Compound type sludge fuel and preparation method thereof

A composite, sludge technology, applied in the chemical industry, can solve the problems of unstable water content of sludge, asynchronous combustion time, mixed combustion of sludge, etc., and achieve the effects of stable calorific value, easy storage and easy combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Single sludge fuel (without adding other components) is prepared. First, dehydrate the sludge with water content to 15%, then extrude it on the molding equipment, and then dry it naturally to obtain the single sludge fuel.

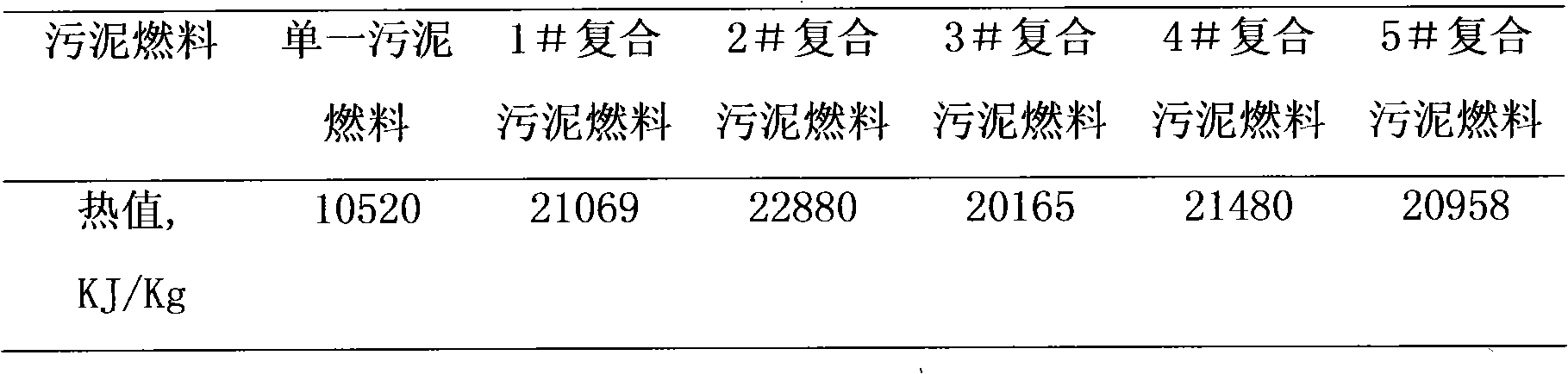

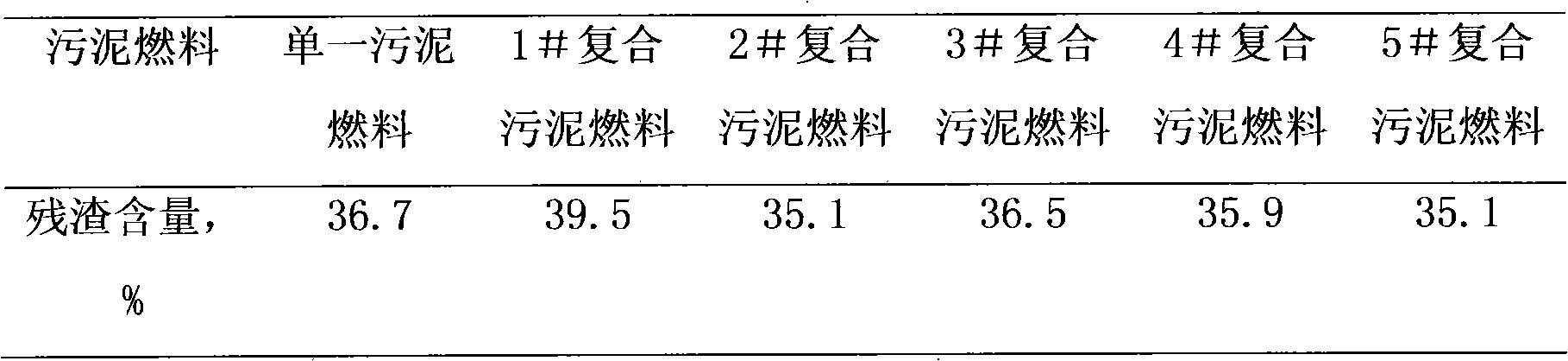

[0024] Weigh 100g of 1# single sludge fuel and put it into a fixed bed incinerator for incineration. After complete incineration, the mass of the residue is weighed, and the content of main heavy metal ions in the residue is determined by inductively coupled plasma atomic emission spectrometry. In addition, an appropriate amount of single sludge sample was taken to determine the calorific value by oxygen bomb combustion method. The specific results are shown in Table 1, Table 2 and Table 3, respectively. Table 1 is the calorific value table of different sludge fuels; Table 2 is the residue content table after combustion of different sludge fuels; Table 3 is the main heavy metal ion content table in the residue after combustion of different sludge f...

Embodiment 2

[0026] The present embodiment adopts the raw material of following weight percent: 30% dried sludge; 40% pulverized coal; 10% residual oil; 10% wood powder (biomass); 7% clay; 3% CaO prepares composite sludge fuel ( 1# composite sludge fuel). First take 30% hydrous sludge based on dry sludge weight, dehydrate the hydrous sludge to 55%, then add 40% coal powder; 10% residual oil; 10% wood flour (biomass); 7% clay and 3% CaO; mixed and stirred evenly, extruded on the molding equipment, and then dried naturally to obtain the composite sludge fuel product.

[0027] Weigh 100g of 1# composite sludge fuel and put it into a fixed bed incinerator for incineration. After complete incineration, the mass of the residue is weighed, and the content of main heavy metal ions in the residue is determined by inductively coupled plasma atomic emission spectrometry. In addition, an appropriate amount of sludge samples were taken to determine the calorific value by the oxygen bomb combustion met...

Embodiment 3

[0029] The present embodiment adopts the raw material of following weight percent: 20% dried sludge; 50% pulverized coal; 20% residual oil; 4% wood flour (biomass); 5% clay; 1% CaO prepares composite sludge fuel ( 2# composite sludge fuel). First take 20% water-containing sludge based on dry sludge weight, dehydrate the water-containing sludge to 45%, then add 50% coal powder, 20% residual oil, 4% wood powder (biomass), and 5% clay and 1% CaO, mixed and stirred evenly, extruded on the molding equipment, and then dried in the sun to obtain a composite sludge fuel product.

[0030] Weigh 100g of 2# composite sludge fuel and put it into a fixed bed incinerator for incineration, weigh the residue after complete incineration, and measure the main heavy metal ion content in the residue by inductively coupled plasma atomic emission spectrometry. In addition, an appropriate amount of sludge samples were taken to determine the calorific value by the oxygen bomb combustion method. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com