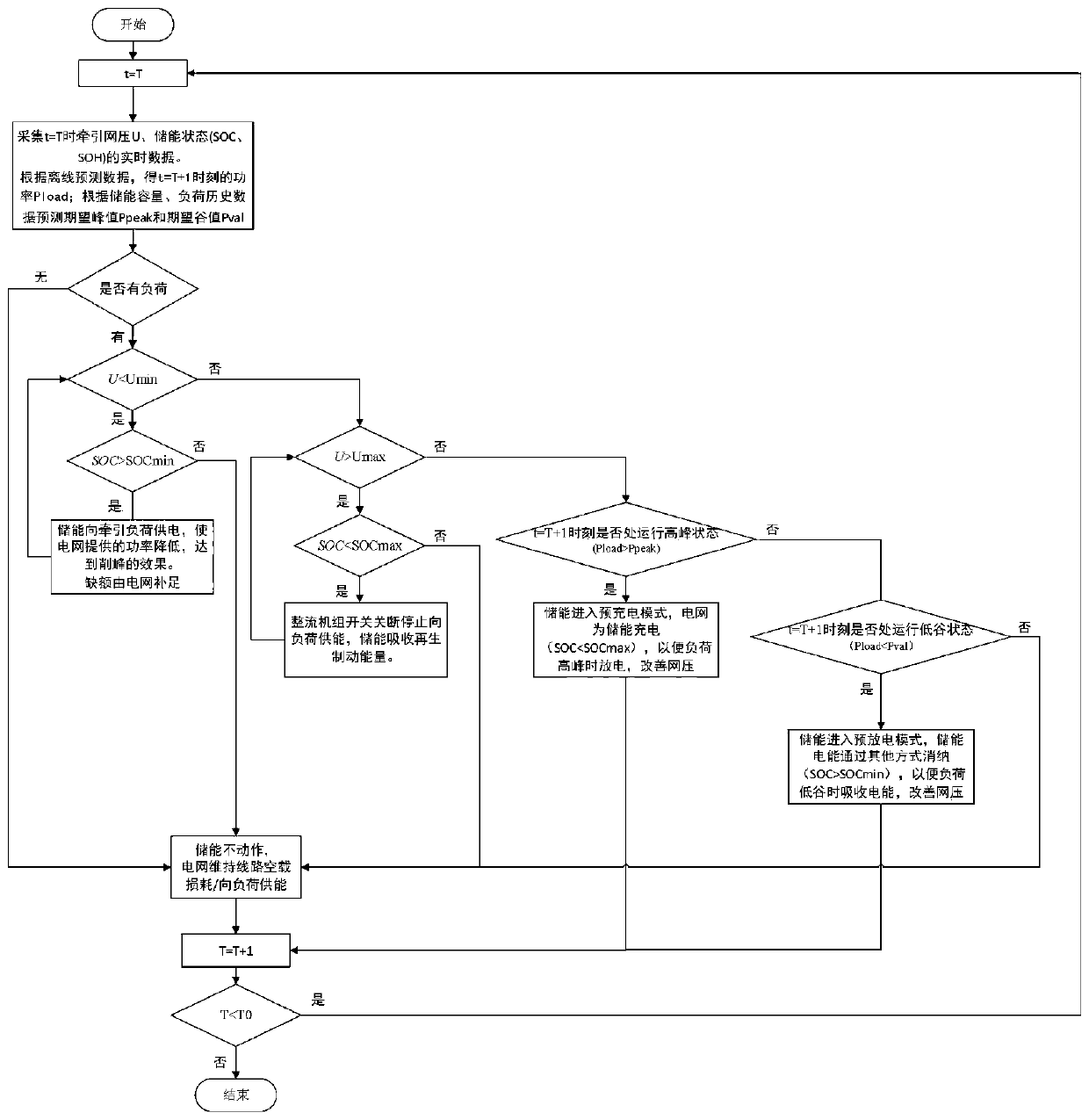

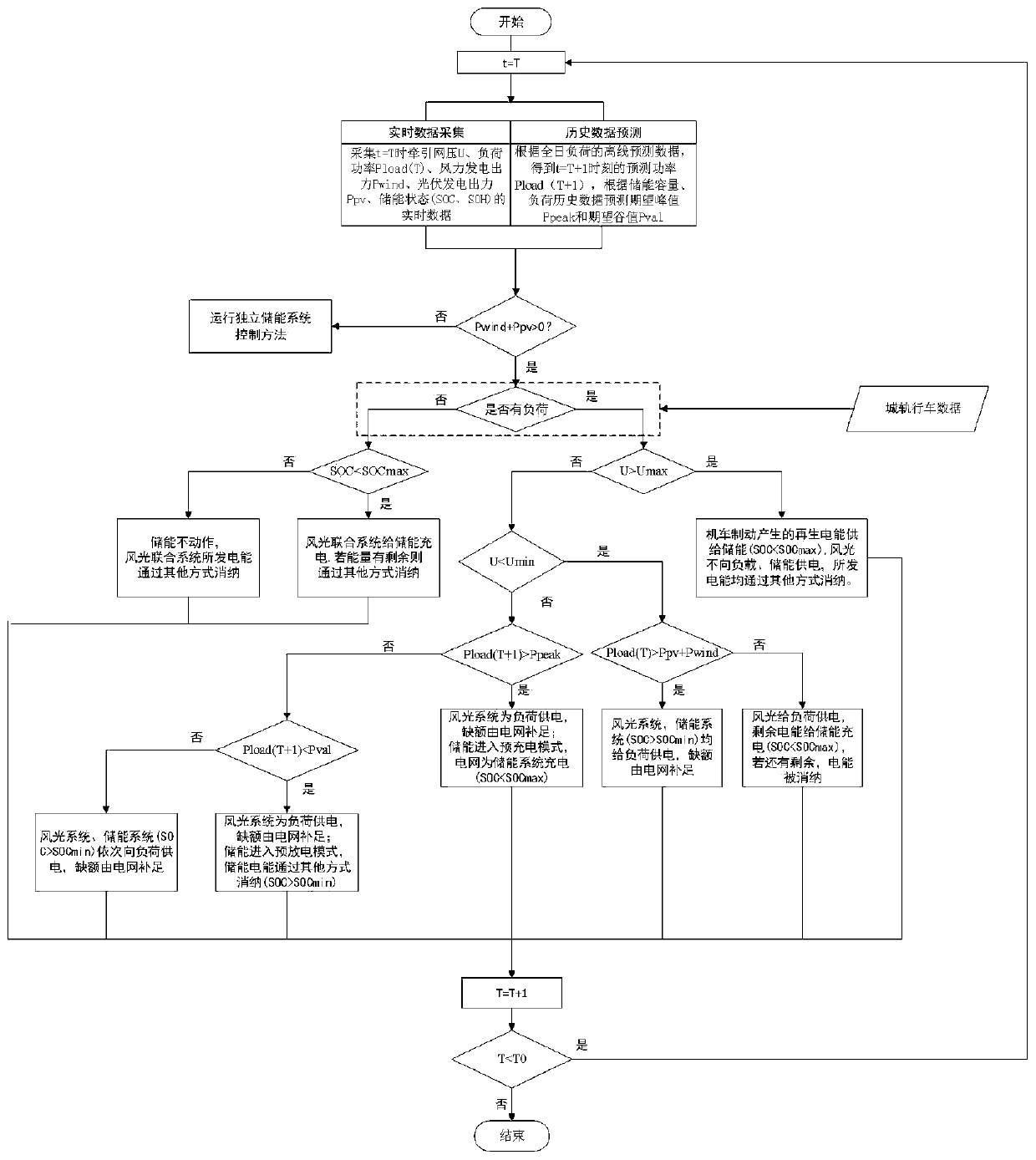

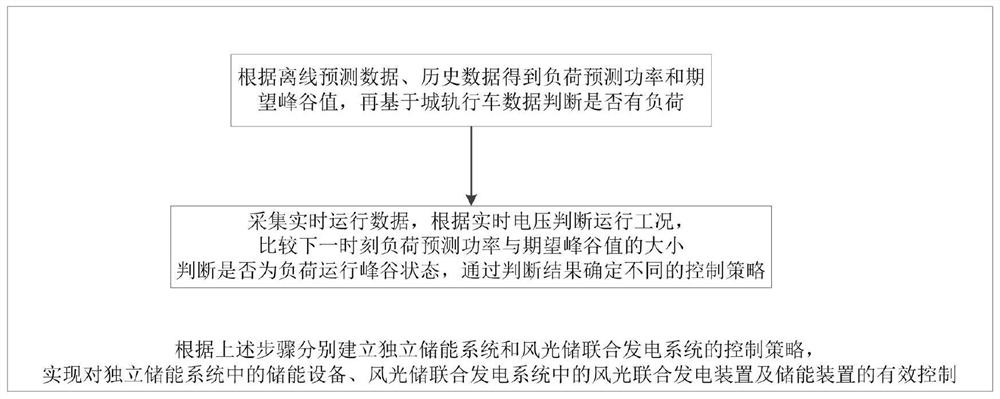

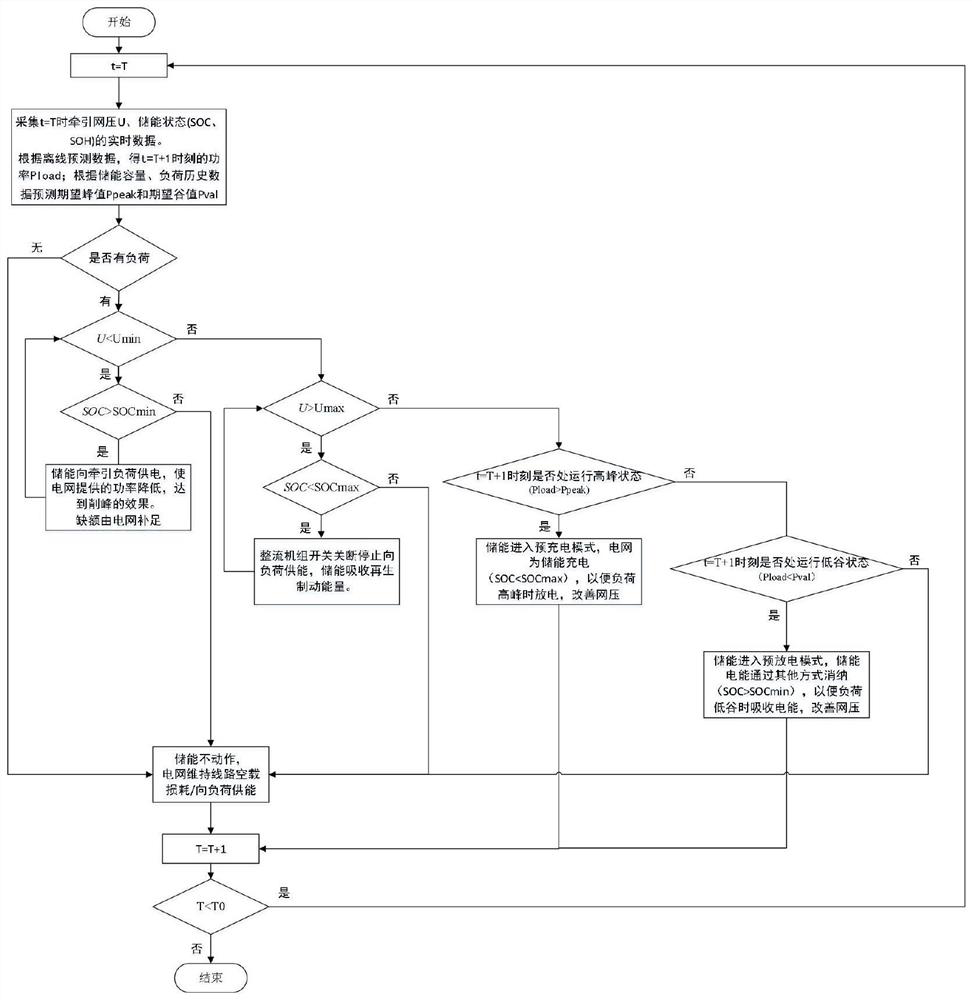

New energy power supply system for urban rail traction network and control method thereof

ActiveCN110460077AEfficient use ofReduce energy storage capacitySingle network parallel feeding arrangementsEnergy storageOperational costsNew energy

The invention discloses a new energy power supply system for an urban rail traction network and a control method. The system comprises an independent energy storage system located in a middle sectionof a line and a wind-photovoltaic-energy storage hybrid power generation system located at a car depot or a parking lot at an end of the line. The method comprises a step of obtaining a load predictedpower and an expected peak-valley value according to offline prediction data and historical data and judging whether there is a load based on urban rail running data, and a step of judging an operating condition based on a real-time voltage, comparing a predicted load power at a next moment and the expected peak-valley value and judging whether a state is a load running peak-valley state, and determining different control strategies through a judgment result to realize the effective control of an energy storage device in an independent energy storage system and a wind-photovoltaic-energy storage hybrid power generation device and an energy storage device in the wind-photovoltaic-energy storage hybrid power generation system. According to the invention, the consumption of renewable energysources such as local wind and light can be promoted, the grid pressure fluctuation is improved, the peak-load shifting is carried out for the load while the regenerative braking energy is effectivelyrecycled, the operating cost of urban rails is reduced, and the economic benefits are good.

Owner:SOUTHWEST JIAOTONG UNIV

Off-grid railway traction power supply system and regulation and control method

The invention discloses an off-grid railway traction power supply system and a regulation and control method. The off-grid railway traction power supply system comprises a catenary, a distributed power substation, an electrical split phase and an electrical split phase switch, wherein the output end of the distributed power substation is connected to the catenary; the electrical split phase is arranged on the catenary between the adjacent distributed power substations; the electrical split phase switch is arranged on the electrical split phase in parallel; the distributed power substation comprises a primary new-energy power generation device, a secondary controllable new-energy backup power supply and single-phase boosting transformers; the primary new-energy power generation device and the secondary controllable new-energy backup power supply are independent of each other, and are connected to the catenary through the respective single-phase boosting transformers. The off-grid railway traction power supply system achieves off-grid operation of a train and improves the stability and the reliability of traction power supply of a microgrid railway; the off-grid railway traction power supply system is applicable to a grid-free area, consumes clean energy on a spot, and achieves energy conservation and emission reduction and green sustainable development of rail transit; the off-grid railway traction power supply system conforms to electric transmission locomotives widely used in China railways and has strong applicability.

Owner:SOUTHWEST JIAOTONG UNIV

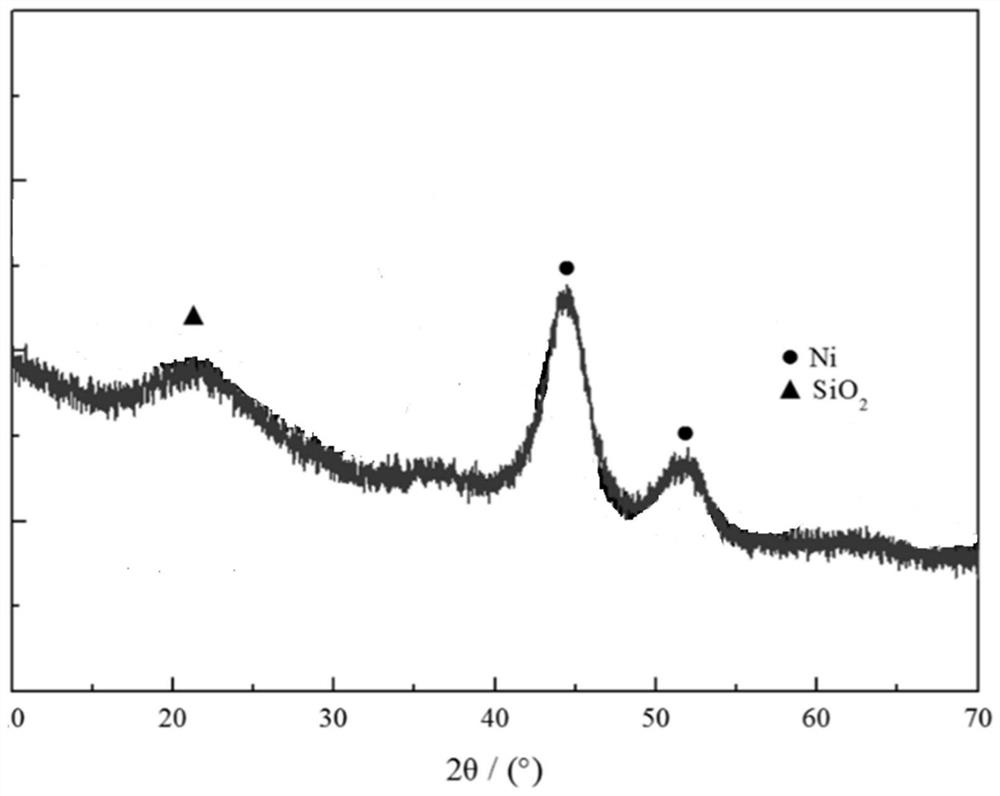

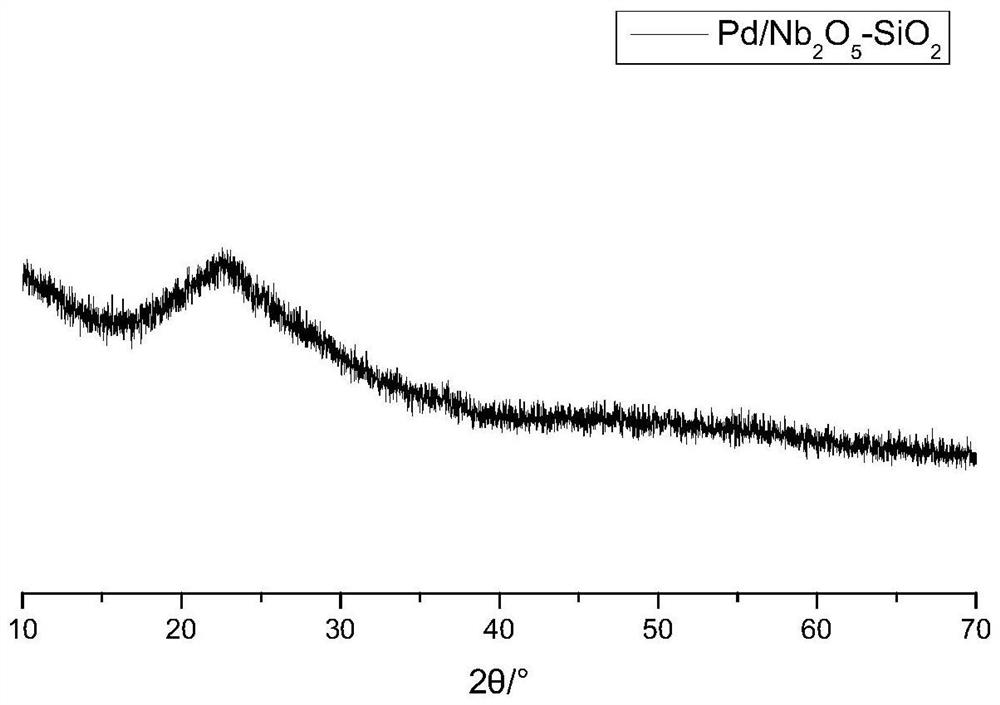

Biological aviation kerosene component oil and preparation method thereof

ActiveCN113444540AEfficient use ofLess side effectsMolecular sieve catalystsTreatment with hydrotreatment processesAlkaneCellulose

The invention provides biological aviation kerosene component oil and a preparation method thereof, and the preparation method comprises the following steps: carrying out aldol condensation reaction on a lignocellulose-based furfural compound and a carbonyl compound to obtain a C8-C16 long-chain oxygen-containing compound; feeding a C8-C16 long-chain oxygen-containing compound into a first reaction zone of a reactor under the condition of no reaction solvent, and carrying out hydrogenation saturation; a hydrogenation saturated product is subjected to hydrodeoxygenation through a second reaction zone of the reactor, and C8-C16 long-chain alkane is obtained; carrying out isomerization treatment on the crude oil and C8-C16 long-chain alkane, and fractionating to obtain biological aviation kerosene component oil; the temperature of the first reaction zone is 50-200 DEG C, and the temperature of the second reaction zone is higher than that of the first reaction zone. The method can realize catalytic conversion based on the biomass sugar platform compound to prepare the biological aviation kerosene component oil, is beneficial to comprehensive utilization of agricultural and forestry wastes, realizes green and sustainable development, further reduces the production cost through a continuous hydrogenation process, and has a good industrial application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +2

Carbon-based lithium ion battery negative electrode material taking sludge as precursor and preparation of carbon-based lithium ion battery negative electrode material

InactiveCN106920966ASolve problems such as limitationsLarge specific surface areaCell electrodesSecondary cellsResource utilizationSludge

The invention relates to a carbon-based lithium ion battery negative electrode material taking sludge as a precursor and preparation of the carbon-based lithium ion battery negative electrode material. During preparation, the sludge is carbonized and processed in advance, and the carbon-based lithium ion battery negative electrode material is obtained by sequentially performing washing and drying after pickling and alkali activation. Compared with the prior art, the carbon-based lithium ion battery negative electrode material has the advantages of greenness, environmental friendliness, simple preparation process and low production cost, the resource utilization of the sludge can be achieved, and the prepared carbon-based lithium ion battery negative electrode material is high in specific area and specific capacity and good in cycle property and has wide application prospect.

Owner:TONGJI UNIV

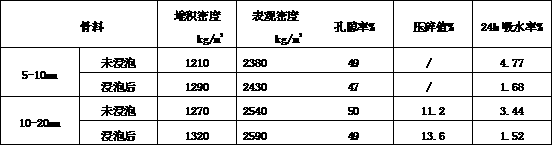

Modified recycled coarse aggregate and method for preparing recycled concrete using modified recycled coarse aggregate

The invention discloses modified recycled coarse aggregate. The recycled coarse aggregate with the granulometric class of 5-10 mm and 10-20 mm are soaked in waste slurry with solid content of 1%-9% and then mixed evenly at the ratio of (35%-45%):(55%-65%). According to the method for preparing recycled concrete using the modified recycled coarse aggregate, the modified recycled coarse aggregate with the volume ratio of (5-25%) replaces natural coarse aggregate with the same volume, and then 45.79-48.61 mixed coarse aggregate, 30.56-32.45 natural sand, 9.80-10.20 cement, 2.65-2.75 fly ash and 3.92-4.08 blast furnace slag powder, 0.29-0.31 water reducer and 7.64-7.96 drinking water are stirred and mixed to prepare the modified recycled coarse aggregate. The modified recycled coarse aggregatehas low surface roughness, low porosity, low water absorption rate and high crushing index, and produced recycled concrete has low collapsibility, high modulus of elasticity, and low dry shrinkage rate and creep deformation.

Owner:HEBEI CONSTR GRP CO LTD

Method for comprehensively utilizing waste liquid generated in process of preparing alkali by ammonia-alkali method

ActiveCN112850770AGuarantee normal productionReduce accumulationCalcium/strontium/barium sulfatesFluid removalEngineeringSlurry pump

The invention belongs to the technical field of mineral development, and particularly relates to a method for cyclically and comprehensively utilizing waste liquid generated in the process of preparing an alkali by an ammonia-alkali method. The method for comprehensively utilizing the waste liquid generated in the process of preparing the alkali by the ammonia-alkali method comprises the following steps: naturally settling the pretreated alkali-making waste liquid, and separating to obtain a light calcium liquid; mixing the light calcium liquid with a salt-making discharged mother liquor, and reacting to generate mixed slurry of calcium sulfate dihydrate and sodium chloride; pumping the mixed slurry into a settling tank by using a slurry pump, and thickening the solid content of the slurry to obtain thick slurry; and carrying out solid-liquid separation on the thick slurry to obtain afiltrate II and filter residues II, and washing the filter residues II with water to obtain gypsum, wherein the filtrate II is a high-concentration NaCl solution, and is injected into a mine well to be extracted. By means of the method, the situation that calcium sulfate generated underground deposits and covers mineral resources at the bottom of the well can be reduced, calcium sulfate and calcium carbonate products can be obtained in the circulation process, and mineral resources are more fully utilized.

Owner:JIANGXI JINGHAO SALINIZATION

Fiber-toughened recycled high-performance concrete self-luminous roadblock and preparation method thereof

ActiveCN111377678AImprove toughnessImprove impact resistanceTraffic signalsRoad signsAluminateSocial benefits

The invention discloses a fiber toughened recycled high-performance concrete self-luminous roadblock which is divided into an inner part and an outer part, wherein the inner part is steel fiber toughened recycled concrete, and the outer part is a polymer waterproof mortar protective layer doped with an energy storage luminous material; the steel fibers introduced into the steel fiber toughened recycled concrete are steel fibers connected into a row by hydrosol; and the energy storage luminescent material is rare earth aluminate. The fiber-toughened recycled high-performance concrete self-luminous roadblock has the characteristics of better toughness, impact resistance and durability; cyclic utilization of environment-friendly self-luminous materials and waste concrete is an important way for realizing green sustainable development of building materials, and the fiber-toughened recycled high-performance concrete self-luminous roadblock has good economic benefits and social benefits.

Owner:JIANGSU SOBUTE NEW MATERIALS

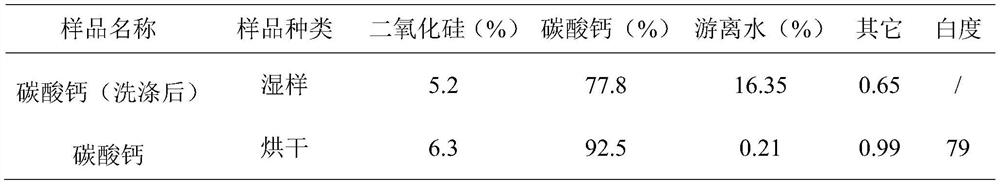

Preparation method of sea pebble, sea sand, seawater and regenerated micro-powder concrete

InactiveCN112062518ASolve the problem of unsustainabilityRealize resource utilizationSoil sciencePlant fibre

The invention provides sea pebble, sea sand, seawater and regenerated micro-powder concrete which comprises the following components in percentage by weight: 7-25% of cement; 0-7.5% of regenerated micro-powder; 0-55% of sea pebble; 0-55% of regenerated broken stone; 20-25% of sea sand; 5-7.5% of seawater; 0-2% of plant fibers; and 0-0.2% of a water reducing agent. The invention further provides apreparation method of the sea pebble, sea sand, seawater and regenerated micro-powder concrete. According to the preparation method of the sea pebble, sea sand, seawater and regenerated micro-powder concrete provided by the invention, resource utilization is carried out on the sea pebbles, the regenerated gravels, the sea sand, the seawater and the regenerated micro-powder, so that the problems ofresource consumption, environmental pollution and the like in concrete production and after scrapping are solved; and the tensile strength and toughness of the sea pebble, sea sand, seawater and regenerated micro-powder concrete are improved through the plant fibers.

Owner:TONGJI UNIV

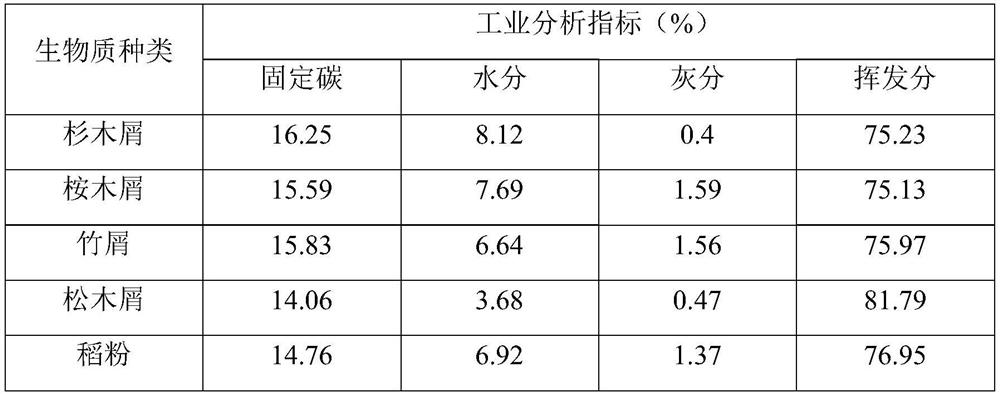

Method for magnetizing and roasting iron tailings through biomass

PendingCN113604659AAvoid agglomerationAchieve high-speed rail gradeMagnetic separationProcess efficiency improvementMagnetiteSilicon

The invention provides a method for magnetizing and roasting iron tailings through biomass. The method comprises the following steps that firstly, crushing the iron tailings, and grinding to -0.074 mm to obtain iron tailing powder; crushing the biomass to obtain biomass powder; separately placing the iron tailing powder and the biomass powder at different parts in the same heat-resistant closed container, and carrying out magnetizing and roasting at 600-750 DEG C; and finally, cooling, grinding and magnetically separating the roasted iron tailing powder to obtain magnetite concentrate. Weakly magnetic oxides such as hematite in the iron tailings are converted into strong magnetic magnetite by reducing gases such as H2 and CO generated by biomass pyrolysis, the biomass and the iron tailings are separately roasted to prevent agglomeration, impurities such as silicon and aluminum are removed by adopting processes such as grinding combined with magnetic separation, and the iron grade and the iron recovery rate of the magnetite concentrate are effectively improved.

Owner:GUANGDONG UNIV OF TECH

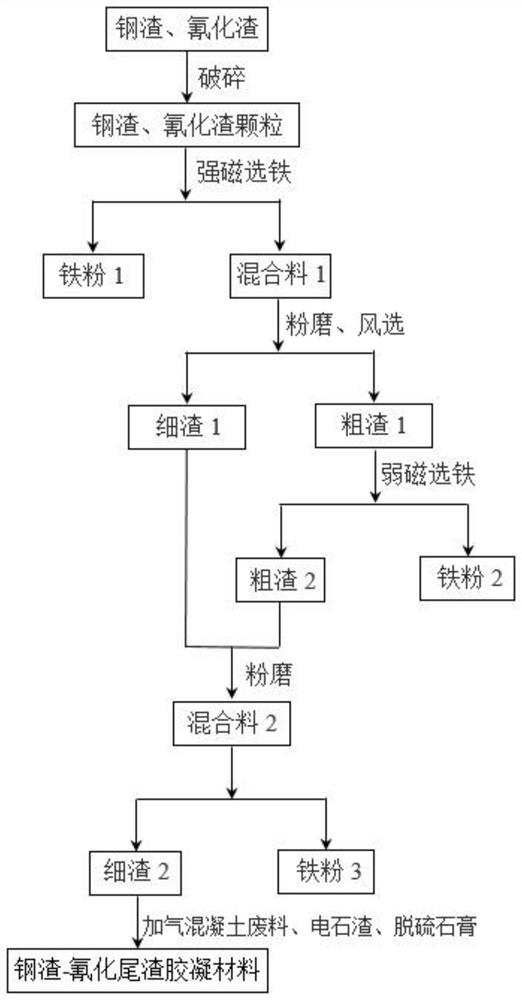

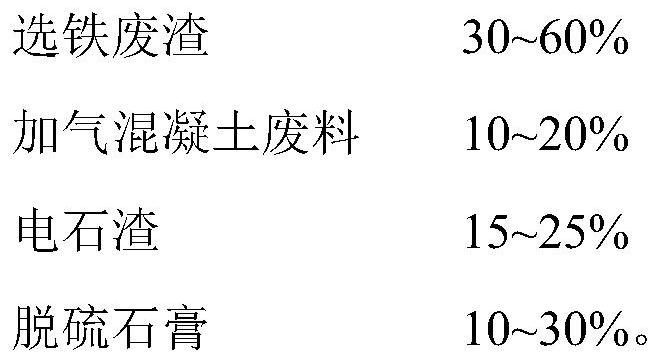

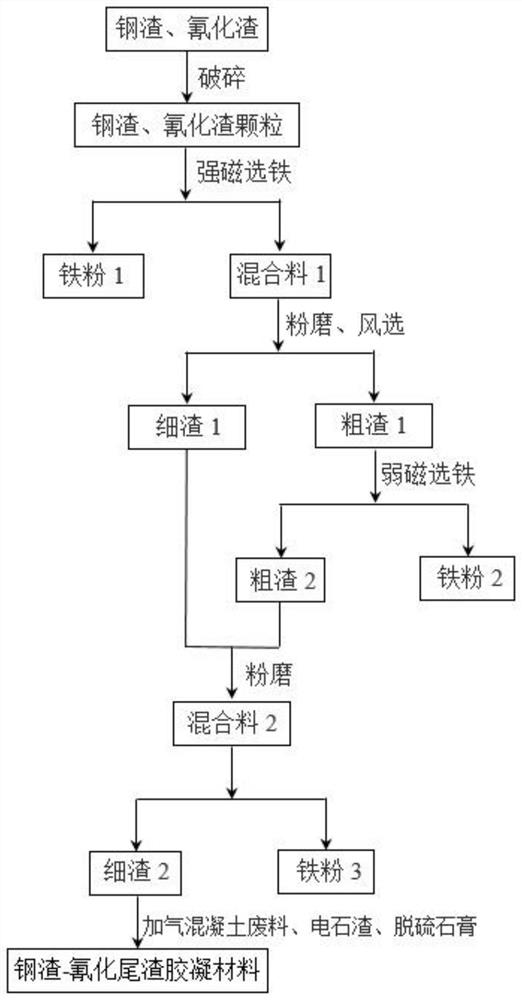

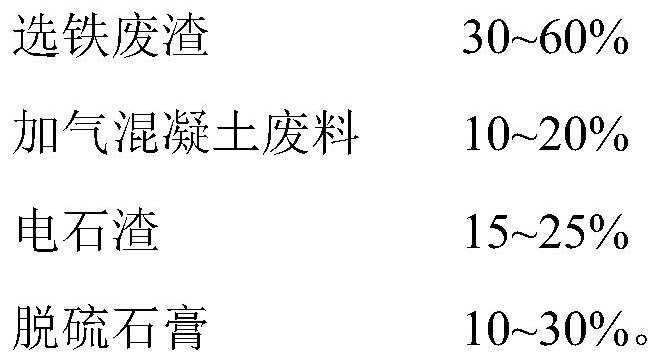

Steel slag-cyaniding tailing cementing material as well as preparation method and application thereof

ActiveCN112408831AEasy to prepareIncrease added valueSolid waste managementMagnetic separationSlagSilicate Cement

The invention provides a steel slag cyaniding tailing cementing material as well as a preparation method and an application thereof. The steel slag cyaniding tailing cementing material is prepared from the following substances in percentage by mass: 30 to 60 percent of iron-selecting waste slag, 10 to 20 percent of aerated concrete waste, 15 to 25 percent of carbide slag and 10 to 30 percent of desulfurized gypsum. The method comprises the following steps: calcining the carbide slag, naturally cooling, and grinding; crushing, drying and grinding the aerated concrete waste; and grinding the desulfurized gypsum, and mixing the ground desulfurized gypsum with the iron separation waste residues of the steel slag cyaniding tailings in proportion to prepare the steel slag cyaniding tailing cementing material; and mixing the cementing material with Portland cement to prepare the steel slag cyaniding tailing cement. The preparation method disclosed by the invention is simple and easy to implement, can realize the synergistic utilization of various wastes, improves the additional value of the wastes, reduces the production cost of the cement, and has good social and economic effects.

Owner:HEBEI UNIV OF ENG +1

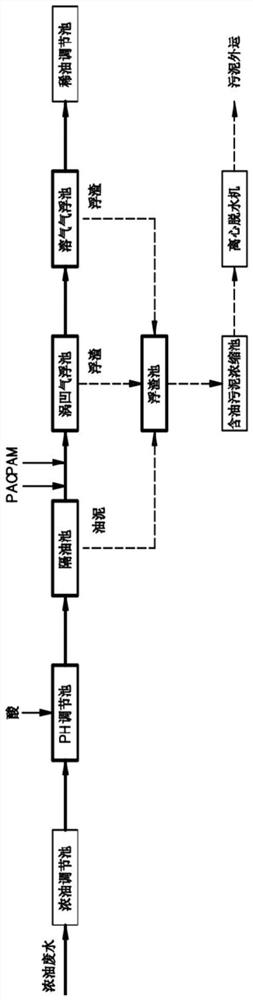

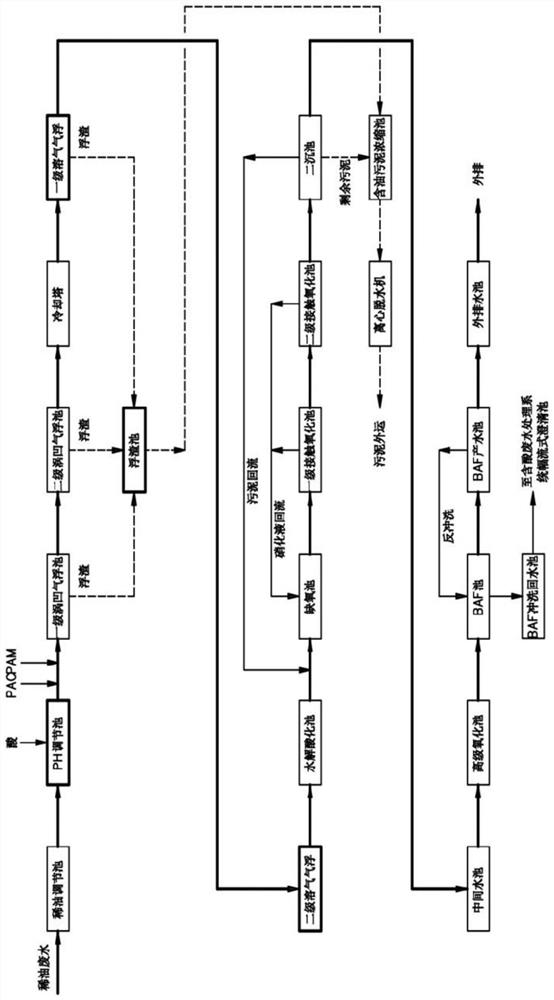

Steel enterprise cold rolling oily wastewater treatment method

InactiveCN112707584AReduce energy consumptionLow costFatty/oily/floating substances removal devicesWater contaminantsIndustrial wastewater treatmentOil separation

The invention discloses a steel enterprise cold rolling oily wastewater treatment method, and belongs to the technical field of industrial wastewater treatment. According to the technical scheme, thick oil wastewater generated in a steel rolling process is treated by a regulating tank, a thick oil pH value regulating tank, a horizontal flow oil separation tank, a thick oil cavitation air floatation tank and a thick oil dissolved air floatation tank in sequence; then the treated thick oil wastewater and thin oil wastewater generated in the steel rolling process are sequentially treated by a thin oil adjusting tank, a thin oil pH value adjusting tank, a two-stage cavitation air floatation tank, a cooling tower, a two-stage dissolved air floatation tank, a hydrolysis acidification tank, an anaerobic tank, a two-stage contact oxidation tank, a secondary sedimentation tank, an advanced oxidation tank and a biological aerated filter, and effluent is discharged to a sewage treatment plant for advanced treatment. The method is low in energy consumption, low in cost, simple in equipment, easy to operate, high in regulation performance and stable in treatment effect, can effectively solve the current water treatment problem of iron and steel enterprises, and has important significance in promoting the iron and steel enterprises to realize energy conservation, emission reduction and green sustainable development.

Owner:HANDAN IRON & STEEL GROUP +1

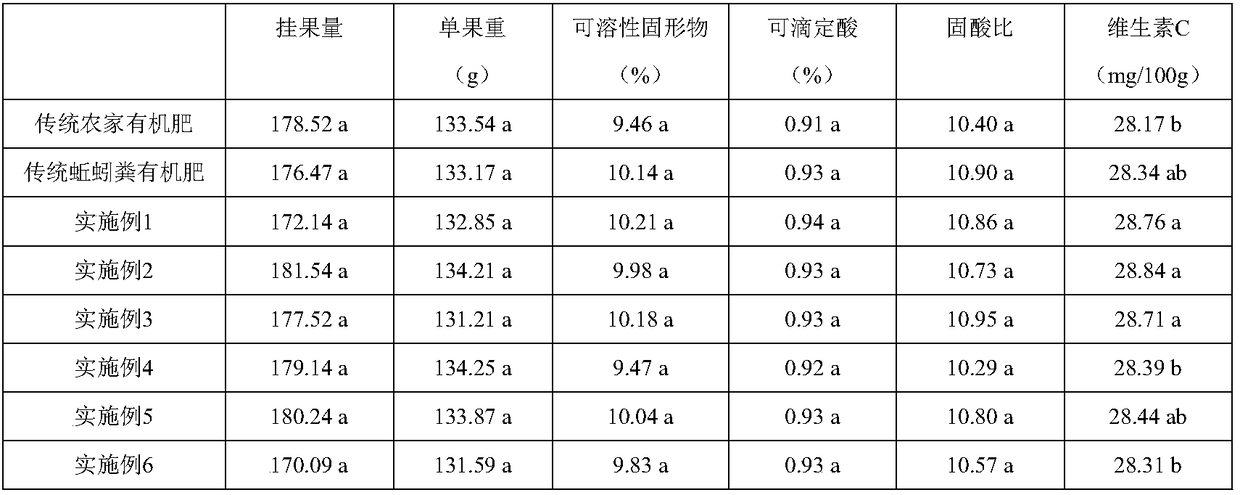

Special organic/inorganic compound fertilizer for earthworm dung-sourced citrus and production method thereof

PendingCN108863476AImprove the environmentImprove qualityFood processingAnimal corpse fertilisersDiseaseInorganic compound

The invention discloses special organic / inorganic compound fertilizer for earthworm dung-sourced citrus and a production method thereof. The special organic / inorganic compound fertilizer is prepared from the following raw materials by weight percent: 60 to 70 percent of earthworm dung, 5 to 10 percent of earthworm amino acid nutritional stock solution and 20 to 35 percent of inorganic fertilizer.The earthworm dung, the earthworm amino acid nutritional stock solution and the inorganic fertilizer are uniformly mixed to obtain organic / inorganic compound fertilizer. By utilizing the earthworm dung, the soil environment of a citrus orchard can be effectively improved, the clay is loosened, the pH of the soil is neutral, the nutrition absorption of the citrus tree can be facilitated, the resistance of the citrus tree for diseases and insect pests can be improved, the soil-borne diseases can be inhibited, and the quality of the oranges can be improved; by adopting an amino acid nutritional solution, the absorption and utilization of the citrus tree to medium and trace elements can be improved by virtue of a complexing effect; and by adopting the inorganic fertilizer, the insufficient part of nutritional elements in the organic raw material can be compensated, and the nutrition requirement of the citrus growth can be met.

Owner:HUAZHONG AGRI UNIV

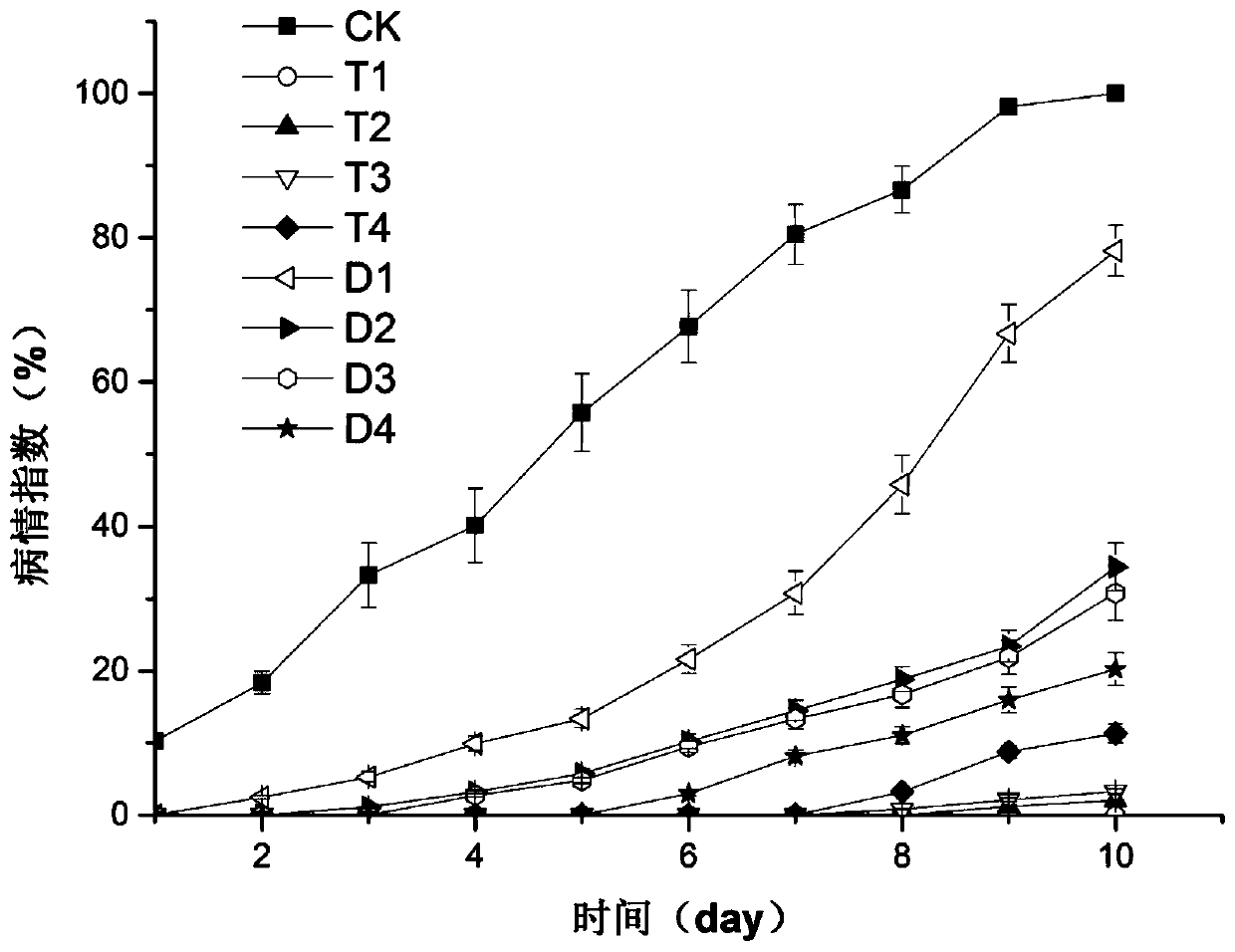

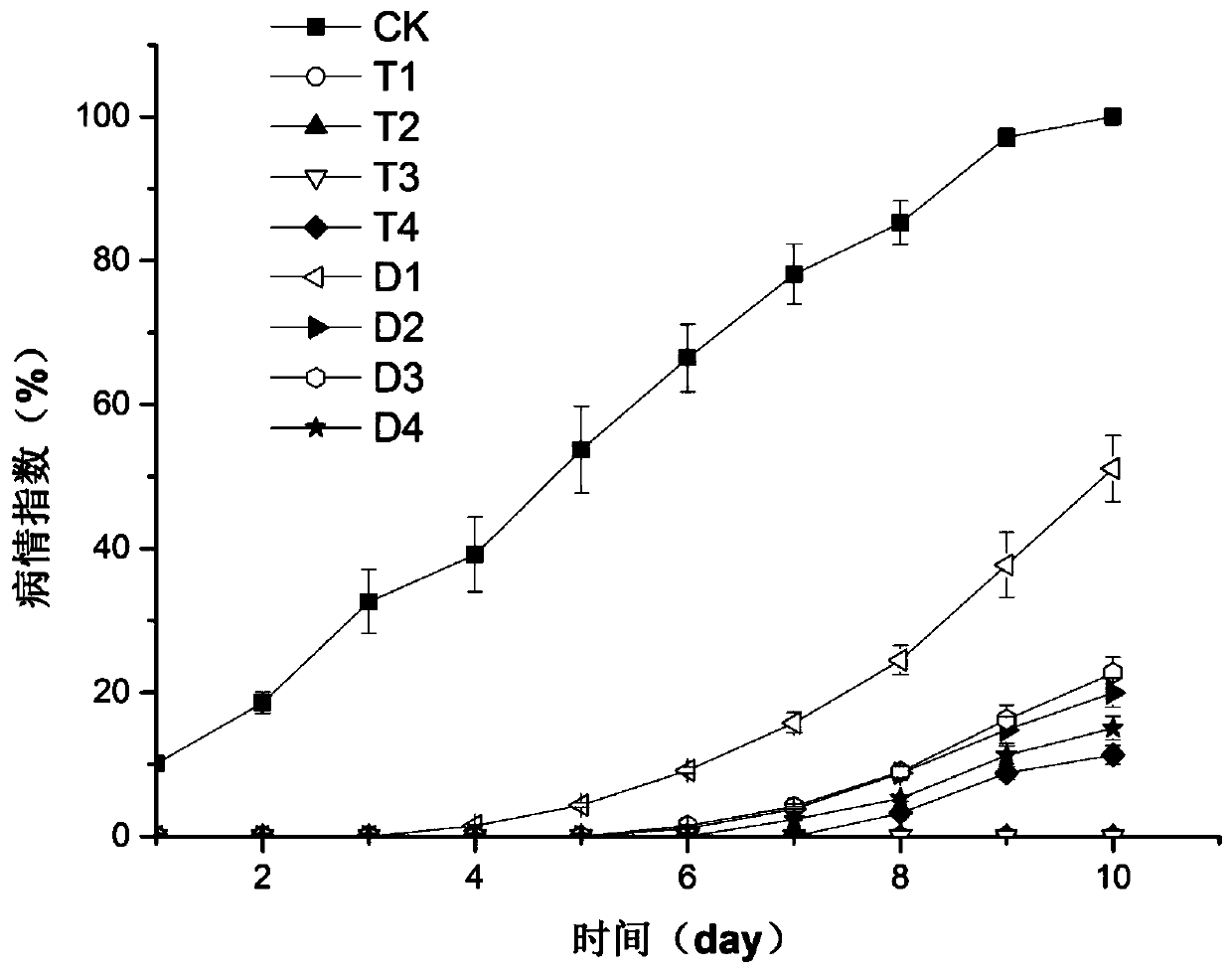

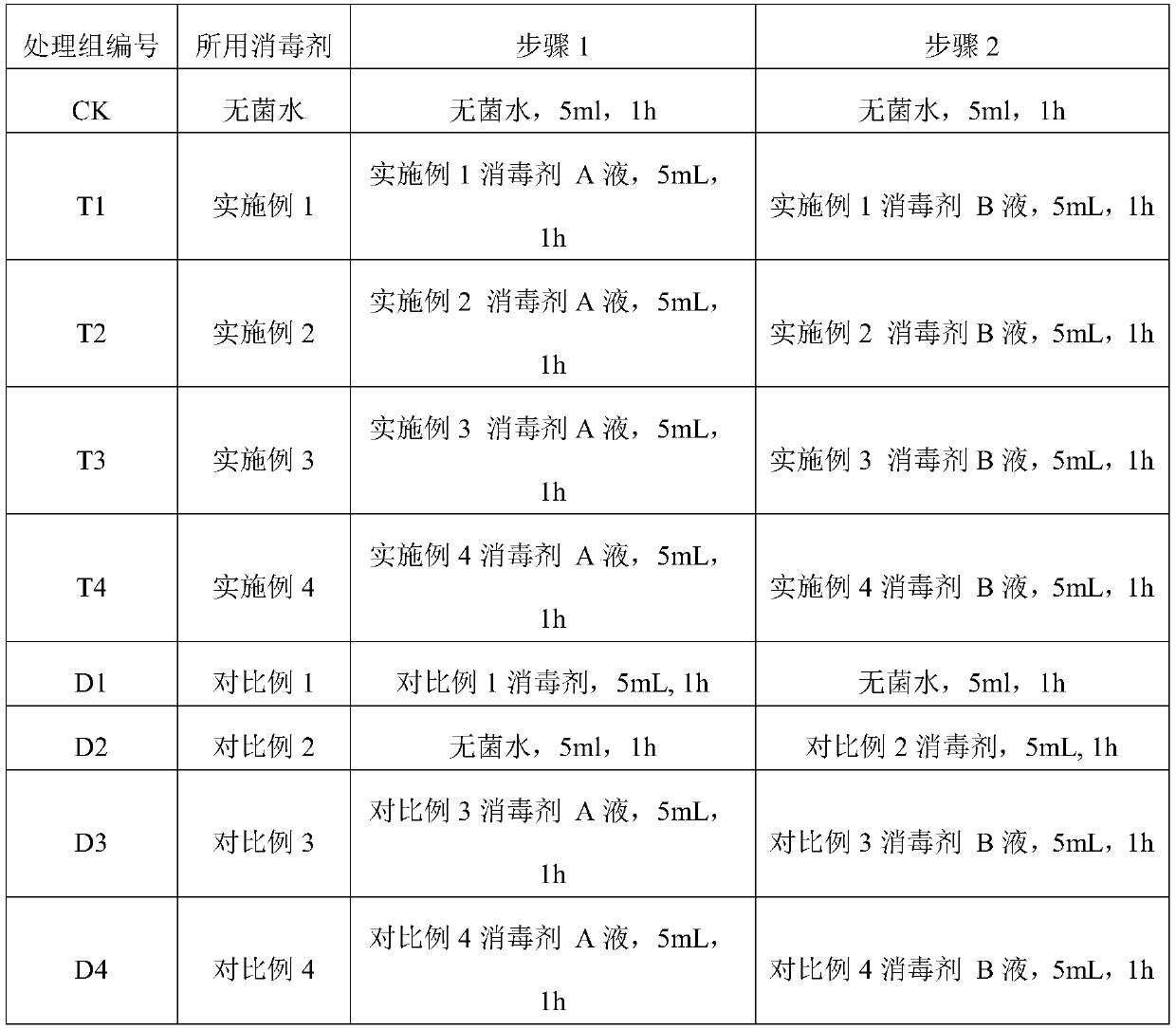

Application of silage seepage in prevention and treatment of bacterial wilt

ActiveCN111202102AFree from harmEfficient killingBiocideDisinfectantsBiotechnologySuperoxide dismutases

The invention relates to application of a silage seepage in prevention and treatment of bacterial wilt. The invention relates to prevention and treatment of bacterial wilt by independently using the silage seepage. An application method comprises following steps: mixing the silage seepage with catalase and superoxide dismutase to prepare a soil disinfectant I for preventing and treating bacterialwilt; combining sodium deacetate and the soil disinfectant I to prepare a soil disinfectant II for preventing and treating of bacterial wilt; wherein various antibacterial and bactericidal effects such as lactic acid inhibition, bacteriocin inhibition, ion wall breaking sterilization and the like are combined, catalase and superoxide dismutase which have oxygen stress resistance protection effecton plants are used as auxiliary materials, pepper planting soil is disinfected through spraying, irrigation or root irrigation and the like, and a good prevention and treatment effect on pepper bacterial wilt is achieved.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

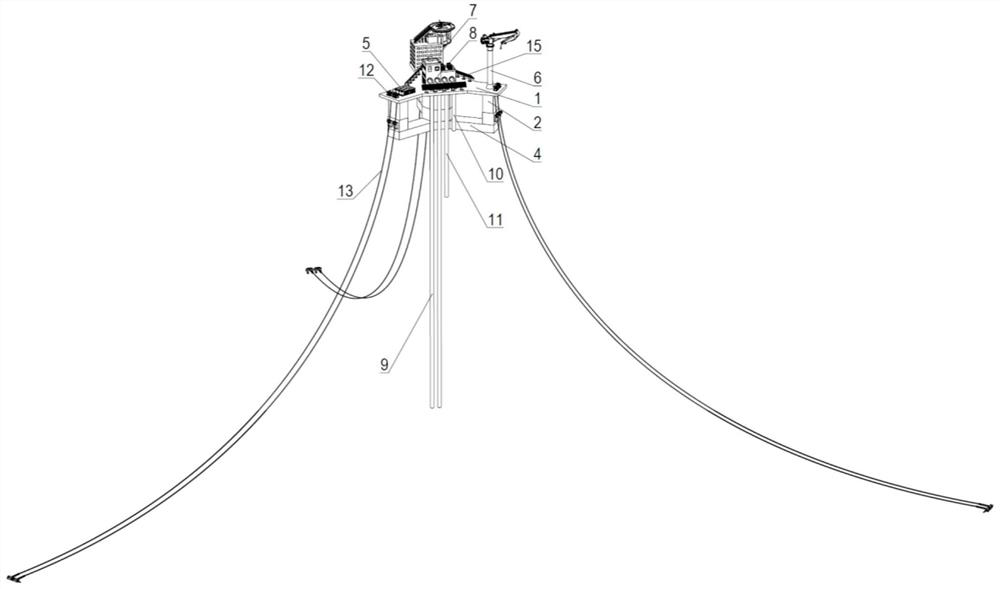

Deep seawater taking development and comprehensive utilization ocean platform and method thereof

PendingCN112722177AReduce shipping costsReduce pollutionPhotovoltaic supportsGeneral water supply conservationEnvironmental engineeringSeawater

The invention relates to a deep sea water intaking development and comprehensive utilization ocean platform, a platform main body comprises an upper deck and a buoyancy tank which has a planar view angle and is profiled with the upper deck, the upper deck comprises a central area and three extension parts which extend from the central area to the periphery and are arranged at equal angles; the lower part of the extension part is fixedly connected with the buoyancy tank through a corner upright post; a center stand column used for storing deep seawater and increasing the waterline area is arranged at the center, located between the upper deck and the buoyancy tank, of the platform body. A deep seawater utilization facility is arranged in the central area above the upper deck; the deep sea water utilization facility is connected with a plurality of deep sea water taking pipes, surface sea water taking pipes and mixed sea water drainage pipes, and the deep sea water taking pipes, the surface sea water taking pipes and the mixed sea water drainage pipes penetrate through the upper deck and extend downwards into sea water.

Owner:SHANGHAI JIAO TONG UNIV

Modified steel slag based on steel dust mud and red mud as well as preparation method and application of modified steel slag

ActiveCN113979655AImprove gelling activityAchieving Scale UtilizationRecycling and recovery technologiesProcess efficiency improvementSlagPolluted environment

The invention discloses modified steel slag based on steel dust and mud and red mud as well as a preparation method and application of the modified steel slag, wherein the modified steel slag comprises steel slag and a composite modifier, and the composite modifier comprises coal gasification residues, the red mud and the steel dust mud; the preparation method comprises the following steps: pretreatment of steel slag, pretreatment of the coal gasification residues, pretreatment of the red mud, pretreatment of the steel dust mud, ball-milling mixing, compression molding, sintering modification and blast quenching. According to the modified steel slag and the preparation method and application thereof, the problems that steel slag, steel dust mud, red mud and coal gasification residues cannot be effectively utilized and pollute the environment can be solved, so that the steel slag, the coal gasification residues, the steel dust mud and the red mud are effectively utilized, and the gelling activity and stability of the steel slag are improved; and meanwhile, waste is turned into wealth, large-scale utilization of waste is achieved, high economic value is generated, and the purposes of green sustainable development, energy conservation, environmental protection and resource utilization of solid waste are achieved.

Owner:CHINA RAILWAY CONSTR GROUP +2

Degradable thin film and preparing method

The invention discloses a degradable thin film and a preparing method thereof. The degradable thin film comprises, by mass, 100 parts of low-density polyethylene, 25-30 parts of starch, 30-40 parts ofa plasticizer, 8-12 parts of a dispersing agent, 2-4 parts of a light stabilizer, 2-4 parts of an antioxidant and 5-8 parts of a degrading agent. The thermal oxidation degrading agent comprises a metal organic frame material UIO-66 and a metal organic frame material MOF-5. In the thermal oxidation degrading agent, the mass ratio of the metal organic frame material UIO-66 to the metal organic frame material MOF-5 is 1:(0.9-1.1). The degradable thin film has the advantage of being degradable.

Owner:温州银润包装有限公司

A control method for a new energy power supply system for urban rail traction network

ActiveCN110460077BEfficient use ofReduce energy storage capacitySingle network parallel feeding arrangementsEnergy storageStored energyRegenerative brake

The invention discloses a new energy power supply system and a control method for urban rail traction network, including an independent energy storage system located in the middle section of the line and a wind-solar-storage combined power generation system located in the depot or parking lot at the end of the line; according to offline prediction data, Obtain load forecast power and expected peak-to-valley values from historical data, and then judge whether there is a load based on urban rail traffic data; judge operating conditions based on real-time voltage, and compare the load forecast power and expected peak-to-valley values at the next moment to judge whether it is load operation According to the peak and valley state, different control strategies are determined by judging the results, so as to realize effective control of the energy storage device in the independent energy storage system, the wind-solar combined power generation device and the energy storage device in the wind-solar-storage combined power generation system. The invention can not only promote the consumption of renewable energy such as local scenery, but also improve grid voltage fluctuations, effectively recycle regenerative braking energy and at the same time cut peak loads and fill valleys, reduce urban rail operating costs, and have good economic benefits.

Owner:SOUTHWEST JIAOTONG UNIV

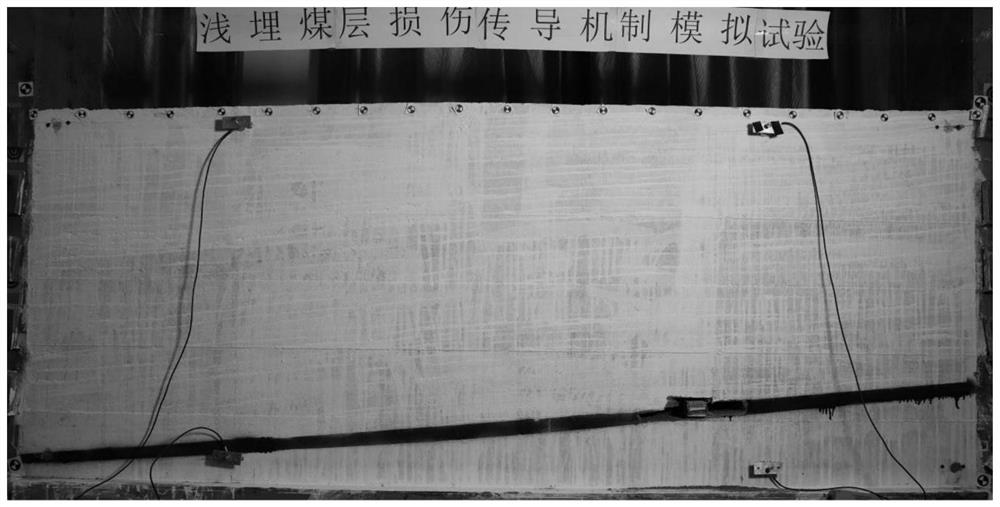

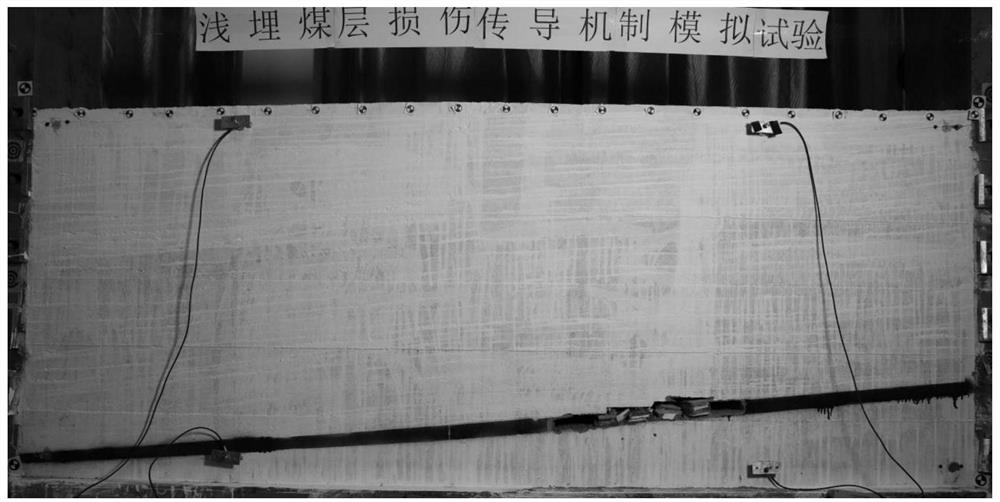

Shallow surface ecological water protection method based on the hysteresis effect of the key layer of mining space

The invention discloses a shallow surface ecological water protection method based on the stagnation effect of key layers in mining space, utilizes the development and closure of hard rock layers (key layers) to separate layers and has a certain delay time, and according to the theory of key layers and the mechanical strength of rock layers, finds out-of-surface layers One or more key layers that are nearest and have a certain development delay time, drill holes in the key layer in advance, and set up a monitoring system in the hole; when the separation layer develops below the key layer, the monitoring system automatically recognizes and starts The grouting pump performs rapid grouting, and fills the separation space with grout before the key layer is broken and bent to block the upwardly conductive mining space, so as to prevent the mining from damaging the shallow rock formation and shallow surface water, and at the same time increase the The strength of the rock mass structure forms a "protective circle" for the shallow surface rock formation, prevents the loss of shallow surface water and surface subsidence, and protects the surface ecological water level, which is beneficial to the ecological protection of the ecologically fragile areas in the west.

Owner:NORTH CHINA INST OF SCI & TECH

A kind of active powder concrete mixed with fly ash and its preparation method

The invention discloses active powder concrete doped with coal ash and a preparation method of the active powder concrete. The active powder concrete doped with the coal ash is prepared from the following materials in parts by weight: 1 part of cement, 1.1 parts of quartz sand, 0.21 to 0.28 part of silica fume, 0.07 to 0.14 part of coal ash, 0.1 part of steel fibers, 0.1 part of small components, 0.2 part of water and 0.015 part of water reducer; and the active powder concrete doped with the coal ash is prepared by virtue of stirring, vibrating molding, mold stripping and high-temperature maintenance. The active powder concrete has the characteristics that the industrial waste slag powder is doped as an active component, and the novel active powder concrete is prepared by virtue of high-temperature maintenance, has the advantages of high strength, good mixability, low cost, environmental friendliness, simple preparation method and the like, is suitable for being popularized and used in real engineering, and conforms to the environment-friendly sustainable development strategy concept of China.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Composite polyolefin skin for surface of construction formwork, and preparation and use method of composite polyolefin skin

InactiveCN110527184AImprove protectionReduce the difficulty of disassemblyForming/stuttering elementsPolymer sciencePolyolefin

The invention relates to the technical field of construction formworks, and discloses a composite polyolefin skin for the surface of a construction formwork, and a preparation and use method of the composite polyolefin skin. The composite polyolefin skin is arranged to be in contact with the surface of the construction formwork, and is prepared from the following components in parts by weight: 80-90 parts of polyolefin, 15-25 parts of a controllable transfer assistant, 15-25 parts of filler, 5-15 parts of a flame retardant, 0.1-5 parts of an antioxidant, 0.1-5 parts of an anti-ultraviolet absorbent and 0.1-5 parts of a dispersant. The composite polyolefin skin adheres to the external surface of an existing construction formwork for use, demoulding performance is good, waterproof performance is good, and the composite polyolefin skin can be reused.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

A method for resource utilization of industrial copper-containing wastewater

ActiveCN113501574BEasy to handleRealize secondary resource utilizationWater contaminantsDispersed particle separationCu2 ionsFlue gas

Owner:CENT SOUTH UNIV

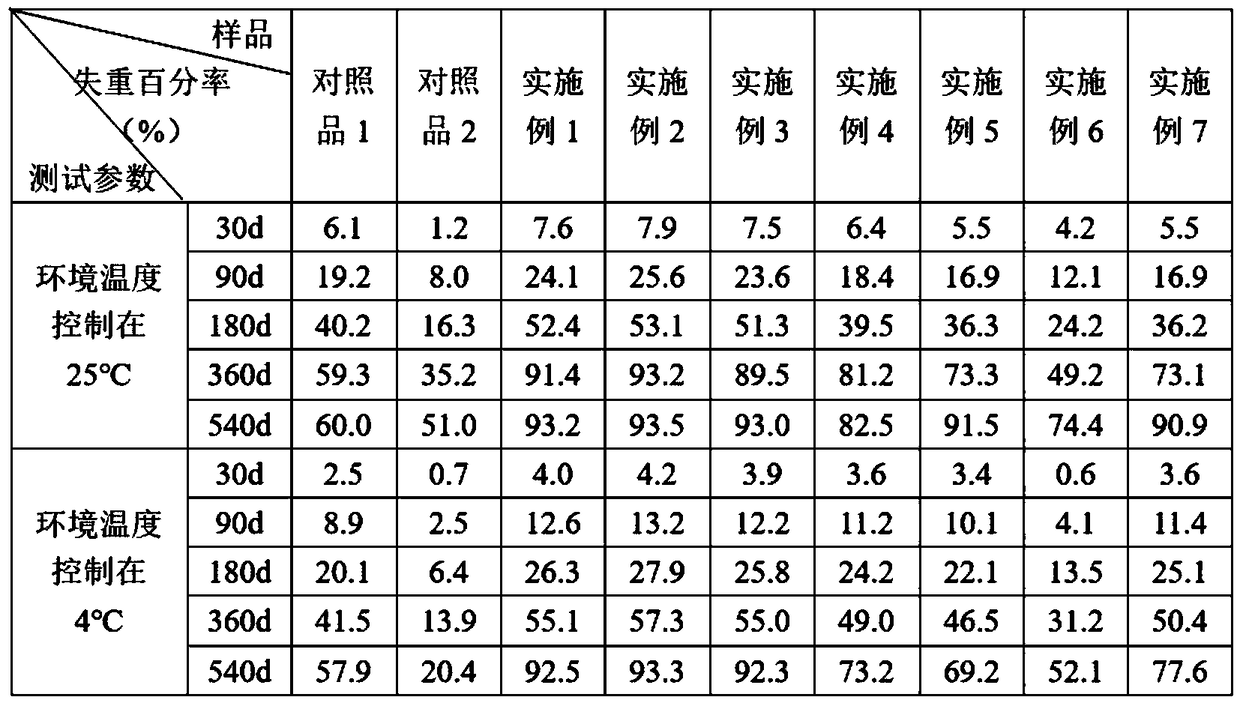

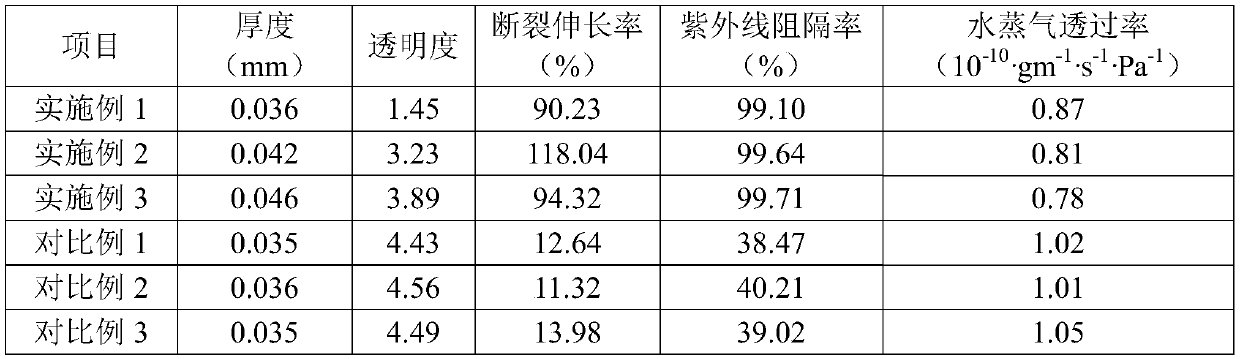

Collagen edible film and preparation method thereof

ActiveCN111187434AImproved ductility and barrier propertiesSimple preparation processComposite materialSilicone resin

The invention belongs to the technical field of packaging, and relates to a collagen edible film and a preparation method thereof. The preparation method comprises the following steps: uniformly stirring and mixing a fish scale collagen matrix liquid, a protocatechuic acid improvement liquid and a plasticizing liquid; then carrying out ultrasonic treatment for uniform mixing of the components anddegassing to obtain an ultrasonic mixed degassed liquid; uniformly pouring the ultrasonic mixed degassed liquid onto organosilicon resin, drying, cooling to room temperature, and uncovering the film to obtain the collagen edible film. The thickness of the collagen edible film prepared by the method is 0.036 to 0.046 mm; the transparency ranges from 1.45 to 3.89; the elongation at break is 90.23 percent to 118.04 percent; the ultraviolet ray blocking rate is 99.10-99.71%, the water vapor blocking rate is 0.78*10<-10> to 0.87*10<-10> gm<-1>.s<-1>.Pa<-1>, the advantages of high ductility, high barrier property and high safety are achieved, the preparation technological process is simple, and no pollution is caused to the environment.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

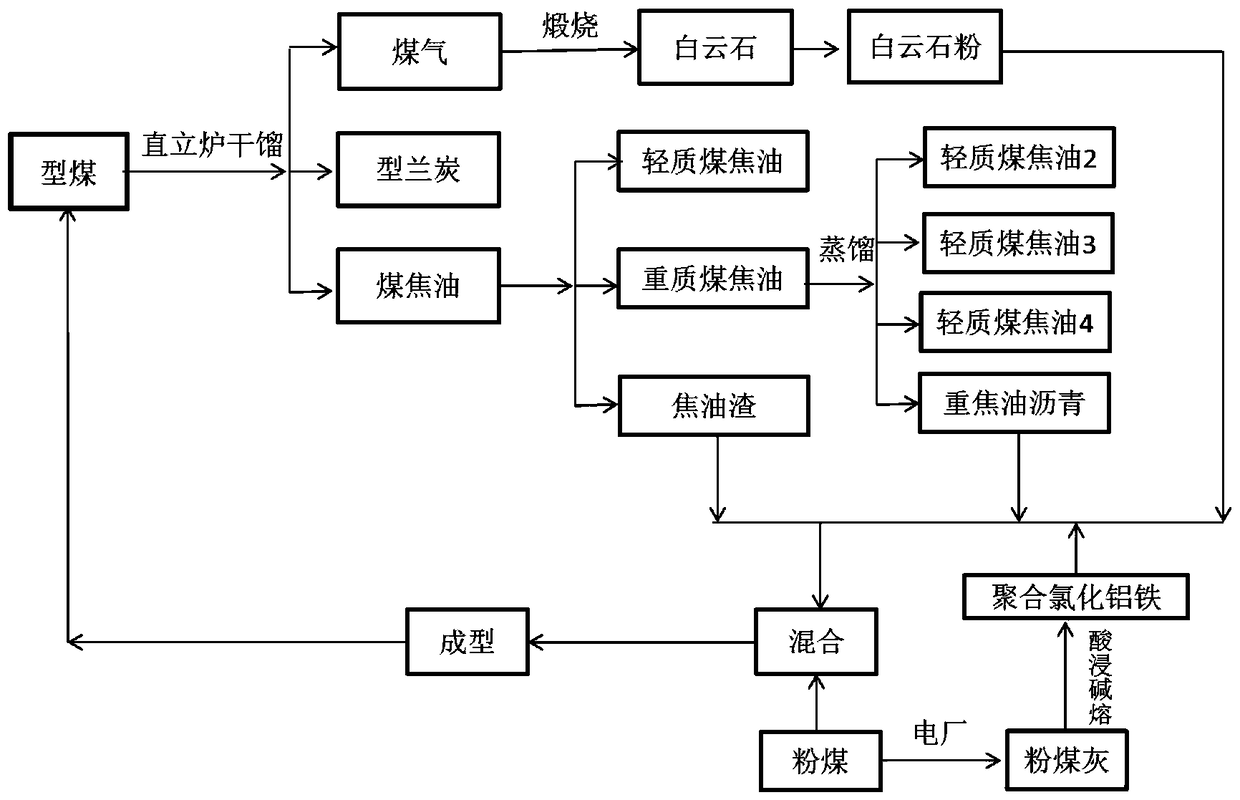

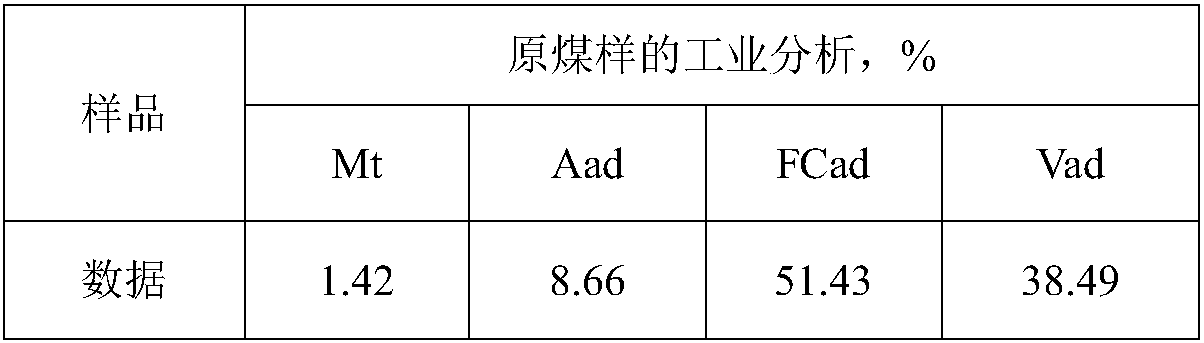

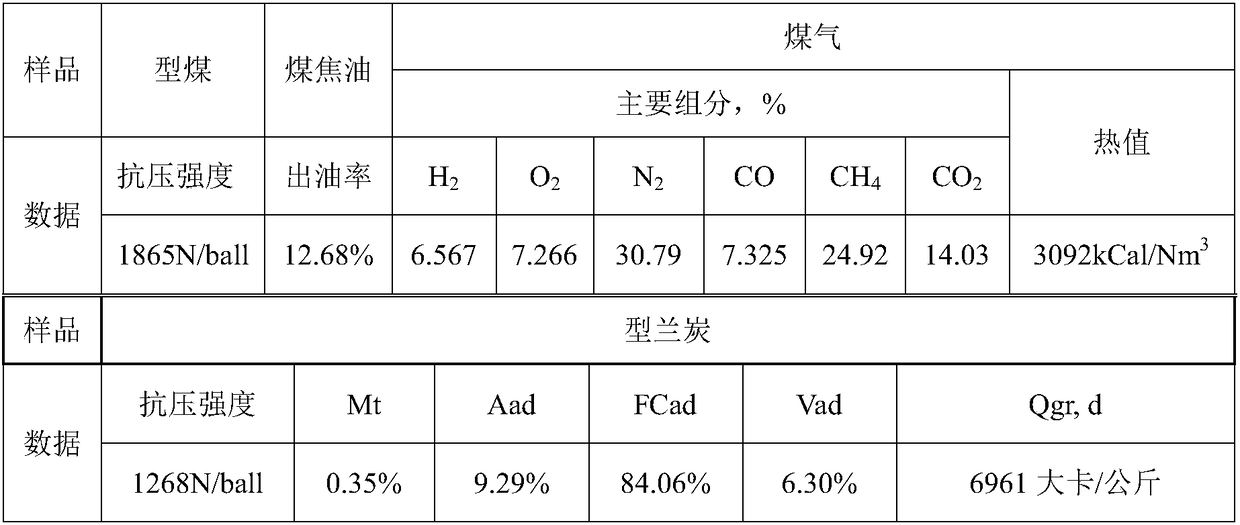

A pulverized coal forming dry distillation method using waste as a binder

ActiveCN106635100BImprove oil yieldExpand the industrial chainSpecial form destructive distillationDolomiteMaterials science

Owner:YULIN UNIV

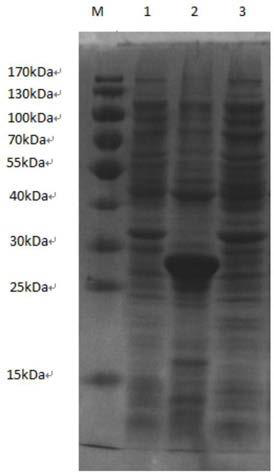

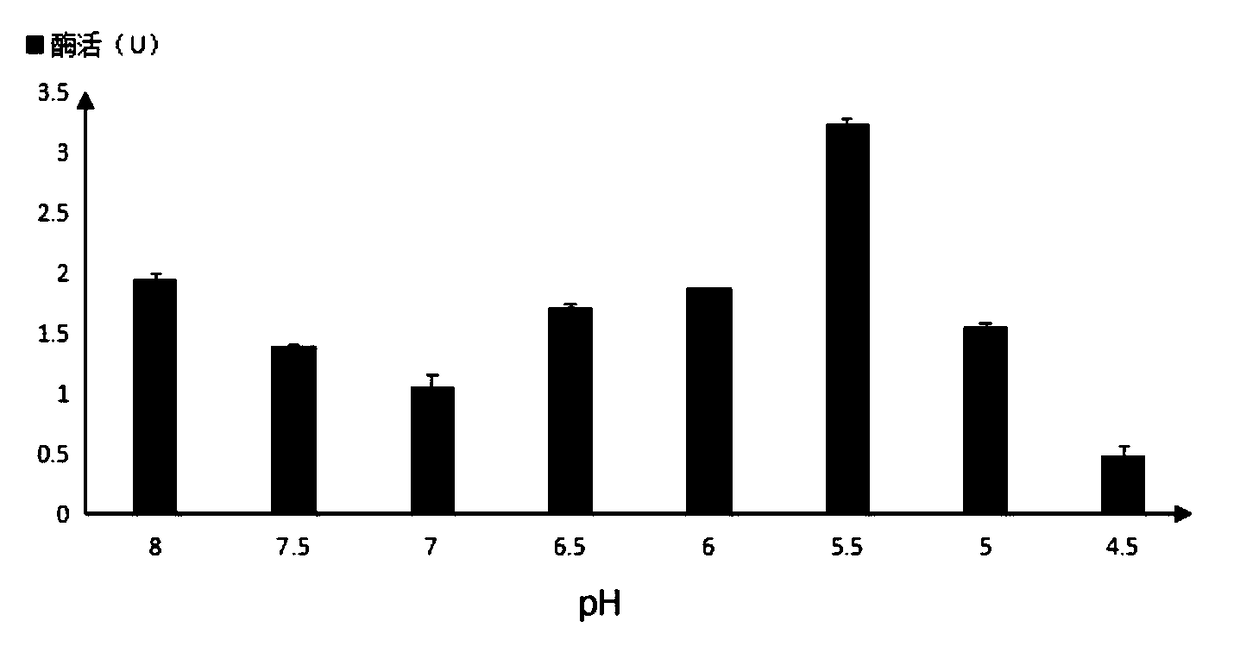

Method for promoting quality of fish scale gelatin

ActiveCN109504665ARealize high-value utilizationGood characterConnective tissue peptidesClimate change adaptationEscherichia coliGelatin

The invention discloses a method for promoting quality of fish scale gelatin. L-proline cis-4-hydroxylase (P4H) is effectively expressed in escherichia coli and is used for modifying fish scale gelatin, so as to promote the quality of fish scale gelatin and expand the application scope thereof in the market.

Owner:JIANGXI NORMAL UNIV

A kind of steel slag-cyanide tailings cementitious material and its preparation method and application

ActiveCN112408831BIncrease added valueEasy to prepareSolid waste managementMagnetic separationCyanidePortland cement

The invention proposes a steel slag-cyanide tailings cementitious material and its preparation method and application. The steel slag-cyanide tailings cementitious material is composed of the following substances in mass percentage: 30-60% of iron-selected waste slag, 10-20% of aerated concrete waste, 15-25% of calcium carbide slag, and 10-30% of desulfurized gypsum %. Carbide slag is calcined, cooled naturally, and ground; aerated concrete waste is crushed, dried, and ground; after desulfurization gypsum is ground, it is mixed with steel slag-cyanide tailings iron selection waste in proportion to prepare steel slag-cyanide tailings cementitious material. The cementitious material is mixed with portland cement to prepare steel slag-cyanide tailings cement. The preparation method of the invention is simple and easy to implement, can realize the coordinated utilization of various wastes, increase the added value of the wastes, reduce the production cost of cement, and has good social and economic effects.

Owner:HEBEI UNIV OF ENG +1

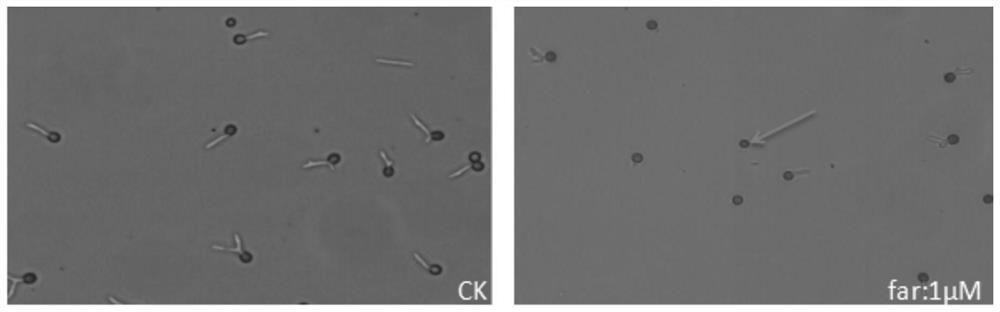

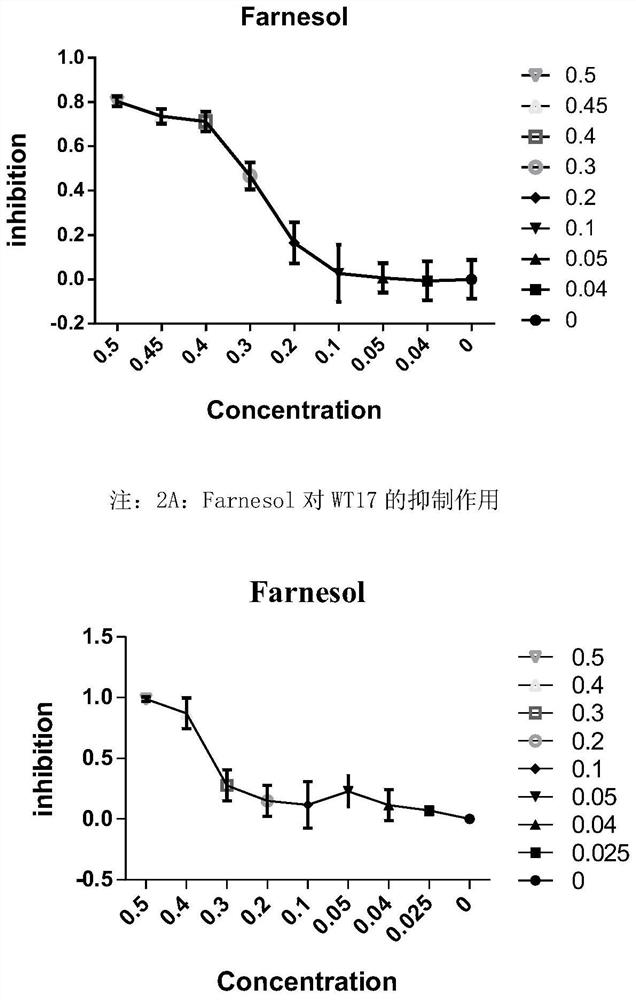

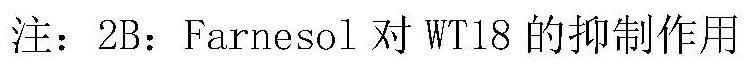

The use of farnesol in the prevention and treatment of smut

ActiveCN108552205BRealize green and sustainable developmentReaching the goal of zero growthBiocideFungicidesBiotechnologyBasidiospore

Owner:SOUTH CHINA AGRI UNIV

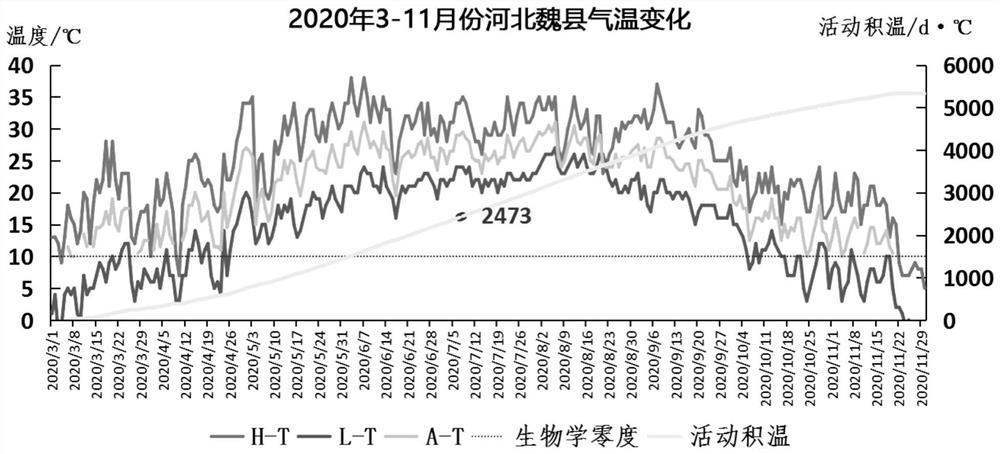

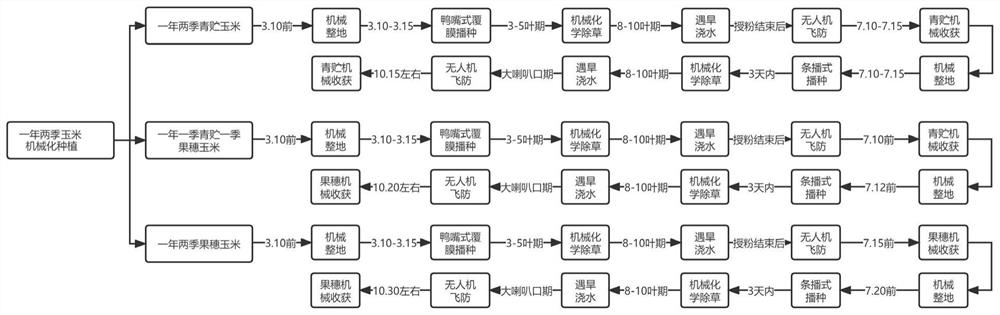

One-year two-season corn mechanical planting method

PendingCN114766301AIncrease the multiple cropping indexHigh yieldPlantingDibble seedersAgricultural engineeringMechanical equipment

The invention discloses a mechanical planting method for two-season corn in one year, relates to the technical field of corn planting, and solves the technical problems that common corn planted in two-season in one year is difficult to completely mature, the first-season corn is difficult to normally grow, and film mulching and sowing integrated mechanical equipment is lacked. Selecting a grain-feed dual-purpose corn variety with a short growth period and an early-maturing corn variety suitable for machine harvesting; 2, determining a planting period from corn sowing to harvesting; step 3, determining a whole-course mechanized planting mode of harvesting two seasons of silage corn in one year, harvesting one season of silage corn and one season of ear corn in one year, and harvesting two seasons of ear corn in one year. According to the method, effective illumination resources from March to October are fully utilized, the corn variety with the short growth period is selected, the multiple cropping index of the land is increased, successful planting and harvesting of two-season corn in one year are achieved, and the total yield of commercial grain corn or silage corn is increased; whole-course mechanical planting is adopted, the planting efficiency is improved, and the requirements of time nodes are met.

Owner:河南金苑种业股份有限公司

Alkali-activated gel material for 3D printing and its printing method

The invention discloses an alkali-activated cementing material for 3D printing and a printing method of the alkali-activated cementing material. The alkali-activated cementing material consists of the following raw materials: industrial wastes, an alkali activating agent, fine aggregates, a defoaming agent, a water reduction agent, water, coarse aggregates, high-strength fiber and a micro nano material. A prepared slurry mixture is fed by two pumps and is printed and molded in a 3D printing mode. The problem that 3D printing concrete is low in early strength is solved, and the slurry properties of the alkali-activated cementing material are effectively improved; as the slurry is fed by two pumps, the problems that the alkali-activated cementing material is high in condensation rate and not applicable to 3D printing are solved; and due to doping of various fibers, final pressure and bending resistance of printed concrete is greatly improved.

Owner:NANJING UNIV OF SCI & TECH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com