Preparation method of amide group modified polystyrene-based ultrahigh crosslinking adsorption resin

A cross-linked resin and amide group technology, which is applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problem of easy fouling of membranes, reduction of resin specific surface area and pore volume, and complicated operation and other problems, to achieve the effect of easy control of reaction conditions, promotion of adsorption capacity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

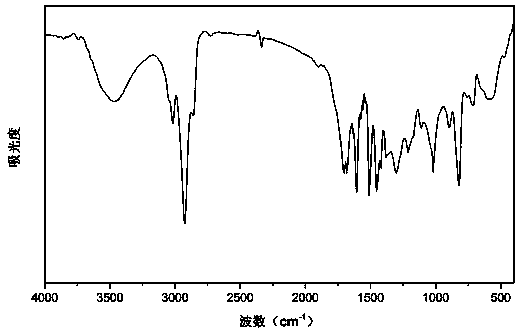

Image

Examples

Embodiment 1

[0042] A preparation method for amide group modified polystyrene crosslinked resin, comprising the following steps:

[0043] S1. Preparation of precursor resin: Add the water phase into a 500mL three-necked flask, add the oil phase into the water phase, pass nitrogen gas for 5 minutes, adjust the speed at 160rpm, raise the temperature to 80°C for 8 hours, wash with hot water and industrial alcohol in sequence until The washing solution was clarified, then Soxhlet extracted for 24 hours, then placed in 45°C and dried in vacuum to constant weight to obtain the premise resin, wherein the water phase contained 0.5% polyvinyl alcohol and 3 drops of methylene blue, the quality of the water phase was 240g, and the composition of the oil phase was Styrene monomer 4g, hydroxyethyl acrylate 16g, crosslinking agent divinylbenzene 20g, porogen toluene 20g and n-heptane 20g, initiator benzoyl peroxide 0.4g;

[0044] Preparation of S2 post-crosslinked resin: add 120mL swelling agent to the ...

Embodiment 2

[0047] A preparation method of amide group-modified styrene-based ultra-high cross-linked adsorption resin, which is basically the same as Example 1, the difference is that the amount of the dispersant polyvinyl alcohol in the water phase in S1 is 1.0%, and the oil phase The mass of styrene monomer is 16g, and the mass of hydroxyethyl acrylate is 4g.

Embodiment 3

[0049] A preparation method of amide group-modified styrene-based ultra-high cross-linked adsorption resin is basically the same as that of Example 1, the difference being that the ester monomer containing double bonds in S1 is glycidyl methacrylate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com