Silicon carbide fiber needle felt and manufacturing method thereof

A silicon carbide fiber, needle felt technology, applied in heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problems of high brittleness of silicon carbide fibers, achieve high total porosity, increase X-Y bidirectional mechanical properties , the effect of small aperture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

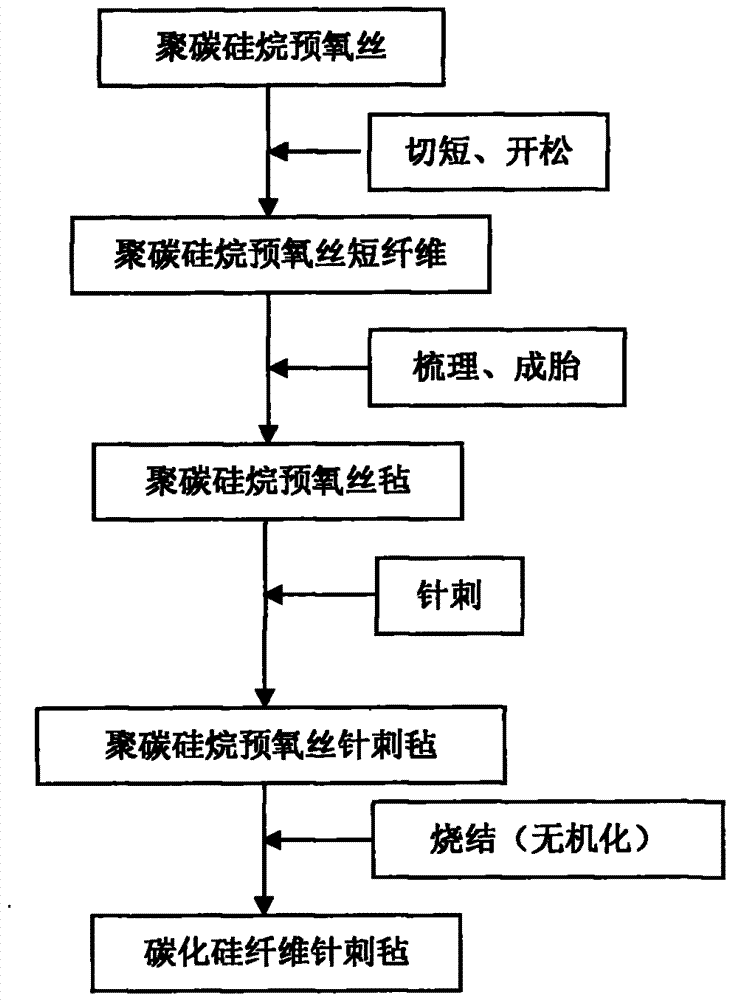

[0030] A method for preparing silicon carbide fiber needle-punched felt, step 1, cutting and opening: select infusible fibers with a Si-H bond reaction degree of 65% to 70% and evenly cut them into short fibers with a length of 5 to 8 cm, and the cutter speed 150r / min; step 2, airflow carding, tire forming: the chopped non-melting fibers pass through the feeding roller to the licker-in roller, and are thrown into the high-speed airflow generated by the fan under the high-speed mechanical action of the licker-in roller, and move together with the airflow. The air flow finally passes through the netting curtain, and the fibers are formed on the netting curtain. The netting speed is 10m / min, the diameter of the main cylinder is 1020mm, and the rotation speed is 160rpm. On, flatten, align, start the acupuncture machine, turn on the pre-acupuncture main shaft, wait for it to stabilize and then increase the feeding and discharging speed, reciprocate acupuncture for 1 back and forth, ...

Embodiment 2

[0032] The difference between this embodiment and Embodiment 1 is that the Si-H bond reaction degree of the polycarbosilane infusible fiber in step 1 is 75% to 80%, the frequency of the pre-punched spindle in step 3 is 10 Hz, and the number of silicon carbide felt layers for 3.

Embodiment 3

[0034] The difference between this example and Example 1 is that in step 4, the heating rate of 550°C to 1100°C is 0.5°C / min, the final temperature is 1300°C, the temperature is kept for 1 hour, and then the temperature is naturally lowered.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com