Straw fuel containing biomass sludge and preparation method of straw fuel

A biomass and straw technology, applied in the direction of biofuel, waste fuel, fuel, etc., to achieve huge economic and environmental benefits, increase fiber content, and improve calorific value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

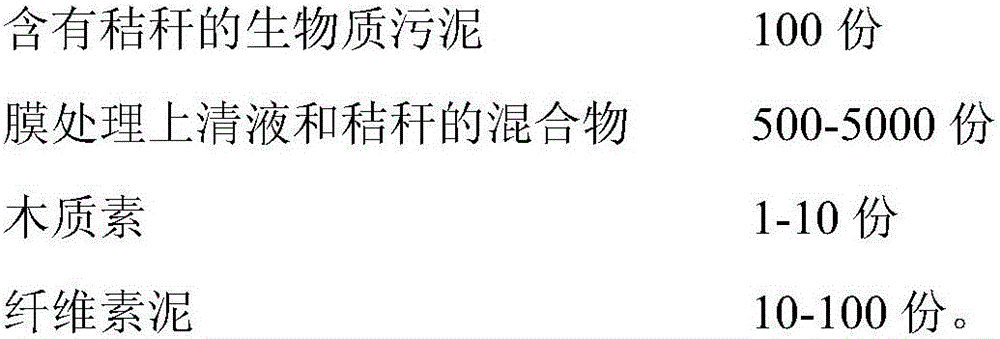

[0049] The composition of raw materials is as follows:

[0050]

[0051]

[0052] The straw is wheat stalk, fine grained, that is, the straw is light ash.

[0053] The membrane treated supernatant has an organic matter content of 3%, a pH value of 12, a suspended matter content of less than 100mg / L, NaOH, Ca(OH) 2 The total content is 8%.

[0054] Lignin is solid: water content 3%, biochemical lignin content 85%, methylol 25%, phenolic hydroxyl 5%, solubility 30g / 100g water at normal temperature and pressure.

[0055] The cellulose mud has a cellulose content of 50wt%, a water content of 45wt%, and an ash content of 5wt%.

[0056] The preparation method is as follows:

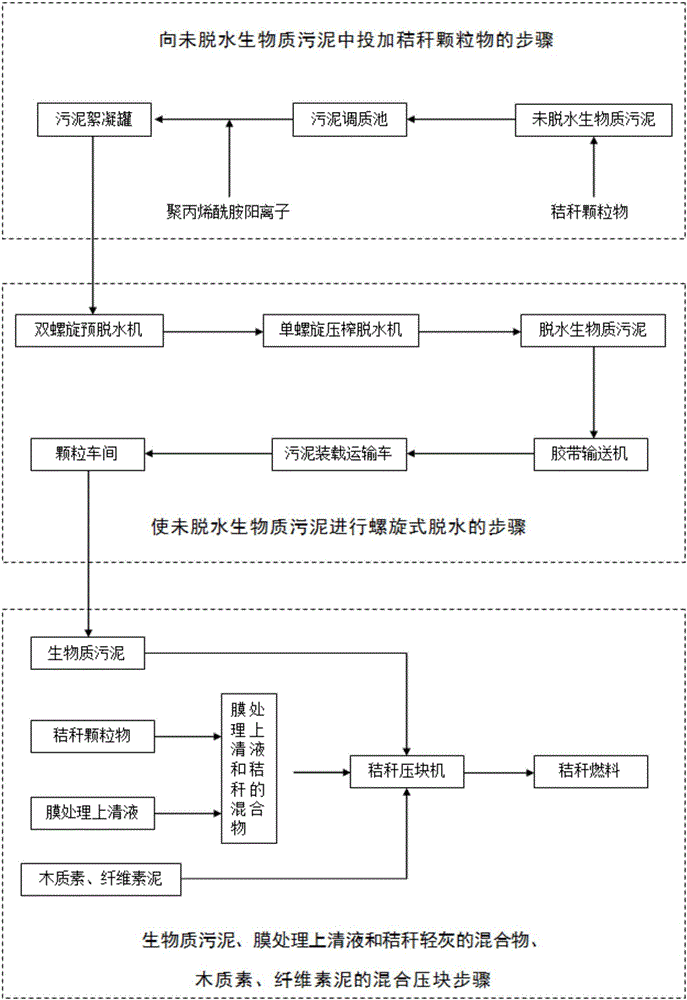

[0057] (1) adding straw particles to the non-dehydrated biomass sludge and performing spiral dehydration to obtain dehydrated biomass sludge containing straw particles;

[0058] (2) Adding the membrane-treated supernatant to the straw particles for mixing to obtain a mixture of the membrane-treated su...

Embodiment 2

[0063] The composition of raw materials is as follows:

[0064]

[0065] The straw is wheat stalk, fine grained, that is, the straw is light ash.

[0066] The membrane treated supernatant has an organic matter content of 3%, a pH value of 12, a suspended matter content of less than 100mg / L, NaOH, Ca(OH) 2 The total content is 8%.

[0067] Lignin is solid: water content 3%, biochemical lignin content 85%, methylol 25%, phenolic hydroxyl 5%, solubility 30g / 100g water at normal temperature and pressure.

[0068] The cellulose mud has a cellulose content of 50wt%, a water content of 45wt%, and an ash content of 5wt%.

[0069] The preparation method is the same as in Example 1.

Embodiment 3

[0071] The composition of raw materials is as follows:

[0072]

[0073] The straw is wheat stalk, fine grained, that is, the straw is light ash.

[0074] The membrane treated supernatant has an organic matter content of 3%, a pH value of 12, a suspended matter content of less than 100mg / L, NaOH, Ca(OH) 2 The total content is 8%.

[0075] Lignin is solid: water content 3%, biochemical lignin content 85%, methylol 25%, phenolic hydroxyl 5%, solubility 30g / 100g water at normal temperature and pressure.

[0076] The cellulose mud has a cellulose content of 50wt%, a water content of 45wt%, and an ash content of 5wt%.

[0077] The preparation method is the same as in Example 1.

[0078] The specific operation steps are as follows:

[0079] Biomass fuel test base: Anhui Geyi Circular Economy Industrial Park Co., Ltd. pellet workshop;

[0080] Briquetting machine manufacturer Henan Derun Boiler Co., Ltd., model HMB series biomass molding machine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| heat | aaaaa | aaaaa |

| dryness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com