Controllable preparation method of monocrystal copper nanowires

A technology of copper nanowires and nanowires, which is applied in the field of liquid-phase reduction controllable preparation of high-yield single crystal copper nanowires, can solve the problems of high production cost, poor uniformity and controllability, and complicated process of copper nanowires, and achieve The effect of cheap raw materials, good uniformity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

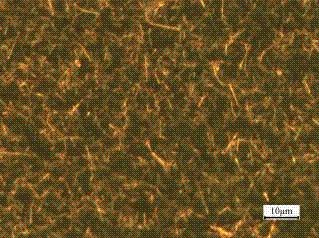

Image

Examples

Embodiment 1

[0028] Determine the Cu(NO 3 ) 2 , EDA, NaOH, H 2 NNH 2 The concentrations are 5.3mM, 0.16M, 8.3M, 68.8mM respectively, the total volume of the mixed solution is selected to be 30ml, and Cu(NO 3 ) 2 Solid and NaOH solid were dissolved in a certain amount of deionized water respectively, and ethylenediamine and hydrazine hydrate were measured and dropped into Cu(NO 3 ) 2 solution and NaOH solution and stir well, cover them and place them in a 60°C water bath for 10 minutes, then transfer them to a glass reactor, and add deionized water dropwise to make the total volume of the solution 30ml, shake well Cover the back and place it in a water bath at 60°C for a heating reaction for 2 hours, then fish out the flaky copper nanowires floating on the upper layer of the solution, wash them with deionized water and absolute ethanol for more than three times in turn, and store them at room temperature and under the protection of Ar gas. After drying for 4 hours, single crystal copp...

Embodiment 2

[0030] Determine the Cu(NO 3 ) 2 , EDA, NaOH, H 2 NNH 2 Concentrations of the solutions are 5.3mM, 0.14M, 8.3M, 8.6mM respectively, and the total volume of the mixed solution is selected to be 30ml. Weigh Cu(NO 3 ) 2 Solid and NaOH solid were dissolved in a certain amount of deionized water respectively, and ethylenediamine and hydrazine hydrate were measured and dropped into Cu(NO 3 ) 2 solution and NaOH solution and stir well, cover and heat in a 60°C water bath for 15 minutes at the same time, then transfer them to a glass reactor, and add deionized water dropwise to make the total volume of the solution 30ml, shake well Cover the back and place it in a water bath at 60°C for a heating reaction for 2 hours, then fish out the flaky copper nanowires floating on the upper layer of the solution, wash them with deionized water and absolute ethanol for more than three times in turn, and store them at room temperature and under the protection of Ar gas. After drying for...

Embodiment 3

[0032] Determine the Cu(NO 3 ) 2 , EDA, NaOH, H 2 NNH 2 The concentrations are 5.3mM, 0.03M, 13.3M, 8.6mM respectively, the total volume of the mixed solution is selected to be 30ml, and Cu(NO 3 ) 2 Solid and NaOH solid, respectively, were dissolved in a certain amount of deionized water. Measure ethylenediamine and hydrazine hydrate, drop into Cu(NO 3 ) 2 solution and NaOH solution and stir well, cover them and place them in a 50°C water bath for 12 minutes, then transfer them to a glass reactor, and add deionized water dropwise to make the total volume of the solution 30ml, shake well Cover the back and place it in a water bath at 50°C for a heating reaction for 2 hours, then fish out the flaky copper nanowires floating on the upper layer of the solution, wash them with deionized water and absolute ethanol for more than three times in sequence, and store them at room temperature and under the protection of Ar gas. After drying for 2 hours, single crystal copper na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com