PS (poly styrene)/PP (propene polymer) fiber material adsorbing underwater benzene serial substances at high rate and preparation method

An adsorption material and water adsorption technology, which is applied in fiber treatment, fiber chemical characteristics, chemical instruments and methods, etc., can solve the problems that the performance and magnification of adsorbing benzene series under water need to be improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A) The raw materials PP, PS (PS / PP=2.5%) and the auxiliary antioxidant 4010 with a mass fraction of 0.02% are pelletized in a twin-screw extruder.

[0034] B) The PP blended pellets obtained in step A) are sent from the hopper 1 to the screw extruder 2 of the melt blown spinning machine for melt extrusion. The temperature of screw one zone, two zone, three zone is respectively set to 175 ℃, 190 ℃, 225 ℃, adjust screw speed to be 40rpm, after material is fully melted, send into filter system 3, here the impurity in the material (such as carbon, ash, etc.), the material enters the metering pump 5 through the melt pipe 4, and the temperature of the metering pump 5 is kept at about 240° C., and the speed is 30 rpm. The melt then passes through the distribution pipeline 6 and is spun in the spinning chamber 8. The filaments spun out of the spinning assembly 7 pass through the cooling window 9 to form primary crystalline filaments. The temperature of the hot air is set at 320...

Embodiment 2

[0037]A) The raw materials PP, PS (PS / PP=5%) and the auxiliary antioxidant 4010 with a mass fraction of 0.02% are pelletized in a twin-screw extruder.

[0038] B) The blended pellets of PS / PP=5% obtained in step A) are sent from the hopper 1 to the screw extruder 2 of the melt blown spinning machine for melt extrusion. Other processes and processing conditions are the same as B) of embodiment 1. The average diameter of the obtained fiber material is 4um (randomly sampled, and the average value of 20 fibers is counted by scanning electron microscope).

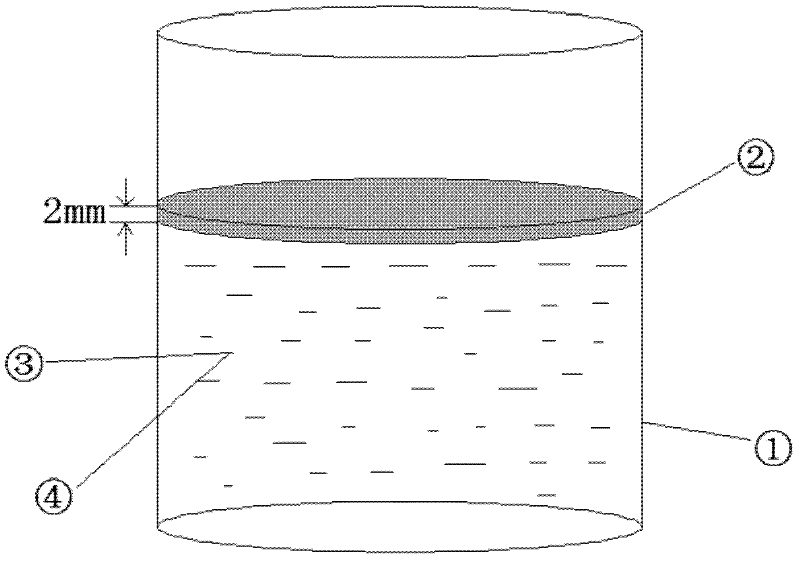

[0039] The prepared PS / PP blended melt-blown fiber material was placed in the simulated device of underwater benzene series ( figure 2 ), the simulation device for benzene series on the water surface ( figure 1 ) and deionized water to test the adsorption rate, see Table 3., and compare it with the PP melt-blown fiber material. From the comparison of the data in Tables 1 and 3, it can be seen that the adsorption ratio of PS / ...

Embodiment 3

[0041] A) The raw materials PP, PS (PS / PP=10%) and the auxiliary antioxidant 4010 with a mass fraction of 0.02% are pelletized in a twin-screw extruder.

[0042] B) The blended pellets of PS / PP=10% obtained in step A) are sent from the hopper 1 to the screw extruder 2 of the melt blown spinning machine for melt extrusion. Other processing and processing conditions are identical with embodiment 1. The average diameter of the obtained fiber material is 4um (randomly sampled, and the average value of 20 fibers is counted by scanning electron microscope).

[0043] The prepared PS / PP blended melt-blown fiber material was placed in the simulated device of underwater benzene series ( figure 2 ), the simulation device for benzene series on the water surface ( figure 1 ) and deionized water to test the adsorption rate, see Table 4., and compare it with the PP melt-blown fiber material. From the comparison of the data in Tables 1 and 4, it can be seen that the adsorption ratio of PS...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt flow rate | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com