Alkali-activated gel material for 3D printing and its printing method

A 3D printing and cementitious material technology, applied in the field of alkali-activated cementitious materials and their preparation, can solve the problems of limited printing concrete height, printing process constraints, poor work performance, etc., and achieve green sustainable development and high early strength , good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

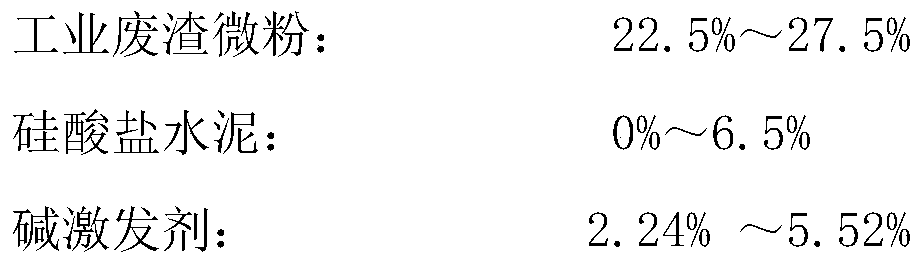

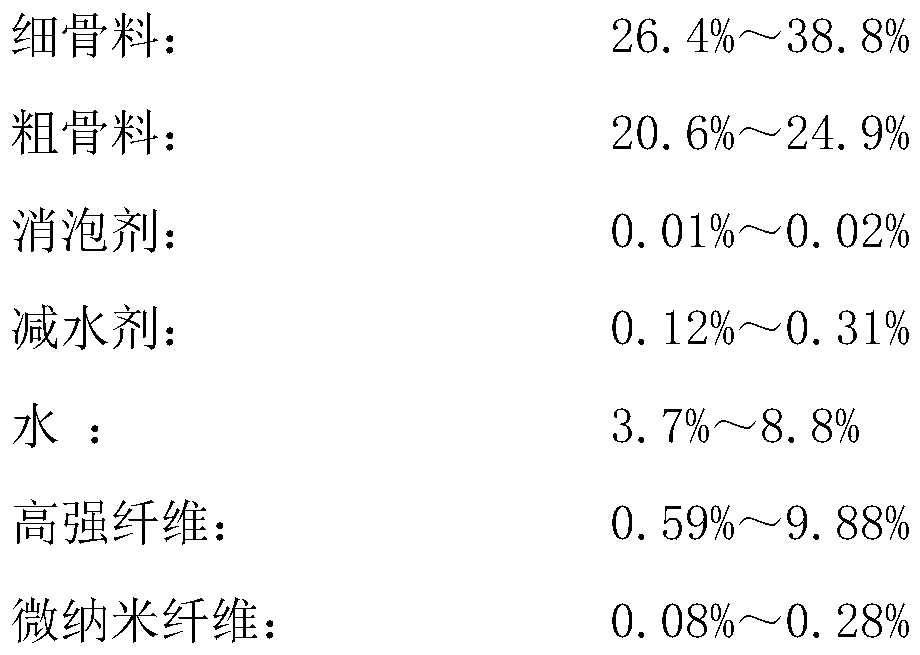

Method used

Image

Examples

Embodiment 1

[0030] Choose the blast furnace slag micropowder (basic index M of 25.8% by weight percentage b =1), put 20.7% coarse aggregate and 30.9% yellow sand fine aggregate into the mixer and mix well, add 0.08% carbon nanofiber to the mixture with 0.01% defoamer, 0.26% water reducer and 8.3% water Ultrasonic dispersion in the liquid and ultrasonic instrument for more than 10 minutes, then add it to the mixer, stir for 5-10 minutes, so that the solid raw material changes from a dispersed state to a viscous slurry state, and then add 9.81% steel fiber evenly to the slurry , a mixture slurry was obtained. Then the water glass solution (modulus is 1.5) and the mixture slurry are transferred to the arm of the printing stirring machine for stirring with a delivery pump. Through the program designed by the computer, the printing mixing robot arm is controlled to print concrete layer by layer until the printing process of the entire building is completed, and finally a 3D printed alkali-act...

Embodiment 2

[0033] Select Portland cement with a weight percentage of 2.9%, fly ash 26.6%, 23.6% coarse aggregate and 29.5% yellow sand fine aggregate and mix them in a mixer, add 0.14% silicon carbide fiber to dissolve 0.01% defoaming water-reducing agent, 0.15% water-reducing agent and 4.9% water, and ultrasonically disperse in an ultrasonic instrument for more than 10 minutes, then add it to the mixer and stir for 5-10 minutes to make the solid raw material change from a dispersed state to a viscous slurry state, and then uniformly add 9.88% steel fibers into the slurry to obtain a mixture slurry. Then the water glass (modulus is 1.8) and the mixture slurry are transferred to the arm of the printing mixer with a transfer pump for stirring. Through the program designed by the computer, the printing mixing robot arm is controlled to print concrete layer by layer until the printing process of the entire building is completed, and finally a 3D printed alkali-activated cementitious material...

Embodiment 3

[0036] Select 6.1% Portland cement by weight, 12.1% steel slag, 12.1% blast furnace slag powder (alkaline index M b =1), put 24.2% coarse aggregate and 33.4% yellow sand fine aggregate into the mixer and mix well, add 0.27% zirconia fiber into the mixture with 0.01% defoamer, 0.23% water reducing agent and 7.1% water Ultrasonic dispersion in the liquid and in an ultrasonic instrument for more than 10 minutes, stirring for 5-10 minutes, so that the solid raw material changes from a dispersed state to a viscous slurry state, and then 0.59% basalt fiber is evenly added to the slurry to obtain a mixture slurry. Then use the delivery pump to transfer the water glass (modulus 1.7) and the mixture slurry to the arm of the printing mixer for mixing. Through the program designed by the computer, the arm of the printing mixer is controlled to print concrete layer by layer until the printing process of the entire building is completed. , and finally get 3D printed alkali-inspired cementi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com