Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76results about How to "Raw material safety and environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Foaming agent for tailing sintering perforated brick and application thereof

InactiveCN102826868ARaw material safety and environmental protectionReduce restrictionsCeramicwarePorosityHeat conducting

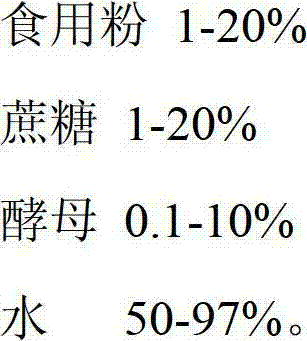

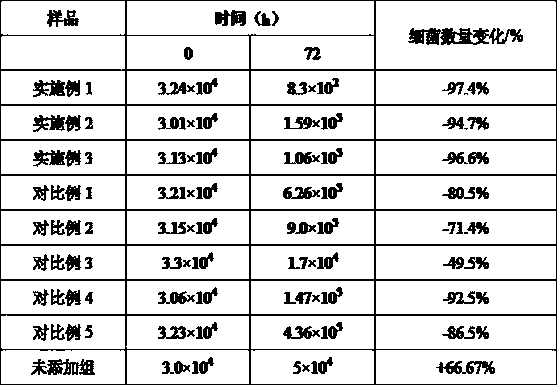

The invention discloses a foaming agent for a tailing sintering perforated brick. The foaming agent comprises the following components in percentage by mass: 1-20 percent of edible powder, 1-20 percent of cane sugar, 0.1-10 percent of yeast and 50-97 percent of water. The foaming agent is applied to a tailing sintering perforated brick by the following steps of: adding a foaming agent of which the amount is 0.1-25 percent by mass of the total amount of slurry which contains 60-90 percent by weight of tailings into the slurry, and fermenting in a die to obtain a green brick; and drying and sintering the green brick to obtain the tailing sintering perforated brick. The foaming agent disclosed by the invention has the advantages of reasonable component mixture ratio, wide raw material source, low cost and capability of foaming at the normal temperature; and the foaming agent is applied to the tailing sintering perforated brick, is mainly made of tailings serving as raw materials, is used for preparing a tailing sintering perforated brick with adjustable porosity, low density, small heat conducting coefficient and high heat-preserving and heat-insulating properties by foaming at the normal temperature and sintering, is suitable to be applied to non-bearing low-density light wall body materials which mainly have framework structures for buildings, and can be widely applied in the field of building wall bodies, ornaments or roof or heat-insulating and heat-preserving materials and the like with framework structures.

Owner:CENT SOUTH UNIV

Environmentally-friendly hot-melt pressure sensitive adhesive and preparation method thereof

PendingCN110093128AUniform molecular weightGood solubilityMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesEnvironmental resistanceAntioxidant

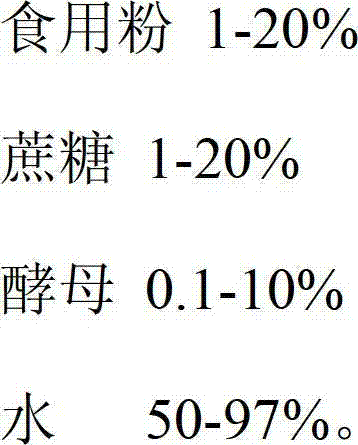

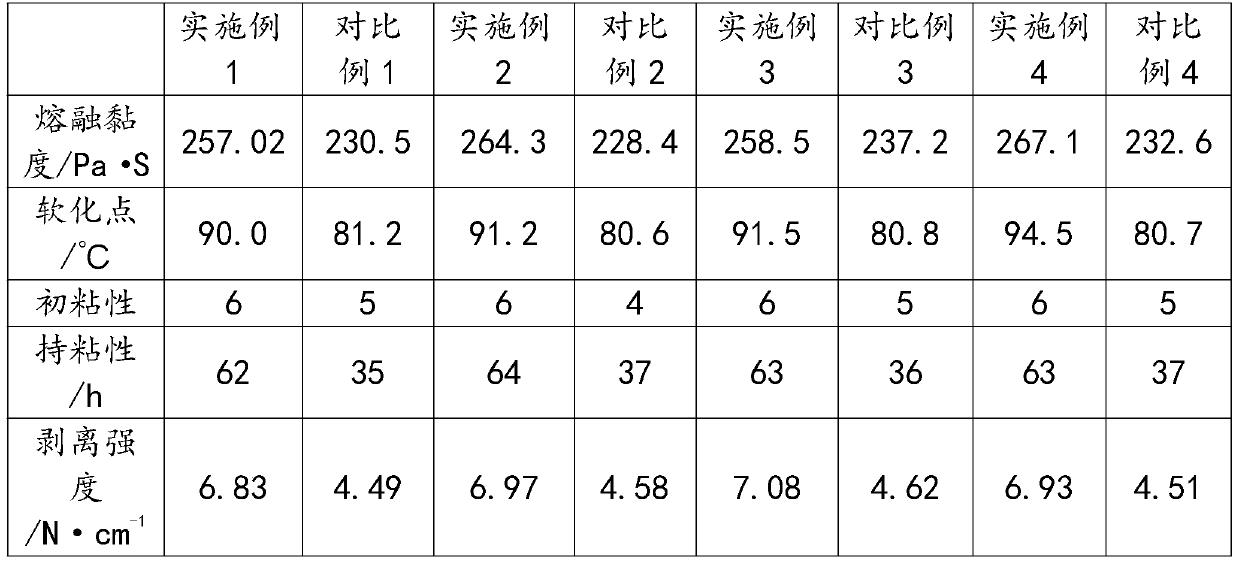

The invention discloses an environmentally-friendly hot-melt pressure sensitive adhesive. The environmentally-friendly hot-melt pressure sensitive adhesive is prepared from, by weight, 25-35 parts ofa thermoplastic elastomer, 28-36 parts of modified petroleum resin, 6-10 parts of natural tackifying resin, 12-20 parts of a plasticizer, 2-3 parts of a modifying filler, 0.2-0.3 part of a coupling agent and 0.2-0.3 part of an antioxidant. The present invention also discloses preparation method of the hot-melt pressure sensitive adhesive. The thermoplastic elastomer is used as a matrix for the hot-melt pressure sensitive adhesive, the modified petroleum resin and the natural tackifying resin are used as tackifying resins, and no organic solvent is needed, so the raw materials are safe and environmentally friendly; the petroleum resin is modified, so the compatibility of the petroleum resin and the thermoplastic elastomer is improved, and the thermal stability of the hot-melt pressure sensitive adhesive is improved; and the reinforcing effect of the modifying filler improves the initial viscosity, the glass strength and the thermal stability of the hot-melt pressure sensitive adhesive are improved, so the environmentally-friendly hot-melt pressure sensitive adhesive with excellent performances is prepared.

Owner:黄敏

Method for preserving primary colors of red and yellow plant disease specimens

InactiveCN107018976ARaw material safety and environmental protectionSimple manufacturing methodDead plant preservationPlant pathologyPlant disease

The invention provides a method for preserving the primary colors of red and yellow plant disease specimens. The method comprises the following steps: (1) collecting, finishing and sterilizing the plant disease specimens; (2) carrying out color fixation; (3) carrying out color repairing; (4) preserving the primary colors. The method creatively comprises the three color processing steps, i.e., color fixation, color repairing and primary color preservation, and the specimens of two colors can be preserved by using one method. The raw materials used in the method are safe and environment-friendly; the method is simple and easy to implement as well as time-saving and labor-saving, can be used for making while collecting, can realize batch production, and is used for preserving the original shapes and primary colors of the specimens; the preserving fluid is clear and transparent; therefore, the method has positive practical significance for application in the field of plant pathology teaching and scientific research.

Owner:GUANGXI AGRI VOCATIONAL COLLEGE

Purifying agent for air purifiers and method for preparing purifying agent

InactiveCN107362680ARaw material safety and environmental protectionImprove adsorption capacityBiocideGas treatmentFiberToxic gas

The invention discloses a purifying agent for air purifiers and a method for preparing the purifying agent, and relates to the technical field of purifying agents. The purifying agent comprises, by weight, 55-65 parts of modified bamboo pulp fibers, 40-42 parts of nanometer bacterium removing agents, 35-40 parts of sustained-release particles, 30-35 parts of expanded vermiculite, 15-25 parts of modified attapulgite, 10-15 parts of mildew-proof and insect-proof agents and 5-7 parts of stabilizers. The purifying agent and the method have the advantages that raw materials for the purifying agent are safe and environmentally friendly, excellent effects of adsorbing toxic gas such as formaldehyde, toluene and dimethylbenzene in the air can be realized, effects of killing germs can be realized, and accordingly indoor environments can be effectively improved.

Owner:HEFEI DONGHENGRUI ELECTRONICS TECH CO LTD

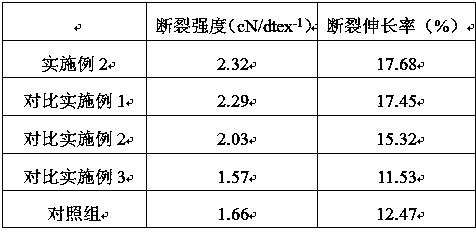

Hydrophilic modification method of polylactic acid fibers

The invention discloses a hydrophilic modification method of polylactic acid fibers. The method has the beneficial effects that the hydrophility of the polylactic acid fibers can be improved to a large extent, so that the wearability of the polylactic acid fibers is substantially improved. The method comprises the following steps: (1) preparing a polylactic acid fiber pretreatment solution from 2 parts of hydroxypropyl methyl cellulose, 5-8 parts of malic acid, 0.2-0.5 part of trehalose and 100 parts of water by weight; (2) putting the polylactic acid fibers into the pretreatment solution to be treated at a constant temperature of 50-55 DEG C for 5-8 minutes, washing up the polylactic acid fibers and drying the polylactic acid fibers under normal temperature; (3) preparing a polylactic acid fiber treating solution from 1 part of hydroxypropyl methyl cellulose, 10 parts of citric acid and 100 parts of water by weight; (4) putting the polylactic acid fibers into the treating solution to be treated at a constant temperature of 50 DEG C for 15-20 minutes; (5) washing up the treated polylactic acid fibers and drying the polylactic acid fibers at 40 DEG C.

Owner:长兴卫峰纺织有限公司

Odor removing agent special for pet excrement treatment, preparation method and application thereof

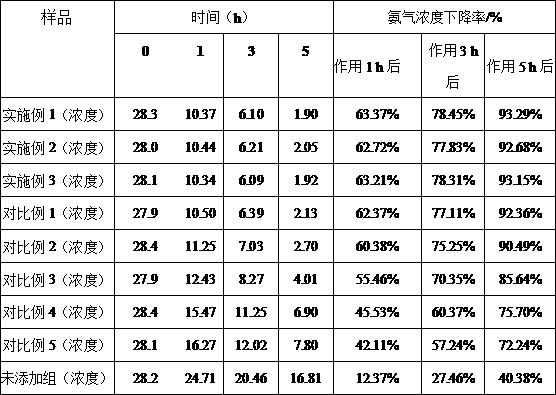

InactiveCN110963655AEasy to deodorizeGood deodorizing effectBiocideGas treatmentBiotechnologyEscherichia coli

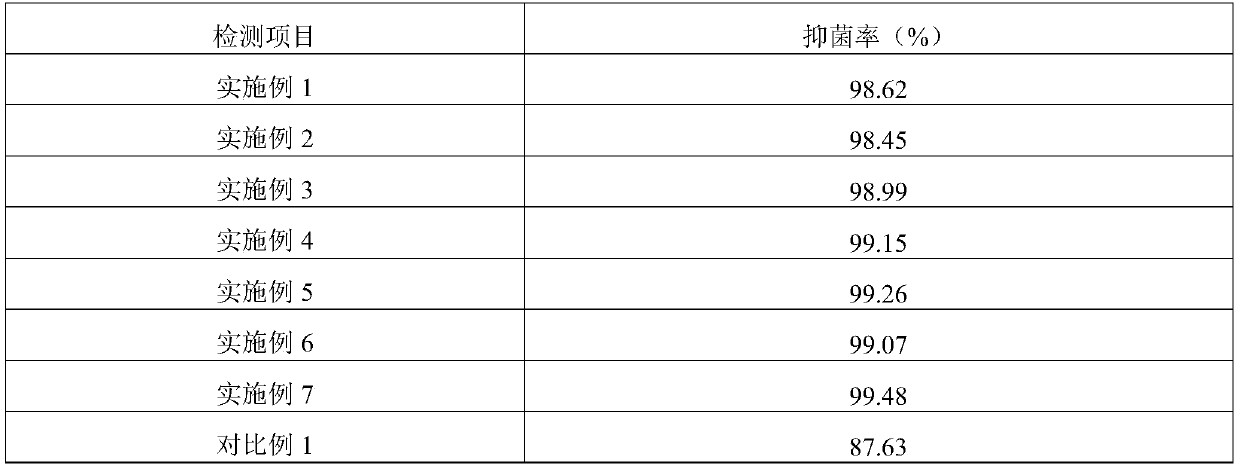

The invention relates to the technical field of pet excrement treatment, particularly to an odor removing agent special for pet excrement treatment, a preparation method and application thereof, and aims to solve the problems that cat litter has poor deodorization effect during use and cannot effectively remove harmful microorganisms in excrement. According to the invention, a complex microbial inoculant, montmorillonite powder, activated carbon powder, citric acid, fermented lentinus edodes powder, bran powder and corn flour are reasonably collocated to prepare the odor removing agent, and the odor removing agent is added as an addition material of cat litter into cat litter for use. Deodorization performance tests find that the odor removing agent can greatly lower the concentration of ammonia gas, and the deodorization and odor removing effects are significant, and bacteriostatic and bactericidal tests find that the odor removing agent can effectively inhibit the growth and propagation of Escherichia coli, salmonella and other harmful microorganisms in pet excrement, and has good bacteriostatic and bactericidal effects, therefore the odor removing agent can effectively improve the use effect of cat litter, and has significant deodorizing, sterilizing and bacteriostatic effects.

Owner:越好生物科技(广州)股份有限公司

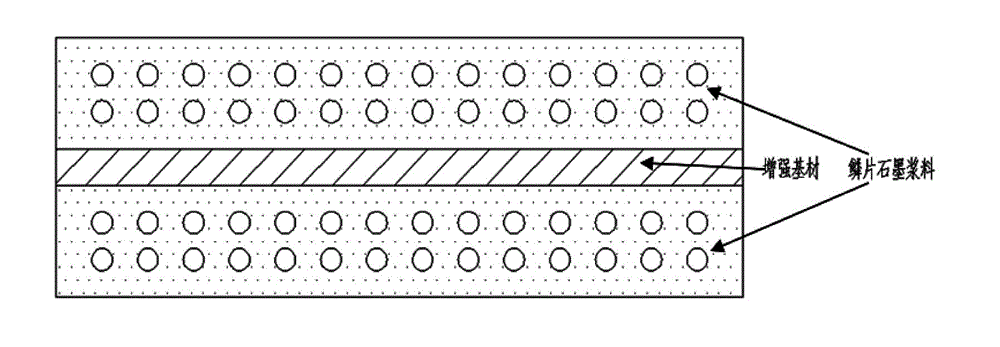

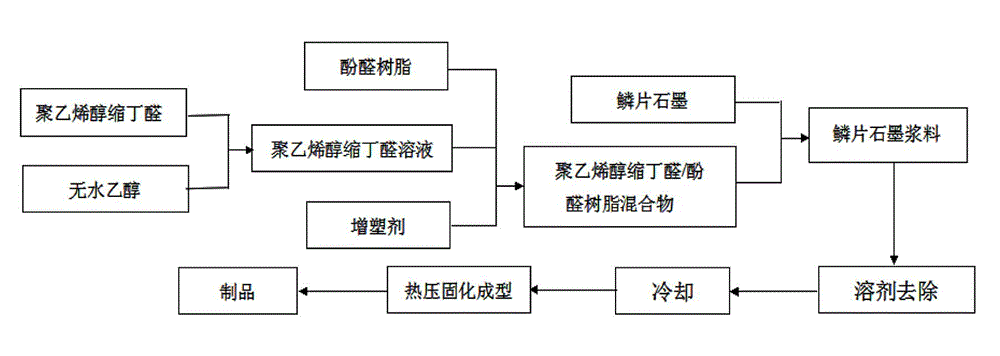

Flake graphite composite sealing plate and manufacturing method

ActiveCN104033607ARaw material safety and environmental protectionSimple forming processEngine sealsCeramic shaping apparatusPlasticizerSizing

The invention relates to a flake graphite composite sealing plate and a manufacturing method thereof. The flake graphite composite sealing plate has a sandwich type composite structure, and belongs to the technical field of shaping and manufacturing of non-metal materials. The composite sealing plate comprises graphite flake powder, an organic bonding agent, a plasticizer and a solvent. The method comprises multiple process links of preparation of a fine flake graphite sizing agent, removal of the solvent, hot-pressing curing molding and the like. The composite sealing plate is environmental friendly and safe, and is low in cost. The manufacturing method is simple, and can be applied to large-scale production.

Owner:宜昌星锐烯碳科技有限责任公司

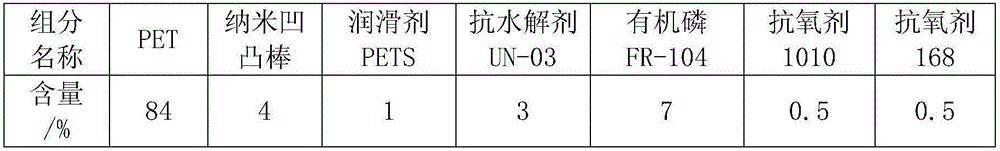

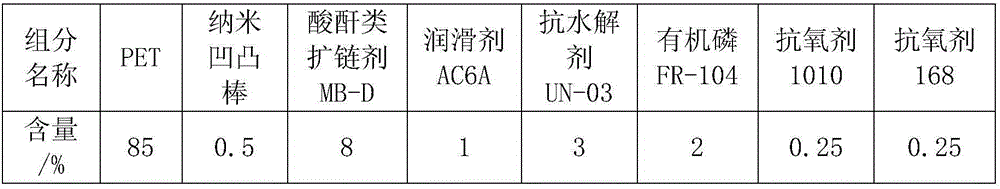

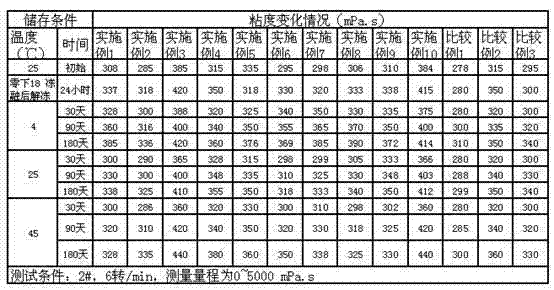

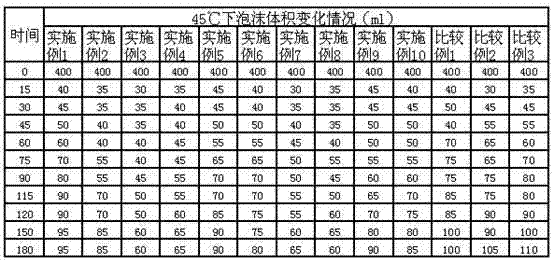

Preparation method of flame-retardant and high-heat-resisting polyethylene terephthalate

The invention discloses a preparation method of flame-retardant and high-heat-resisting polyethylene terephthalate. The preparation method is characterized by comprising the following steps: drying raw materials; uniformly mixing the dried raw material, namely polyethylene terephthalate aggregates, a blended polymer, a nucleating agent, a chain extender, a fire retardant, a stabilizer, a hydrolysis resisting agent and a lubricating agent; adding a mixed material into a double-screw extruder; performing melting extrusion, cooling, dicing and drying, thus obtaining the lame-retardant and high-heat-resisting polyethylene terephthalate with the characteristics of good heat resistance, mechanical property and processing performance; a sheet obtained by compression moulding forming of master batches or a coiled material obtained by a flow casting method can be continuously used at the high temperature of 240DEG C for 30 minutes. The PET master batches obtained by the preparation method disclosed by the invention can be processed into forms such as fibers, fabrics, thin films and sheets, replaces traditional PET and CPET for being applied to the fields with higher heat resisting requirements, such as aviation meal boxes, or can replace nylon with high cost.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Preparation method of flame-retardant coating for fireproof wooden doors

InactiveCN107345103ALow VOC contentReduce thicknessFireproof paintsPolyester coatingsWater basedEmulsion

The invention discloses a preparation method of a flame-retardant coating for fireproof wooden doors. The flame-retardant coating is prepared from water-based resin, two types of flame retardants, melamine, modified ammonium polyphosphate, nanoscale silicon dioxide, organosilicone-modified styrene-acrylic emulsion, dispersant, defoaming agent, stabilizer, filler and water. The VOC (volatile organic compound) content of the coating is low, halogen flame retardant is not contained, the fireproof property is excellent, the physicochemical properties are excellent, and the flame-retardant coating does not produce highly carcinogenic and poisonous gas and smoke when encountering fire; the thickness of the coating layer is small, the materials for preparation are environment-friendly and safe, the preparation method is simple and efficient, and the degree of industrialization is high; furthermore, when the flame-retardant coating is applied to the finishing of a wooden door, under the premise of environment protection and safety, the flame-retardant, heat-insulating and fireproof properties of the wooden door are effectively increased, and thereby the application of the wooden door in certain places with high fireproof requirement is greatly broadened.

Owner:JURONG HOUBAI TOWN FULINMEN WOODEN DOOR PROCESSING FACTORY

Hydrophilic polyurethane foamed plastic and foaming technique

InactiveCN103087502AImprove hydrophilicityImprove water locking abilityCelluloseCarboxymethyl cellulose

The invention relates to the technical field of high polymer materials, and in particular relates to a hydrophilic polyurethane foamed plastic and a foaming technique. The hydrophilic polyurethane foamed plastic comprises components A and B according to the proportion of (1.5:1)-(3:1), the component A consists of ingredients in parts by weight: 1-5 parts of sodium carboxymethyl cellulose, 0.5-2 parts of surfactant and 90-95 parts of water, and the component B comprises the polyurethane prepolymer. The hydrophilic polyurethane foamed plastic is good in hydrophilicity, and obvious in water sucking and retaining effects, and has wide application prospects in the fields of medical, female sanitary towels, baby diapers and the like; and the foaming technique is conducted under atmospheric pressure, is low in equipment requirement, little in energy consumption, low in technique cost, less in pollution emission in a production process, and beneficial to environment friendliness.

Owner:东莞市帕瑞诗贸易有限公司

Green and environmentally-friendly building material and preparation method thereof

ActiveCN106186900AContinuous controllable adjustmentGood heat storage and release characteristicsCross-linkEmulsion

The invention discloses a green and environmentally-friendly building material and a preparation method thereof. The building material is prepared from, by weight, 90-110 parts of foamable thermosetting phenolic resin, 100-120 parts of thermosetting linear urea-formaldehyde resin, 3-5 parts of titanium dioxide powder, 90-95 parts of Tween, 20-25 parts of a modified acrylic emulsion, a filler, a cross-linking agent, and 10-15 parts of a composite assistant. The foamable thermosetting phenolic resin, the thermosetting linear urea-formaldehyde resin and modified acrylate are compounded, so the product combines the advantages of above three components, and is a novel building material with the advantages of smooth surface, good flame retardation and heat insulation properties, good strength and high cost performance.

Owner:NANJING UNIV OF TECH

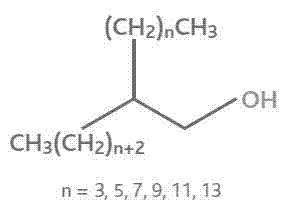

Preparation method for stable higher fatty alcohol degassing agent

InactiveCN104707368AImprove temperature resistanceModerate and low costFoam dispersion/preventionAlcoholActive agent

The invention discloses a preparation method for a stable higher fatty alcohol degassing agent. The preparation method comprises the following steps: 1, feeding higher fatty alcohol, fatty acid ester, wax, a hydrophilic surfactant and Guerbet alcohol into a reaction kettle according to the ratio, heating to 75-95 DEG C, keeping the temperature, and stirring for 2 hours under the speed of 500 r / min to ensure that the system is uniformly mixed;2, heating the hydrophilic surfactant (which accounts for 0.01-10 percent of the whole system), deionized water and an adhesion controller according to a calculating ratio together to 75-95 DEG C, and keeping the temperature for 2 hours for later use; 3, quickly pouring liquid in the step 2 into a mixture in the step 1, emulsifying by a homogenizing machine under the temperature of 75-100 DEG C for 20-30 minutes, and then quickly adding biological polysaccharide alcohol (which accounts for 0.1-5 percent of the whole system) according to the calculating ratio for stirring for 20-60 minutes; 4, quickly cooling the mixed in the step 3 to 20-45 DEG C to obtain the stable higher fatty alcohol degassing agent.

Owner:JIANGSU JINGKE TOTAL SOLUTIONS LTD

Method for preparing ramie artificial wig fiber

InactiveCN109295534AImprove toughnessAntibacterialFlame-proof filament manufactureMonocomponent cellulose artificial filamentSolution treatmentEnvironmental resistance

The invention discloses a method for preparing ramie artificial wig fiber. The method comprises the following steps: (1) acid solution treatment; (2) alkali lye treatment; (3) pulverization treatment;(4) immersion treatment; and (5) preparation of ramie fiber. The artificial wig fiber finally obtained by the invention has excellent toughness, and has the characteristics of antibacterial, anti-mite, heatproof, temperature-resistant and flame retardant performance, the raw materials are safe and environmentally friendly, and have a wide range of sources, which are beneficial to the human body,so that the artificial wig fiber has great market application value.

Owner:太和县慧美发制品有限公司

High-temperature-resistant environment-friendly adhesive and preparation method of same

InactiveCN107286889ALittle influence of temperatureImprove adhesionMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesEpoxyAdhesion force

The invention discloses a high-temperature-resistant environment-friendly adhesive and a preparation method of same, and relates to the technical field of adhesives. The adhesive includes 65-70 parts of organic silicon modified epoxy resin, 55-65 parts of modified starch, 25-35 parts of filler, 10-15 parts of redispersible latex powder, 20-25 parts of additives, and 45-55 parts of water. The adhesive is less in influence due to temperature, has good adhesion force, and is prepared from safe and environment-friendly raw materials.

Owner:HEFEI DAZHUO ELECTRIC POWER CO LTD

Preparation method of paper handle agent

ActiveCN106317323AHigh viscosityComplete copolymerizationNon-fibrous pulp additionPaper/cardboardGlycidyl methacrylateNitrogen

A preparation method of a paper handle agent comprises: (1) taking, by molar percentage, 70-80% of acrylamide, 20-30% of N-methylolacrylamide, 8-15% of glycidyl methacrylate, 0.01-5% of a crosslinking agent and 0.05-5% of a chain transfer agent, and adding them in water while stirring to obtain mixed aqueous solution; introducing nitrogen, adding an initiator and a catalyst, heating to 60-90 DEG C, and polymerizing for 30-90 min to obtain polyacrylamide copolymer; (2) adding suitable organic amine in the product of step (1), carrying out aminomethylation condensation at 60-90 DEG C; cooling the reaction product to 50 DEG C and below, and adding an acid to adjust pH of polymer solution to 6-9; the paper handle agent has the advantages that by adding the handle agent into pulp, finished paper is better in toughness and stiffness and has improved bulkiness and texture.

Owner:GUANGDONG PAPER IND RES INST

Ultralow-temperature drilling fluid base fluid as well as preparation method and application thereof

ActiveCN114836180AEasy to prepareRaw material safety and environmental protectionHydrocarbonsDrilling compositionPtru catalystThermodynamics

The invention provides ultralow-temperature drilling fluid base fluid as well as a preparation method and application thereof. The ultralow-temperature drilling fluid base fluid is prepared from alpha-olefin through polymerization reaction under the action of a cocatalyst zinc chloride and a main catalyst montmorillonite K-10. According to the invention, the problems of poor low-temperature resistance, high irritation and the like of the drilling fluid base fluid in the polar region drilling process are solved; the obtained ultralow-temperature drilling fluid base fluid can be used at the ultralow temperature of-55 DEG C in a polar region, has no pungent smell, and provides technical support for research and development of polar region drilling fluid.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Anti-settling electrorheological fluid and control method thereof

Anti-settling electrorheological fluid is characterized by being preared from dispersed particles, base liquid and an additive, wherein the dispersed particles adopts titanium-oxygen particles; the base liquid adopts silicon fluoride oil and chlorinated paraffin; and the additive is a surfactant containing a polar functional group. The molecular structures of the dispersed particles, the base liquid and the additive are reasonably designed, components and a proportion are optimized, the base liquid with large density and long chain is designed to improve the suspending property of the particles, and the anti-settling property is improved; the surfactant containing the polar functional group serves as the additive, so the strength and the anti-settling property of electrorheological fluid are greatly improved, the electrorheological fluid with high anti-settling property is obtained, and the 30-day anti-settling stability is more than or equal to 99 percent; furthermore, a device capable of applying an electric field is additionally arranged at a storage position of the electrorheological fluid, and the problem of settling is completely solved through the action of the electric field. The proportion is reasonable, the raw materials are safe and environmentally friendly, the electrorheological fluid has excellent electrorheological efficiency, also has high anti-settling property, and has wide application prospect.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Environment-friendly material with parasite expelling and purification functions as well as manufacturing method and application of environment-friendly material

InactiveCN106752474AImprove performanceEfficient removalAntifouling/underwater paintsPaints with biocidesEpoxyHazardous substance

The invention discloses an environment-friendly material with parasite expelling and purification functions. The environment-friendly material is prepared from the following raw materials in parts by weight: 30 to 50 parts of epoxy modified vinyl acetate-acrylate resin emulsion, 18 to 25 parts of acrylate resin, 3 to 8 parts of glass fiber, 1 to 3 parts of nano titanium dioxide, 1 to 3 parts of nano silver ion, 1 to 3 parts of nano ceramic powder, 5 to 10 parts of active carbon, 12 to 18 parts of filling, 1 to 3 parts of a parasite expelling agent, 0.5 to 1.5 parts of a drier and 15 to 30 parts of water. The environment-friendly material with the parasite expelling and purification functions, disclosed by the invention, can be used for effectively preventing parasites and killing the parasites, and adsorbing harmful substances in the air, has very good far-infrared effect, antibacterial effect and health-care effect; the nano ceramic powder has a catalytic oxidation function, can be used for effectively removing indoor harmful substance and has a sterilization function; the obtained environment-friendly material is safe and environmentally friendly, has no toxin or harms, can be widely applied to interior decorations, has good performance and is comprehensively worthy of being popularized.

Owner:MOBAO CO LTD

Fluorine-free anti-splashing spray for fabrics and preparation method of fluorine-free anti-splashing spray

ActiveCN109763345ANot easy to depositNot easy to degradeTextiles and paperWater basedEnvironmental resistance

The invention relates to fluorine-free anti-splashing spray for fabrics and a preparation method of the fluorine-free anti-splashing spray. The fluorine-free anti-splashing spray is prepared from thefollowing components in parts by weight: 2-25 parts of a fluorine-free waterproof agent, 0.5-15 parts of a crosslinking agent, 1-25 parts of a synergist, 0.05-1 part of s conventional additive, an appropriate quantity of a pH regulator and the balance of deionized water. The fluorine-free anti-splashing water spray for the fabrics is a water-based liquid spray product, is safe to carry and convenient to use, is waterproof and antifouling by slight spraying, is used for waterproof finishing of common synthetic fiber fabrics, shoes and boots, tablecloths, chair covers and other household fabrics, is non-flammable, does not contain harmful VOCs (volatile organic chemicals), fluorocarbon compounds or PFOA, PFOS and APEO, does not have irritating and unpleasant odor and is danger-free, safe andenvironmentally friendly.

Owner:XIAN KAIMI

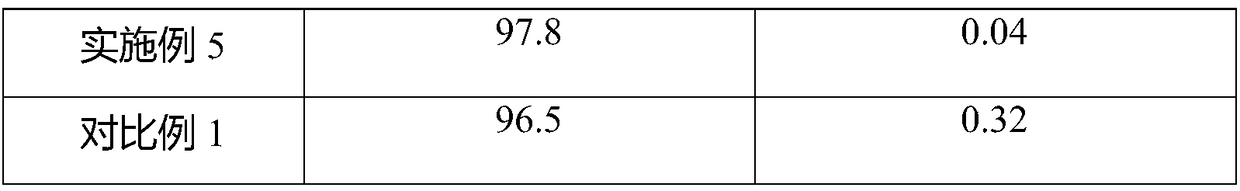

Dual-purpose vitamin moisturizing gel for skins and hair and method for preparing dual-purpose vitamin moisturizing gel

InactiveCN106038361APrevent hair lossReduce forksCosmetic preparationsHair cosmeticsPolyethylene glycolCarboxylic acid

The invention provides dual-purpose vitamin moisturizing gel for skins and hair and a method for preparing the dual-purpose vitamin moisturizing gel. The dual-purpose vitamin moisturizing gel is prepared from, by weight, 1-4% of water-soluble vitamin E, 1-2% of D-panthenol, 1-2% of sodium pyrrolidone carboxylic acid PCA-Na, 0.5-2% of nicotinamide, 0.1-0.5% of PEG-40 (polyethylene glycol-40) hydrogenated castor oil, 0.02-0.04% of rosemary essential oil, 0.2% of Germall-2 and the balance water. The dual-purpose vitamin moisturizing gel and the method have the advantages that the dual-purpose vitamin moisturizing gel can be used for the skins and the hair and has dual-purpose functions, accordingly, resources and spaces can be saved, the skins are fine, smooth, bright, white and glossy after the dual-purpose vitamin moisturizing gel is used for the skins, and effects of fading spots and preventing wrinkles can be realized; the hair is black, bright and smooth after the dual-purpose vitamin moisturizing gel is used for the hair, and splitting ends and hair loss can be prevented; the dual-purpose vitamin moisturizing gel is made of safe and environment-friendly raw materials, processes for producing the dual-purpose vitamin moisturizing gel are simple, and the dual-purpose vitamin moisturizing gel is environmentally friendly, is free of pollution and can be used conveniently and comfortably.

Owner:XUCHANG UNIV

Disincrustant for cleaning heavy oil dirt for food processing equipment

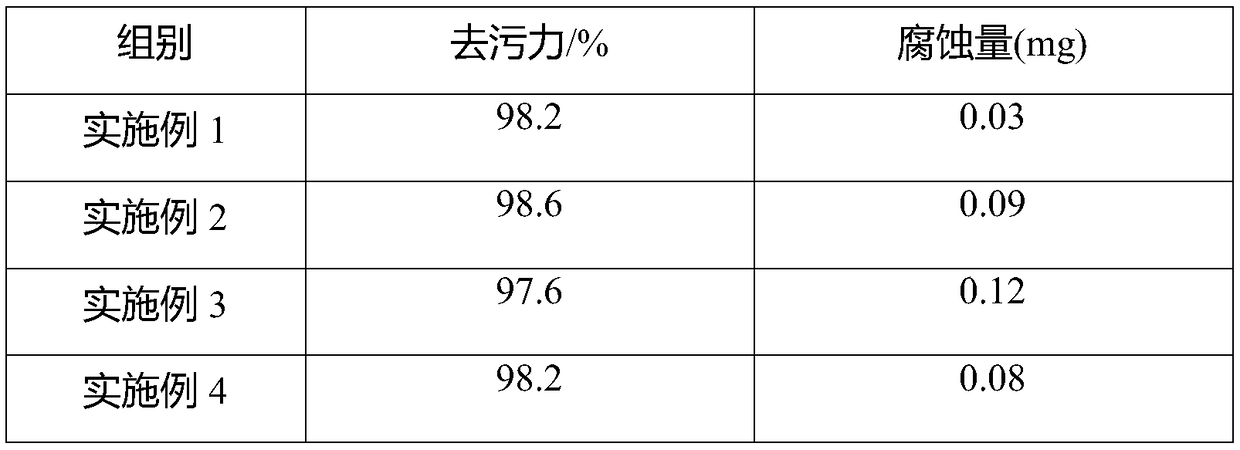

ActiveCN103436379ARaw material safety and environmental protectionNo food safety hazardOrganic detergent compounding agentsSurface-active detergent compositionsSuccinic acidSodium salt

The invention belongs to the field of equipment oil dirt cleaning, and particularly relates to a disincrustant for cleaning heavy oil dirt for food processing equipment. The disincrustant comprises the following components by weight percent: 10-20% of dodecyl dimethyl amine ethyl ester, 10-20% of laurinol polyoxyethylene ether, 5-15% of sulfonating succinic acid dioctyl phthalate sodium salt, 1-10% of propylene glycol, 1-10% of beta-hydroxyl tricarballylic acid, 1-10% of citric acid, 1-10% of calcium chloride, 0.1-1% of acid proteinase and the balance of deionized water. The raw materials used in the disincrustant are safe and environment-friendly, have no food potential safety hazard, have good effect on removing heavy dirt containing animal fat and vegetable fat, mineral grease, calcium and magnesium incrustation, and do not corrode the equipment.

Owner:YANTAI XIWANG FOOD

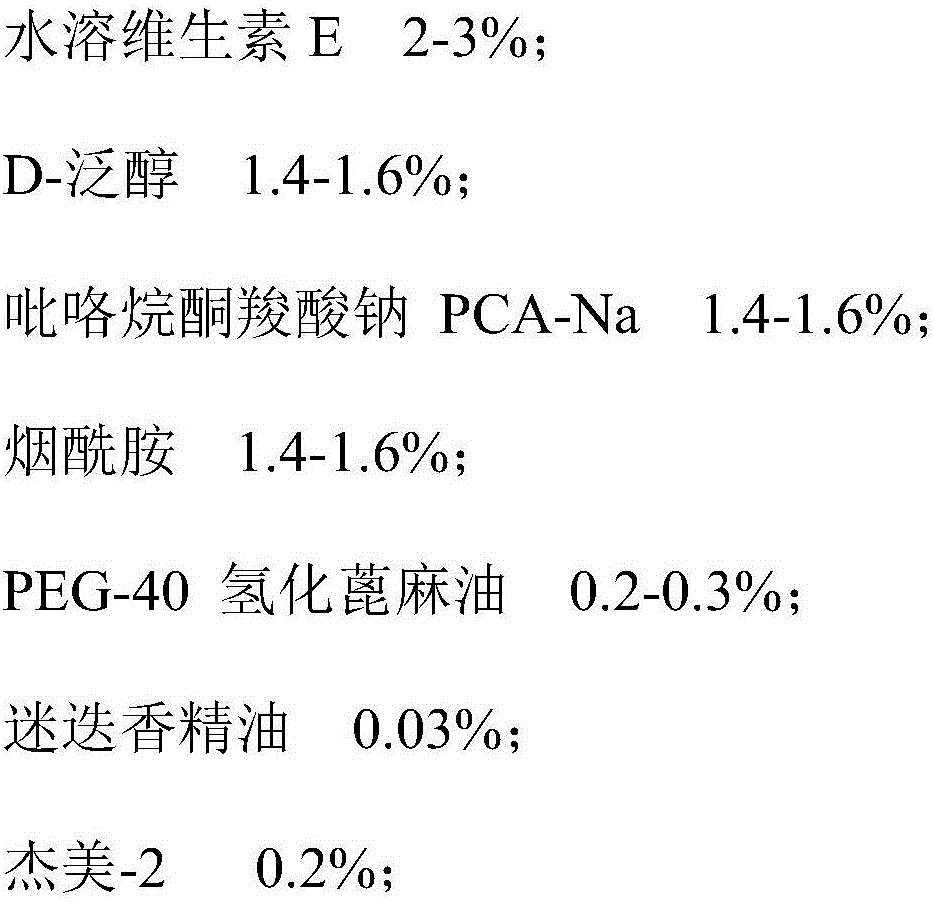

Odor neutralizer and preparation method thereof

InactiveCN109821384AGood removal effectSafe and efficient removalDispersed particle separationPhellandreneZinc ricinoleate

The invention belongs to the technical field of daily use chemical cleaning supplies and discloses an odor neutralizer. The odor neutralizer is composed of, by weight part, 1-5 parts of tea polyphenols, 5-20 parts of terpilenol, 5-17 parts of white vinegar, 3-15 parts of chitosan, 0.5-15 parts of 4-ethyl-4-soy-based ethyl sulfate morpholine, 0.5-10 parts of soybean ethyl sulfate morpholine, 0.2-0.8 part of zinc diricinoleate, 0.5-2 parts of phellandrene, 0.1-1 part of 5-chloro-2-(2, 4-dichlorophenoxy)phenol and 80-130 parts of deionized water. The preparation method of the odor neutralizer isa step-by-step mixing method comprising dissolving white vinegar in water, adding in chitosan, terpilenol, tea polyphenols and the like into the vinegar aqueous solution to obtain a premixed solutionI, then sequentially adding 4-ethyl-4-soy-based ethyl sulfate morpholine, soybean ethyl sulfate morpholine and zinc diricinoleate into deionized water to obtain a premixed solution II, mixing the premixed solution I with the premixed solution II, and uniformly mixing in phellandrene and 5-chloro-2-(2, 4-dichlorophenoxy)phenol to obtain the odor neutralizer. The odor neutralizer solves the problemsof low deodorization efficiency and poor safety of odor neutralizers in the prior art.

Owner:石家庄多美斯日化用品有限公司

Gel cleaning agent used for kitchen

InactiveCN108690733AStrong adhesionProlong the action timeInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAlcoholCleansing Agents

The invention discloses a gel cleaning agent used for kitchen. The gel cleaning agent comprises the following components: a surfactant, a chelating agent, an alcohol ether solvent, a rheological modifier, a pH conditioning agent, and water. The raw materials used by the cleaning agent has the advantages of safety and environmental protection, low stimulation on skin, no damage on surface of metallic glass, and good cleaning effect.

Owner:苏州绿叶日用品有限公司

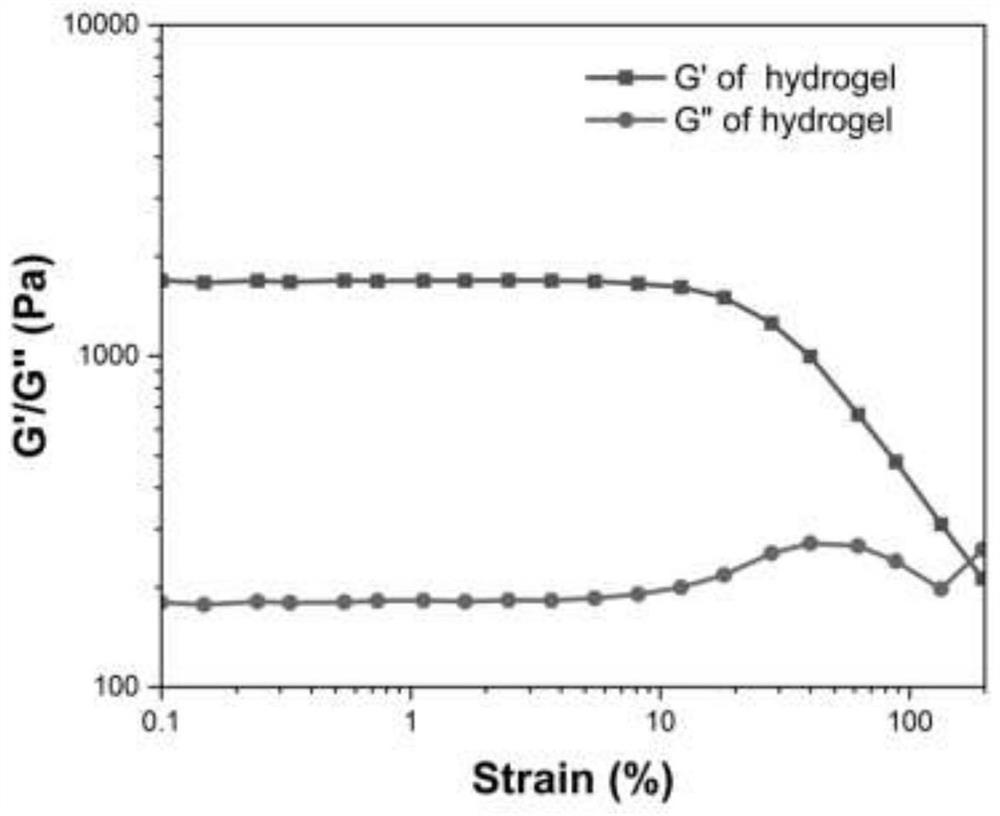

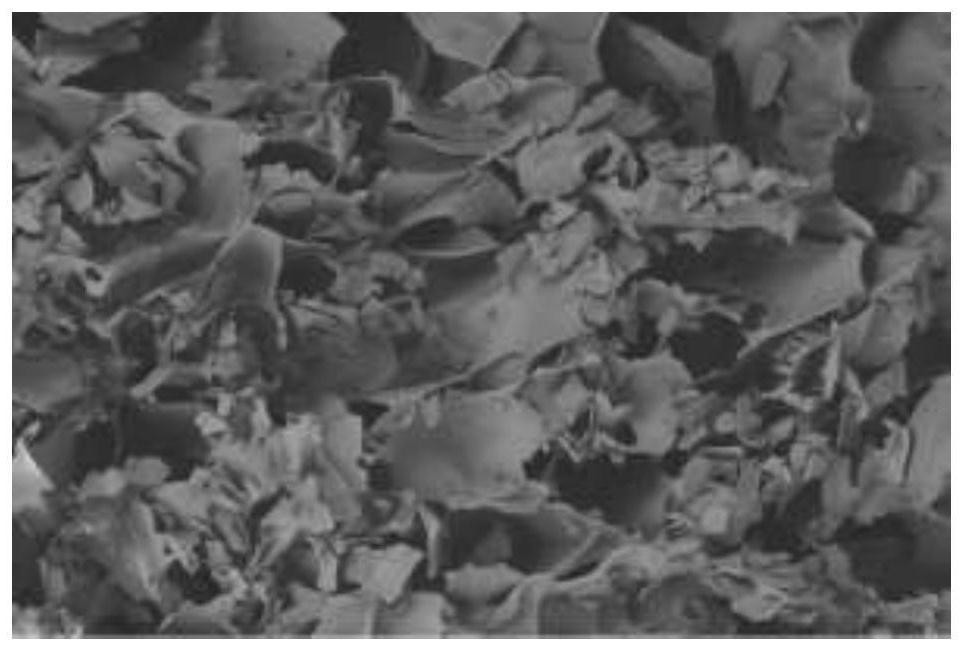

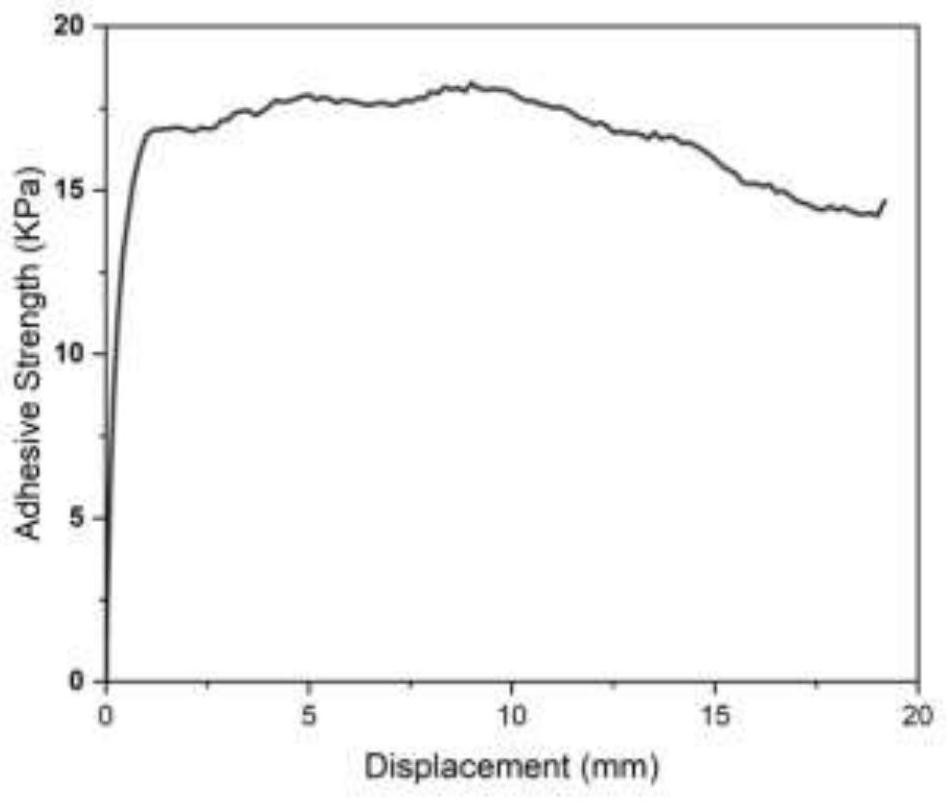

Bioglass-entrapped dual-network self-healing hydrogel as well as preparation method and application of bioglass-entrapped dual-network self-healing hydrogel

The invention provides bioglass-entrapped dual-network self-healing hydrogel as well as a preparation method and application thereof. The preparation method comprises the following steps: forming a first cross-linked network by hydrogen bond cross-linked xanthan gum; oxidized sodium alginate and calcium ions are chelated to form a second cross-linked network, the calcium ions are derived from slow release of bioglass entrapped in the system, dopamine and oxidized sodium alginate form covalent linkage under the action of Schiff base, the adhesion of the system is improved, and fucoidan entrapped in gel can realize long-time slow release; the bioglass-entrapped dual-network self-healing hydrogel system disclosed by the invention has good adhesion performance and biological safety, and can keep a moist environment for a wound and accelerate healing of the wound; the preparation method disclosed by the invention is short in preparation period, simple and feasible, and environment-friendly and safe in raw materials, thereby having a good popularization prospect.

Owner:TONGJI UNIV

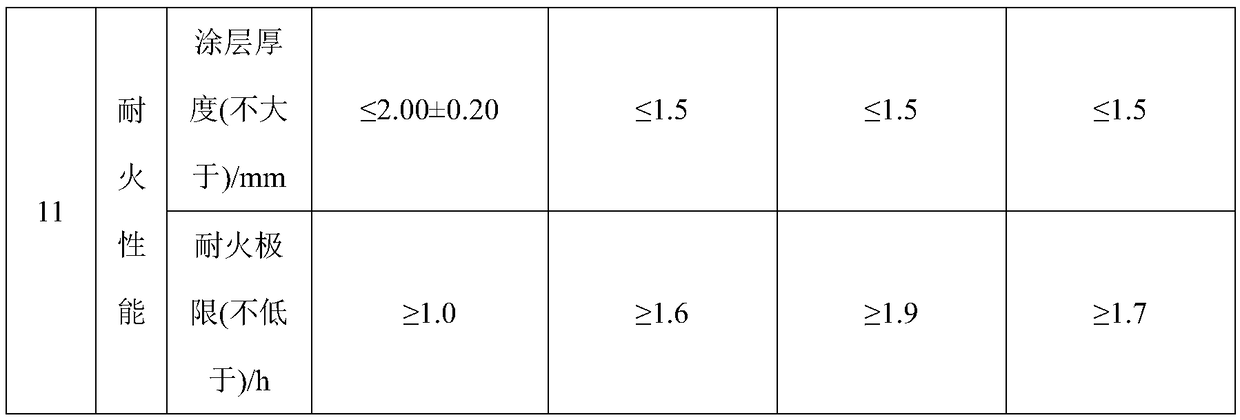

Ultra-thin section steel structure weather-resistant fireproof paint, and preparation method thereof

ActiveCN108753020AGood weather resistanceImprove corrosion resistanceFireproof paintsAntifouling/underwater paintsPolyesterMelamine phosphate

The invention relates to an ultra-thin section steel structure weather-resistant fireproof paint, and a preparation method thereof. The ultra-thin section steel structure weather-resistant fireproof paint is composed of, by weight, 20 to 35 parts of modified acrylic resin, 10 to 18 parts of a nonsaturated polyester, 5 to 15 parts of alkyd resin, 10 to 20 parts of melamine phosphate, 4 to 10 partsof hydrated zinc borate, 5 to 10 parts of nanometer calcium carbonate, 3 to 7 parts of vermiculite, 25 to 40 parts of a solvent, 1 to 10 parts of modified barium metaborate, 1.5 to 3.6 parts of bentonite, 1 to 3 parts of a plasticizer, 0.5 to 3 parts of a levelling agent, and 1 to 5 parts of an ultraviolet ray absorber. The preparation process is simple; energy consumption is low; production costis low; the ultra-thin section steel structure weather-resistant fireproof paint possesses excellent flame resistance, weather resistance, bonding performance, sealing performance, is friendly to theenvironment, is wide in application range, and shedding is not easily caused.

Owner:CHANGZHOU UNIV

Water-based propylene marker pen ink and preparation method thereof

The invention discloses water-based propylene marker pen ink and a preparation method thereof. The water-based propylene marker pen ink comprises 10-20% of titanium dioxide, 0-4% of pigment, 5-8% of an interphase modifier, 40-50% of an acrylic resin emulsion film-forming agent and 25-40% of water, wherein the interphase regulator comprises an amphiphilic polymer and a polymer with a moisturizing effect. According to the ink, titanium dioxide and pigment are used, an environment-friendly non-toxic polymer is used as a functional interphase regulator, and a film-forming emulsion is matched, so that the ink which is stable in performance, smooth in water discharging, uniform in distribution and high in color fastness is obtained. The raw materials of the ink are cheap and easily available, the preparation process is simple and feasible, the process and the product are environment-friendly and non-toxic, and the ink does not contain any volatile organic small molecular substances.

Owner:苏州雄鹰笔墨新材料有限公司 +1

Green and environment-friendly packaging material and preparation method thereof

InactiveCN108178843ARaw material safety and environmental protectionGood mechanical propertiesFlexible coversWrappersCorn starchFood packaging

The invention discloses a green and environment-friendly packaging material. The material comprises the following raw materials by weight: 40-50 parts of corn starch, 20-35 parts of persimmon peel powder, 6-10 parts of fulvic acid, 10-15 parts of pea protein, 10-20 parts of linear low density polyethylene, 5-8 parts of polylactic acid, 10-15 parts of crab shell powder, 4-8 parts of ginger powder,4-9 parts of nano titanium dioxide, 2-5 parts of sodium alginate, 0.1-3 parts of anthocyanin, 2-6 parts of sodium glutamate, 2-5 parts of beta-carotene, and 1-6 parts of beta-cyclodextrin. The packaging material provided by the invention has the advantages of safe and environment-friendly raw materials, degradability, good mechanical properties and good antibacterial properties, and is very suitable for food packaging.

Owner:苏州仁尔必思电子科技有限公司

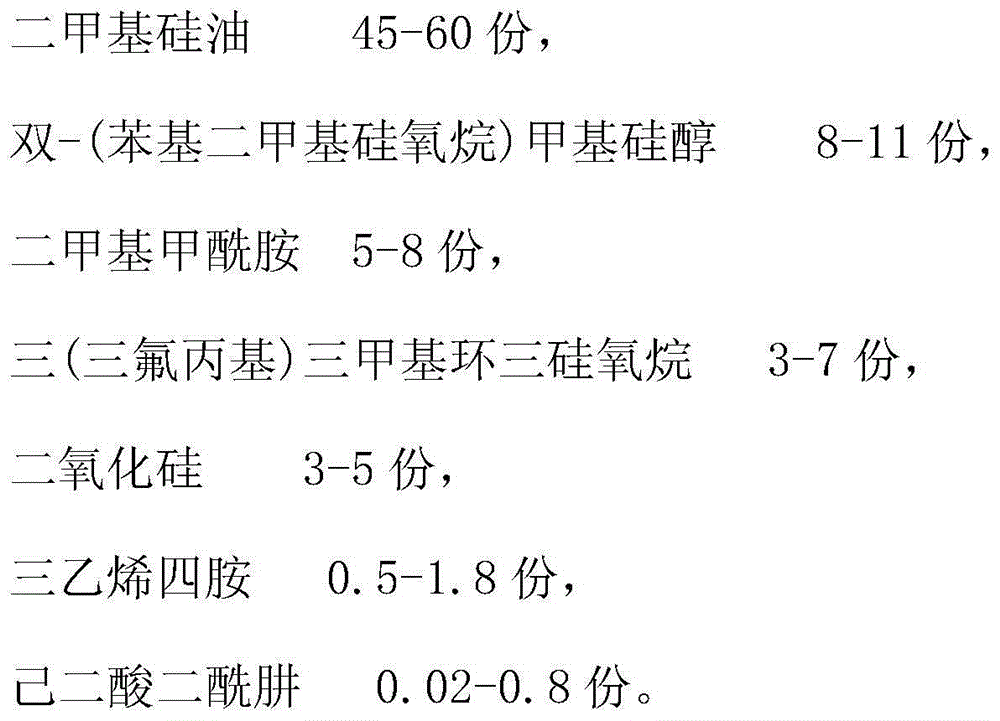

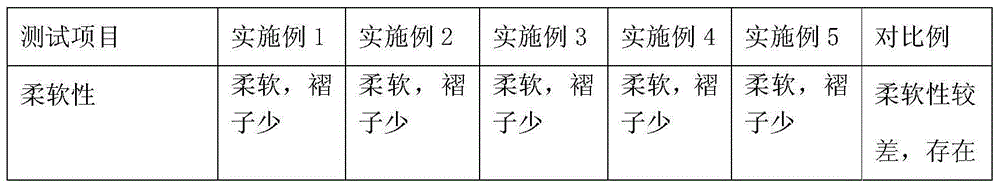

Smoothing agent for fabrics and preparation method thereof

The invention discloses a smoothing agent for fabrics and a preparation method thereof. The smoothing agent for fabrics is prepared from the following components in parts by weight: 45-60 parts of simethicone, 8-11 parts of bis-(phenyldimethylsilane)-methylsilanol, 5-8 parts of dimethylformamide, 3-7 parts of tri(trifluoropropyl) trimethylcyclotrisiloxane, 3-5 parts of silicon dioxide, 0.5-1.8 parts of triethylene tetramine and 0.02-0.8 part of diacid dihydrazide.

Owner:SUZHOU KAICHENG SEWING EQUIP

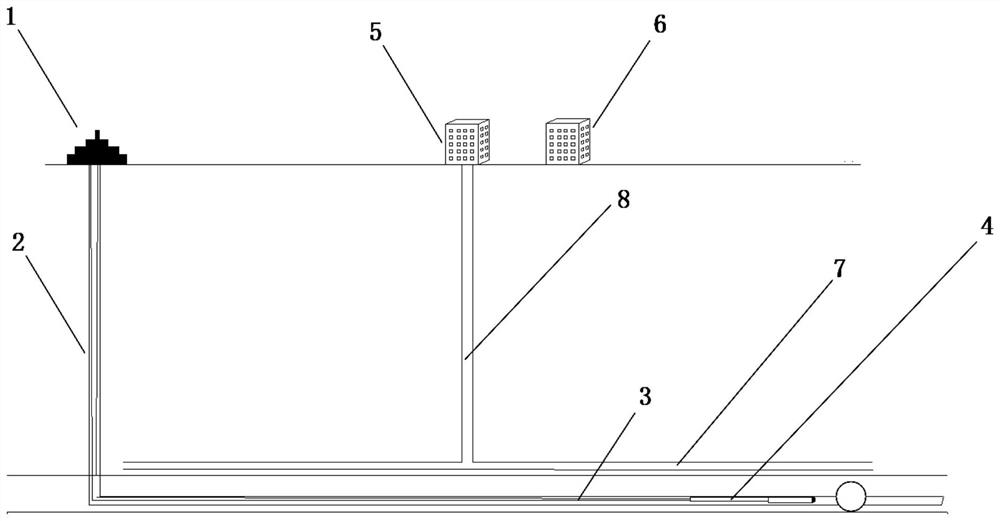

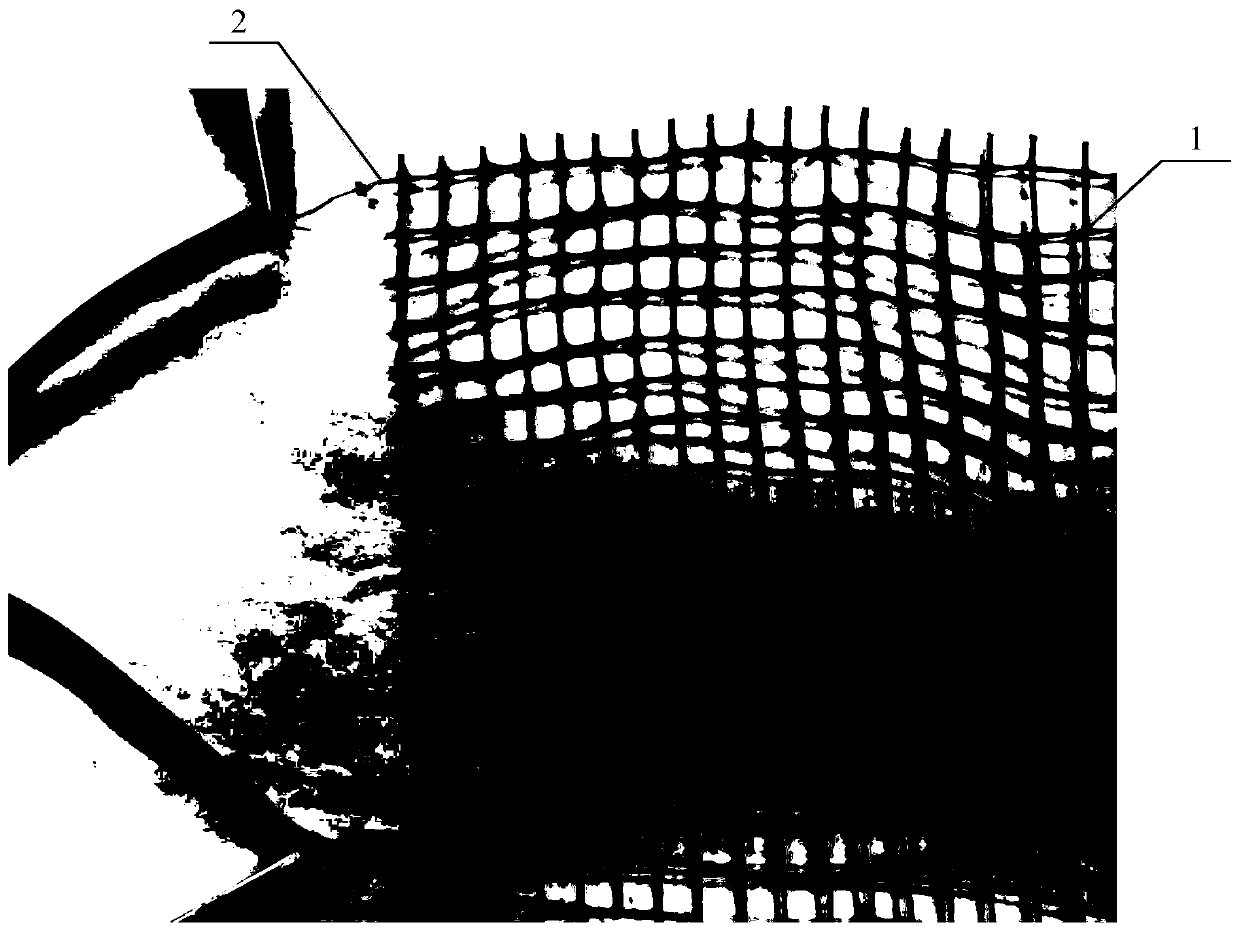

Equipment and method for exploiting coalbed methane by kilometer drilling and subsection water explosion fracturing

ActiveCN112096349AFacilitate desorptionPromote formationCleaning apparatusFluid removalMining engineeringWater resources

The invention discloses equipment and method for exploiting coalbed methane by kilometer drilling and subsection water explosion fracturing, and belongs to the field of engineering. The equipment comprises a kilometer drilling machine (1), wherein the kilometer drilling machine (1) excavates to form a vertical drill hole (2), a horizontal drill hole (3) intersected with the vertical drill hole (2), and a high drainage roadway (7) not intersected with the vertical drill hole (2), the horizontal drill hole (3) is located in a coal seam, a plurality of hydrothermal cracking cylinders (4) are arranged in the horizontal drill holes (3), and the high-pressure drainage roadway (7) is located in the center line of a blasting fissure zone above the coal seam. According to the equipment, the problems that existing coal mining equipment is not economical, not environmentally friendly, heavy and the like are solved, a novel water explosion fracturing technology is applied to coal mining operation,the fracturing range is effectively widened, pressure is more effectively relieved, coal bed gas desorption and gas production channel formation are more effectively promoted, meanwhile, water resources used by the water explosion fracturing technology are fewer, and the used ionic aqueous solution does not cause pollution and is simple and efficient to implement.

Owner:CHINA UNIV OF MINING & TECH

Flexible graphene electric heating net and preparation method thereof

InactiveCN110650558AGuarantee the safety of useReduce radiation doseHeating element materialsPhysical chemistryGraphite

The invention discloses a flexible graphene electric heating net and a preparation method thereof. The flexible graphene electric heating net comprises a substrate layer, a graphene electric heating layer and a protective insulating layer which are stacked in sequence. The substrate layer is made of an anti-radiation mesh material. The graphene electric heating layer is prepared from the followingcomponents in parts by mass: 100 parts of a high polymer material, 1-3 parts of graphene, 0.1-1 part of a dispersing agent, 20-30 parts of de-ionized water and 1-2 parts of a curing agent. The protective insulating layer is composed of the following components in parts by mass: 100 parts of a high polymer material, 1-2 parts of a curing agent and 20-30 parts of de-ionized water. The flexible graphene electric heating net can be suitable for a heating environment with a complex surface, can also be suitable for a large-area heating environment, can weaken the magnetic field itself, and has less electromagnetic wave radiation.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com