Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Microporous increase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

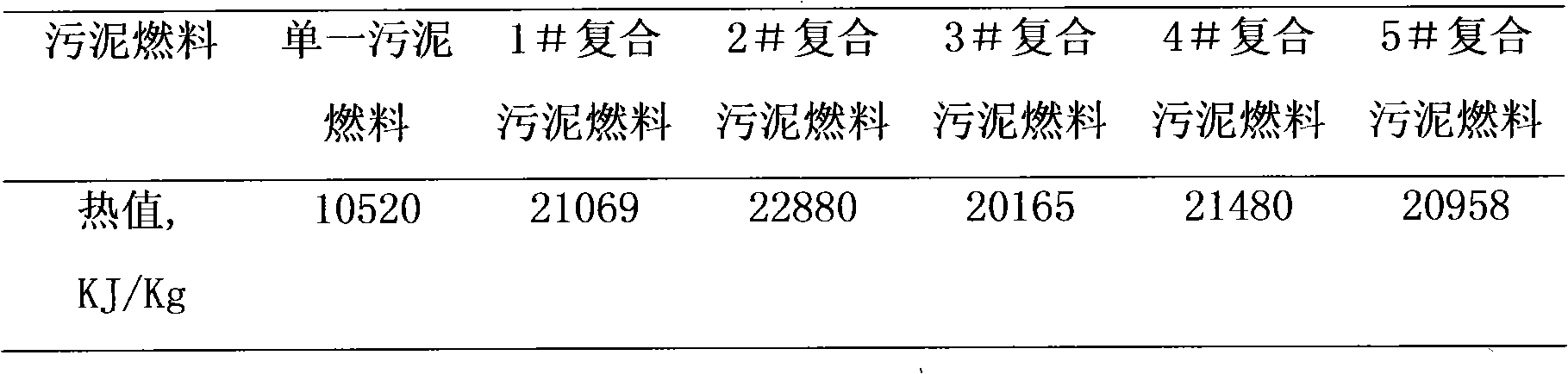

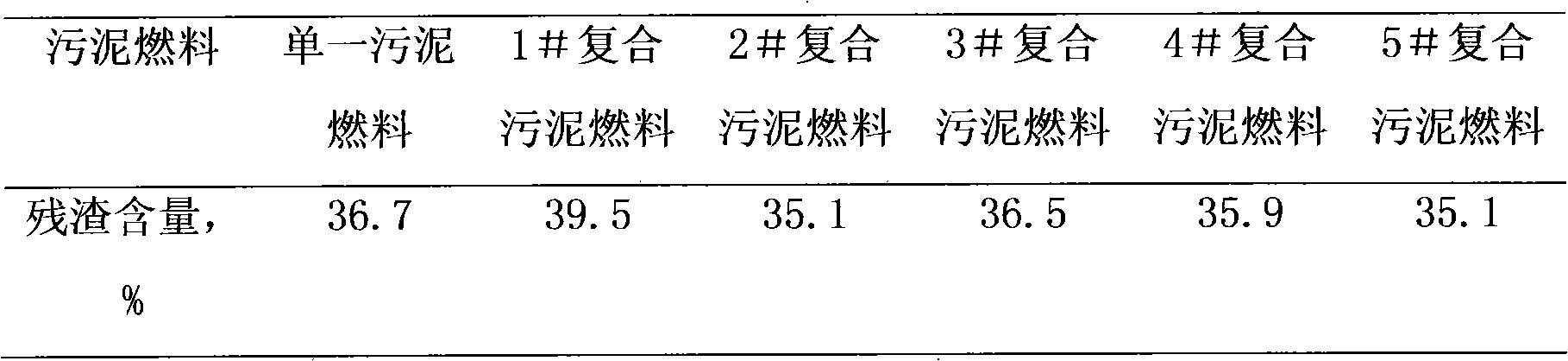

Compound type sludge fuel and preparation method thereof

The invention discloses a compound type sludge fuel, which comprises the following raw materials in percentage by weight: 20-50% of dry sludge, 20-50% of coal dust, 10-20% of residual oil, 5-10% of clay and 4-10% of biomass. The invention also discloses a preparation method of the compound type sludge fuel. Compared with a single dry sludge formed solid, the compound type sludge fuel increases the heat value by 1 time, and is easier to burn; and the curing rate is increased by 5-10%.

Owner:SHAOXING UNIVERSITY

Method for preparing cold-bonded pellets from iron containing sludge by compound adhesive

InactiveCN101775489AReduce the amount of non-ferrous materialsReduce pollutionCelluloseSodium Bentonite

The invention relates to a method for preparing cold-bonded pellets from sludge containing iron by an compound adhesive, belonging to the technical field of adhesives for metallurgical ironmaking. The method of the invention comprises the following concrete steps: adopting the compound adhesive of an inorganic adhesive and an organic adhesive, wherein the organic adhesive in the compound adhesive comprises the following raw materials: vinyl acetate, acroleic acid, sodium cellulose glycolate, polyvinyl alcohol, polyisobutylene, molasses and coal tar; and the inorganic adhesive comprises the following raw materials: bentonite, calcium oxide, basic sodium silicate, sodium chloride, talcum powder and light calcium carbonate. When the organic adhesive and the inorganic adhesive in the adhesive are prepared, the components are proportioned and controlled strictly in a proper order, so that the defects of one adhesive singly used can be avoided, and the compound adhesive has good caking property on the iron containing sludge. The method of the invention recycles iron from iron containing sludge and changes waste into resources, thereby reducing pollution of storage and transport on the environment, and saving the energy consumption in the sintering and high furnace production.

Owner:TONGJI UNIV

Preparation method and application of activated carbon fiber-based adsorbent for removing hydrogen sulfide, hydrogen phosphide, arsenic hydride and ammonia gas

ActiveCN112371087AImprove removal efficiencyImprove anti-pollution performanceGas treatmentOther chemical processesFiberActivated carbon

The invention provides a preparation method and application of an activated carbon fiber-based adsorbent for removing hydrogen sulfide, hydrogen phosphide, arsenic hydride and ammonia gas, and belongsto the technical field of air pollution prevention and control. The method comprises the following steps: firstly, carrying out remote argon plasma treatment on the activated carbon fiber, and then carrying out ultrasonic impregnation by using a hydrogen peroxide solution, so that the number of oxygen-containing functional groups such as phenolic hydroxyl, lactone and carboxyl on the surface of the activated carbon fiber is remarkably increased; modified activated carbon fibers and a copper nitrate solution are mixed and subjected to rotary evaporation, copper salt is loaded on the surfaces of the activated carbon fibers, the copper salt is converted into copper oxide after being roasted in a microwave muffle furnace, the copper oxide can serve as an active component for removing hydrogensulfide, hydrogen phosphide, arsenic hydride and ammonia gas, and therefore the removal efficiency of harmful gas is improved; the roasted activated carbon fiber is subjected to remote oxygen plasmatreatment, so that oxygen-containing functional groups on the surface of the activated carbon fiber can be enhanced, the anti-pollution performance of the activated carbon fiber-based adsorbent is improved, and the service life of the activated carbon fiber-based adsorbent is prolonged.

Owner:KUNMING UNIV OF SCI & TECH

A method of preparing a hierarchical porous carbon material as a supercapacitor electrode material

InactiveCN107098330ASimple processAvoid complicatedHybrid capacitor electrodesCarbon preparation/purificationCapacitancePotassium hydroxide

The invention relates to a method of preparing a hierarchical porous carbon material as a supercapacitor electrode material. Firstly an RF / PAM interpenetrating polymer network is prepared, and then is mixed with an activating agent that is potassium hydroxide, the mixture is put into a tubular furnace and heated and reacted under inert gas protection, and a product is cooled to obtain the target product that is the hierarchical porous carbon material. Compared with the prior art, the method is novel and simple in process, and when the obtained hierarchical porous carbon material is adopted as a supercapacitor electrode material, and under a current intensity of 1 A g<-1>, the highest specific capacitance can reach 261 F g<-1>, the capacity retention ratio after 10000 times of cyclic charging and discharging is 90.8%, and the specific capacitance can still be 216 F g<-1> under a large current intensity of 20 A g<-1>, and therefore the hierarchical porous carbon material shows a high specific capacitance, excellent rate capacity, and good cycle stability.

Owner:TONGJI UNIV

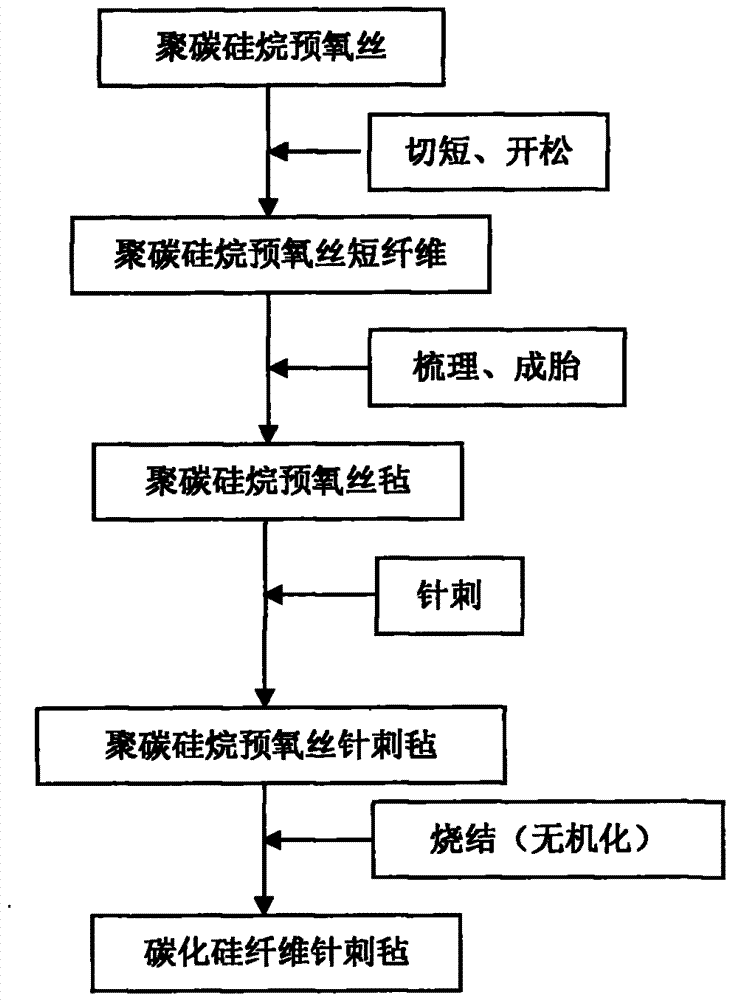

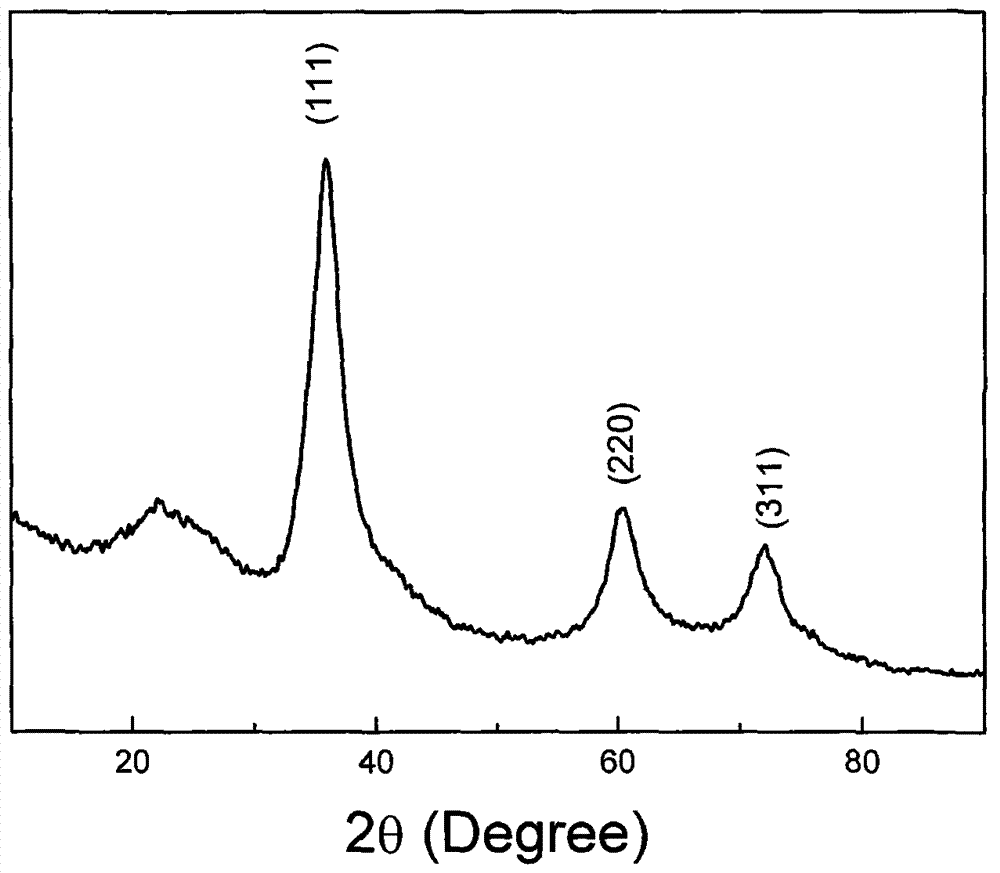

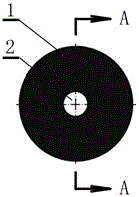

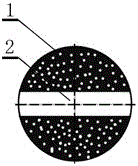

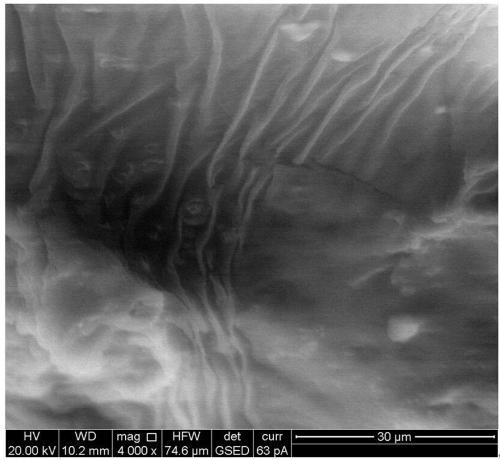

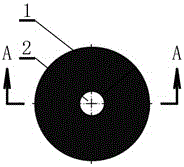

Silicon carbide fiber needle felt and manufacturing method thereof

ActiveCN103668779AUniform diameterUniform densityHeating/cooling textile fabricsNon-woven fabricsSic fiberMechanical property

The invention relates to silicon carbide fiber needle felt and a manufacturing method of the silicon carbide fiber needle felt. Polycarbosilane non-fusible fibers are cut short, loosened, carded through air flow, manufactured into a base, needled and made inorganic at high temperature to form the felt. According to the manufactured silicon carbide fiber needle felt, on the basis of an original silicon carbide overall felt, single-layer needling and stacked layer needling are carried out in the Z direction. Thus, while the Z-direction mechanical properties are greatly improved, the X-direction mechanical properties and thermophysical properties and the Y-direction mechanical properties and thermophysical properties are obviously improved compared with those of non-needled felt, the application range of the silicon carbide fiber needle felt is greatly expanded, and the silicon carbide fiber needle felt has wide application prospects particularly in the fields of high-temperature filtering, high-temperature catalyzing, manufacturing of SiCf / SiC composite materials and the like.

Owner:SUZHOU SAIFEI GRP

Controlled-release fertilizer as well as producing method and using method of controlled-release fertilizer

ActiveCN104230532ALow in alkaloidsRaise the ratioFertilising methodsFertilizer mixturesResin coatingCopolymer

The invention provides a controlled-release fertilizer. The controlled-release fertilizers comprises 50-75 parts of a base fertilizer which is obtained by mixing urea, a calcium magnesium phosphate fertilizer and potassium sulfate in a ratio of 8 to 4 to 17. The controlled-release fertilizer is characterized by further comprising the following components in parts by weight: 2-4 parts of a micro fertilizer which is obtained by mixing borax, zinc sulfate and bunge corydalis herb in a ratio of 1 to 1 to 1.8, 3-5 parts of powder prepared by extracts of aconite, rhizoma anemarrhenae, asarum, siberian cocklebur fruit and Chinese stellera, 10-15 parts of plant ashes, 3-5 parts of modified starch, 2-4 parts of starch-grafted copolymer, 3-5 parts of lignin, 6-8 parts of potassium fulvate, and 5-8 parts of coating materials, wherein the coating materials can be any one of sulfur coating materials, resin coating materials or urease inhibitor coating materials. The controlled-release fertilizer is simple in proportion, convenient to use, long in curative effect, controlled-release in release, comprehensive in nutrition and capable of effectively preventing soil pests and diseases.

Owner:青岛亚星化肥有限公司

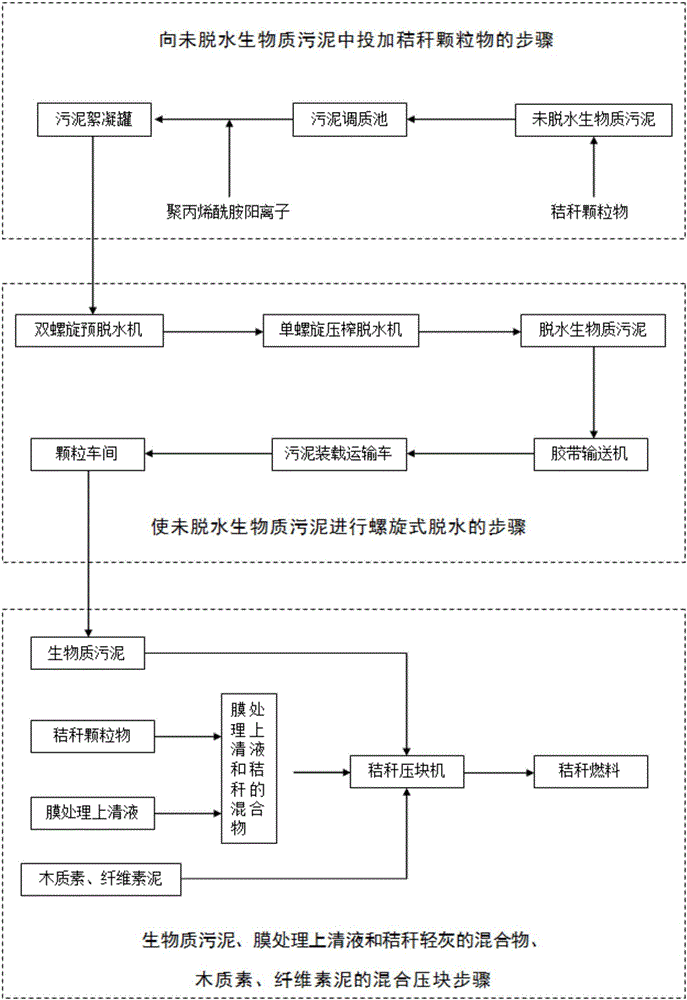

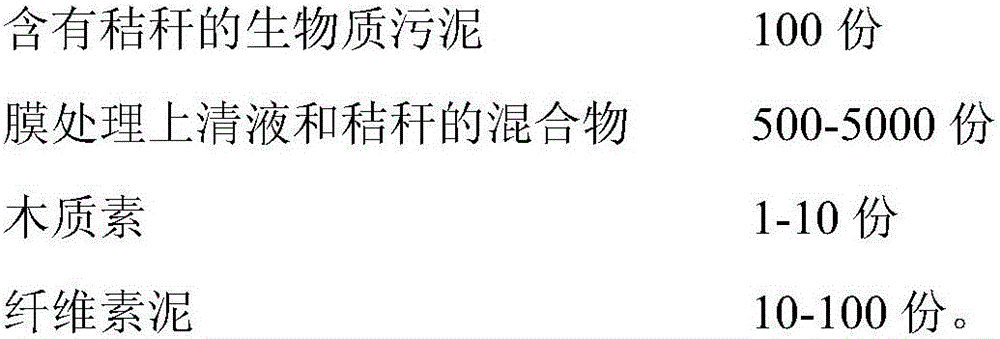

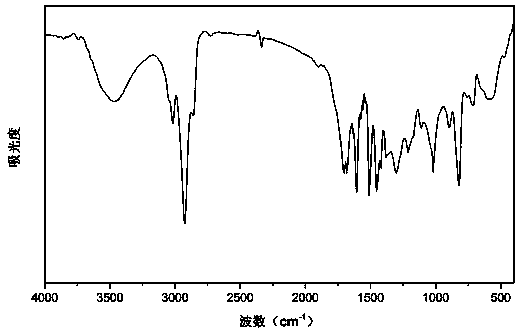

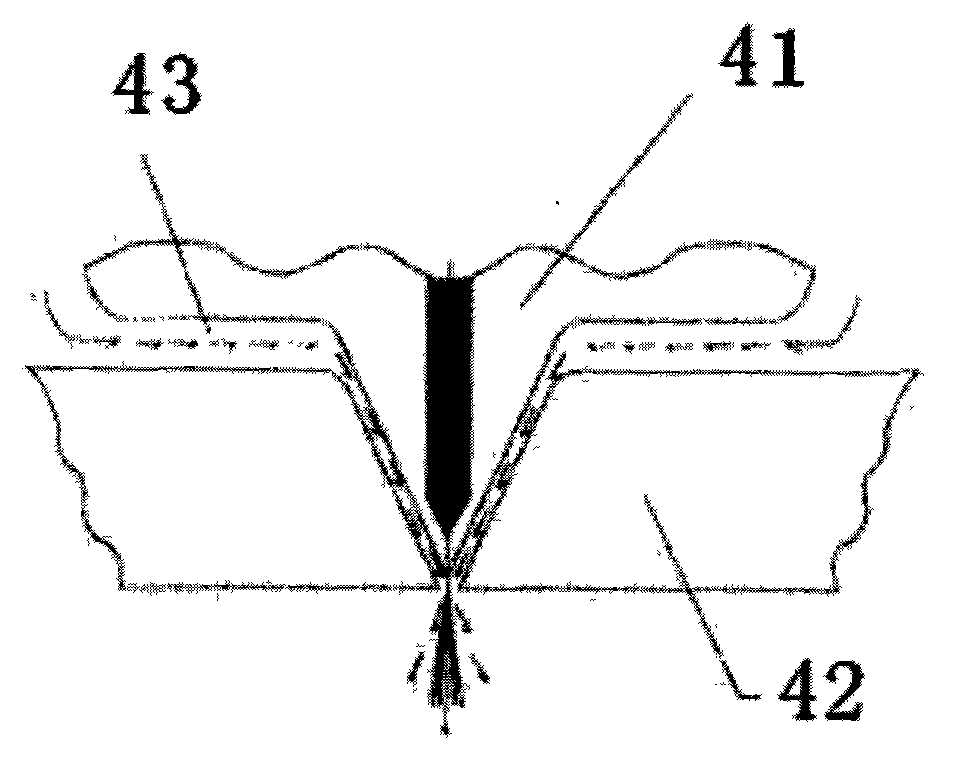

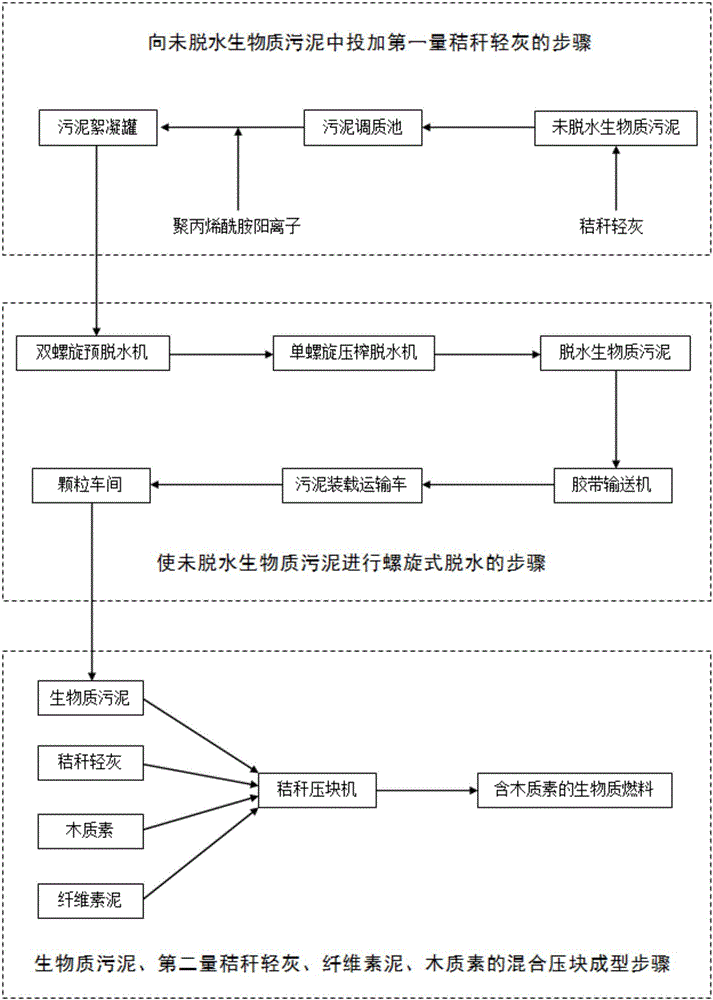

Straw fuel containing biomass sludge and preparation method of straw fuel

The invention belongs to the technical field of fuel preparation, and particularly relates to straw fuel containing biomass sludge and a preparation method of the straw fuel. The straw fuel containing the biomass sludge is prepared from the biomass sludge containing straw, a mixture of membrane treatment supernate and straw, lignin and cellulose mud. According to the straw fuel, organic waste obtained through biomass resource treatment is fully utilized, and great economic benefits and environmental friendliness benefits are achieved. In addition, straw particles and other plant materials are added into sludge which is not dewatered, and the thermal value of the dewatered sludge can be increased; due to the fact that the straw particles and other plant fibers are mixed in the sludge, the friction force of the pre-dewatered sludge in a spiral squeezing dehydrator is increased, then the operation frequency of the spiral squeezing dehydrator can be improved, and the operation efficiency and output sludge dryness of the machine are effectively improved.

Owner:ANHUI GEYI CYCLIC ECONOMY IND PARK

Preparation method of amide group modified polystyrene-based ultrahigh crosslinking adsorption resin

InactiveCN109847715AIncrease polarityEvenly distributedOther chemical processesAlkali metal oxides/hydroxidesCross-linkSorbent

The invention discloses a preparation method of an amide group modified polystyrene crosslinking resin. The method comprises the following steps: preparing an ester group modified precursor resin by asuspension polymerization of a water phase and an oil phase, adding a swelling agent and a Lewis acid catalyst to the precursor resin for a Friedel-Crafts reaction to obtain a post-crosslinking resin, and adding an aminating agent to the post-crosslinking resin for an amination reaction to prepare the cross-linking resin. In the preparation method, ester monomers containing double bonds are introduced, polarity of the resin is improved, numbers of micropore and mesoporous of the resin are increased by the Friedel-Crafts crosslinking reaction, and amide groups are formed by introducing the aminating agent. The specific surface area of the adsorbent can reach to be 900-1500 m2 / g, the pore capacity is 1.012-1.412 cm<3> / g, and the average pore size is 1-20 nm. The hydrophobic force and hydrogen bond action with adsorbed substances are easy to form when adsorbing, thus the adsorption performance of the resin is improved. The preparation process is simple, and reaction conditions are easy to control, so that the resin can be suitable for industrialized production.

Owner:GUANGDONG UNIV OF TECH

Earthworm amino acid stable organic-inorganic soil conditioner and processing technology thereof

InactiveCN105330388ASolve hidden dangersSolve the hazardFertilizer mixturesDigestionOrganic inorganic

The invention especially relates to an earthworm amino acid stable organic-inorganic soil conditioner and a processing technology thereof, belonging to the field of soil conditioners. The soil conditioner comprises an earthworm amino acid solution, urea, earthworm cast, humic acid, fly ash and a long-acting agent. The composition of the above-mentioned components by mass is that 20 to 50 parts of the earthworm amino acid solution containing 90% of water, 15 to 50 parts of urea containing 46.3% of nitrogen and 1% of water, 10 to 36 parts of earthworm cast containing 1% of nitrogen, 25% of water and 42% of organic matters, 5 to 25 parts of humic acid containing 80% of organic matters and 20% of water, 1 to 35 parts of fly ash containing 8% of organic matters and 8% of water and 0.5 to 13 parts of the long-acting agent containing 40.4% of a digestion inhibitor and 16.28% of a urease inhibitor. The urease inhibition rate and digestion inhibition rate of the soil conditioner provided by the invention exceed requirements prescribed in international stability standard HG / T4135-2010; and the soil conditioner has increased nitrogen content, good stability effect and a high utilization rate, is rich in calcium, magnesium, silicon and 18 amino acids favorable for crop growth, and provides effective guarantee for high and stable yield of crops.

Owner:TIANJIN JIALIMING EARTHWORM BREEDING

Preparation method of high-adsorption-performance biochar fertilizer

InactiveCN107311712AIncrease organic matterMicroporous increaseFertilizer mixturesLivestock manureCarbonization

The invention discloses a preparation method of a high-adsorption-performance biochar fertilizer. The preparation method comprises: (1) respectively drying a biomass raw material and human-livestock manure or baking a biomass raw material and human-livestock manure, and crushing into powder so as to be spare; (2) weighing and mixing the treated biomass raw material, the treated human-livestock manure and a catalyst according to a mass ratio of 3:2:1; (3) carrying out immersion treatment; (4) carrying out dehydration-oxygen discharging; and (5) carrying out cracking carbonization. According to the present invention, the method is simple; the prepared biochar fertilizer has strong heavy metal ion adsorption capacity and high fertilizer efficiency; and after the high-adsorption-performance biochar fertilizer is applied in the soil, the soil structure can be improved, and the high-adsorption-performance biochar fertilizer can act as the fertilizer so as to well meet the growth needs of crops.

Owner:黄名义

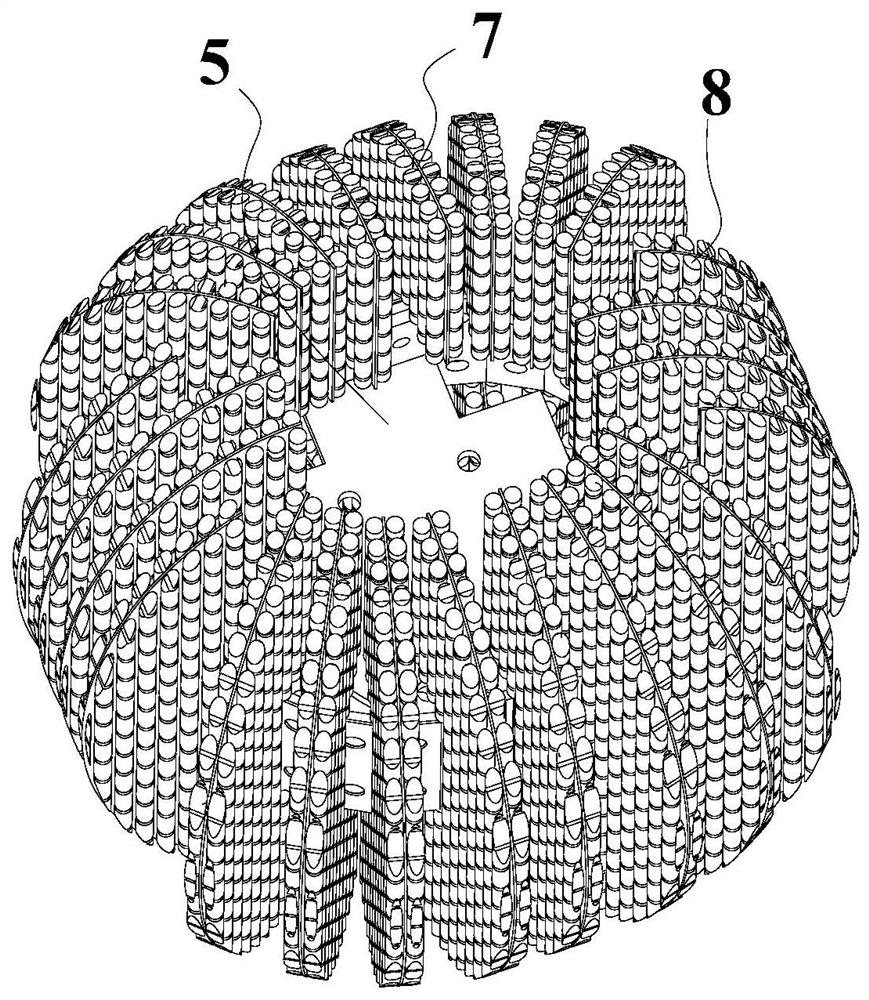

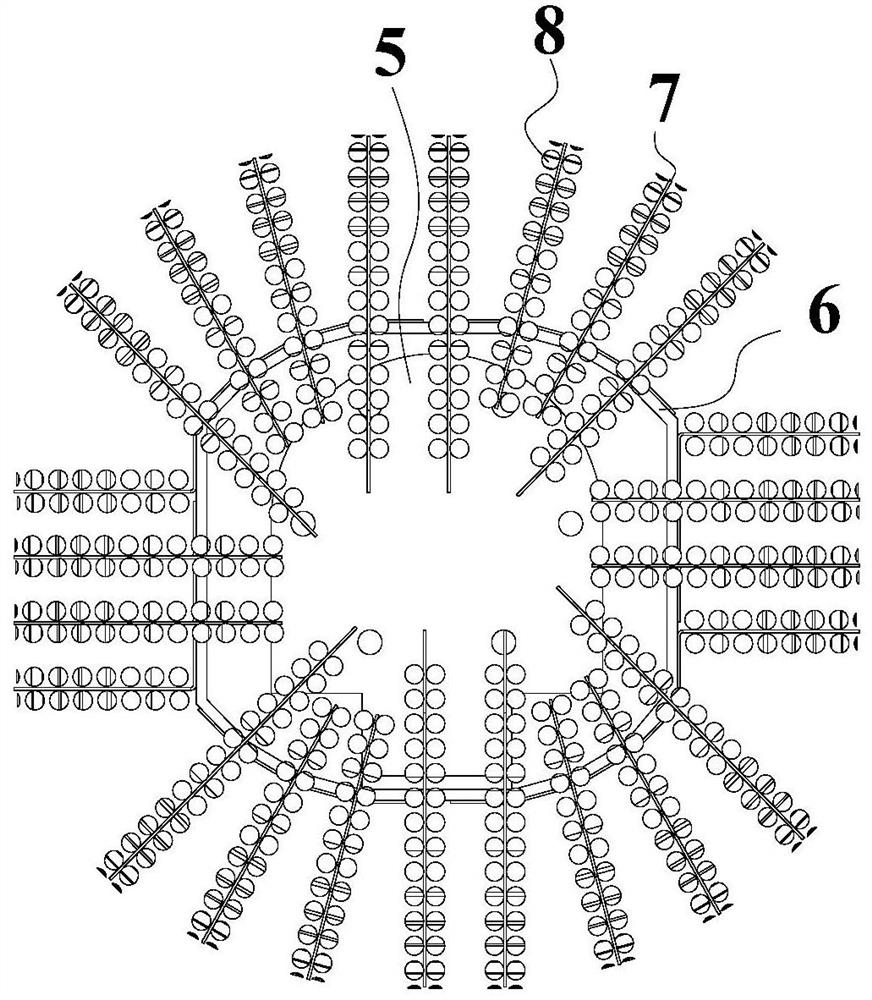

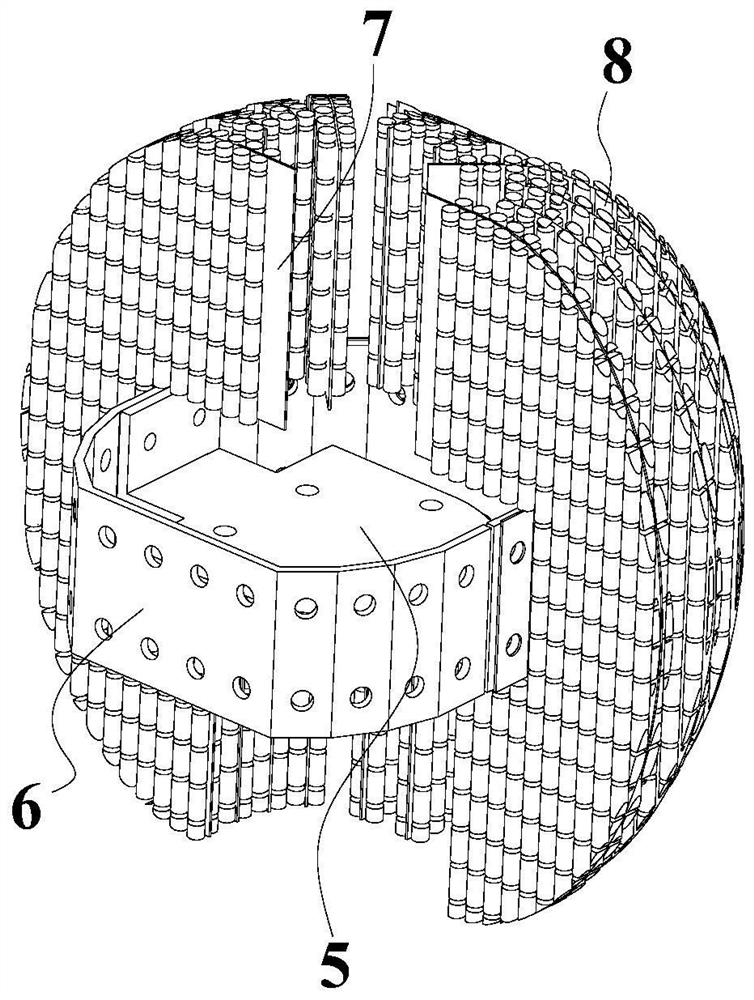

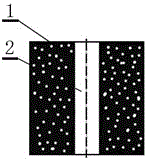

Adsorption array and cryogenic pump with adsorption array

InactiveCN112523993AImprove performanceIncrease pumping speedPumpsPositive-displacement liquid enginesInternal radiationMechanical engineering

The invention discloses an adsorption array and a cryogenic pump with the adsorption array. The adsorption array comprises a heat transfer plate and a connecting plate, wherein a plurality of cryogenic plates are arranged on the heat transfer plate, the outer contours of the cryogenic plates are in a circular arc shape, and the outer contours of all the cryogenic plates are located on the same virtual spherical surface; and an adsorption material is arranged on each cryogenic plate. The cryogenic pump comprises the adsorption array, a refrigerating machine and a shell, wherein a radiation shield is arranged in the shell; the adsorption array is installed at the end part of a second-stage cooling stage through the connecting plate; the connecting plate is perpendicular to the axis of the second-stage cooling stage; the second-stage cooling stage and the adsorption array are both located in the radiation shield; a baffle is arranged at an opening of the radiation shield; a pump opening flange is arranged at the opening of the shell; and the opening direction of the radiation shield is the same as that of the shell, the axis of the radiation shield coincides with the axis of the shell, and the axes of a first-stage cooling stage and the second-stage cooling stage are perpendicular to the axis of the radiation shield. The cryogenic pump has the advantages that H2 can directly and quickly reach the adsorption material and is captured, and the pumping speed of the cryogenic pump on the H2 is increased.

Owner:VACREE TECH

PS (poly styrene)/PP (propene polymer) fiber material adsorbing underwater benzene serial substances at high rate and preparation method

ActiveCN102505172ASmall adsorption ratioReduce the amount of adsorptionOther chemical processesSpinning head liquid feederChemistryHigh rate

The invention discloses a PS(poly styrene) / PP (propene polymer) fiber material adsorbing underwater benzene serial substances at a high rate. The material has stronger adsorption selectivity to underwater benzene serial substances (toluene, dimethylbenzene and the like), namely, the adsorption rate to the underwater benzene serial substances is remarkably improved, and the adsorption ability to the benzene serial substances on the water surface is also improved while the water adsorption is reduced to a certain extent. The PS / PP fiber adsorption material adsorbing underwater benzene serial substances at a high rate disclosed by the invention is prepared from the following raw materials in part by weight: 100 parts of PP, 1-15 parts of PS and 0.01-1 part of auxiliaries.

Owner:克拉玛依智源博创环保科技有限公司

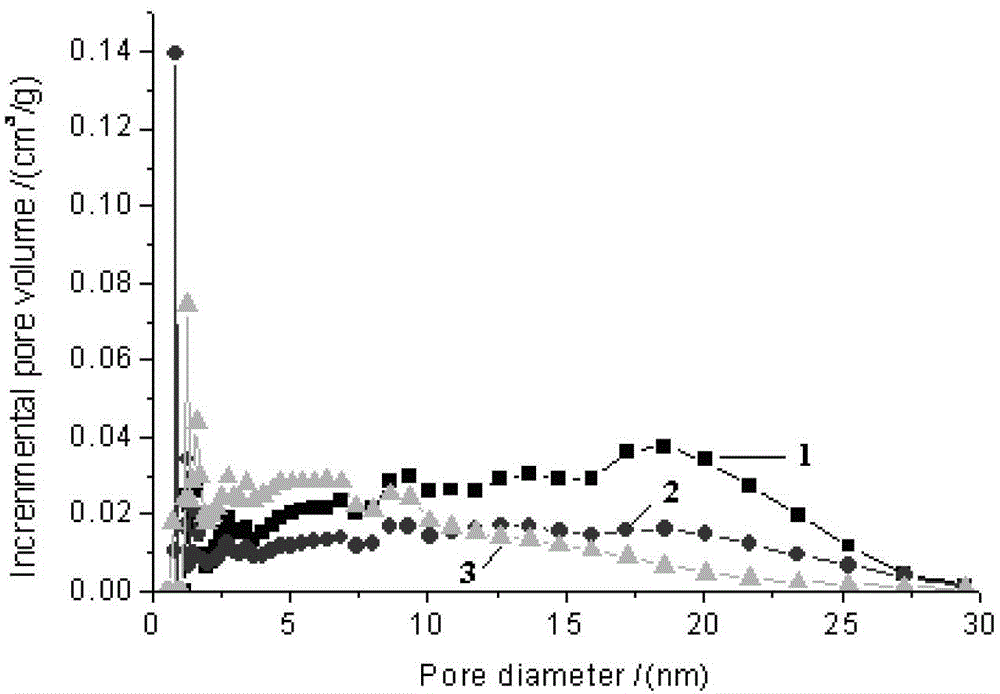

Cross-linking agent modified XAD-4 resin and method for preparing same

InactiveCN102977487AImprove pore structureNarrow pore size distributionOther chemical processesPore diameterFriedel–Crafts reaction

The invention discloses a cross-linking agent modified XAD-4 resin, which is a mesoporous resin containing rich micropores and prepared from a cross-linking agent and an XAD-4 resin through Friedel-Crafts reaction, wherein the pore diameters of the mesoporous resin are distributed between 1 to 9.5 nm, the average pore diameter is 2.58-4 nm, the specific surface area is 721-1284 m<2> / g, and the pore volume is 0.67-1.1 cm<3> / g. The method for preparing the cross-linking agent modified XAD-4 resin comprises the following step of carrying out the Friedel-Crafts reaction between the cross-linking agent and the XAD-4 resin to prepare the modified XAD-4 resin, wherein the dosage of the cross-linking agent is 50-100% of the quantity of the XAD-4 resin material. The adsorbent has the characteristics of large specific surface area, narrow pore diameter distribution and easily controllable porous structure, and is obviously superior to the XAD-4 resin in the adsorption capability to nonpolar and weakly polar materials; and therefore, the adsorbent is wide in application prospect in fields of treating and recycling phenols wastewater and the like.

Owner:CENT SOUTH UNIV

Anti-corrosion silicon carbide wear-resistant material and preparation method thereof

The invention discloses an anti-corrosion silicon carbide wear-resistant material and a preparation method thereof. The anti-corrosion silicon carbide wear-resistant material is prepared from the following raw materials by weight: 25-30 parts of silicon carbide, 12-15 parts of a reinforcing agent, 3-5.5 parts of zinc oxide, 12-15 parts of phenolic resin, 8-10 parts of nano-graphite, 3-5 parts of aluminum oxide, 6-8 parts of a dispersing agent and 40-50 parts of deionized water. The reinforcing agent is prepared in the preparation process, the reinforcing agent contains modified nano activated carbon, the surface of the reinforcing agent contains a large number of copper ions, the copper ions easily form copper oxide with oxygen, meanwhile, the reinforcing agent contains an intermediate F, the intermediate F belongs to aromatic polyamide, the intermediate F contains an alkyl long-chain structure and two nitryl groups, nitryl is a hydrophobic group, so that the water solubility of the intermediate F is greatly reduced, the anti-corrosion silicon carbide wear-resistant material does not have the phenomenon of wear-resistant substance loss after being soaked in water, and the wear resistance and corrosion resistance of the anti-corrosion silicon carbide wear-resistant material are further ensured.

Owner:宜兴市中电耐磨耐火科技有限公司

Rice husk rapid charring method and carbonization furnace

InactiveCN101200645AImprove efficiencyIncrease productivityBiofuelsSpecial form destructive distillationFood additiveCarbonization

The present invention discloses a method for fast carbonizing rice husk and a carbonizing furnace. The method is that self-igniting type rice husk is directly heated to manufacture char, the bottom of the carbonizing furnace is provided with a layer of the rice husk or other raw materials as a fixing layer, and igniting material is used to ignite the fixing layer. The method of continuously feeding above the furnace and the method of inducing air under the furnace are adopted, after the rice husk is carbonized, the air inducing is stopped, and a spraying cooling method is used to activate and cool the rice husk. The present invention combines the fast carbonizing technology and the activating technology subtly to reduce the carbonization time, ensure the continuous production, improve the production efficiency and save the production cost. The present invention adopts the technology of spraying hydrosphere for cooling and activating, which effectively improves the char absorption capability and ensure that the char has better activity. The finished product of a rice husk char of the present invention has wide application range and can be used as fertilizer sustained-release agent, feed additive, smelting melting agent, food additive, medical additive etc. The present invention can make the raw material into granules, then is carbonized to be directly used in absorbent, antistaling agent and order absorber and also can be used as the fuel for high-grade barbecue and field operation personnel.

Owner:徐克文

Preparation method of nitrified modified biochar fertilizer

InactiveCN107311790AIncrease organic matterMicroporous increaseFertilizer mixturesLivestock manureDesorption

The invention discloses a preparation method of a nitrified modified biochar fertilizer. The preparation method comprises: (1) respectively drying a biomass raw material and human-livestock manure in the sun or baking the material, and crushing into powder; (2) weighing and mixing the treated biomass raw material, the treated human-livestock manure and a catalyst according to a mass ratio of 3:2:1; (3) carrying out dewatering and oxygen discharging; (4) carrying out cracking carbonization; (5) adding the mixed liquid of concentrated sulfuric acid and concentrated nitric acid to a biochar fertilizer, and carrying out nitrification treatment to obtain a nitrified biochar fertilizer; and (6) adding water and stannous chloride to the nitrified biochar fertilizer, and carrying out heating reflux treatment to obtain the nitrified modified biochar fertilizer. According to the present invention, the preparation method is simple; the prepared nitrified modified biochar fertilizer has the substantially improved heavy metal ion adsorption performance, can be recycled through the desorption regeneration after the adsorption, and has the high fertilizer efficiency; and after the application of the nitrified modified biochar fertilizer in the soil, the soil structure can be improved, and the nitrified modified biochar fertilizer can be used as the fertilizer so as to well meet the requirements of the growth of crops.

Owner:黄名义

Mixture of concrete roadbase

The invention belongs to the technical field of solid waste resource utilization, and particularly relates to a mixture of a concrete roadbase. The mixture is prepared from the following components inparts by weight: 496-513 parts of thiourea waste residues, 350-469 parts of thermoelectric furnace slag, 75-84 parts of cement, 246-265 parts of fly ash, 96-113 parts of cyanamide residues and 398-423 parts of stones or building crushed materials. By the adoption of the method, thiourea can be comprehensively utilized for producing waste residues, meanwhile, soil filling smashing and compacting are facilitated, the strength of the roadbase can be improved, influences of compression deformation and shrinkage deformation are reduced, the water stability and durability of the roadbase are improved, the resource utilization level is improved, and the production cost is reduced.

Owner:山东京博环保材料有限公司

Modified slag adsorbent for anionic dye wastewater treatment and preparation method thereof

The present invention belongs to the technical field of environmental materials, and discloses a modified slag adsorbent for anion dye wastewater treatment, and a preparation method thereof. The preparation method comprises: washing, drying, crushing and screening slag; preparing a sodium chloride solution, and mixing the sodium chloride solution and hydrochloric acid to obtain a mixed solution; and slowly adding the mixed solution to the slag, carrying out a stirring reaction, standing, drying, and grinding to obtain the modified slag adsorbent. According to the present invention, the preparation method has characteristics of simpleness, rich raw material source, low price, and waste recycling; after the modification, the micro-pores of the slag are increased, the specific surface area is increased, and the adsorption capacity of the adsorbent is further enhanced; and the adsorbent of the present invention has the good anion dye wastewater treatment effect, has the high equilibrium adsorption capacity, and especially has the good Acid Green 27 adsorption effect.

Owner:GUANGDONG UNIV OF EDUCATION

Iron tailing-fly ash-polystyrene blended concrete wall material and preparation method thereof

The invention relates to an iron tailing-fly ash-polystyrene blended concrete wall material and a preparation method thereof, and belongs to the technical field of building material engineering, the iron tailing-fly ash-polystyrene blended concrete wall material comprises the following raw materials by weight: 45 parts to 60 parts of iron tailings, 12.4 parts to 15 parts of cement clinker, 4.2 parts to 5 parts of micro silica fume, 7 parts to 11.4 parts of machine-made sand, 16 parts to 23 parts of fly ash, 0.4 part to 0.6 part of polystyrene foam particles, 0.2 part to 0.4 part of polypropylene fiber, 20 parts to 30 parts of water, 0.8 part to 1.5 parts of a high-efficiency water reducing agent, 0.05 part to 0.2 part of hydroxypropyl methyl cellulose HPMC and 0.05 part to 0.2 part of redispersible latex powder. The material has the advantages that the cost is reduced, the environmental pollution is reduced, and the resource waste is avoided; the process is simple, operation is convenient, and installation is convenient; and the material has the advantages of light weight, fire resistance, sound insulation, moisture resistance, shock resistance, good durability, strong adhesiveness and the like.

Owner:NORTHEASTERN UNIV +1

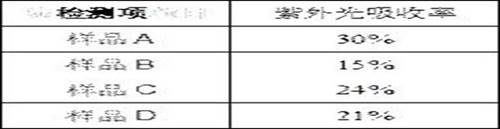

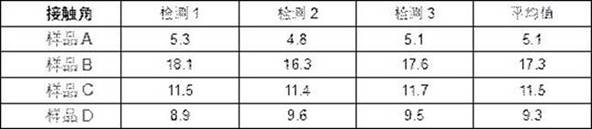

Self-cleaning glass with strong adhesive force, and preparation method thereof

ActiveCN112373134ASmall specific surface areaAvoid photocatalytic activity effectsLamination ancillary operationsLaminationSilanesManganese

The invention discloses strong-adhesion self-cleaning glass and a preparation method thereof. The strong-adhesion self-cleaning glass comprises a glass base layer, wherein a strong-adhesion bonding layer is attached to the glass base layer, a self-cleaning nano material layer is arranged on at least one side of the bonding layer, the thickness of the glass base layer is 3-12 mm, metal is any one of chromium, magnesium, tin, aluminum and manganese, the bonding layer adopts a silanized metal layer, the metal silylated glass is immersed in titanium dioxide sol for dipping, and a dip-coating process is adopted to prepare the film, and comprises the following steps: immersing the obtained metal silanized glass sheet in the prepared titanium dioxide sol for 1 min. According to the invention, Si-O-Me covalent bonds are formed through silane metal ions to form a silanized metal layer, and SiOH groups and the surface of glass form a silane film with a Si-O-Si three-dimensional network structure, so that the adhesive force between the film and the glass is greatly improved, the silane metal layer and the titanium dioxide nano layer are partially compounded, and the photocatalysis rate and the hydrophilic performance of the self-cleaning glass are enhanced.

Owner:佛山市金耀华玻璃新材有限公司

High-performance sound-absorption and thermal-insulation material production line

InactiveCN102797112AStretch smoothlyEffective stretchMelt spinning methodsNon-woven fabricsProduction lineProcess equipment

The invention relates to a high-performance sound-absorption and thermal-insulation material production line which comprises a main frame, wherein a plastic extruding machine is arranged above the main frame; a round roller net forming machine is arranged in the main frame; a melt-blow spinning box, a dosing pump and a filter are connected together and arranged above the round roller net forming machine; the melt-blow spinning box is connected with a plastic extruding machine; a wind heater is arranged on a side part of the round roller net forming machine; an induced draft fan and a blower are arranged on a side part of the wind heater; the wind heater is communicated with the centrifugal induced draft fan and the blower through pipelines; a dot hot-rolling roller and a dividing and cutting machine are arranged on a side part of the main frame; a spinneret and a spinning micropore are arranged below the melt-blow spinning box; and the micropore diameter ranges from 0.3 mm to 0.4 mm. In the invention, through the technical improvement on key process equipment, such as melt-blow, filling, sewing and the like, the high-performance sound-absorption and thermal-insulation material production line is built, and the procedures of product melt-blow, filling and sewing are accomplished in the same production line.

Owner:亿得宝科技发展有限公司

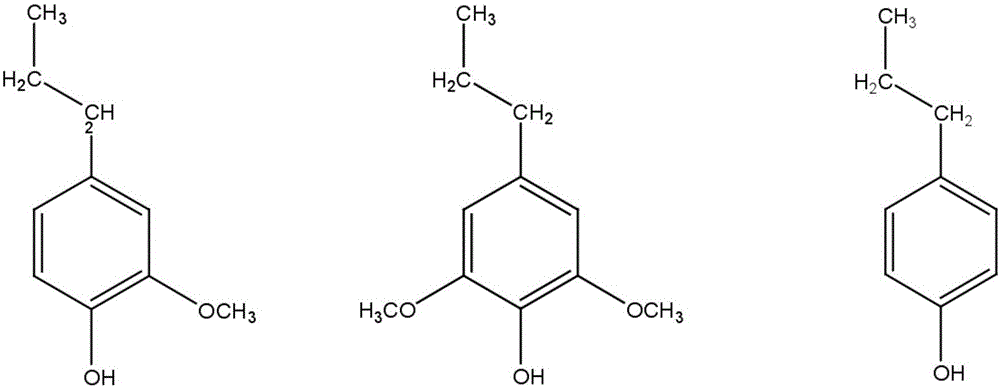

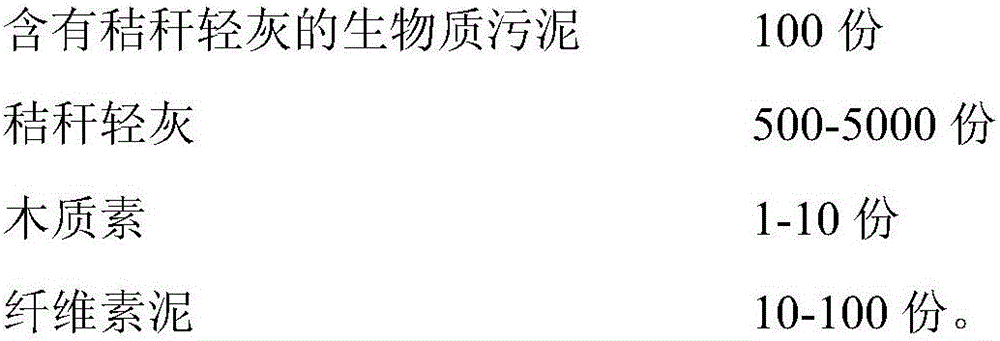

Lignin-containing biomass fuel and preparing method thereof

InactiveCN106433841AHigh calorific valueIncrease frictionSludge treatment by de-watering/drying/thickeningBiofuelsFiberEconomic benefits

The invention belongs to the technical field of fuel preparing, and particularly relates to a lignin-containing biomass fuel and a preparing method thereof. The lignin-containing biomass fuel is prepared from straw-light-ash-containing biomass sludge, straw light ash, lignin and cellulose mud. According to the biomass fuel, organic waste obtained through biomass resource treatment is fully used, and enormous economic benefits and enormous environment-protection benefits are achieved. In addition, plant materials such as the straw light ash are added into non-dewatered sludge, and the heat value of dewatered sludge can be increased; as plant fibers such as the straw light ash are mixed into the sludge, the frictional force of pre-dewatered sludge in a screw squeezing dewatering machine is improved, the running frequency of the screw squeezing dewatering machine can be further increased, and the running efficiency and the mud-discharging dryness degree of the machine are effectively increased.

Owner:ANHUI GEYI CYCLIC ECONOMY IND PARK

Method for reducing emission of nitrous oxide in soil of camellia oleifera forest by utilizing bamboo reed charcoal

InactiveCN110935417ABET specific surface area is highImprove adsorption capacityOther chemical processesContaminated soil reclamationCamellia oleiferaCarbonization

The invention discloses a method for reducing the emission of nitrous oxide in the soil of a camellia oleifera forest by utilizing bamboo reed biochar, belonging to the field of emission reduction ofgreenhouse gas. The method comprises the following specific steps: step 1, preparation of a raw material: harvesting mature bamboo reeds, cutting the stems of the mature bamboo reeds into bamboo reedpieces with lengths in a range of 1-3 cm, drying the bamboo reed pieces in the air for 1 day, and drying the bamboo reed pieces in a drying oven for a plurality of hours; step 2, carbonization of thebamboo reed pieces: transferring the bamboo reed pieces into a muffle furnace, carrying out heating to a carbonizing temperature in an inert gas atmosphere, keeping the carbonized bamboo reed pieces at a constant temperature for a plurality of hours, and performing natural cooling to room temperature to obtain the bamboo reed biochar; step 3, treatment of the bamboo reed biochar: grinding and sieving the bamboo reed biochar, taking bamboo reed biochar with fineness of 80 to 40 meshes, and treating the bamboo reed biochar with 200 ml of a hydrogen chloride solution with a concentration of 1 mol / L for 10 hours to remove ash in the bamboo reed biochar; step 4, biochar activation: activating the biochar by adopting a KOH method, wherein the BET specific surface area of the activated biochar isnot less than 1200 m<2> / g; and step 5, biochar-soil mixing: mixing the bamboo reed biochar with soil according to a ratio of 1%-5%, adding water after uniform mixing, and enabling the water content of the soil to reach 60% or above.

Owner:ANHUI SCI & TECH UNIV

Spherical light kaolin ceramsite with air purification function and through holes

InactiveCN106431281AContinuous adsorptionContinuous degradabilityCeramic materials productionCeramicwareSodium aluminateMoisture absorption

The invention discloses spherical light kaolin ceramsite with an air purification function and through holes. The technical scheme mainly includes that ingredients for the spherical light kaolin ceramsite include attapulgite pottery clay powder with an air purification function, kaolin, activated argil waste residues, white carbon black, activated aluminum oxide, sodium aluminate, sodium dodecyl sulfate, kaolin photocatalyst spray liquid capable of being scrubbed and the like; the ingredients are subjected to stirring, extrusion granulation, drying, calcination, heat-insulation treatment, sieving, soaking, drying, sieving and hermetic packaging to obtain the spherical light kaolin ceramsite with the air purification function and the through holes. The spherical light kaolin ceramsite with the air purification function and the through holes has the advantages of large specific surface area, low stacking density, high moisture absorption, excellent adsorption performance, good lightweight strength and micropore and macropore integration. Besides, the spherical light kaolin ceramsite is suitable to be arranged in indoor environments, furniture and cupboards, vehicles, aircrafts, ships or other buildings, pollutants such as formaldehyde, ammonia, benzene and TVOC (total volatile organic compounds) can be adsorbed and degraded by the spherical light kaolin ceramsite, and accordingly the purpose of purifying air can be achieved.

Owner:甘肃华晨生态治理有限公司

Biological oligopeptide anti-wrinkle essence containing complex plant-derived active factors and preparation method of biological oligopeptide anti-wrinkle essence

PendingCN111588667ADelay skin agingGood hydrophilicityCosmetic preparationsToilet preparationsWrinkleNutrition

The invention provides biological oligopeptide anti-wrinkle essence containing complex plant-derived active factors and a preparation method of the biological oligopeptide anti-wrinkle essence. The essence adopts the plant-derived active factors and biological oligopeptide as main active components, by means of type selection and functional modification for the biological oligopeptide, permeationand firming effects of the biological oligopeptide for the skin are promoted, nutritional active components are enabled to rapidly permeate into the deep layer of the skin, the effects of smoothing the skin and fading fine lines and wrinkles are realized, a deep moisturizing function can be realized by long-term use, wrinkles are obviously reduced, and good face skin firming and anti-wrinkle functions are realized. Meanwhile, the prepared anti-wrinkle firming essence is safe, stable, good in permeability and easy to absorb, and the face is fresh and non-greasy after using of the essence; and the preparation method is simple, the conditions are controllable, the process is stable, and the essence can be popularized and applied.

Owner:蒋艳伟

A kind of preparation method of degradable corn cob biomass water retaining agent

ActiveCN106749924BReduce manufacturing costInternal access to loose and unobstructedBiomassPolymerization

The invention discloses a preparation method of a biodegradable corncob biomass water-retaining agent. The water-retaining agent is prepared by taking modified corncob and acrylamide as main raw materials, adding a crosslinking agent and an initiator, and performing crosslinking and polymerization through reaction. The preparation method has the advantages that the waste corncob is adopted as a raw material, so that production cost of the water-retaining agent is greatly reduced; a special structural characteristic that a plurality of fine pores are in the surface and the inside of the modified corncob is fully used, and the prepared degradable water-retaining agent has quite good water absorption performance and degradation performance.

Owner:甘肃有色冶金职业技术学院

Wormwood active carbon insoles and manufacturing method thereof

The invention discloses wormwood active carbon insoles and a manufacturing method of the wormwood active carbon insoles, and belongs to the technical field of daily supplies. In order to solve the technical problems, the wormwood active carbon insoles and the manufacturing method of the wormwood active carbon insoles are provided, the technology is simple, and the manufactured insoles are comfortable, play a role in health care, emit fragrance and have a good physiotherapy effect on the cerebrovascular disease and the heart disease. According to the technical scheme, the manufacturing method of the wormwood active carbon insoles includes the following steps that step1, an adhesion agent is obtained through blending; step2, sandwich layers are manufactured; step3, sewing forming is performed; step4, edge stitching is performed. The health care insoles which are comfortable and emit fragrance are manufactured and can have the good physiotherapy effect on the cerebrovascular disease and the heart disease if people often wear the insoles.

Owner:永济市申华科技有限公司

Crushed stone-type alumina light ceramsite with air purifying function

InactiveCN106396630APromote productionHas the function of purifying airCeramic materials productionCeramicwareThermal insulationSodium aluminate

The invention discloses a crushed stone-type alumina light ceramsite with an air purifying function. Ingredients of the ceramsite comprise attapulgite clay powder with an air purifying function, alumina, activated carclazyte residues, white carbon black, sodium aluminate, hollow beads, calcined gypsum powder, sodium dodecyl sulfate and a scrubable alumina photocatalyst spray liquid. Through ingredient stirring, extruded granulation, drying, crushing, screening, roasting, thermal insulation, screening, immersion, drying, screening and sealed packaging, the crushed stone-type alumina light ceramsites with an air purifying function are obtained. The crushed stone-type alumina light ceramsite with an air purifying function has a specific surface area, low bulk density, light weight, high strength, high moisture absorption and excellent adsorption and purification performances, is suitable for being used in a room, a furniture cabinet, a vehicle, a ship or other buildings, has effects of adsorption and degradation of pollutants such as formaldehyde, ammonia, benzene and TVOC and realizes the purpose of purifying the air for a long time.

Owner:蒋文兰

Cylindrical lightweight kaolin through-hole ceramsite with air purification function

InactiveCN106431291AGood adhesionHas the function of purifying airCeramic materials productionCeramicwareCarbon blackBenzene

The invention discloses cylindrical lightweight kaolin through-hole ceramsite with an air purification function. According to the technical scheme, ingredients comprise attapulgite pottery clay powder with the air purification function, kaolin, activated argil residues, white carbon black, activated alumina, sodium aluminate, sodium dodecyl sulfate, a scrubbed kaolin photocatalyst spray coating solution and the like. The cylindrical lightweight kaolin through-hole ceramsite with the air purification function is obtained by performing stirring, extrusion granulation, drying, roasting, heat preservation, screening, impregnation, drying, screening and sealing packaging on the ingredients. The cylindrical lightweight kaolin through-hole ceramsite with the air purification function has the characteristics of large specific surface area, low bulk density, high moisture absorption, high adsorption performance, lightweight, strong strength and integration of micropores and a macropore, and is applicable to adsorption and degradation of pollutants such as formaldehyde, ammonia, benzene and TVOC for fulfillment of the aim of air purification in a room, a cupboard, a vehicle, an airplane, a ship or another building.

Owner:甘肃华晨生态治理有限公司

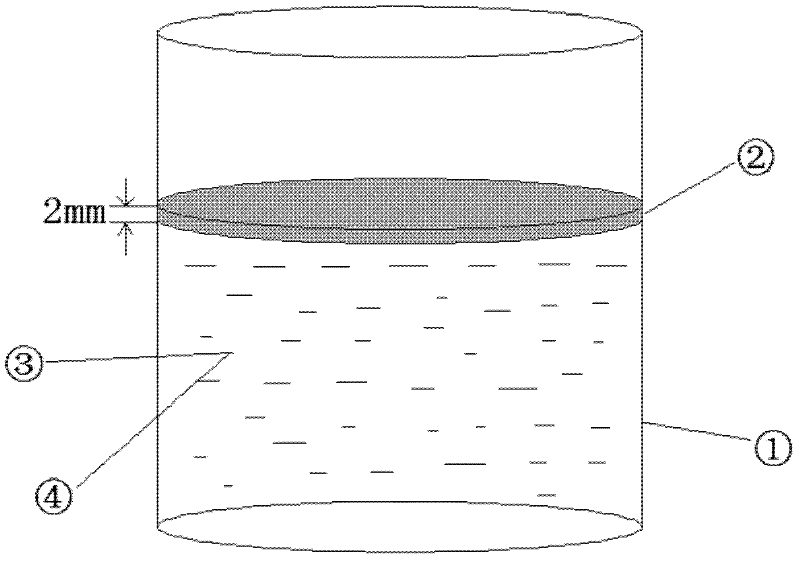

Mesh cloth for sewage treatment and preparation method of mesh cloth

ActiveCN105536742ALow costMild chemical reactionOther chemical processesWater contaminantsBursting strengthSewage

The invention relates to mesh cloth for sewage treatment. The mesh cloth for sewage treatment is characterized in that the mesh cloth is prepared through three-dimensional knitting by a warp knitting machine and has the thickness of 10-50 mm, the permeable capacity larger than 1,800 mm*s<-1> and the bursting strength larger than 2,000 N. With the adoption of the structure of the mesh cloth, in the process of sewage treatment, warp in the vertical direction can be well contacted with heavy metals in sewage, and the problem that the adsorbing effect is weakened due to the fact that the contact surface of traditional fabric with the sewage is reduced due to the overlapped structure is solved.

Owner:HENGYANG NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com