A pulverized coal forming dry distillation method using waste as a binder

A binder and waste technology, which is applied in the field of semi-coke production in coal chemical industry, can solve the problems of threatening human health, polluting air, polluting water and soil, etc., to achieve green and sustainable economic development, improve oil yield, expand The effect of the industrial chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

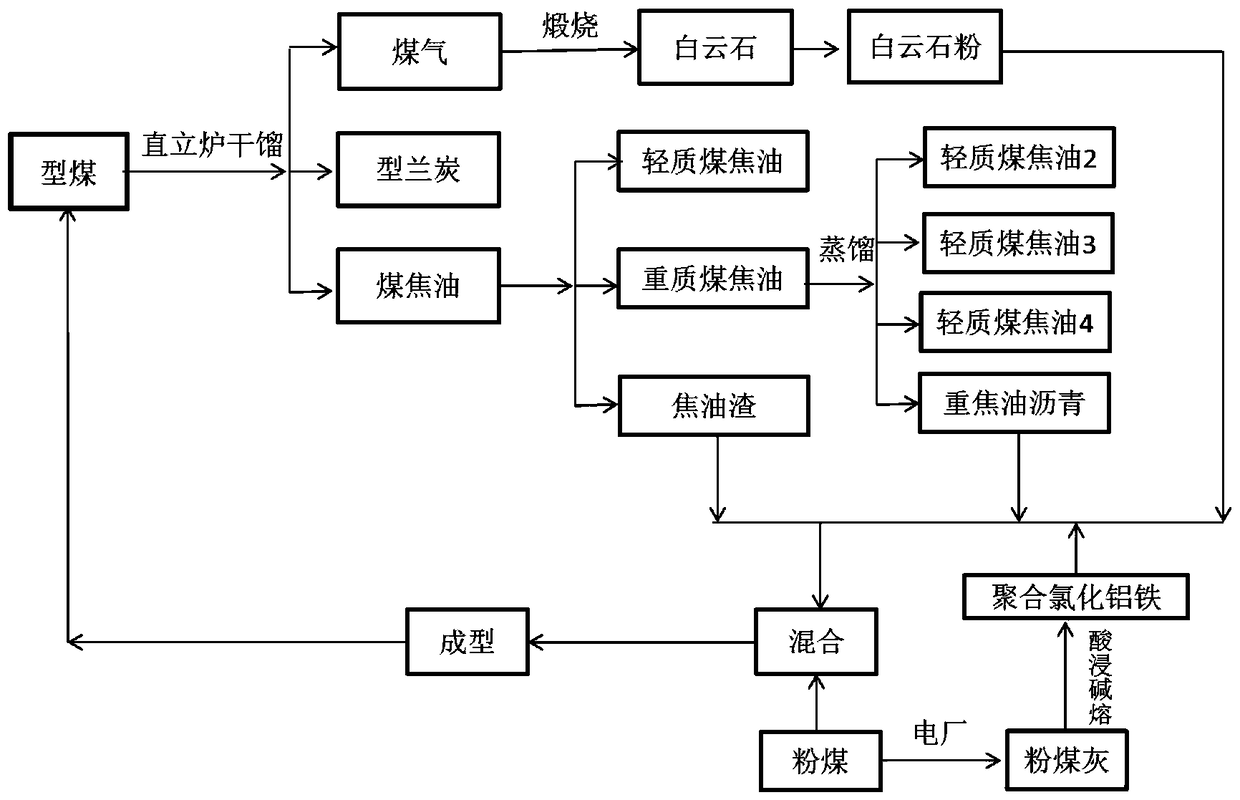

[0032] Such as figure 1 Shown, a kind of pulverized coal carbonization method using waste as binder, comprises the following steps:

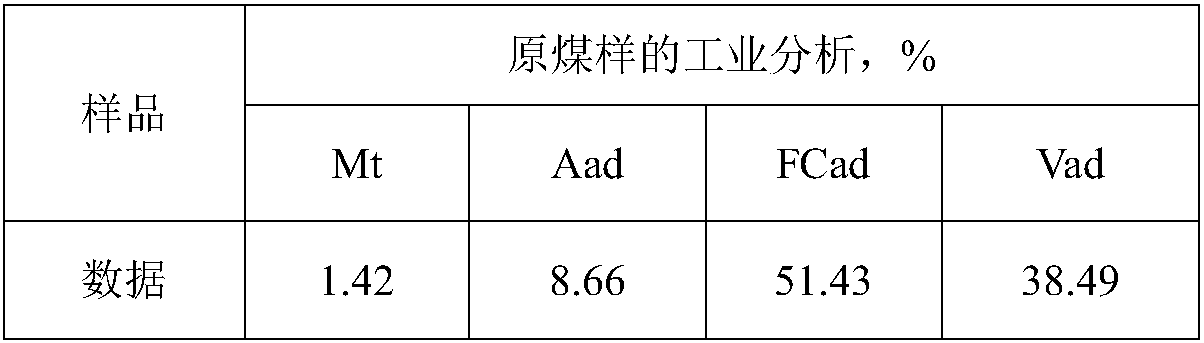

[0033] (1) The coal is crushed and screened to obtain pulverized coal;

[0034] (2) Raise the temperature of the water to 80°C. At this temperature, mix heavy coal tar pitch, tar residue, and polyaluminum ferric chloride in sequence and stir well. When the mixture softens, pour dolomite powder into it and heat and stir. Make a viscous pasty substance to obtain a binder;

[0035] (3) Compounding the binder prepared in step (2) with the pulverized coal in step (1) and fully mixing to obtain a mixture;

[0036] (4) The mixture of step (3) is cold-pressed with 10MPa pressure in a molding die to obtain briquettes;

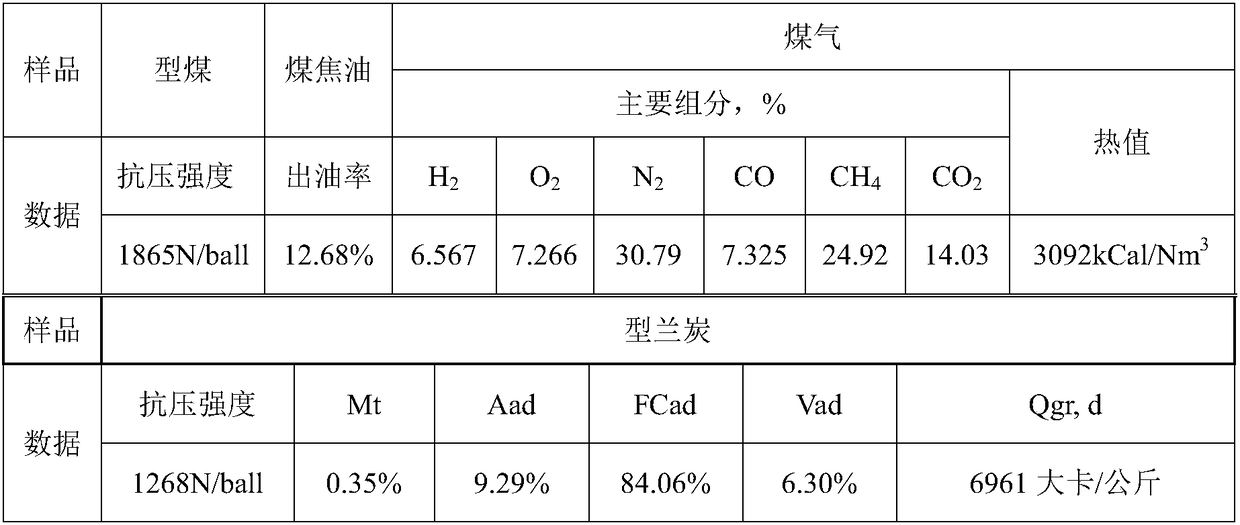

[0037] (5) Pyrolyzing the briquette product obtained in step (4) at 500° C. for 4 hours in a retort furnace to obtain briquette, coal tar and gas.

[0038] According to the percentage by weight, mix 5% of tar residue, 5% of heavy coal...

Embodiment 2

[0043] A pulverized coal forming dry distillation method using waste as a binder, comprising the following steps:

[0044] (1) The coal is crushed and screened to obtain pulverized coal;

[0045] (2) Raise the temperature of the water to 100°C. At this temperature, mix heavy coal tar pitch, tar residue, and polyaluminum ferric chloride in sequence and stir well. When the mixture softens, pour dolomite powder into it and heat and stir. Make a viscous pasty substance to obtain a binder;

[0046] (3) Compounding the binder prepared in step (2) with the pulverized coal in step (1) and fully mixing to obtain a mixture;

[0047] (4) the mixture of step (3) is cold-pressed with 18MPa pressure in the molding die to obtain briquettes;

[0048] (5) Pyrolyzing the briquette product obtained in step (4) at 600° C. for 3 hours in a retort furnace to obtain briquette, coal tar and gas.

[0049] The coal blending ratio is shown in Table 3.

[0050] table 3:

[0051]

[0052] Table 4 sh...

Embodiment 3

[0056] A pulverized coal forming dry distillation method using waste as a binder, comprising the following steps:

[0057] (1) The coal is crushed and screened to obtain pulverized coal;

[0058] (2) Raise the temperature of the water to 90°C. At this temperature, mix the heavy coal tar pitch, tar residue, and polyaluminum ferric chloride in sequence and stir well. When the mixture softens, pour in dolomite powder and heat and stir. Make a viscous pasty substance to obtain a binder;

[0059] (3) Compounding the binder prepared in step (2) with the pulverized coal in step (1) and fully mixing to obtain a mixture;

[0060] (4) the mixture of step (3) is cold-pressed with 20MPa pressure in the molding die to obtain briquettes;

[0061] (5) Pyrolyzing the briquette product obtained in step (4) at 750° C. for 24 hours in a retort furnace to obtain briquette, coal tar and gas.

[0062] The coal blending ratio is shown in Table 5.

[0063] table 5:

[0064]

[0065] Table 6 s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com