Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

108results about How to "Meet electrical performance requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

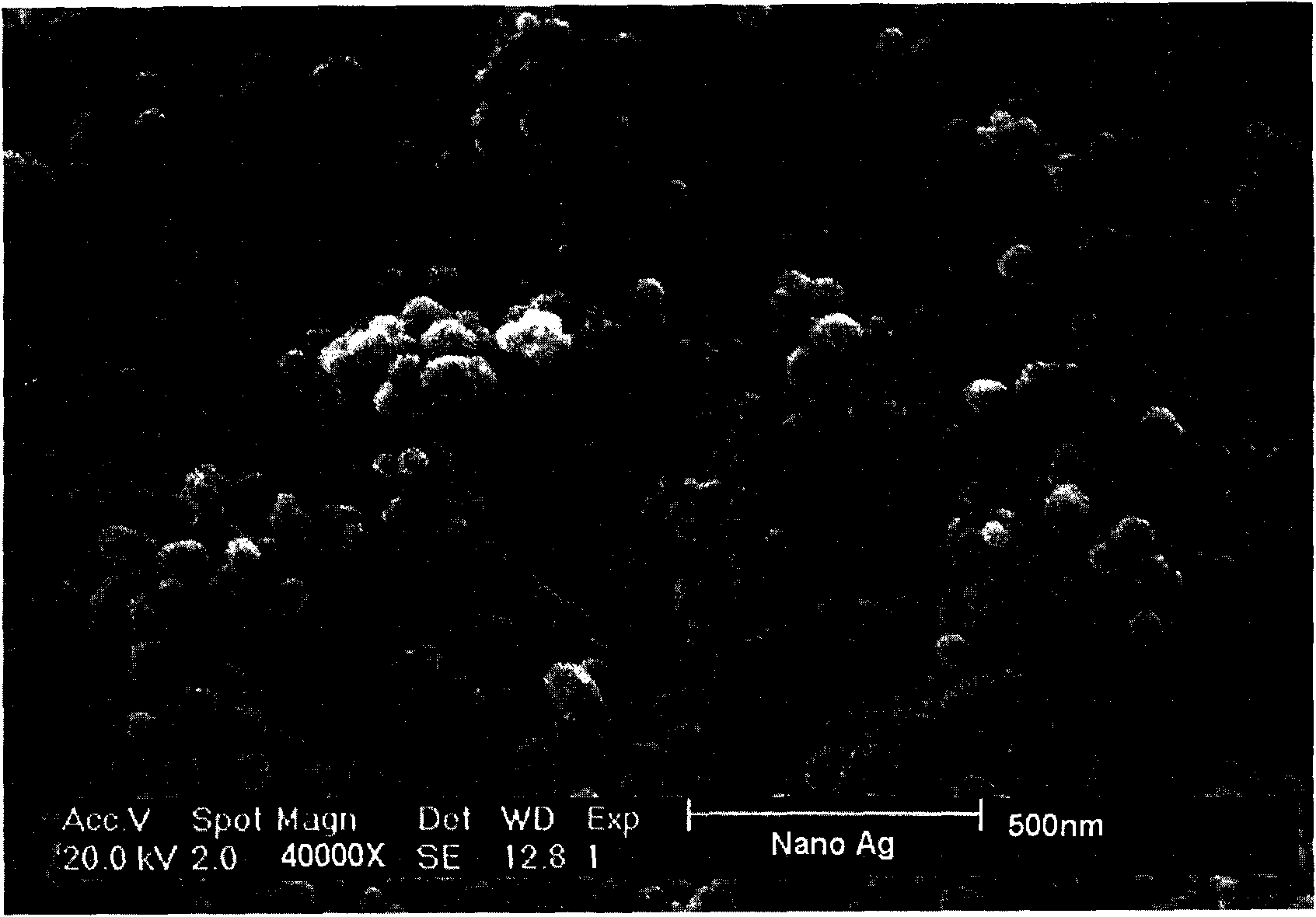

Method for preparing nano-scale silver powder

The invention discloses a method for preparing nano-scale silver powder and comprises the steps of reduction reaction, solid-liquid separation and washing and drying. In the reduction reaction, aqueous solution with the silver-bearing concentration being 30-200g / L is dropwise added into the reducing solution, or aqueous solution of reducing agent is dropwise added into silver oxide suspending liquid with the silver-bearing concentration being 30-200g / L, the reaction temperature is controlled at 20-60 DEG C, and synchronously pH regulating agent is added, the pH value of the reaction solution is controlled at 10-14, then the reaction solution is stirred to obtain the silver suspending liquid. The method process is simple and easy to carry out, the obtained nano silver powder has high purity, good dispersivity, small particle diameter, higher specific surface and tap density and high drying temperature range of the powder, the self-sintering or agglomeration of the powder can be effectively controlled, and the powder can be easily dispersed in an organic carrier.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

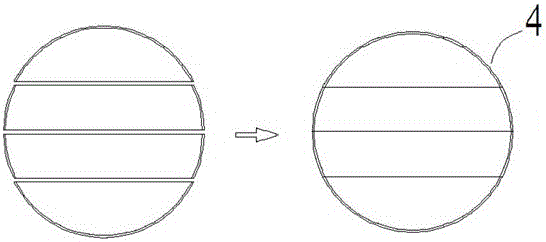

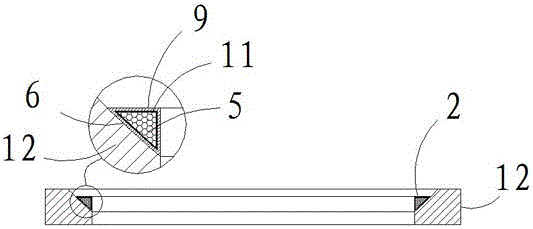

PMI (polymethacrylimide) foam sandwich aircraft radar cover and manufacturing method thereof

A PMI (polymethacrylimide) foam sandwich aircraft radar cover comprises a concave cover body and a flange ring, wherein the concave cover body and the flange ring consist of a skin layer, a cover body adhering layer and a PMI sandwich layer. A manufacturing method of the PMI foam sandwich aircraft radar cover comprises the process steps of flange foam blank milling molding, cover body PMI foam blank block molding and skin adhering molding and curing. The product provided by the invention has the advantages of light weight, high rigidity and signal stability, and completely can meet electrical property, mechanical property and environment-resistant property test index requirements required by design. According to the PMI foam sandwich block molding process, the variable quantity of foam thickness is small after thermal molding and bending of flat foam, so the electrical property requirement of the radar cover is met to the greatest extent, and the wave transmission property becomes poor due to large variable quantity of foam density and thickness after molding by the integral molding process is effectively avoided.

Owner:SICHUAN TIANYUAN MACHINERY CO LTD OF 081 ELECTRONICS GRP

Electric silicon rubber

ActiveCN101260238AImprove conductivityGood for healthNon-conductive material with dispersed conductive materialHigh rateVolumetric Mass Density

A conductive silicon rubber relates to a material used in the accessories of electric wire and cable, and comprises reinforced silicon rubber, acetylene carbon black, structural inhibitor, liquid silicon rubber and vulcanizing agent, wherein the acetylene carbon black is granular. The making process of the conductive silicon rubber is as follows: the acetylene carbon black, hydroxyl silicon oil and water are mixed according to the proportion of 100:4.5-5.5:0.2-0.5, and then are added in a granulator to be made into granules. The conductive silicon rubber has the advantages that: because acetylene carbon black, the main raw material of the conductive silicon rubber, is turned into spheric granules with the diameter approximately equal to 1 mm from the original powdery state after pretreatment, the conductive silicon rubber has increased stacking density and is nondusty and easy to disperse, thereby substantially improving manufacturing environment and doing good to the physical health of operation staff; moreover, the acetylene carbon black has good conductive effect and can meet the requirements of electrical property with a small amount of addition (15 to 22 percent). In addition, due to the addition of gluing auxiliary agent, liquid silicon rubber, the conductive silicon rubber can be well glued to insulating glue, thereby obtaining higher rate of qualified product as well as mechanical property and electrical property superior to the requirements of national standards.

Owner:ZHEJIANG WANMA GROUP ELECTRIC

Modified PTFE (polytetrafluoroethylene) fiberglass cloth for copper-clad plates and preparation method of fiberglass cloth

ActiveCN105904806AHigh hardnessHigh dielectric constantSynthetic resin layered productsElectrical equipmentGlass fiberEmulsion

The invention relates to modified PTFE (polytetrafluoroethylene) fiberglass cloth for copper-clad plates and a preparation method of the fiberglass cloth. The modified PTFE fiberglass cloth comprises a fiberglass cloth body which is coated with modified polytetrafluoroethylene glue solution in the coating amount of 80-260g / m<2>. The preparation method includes uniformly mixing ceramic powder, silicon dioxide powder, silane coupling agent, water and PTFE emulsion to form the modified polytetrafluoroethylene glue solution, soaking the fiberglass cloth in the modified polytetrafluoroethylene glue solution at constant speed, removing excessive glue solution via extrusion of an extrusion roll, putting the soaked fiberglass cloth in a drying oven for drying, and finally cutting and reeling. The preparation method is simple and easy for step operation, the prepared modified PTFE fiberglass cloth can meet the requirements for electrical performance of the plates, subsequent processing cost can be lowered, addition amount of the ceramic powder is controlled to regulate the size of dielectric constant, and the copper-clad plates prepared can be applied to more fields.

Owner:宜兴富仕德高频科技有限公司

Method for preparing crystal polymer/carbon nano-tube conductive composite material

InactiveCN101200563AImprove processing efficiencyMeet electrical performance requirementsCarbon nanotubeElectronic instrument

The present invention relates to a preparation method of crystal polymer / carbon nano-pipe conductive composite material. The method is characterized in that crystal polymer, carbon nano-pipe and inorganic powder are mixed according to a certain proportion and then the processing equipment of macromolecular material is adopted for fusing, mixing and completing the granulation. The present invention with simple method and easy operation can obtain the conductive composite material with good electric conduction and good comprehensive performance through one-step method, and can be applied in the fields of automobile, electric and electronic instrument, office equipment and industrial machinery. The present invention can meet and expand the requirements of crystal macromolecular material for various purposes.

Owner:TSINGHUA UNIV

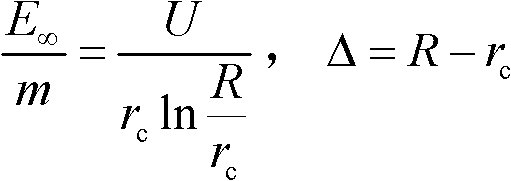

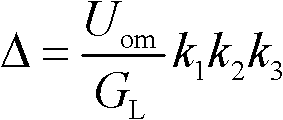

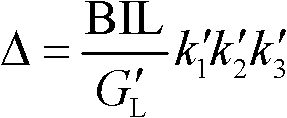

Insulation Thickness Design Method for High Voltage XLPE DC Cable

ActiveCN102290155AGuaranteed uptimeMeet electrical requirementsInsulatorsInsulating conductors/cablesReliable transmissionEngineering

The invention relates to a design method for insulation thickness of a high-voltage cross-linked polyethylene direct current (DC) cable. The design method comprises the following steps of: determining the form of design voltage; calculating the amplitude of the design voltage; determining the form of design field intensity corresponding to the form of the voltage design; testing and calculating the amplitude of the design field intensity; and calculating and determining the design thickness of the high-voltage cross-linked polyethylene DC cable. For the high-voltage cross-linked polyethylene DC cable product designed by the design method for the insulation thickness, the cross-linked polyethylene insulation can withstand the action of long-term operating voltage of DC power transmission lines, power frequency alternating current (AC) voltage superimposed on the DC, voltage in a system, polarity inverse voltage produced through current reversal, operation impulse voltage produced through on / off actions and lightning impulse atmospheric over voltage, meets the requirements on electrical properties of cable insulation, ensures the long-term stable operation of the cable and realizes the reliable transmission of electric energy.

Owner:XI AN JIAOTONG UNIV +1

Conductive composite material and its preparation method

InactiveCN103849120AImprove connection efficiencyImprove conductivityNon-conductive material with dispersed conductive materialMaterials preparationConductive polymer

The invention provides a conductive composite material and its preparation method, and the conductive composite material is prepared by use of synergistic effects of carbon nanotubes and a graphene filler. The conductive composite material comprises the following components by weight: 92 to 99 parts of a polymer; 0.9 to 6 parts of the carbon nanotubes and 0.1 to 2 parts of graphene. Compared with traditional conductive composites, the conductive composite material uses the synergistic effects of the carbon nanotubes and the graphene filler to realize the following effects of the composite system: first, by mutual connection among the conductive filler, the connection efficiency among the conductive filler is improved, and the conductivity of the conductive composite material is improved; second, the conductive filler plays the purpose of synergistic dispersion to reduce the use amount of the conductive filler; and third, the use amount of the carbon nanotubes and the graphene is reduced, the material preparation cost is saved, mechanical properties of the composite material are not lost, the preparation operation step is simple, consumption of a large amount of solvents is not needed, and the conductive composite material is suitable for large-scale industrial production.

Owner:HEFEI GENIUS NEW MATERIALS

Buried resistance printed board and manufacturing method thereof

InactiveCN104427762AMeet electrical requirementsAvoid surface spacePrinted resistor incorporationMultilayer circuit manufactureLean manufacturingEngineering

The invention relates to a printed board, provides a manufacturing method for a buried resistance printed board, and provides a buried resistance printed board manufactured by adopting the manufacturing method. According to the manufacturing method, a resistor is arranged on the inner layer of the printed board by etching, and good electrical conduction is formed through etched relevant circuits, blind holes and the like, so that the electrical requirement of the printed board is met, the surface space of the printed board is not occupied, and the miniaturization and multifunctional development of the printed board are facilitated; when each plate is laminated, the surfaces of inner layer plates are subjected to brown oxidation, so that bonding force among the plates can be improved; the printed board manufacturing by adopting the method is simple in structure, is large in surface space, and can be applied to various electronic products.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

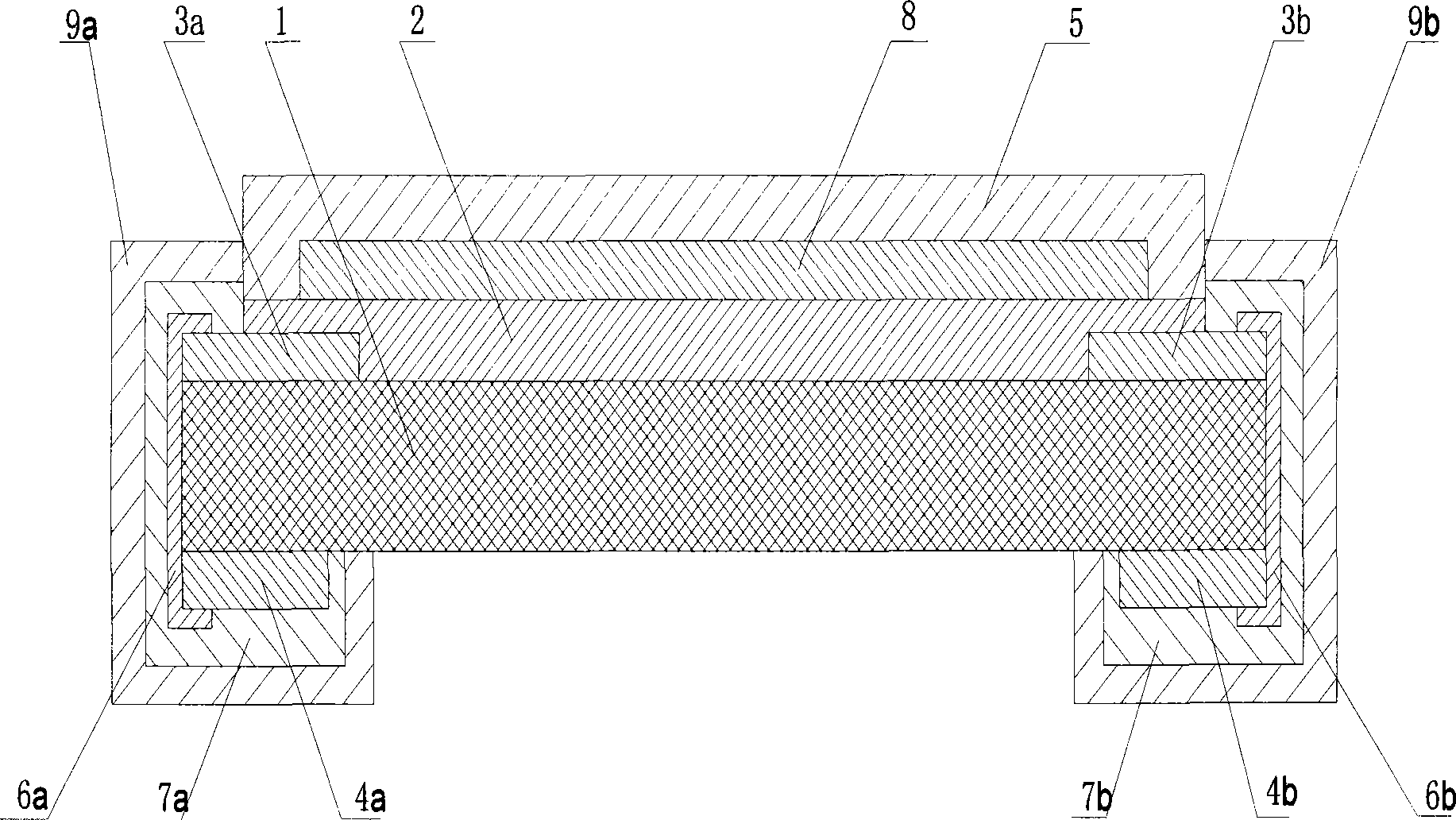

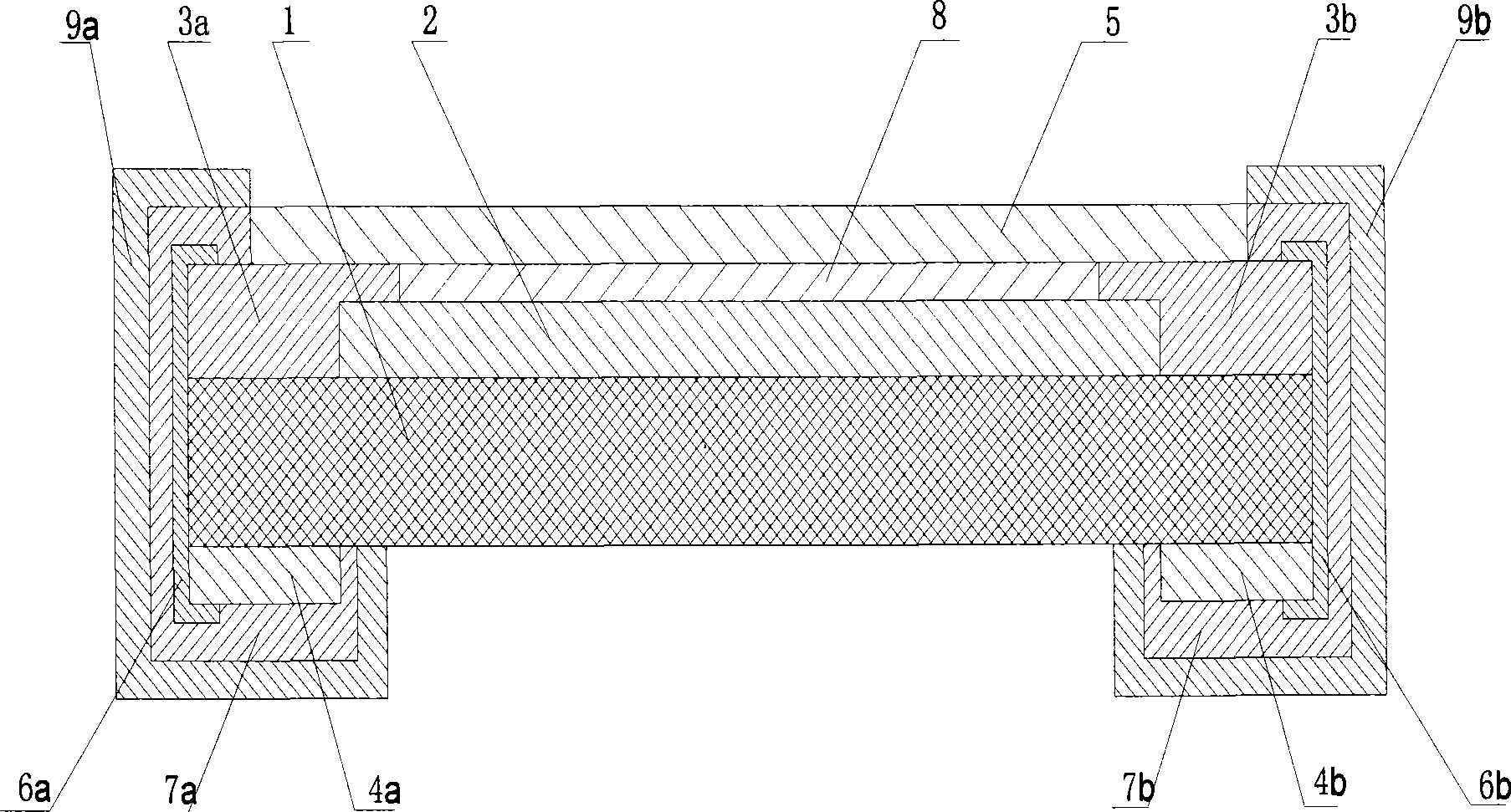

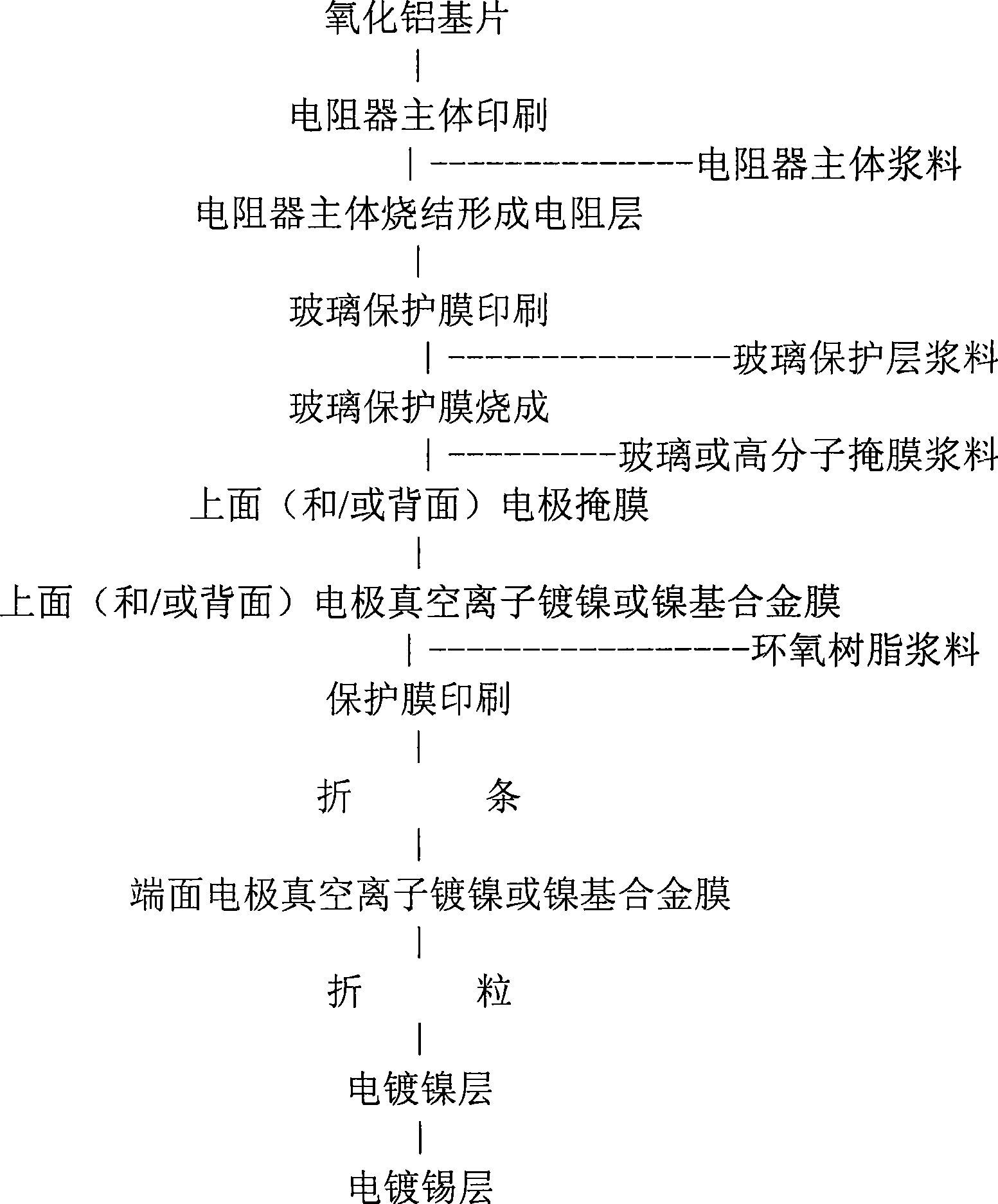

Nickel or nickel base alloy electrode sheet type resistor and method of producing the same

InactiveCN101369478AImprove reliabilityMeet electrical performance requirementsResistor chip manufactureResistor terminals/electrodesElectrical resistance and conductanceState of art

The invention discloses an electrode chip resistor of nickel or nickel base alloy and manufacture method thereof, which is invented for solving the problem that a chip resistor fault is easy to produce in the prior art. The resistor comprises an insulating substrate, on at least one side of which is formed with a resistor layer, and a pair of upper electrode layers formed at least on the upper of the resistor layer terminal and the upper of the insulating substrate, the resistor layer and the electrode layers are jointed together by physical joint between metal and metal, the electrode layers are nickel or nickel base alloy layers. The resistor formed adopting this method does not generate phenomenons of metallic layer separation and chemical reaction in actual use, because of using nickel or nickel base alloy to replace silver as electrode, not only can completely satisfy requirement of electric performance of the resistor, but also can reduce the processing procedure, greatly improves reliability of resistor use, the chip resistor of good electric performance can be manufactured with high efficiency and low cost.

Owner:杨金波 +1

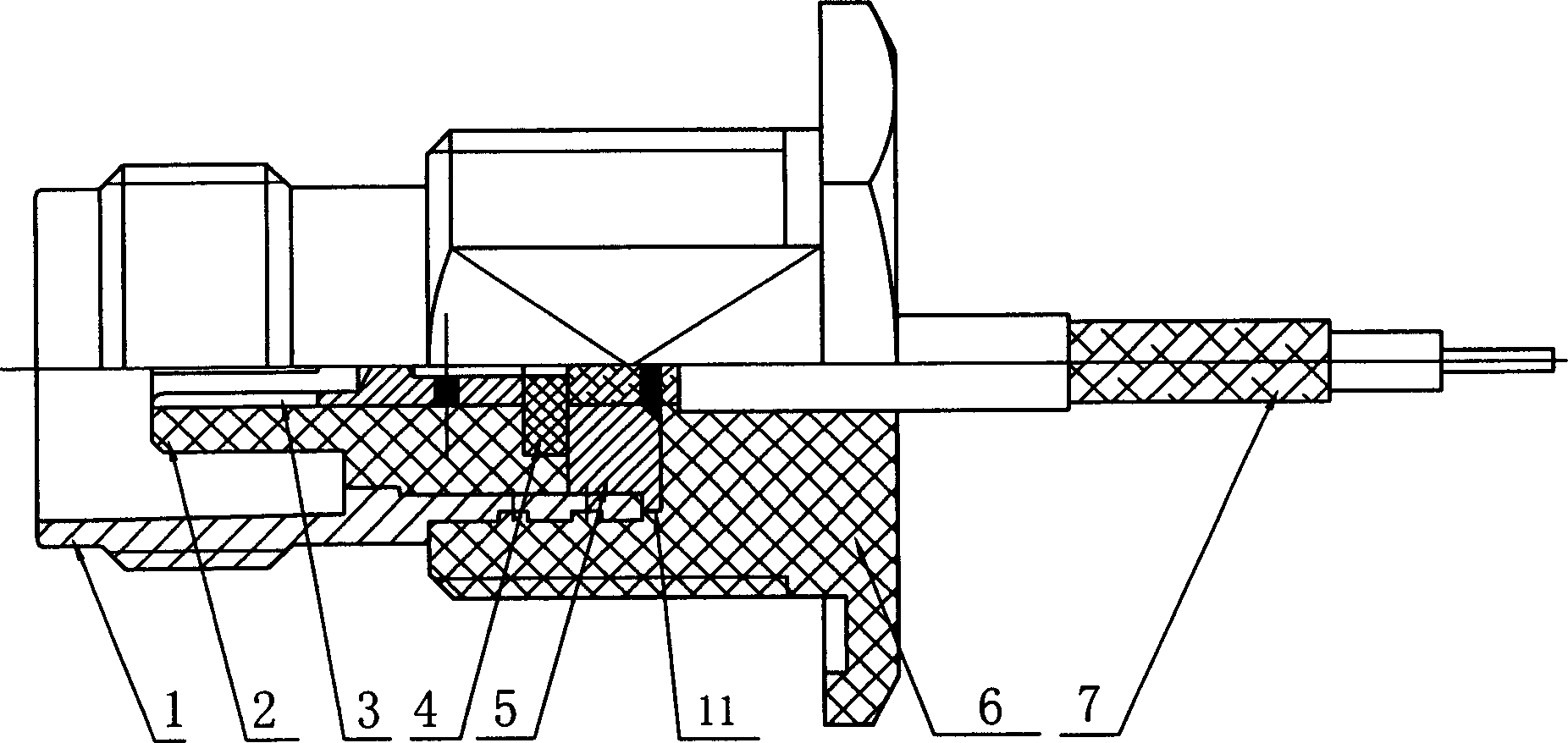

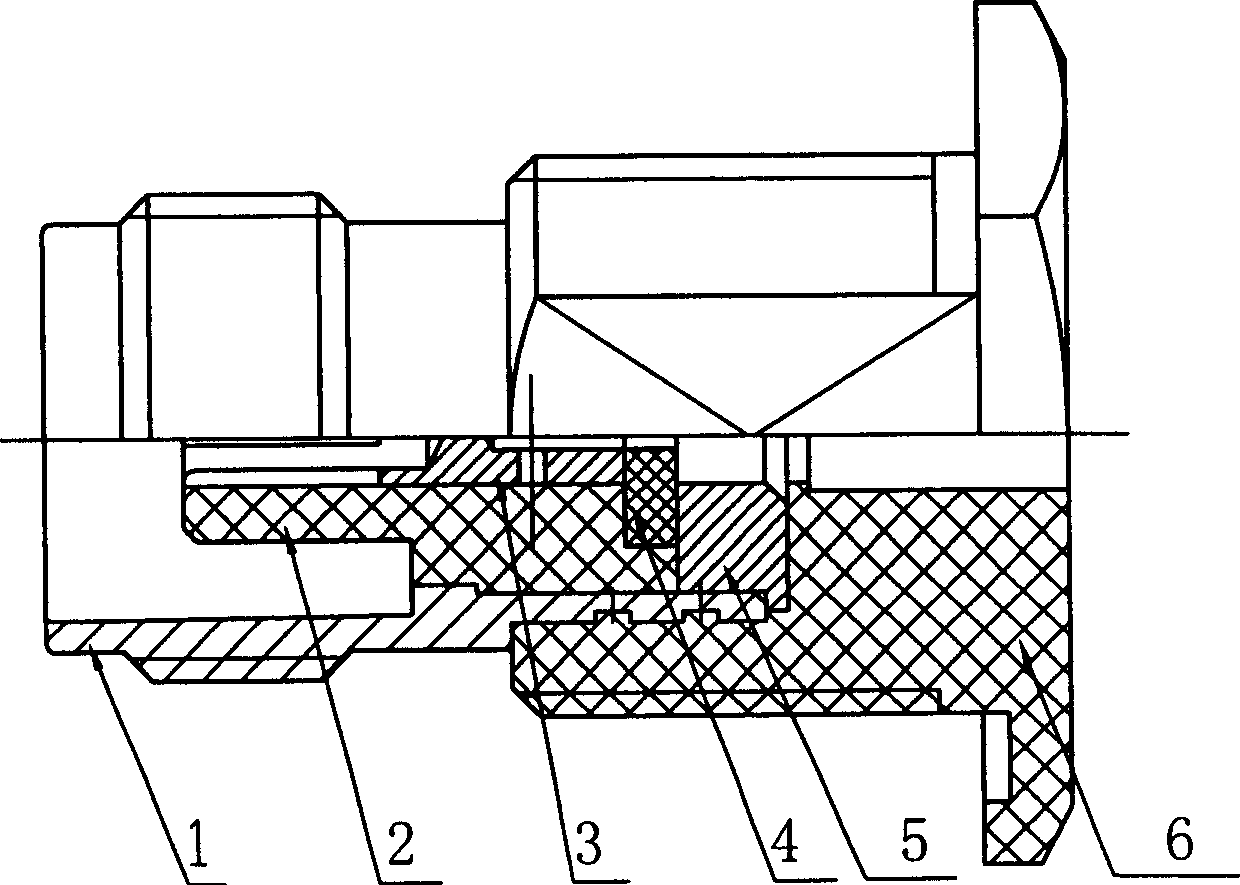

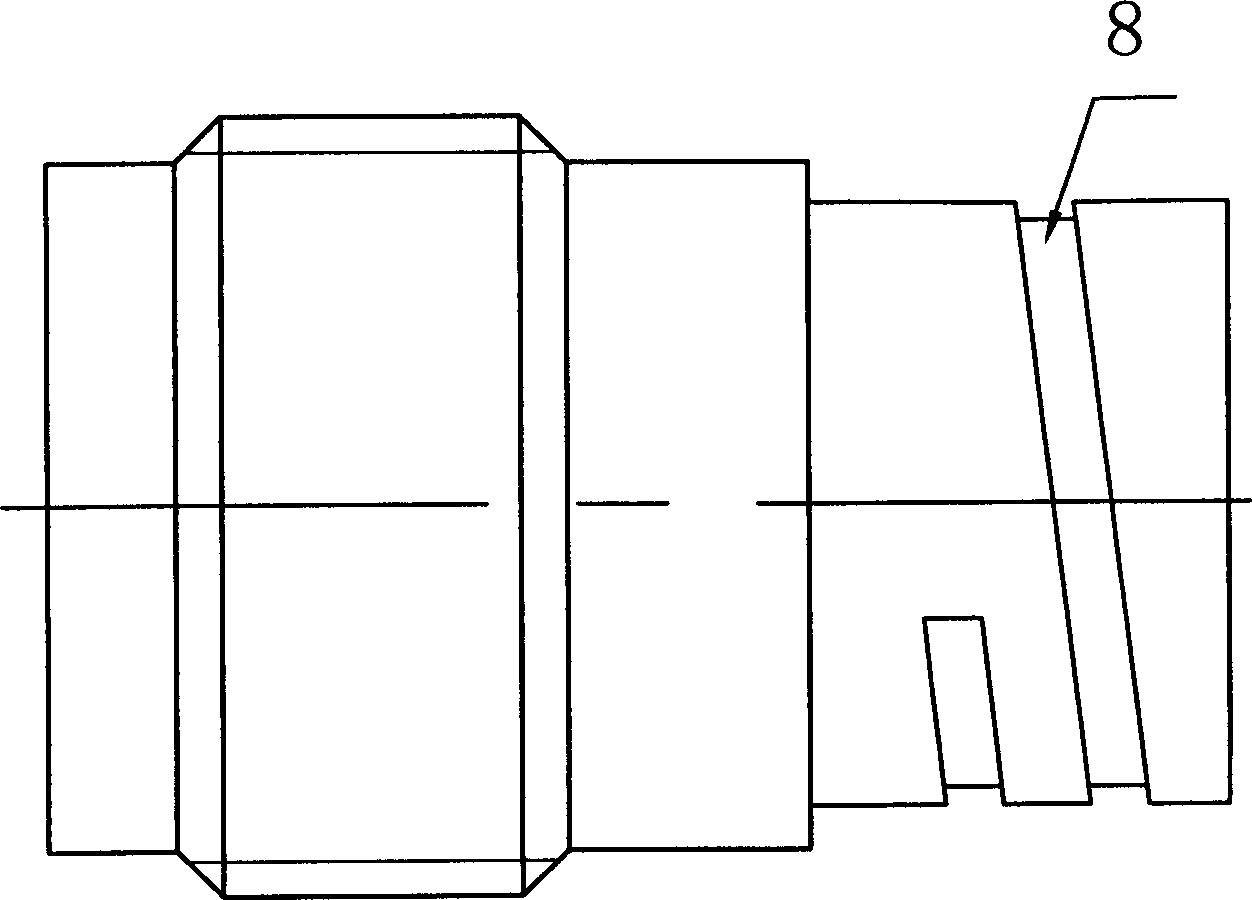

RF coaxial connector

InactiveCN1835299AReduce usageIncrease productivityCoupling device detailsTwo-part coupling devicesMetallic enclosureElectrical conductor

The coaxial connector in radio frequency is composed of body case, insulator inside the case, inner conductor inside the insulator. Characters are that the case consists of fixed connected metal case and plastic case. Gaskets or insulating pads can be setup at inner ends of the metal case. Under precondition of satisfying performance, the disclosed coaxial connector reduces use of noble metal greatly. Features are: high production efficiency, low cost, stable performance, simple structure, and easy of fabrication etc. the disclosed coaxial connector is suitable to communication system in signal of radio frequency and power transmission specially.

Owner:SICHUAN HUAFENG ENTERPRISE GRP

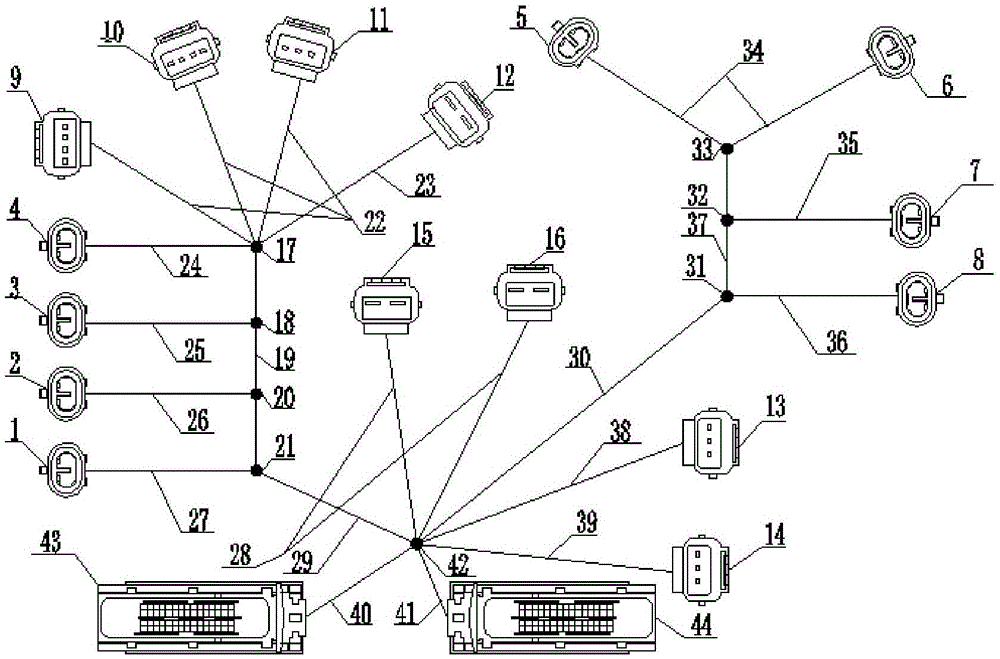

V-shaped eight-cylinder double-ECU electric engine harness

ActiveCN105545476AMeet electrical requirementsEasy to assemble and disassembleMachines/enginesEngine componentsRail pressureCam

The invention provides a V-shaped eight-cylinder double-ECU electric engine harness. The V-shaped eight-cylinder double-ECU electric engine harness comprises a one-cylinder oil sprayer joint, a two-cylinder oil sprayer joint, a three-cylinder oil sprayer joint, a four-cylinder oil sprayer joint, a five-cylinder oil sprayer joint, a six-cylinder oil sprayer joint, a seven-cylinder oil sprayer joint, an eight-cylinder oil sprayer joint, an intake temperature pressure sensor joint, a machine oil temperature pressure sensor joint, a first rail pressure sensor joint, a crankshaft rotating speed sensor joint, a second rail pressure sensor joint, a cam shaft rotating speed sensor joint, a fuel metering unit sensor joint, a water temperature sensor joint and leads for respectively connecting with all the devices, and further comprises a first fulcrum, a second fulcrum, a third fulcrum, a fourth fulcrum, a fifth fulcrum, a sixth fulcrum, a seventh fulcrum, an eight fulcrum, a main ECU plug and a slave ECU plug. The V-shaped eight-cylinder double-ECU electric engine harness is simple in structural distribution, prevents renewed development of ECU under the precondition of satisfying use requirements, reduces the design cost and period, and improves the economy.

Owner:CHINA NORTH ENGINE INST TIANJIN

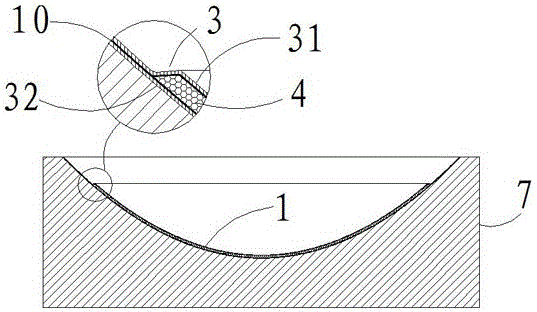

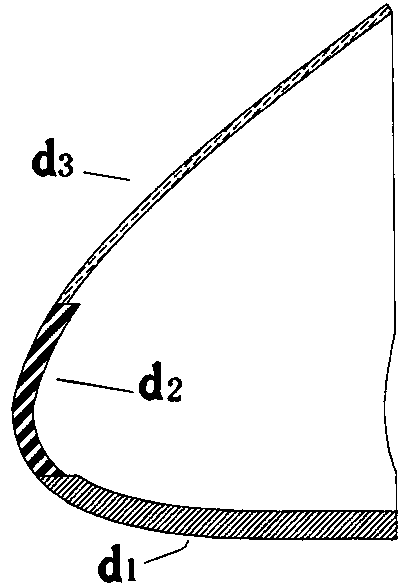

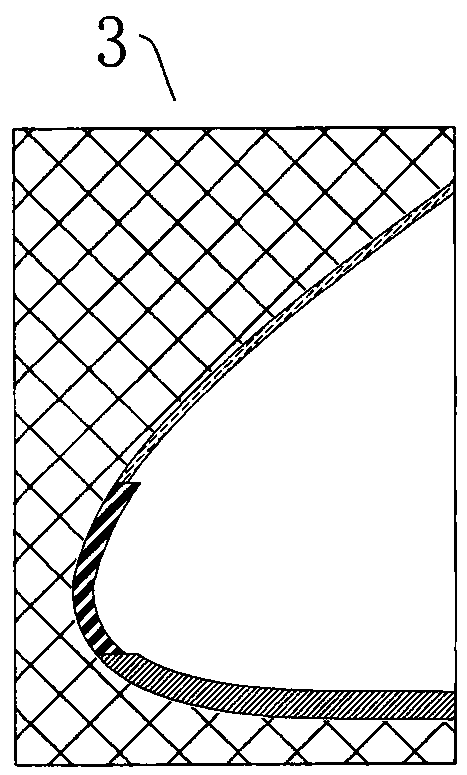

Airplane radome with PMI foam sandwich structure and design method and manufacturing method of airplane radome

InactiveCN109130235AImprove rigidityMeet electrical requirementsGeometric CADDomestic articlesJet aeroplaneVariable thickness

The invention provides an airplane radome with a PMI foam sandwich structure and a design method and a manufacturing method of the airplane radome. By calculation of the incident angle of the radome,different regions are divided, the thickness of the corresponding optimal sandwich layer is designed, and PMI foams with different thicknesses are used in the different regions. By the design of the variable-thickness sandwich structure, the airplane radome has the advantage of high transmission efficiency, and an electric property required for design can be met completely. In the manufacturing method, the radome is formed by PMI foam blocks with different thicknesses, the sandwich layer are integrally formed after the blocks are assembled, by the variable-thickness sandwich layer, the requirement for the electric property of the radome is met to a maximum extent, the processing cost is reduced, the processing time is saved, and the problem that the transmission efficiency of the equal-thickness radome becomes poor due to change of an angle of incidence is solved.

Owner:SICHUAN TIANYUAN MACHINERY CO LTD OF 081 ELECTRONICS GRP

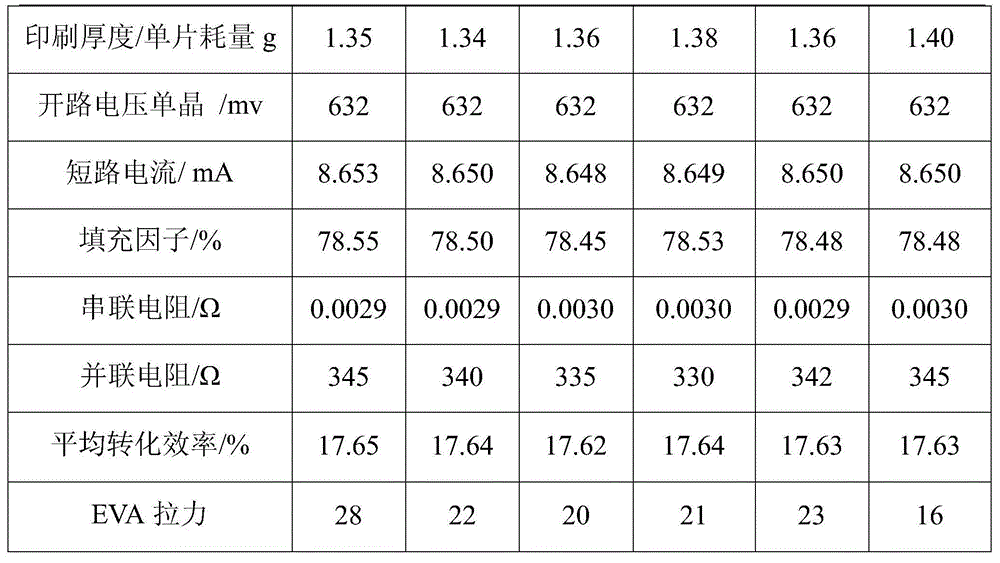

Crystal silicon solar cell high adhesive force back surface field aluminum electrocondution slurry and preparation method

InactiveCN104575685AImprove conversion efficiencyGuaranteed reliabilityNon-conductive material with dispersed conductive materialCable/conductor manufactureSilicon alloyBack surface field

The invention discloses crystal silicon solar cell high adhesive force back surface field aluminum electrocondution slurry which comprises 68%-80% of aluminite powder, 1%-6% of glass powder, 16%-25% of organic bond and 1%-3% of auxiliaries. The auxiliaries are composed of 60% of wetting dispersant and 40% of diffusion pump oil. The aluminum electrocondution slurry is printed on the back surface of a crystal silicon solar cell piece. Aluminium-silicon alloy reaction is performed on aluminum and substrate silicon through infrared quick calcining technology. A preparation method for the aluminum electrocondution slurry comprises the following steps that the aluminite powder, the glass powder, the organic bond and the auxiliaries are put in a vacuum mixer to be mixed, and dispersed by a three-high mill to obtain aluminum electrocondution slurry with less than or equal to 15Mum of precision and 20-40 Pa.s viscosity. The aluminum electrocondution slurry is good in property, and suitable for the use of a crystal silicon solar cell back surface field. A calcined aluminum film and a silicon substrate have good adhesive force and water resistence, aluminium pills and aluminium blisters do not exist, the calcined cell piece is small in bending, and the conversion efficiency is higher.

Owner:ZHEJIANG GUANGLONG ENERGY TECH

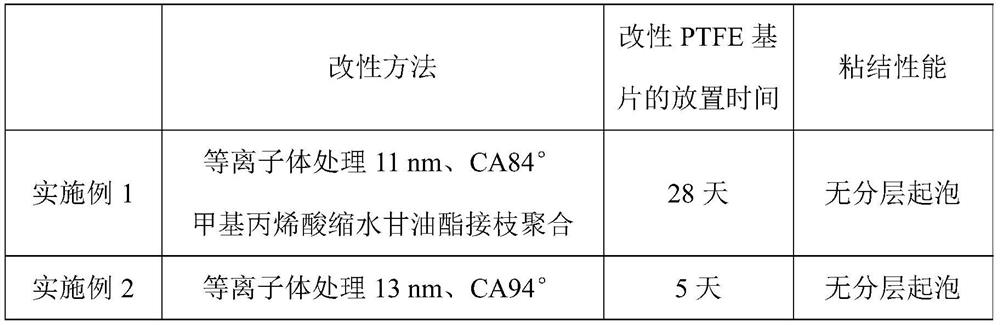

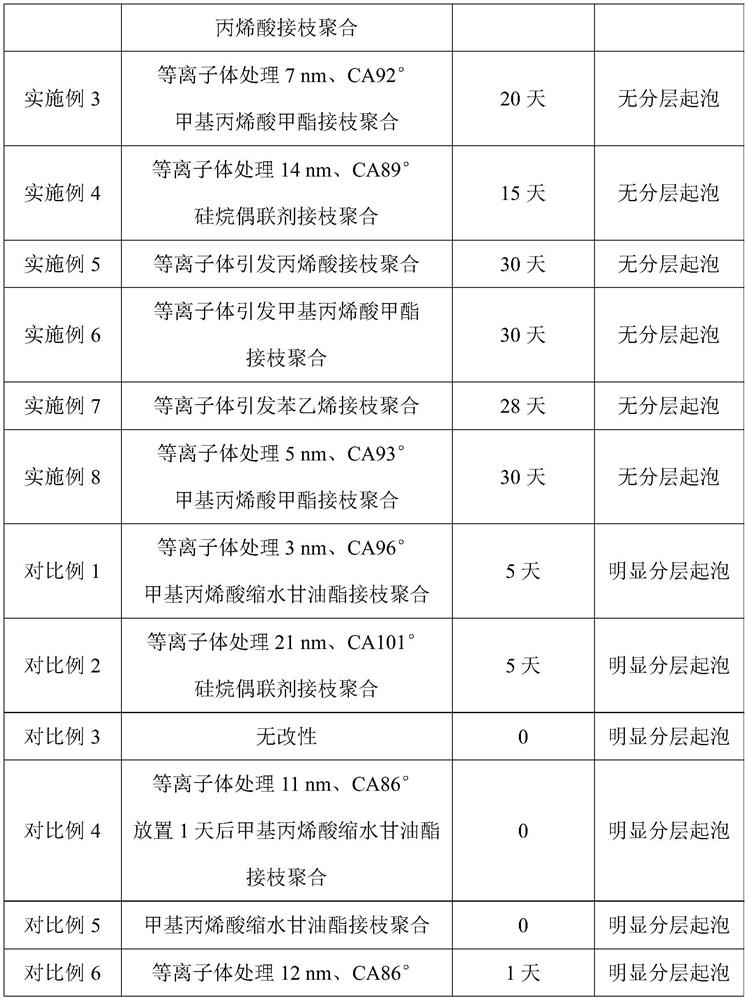

Inter-layer bonding sheet for multi-layer board and preparation method and application of inter-layer bonding sheet

ActiveCN112538186AMeet electrical performance requirementsExcellent dielectric propertiesPolyether coatingsMultilayer circuit manufactureDielectricPhysical chemistry

The invention provides an inter-layer bonding sheet for a multi-layer board and a preparation method and application of the inter-layer bonding sheet. The inter-layer bonding sheet for the multi-layerboard comprises a modified PTFE substrate and a dielectric resin layer bonded to the surface of the modified PTFE substrate. The modified PTFE substrate is a modified PTFE substrate of which the surface is subjected to plasmon and monomer graft polymerization treatment. A long-time-efficiency activation layer is formed on the PTFE substrate through the synergistic cooperation of plasma treatmentand monomer graft polymerization treatment, the activation property of the activation layer can be kept for 30 days, and the requirements of a manufacturing process and the requirements on product performance are fully met. According to the inter-layer bonding sheet for the multi-layer board provided by the invention, through the synergistic cooperation of the modified PTFE substrate and the dielectric resin layer, the dielectric property, the bonding strength, the mechanical property and the resistance are good, the bonding stability of the multi-layer board containing the inter-layer bondingsheet for the multi-layer board at high temperature is high, and the requirements of the multi-layer board for high frequency of signals, stability and reliability can be fully met.

Owner:GUANGDONG SHENGYI SCI TECH

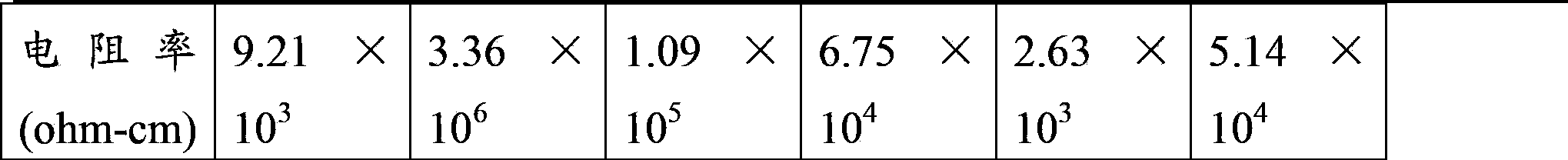

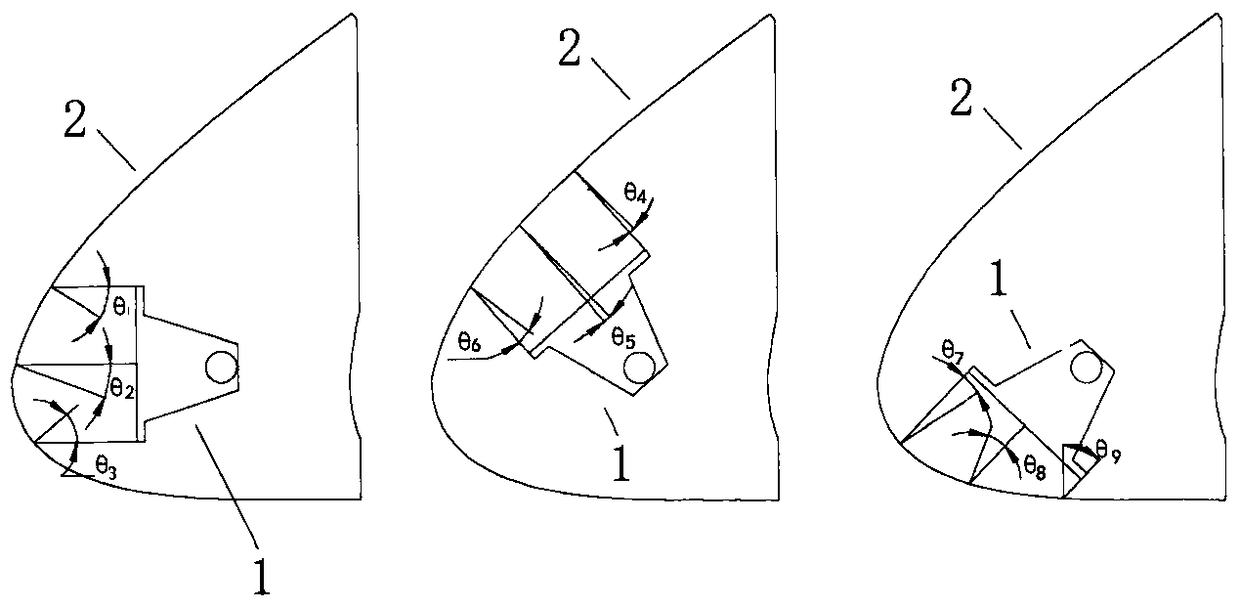

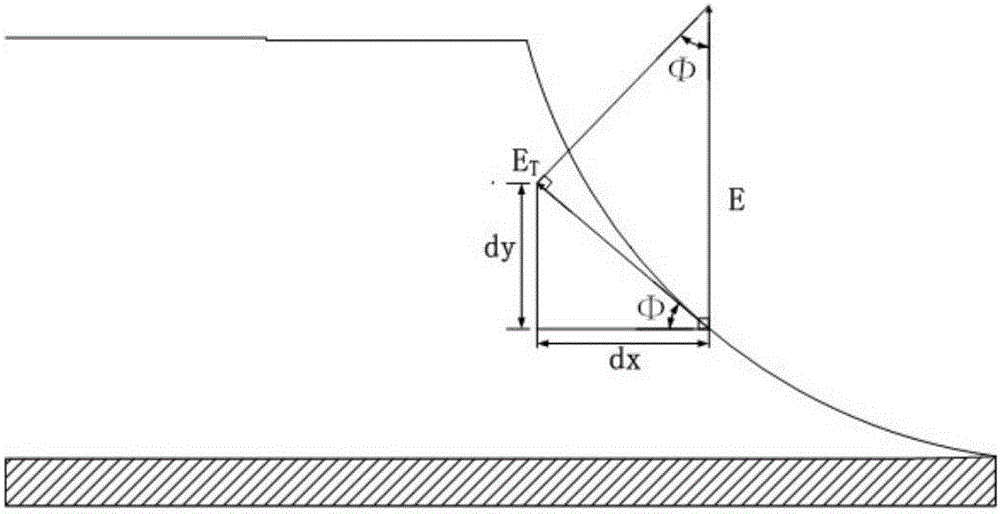

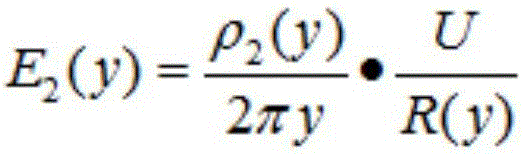

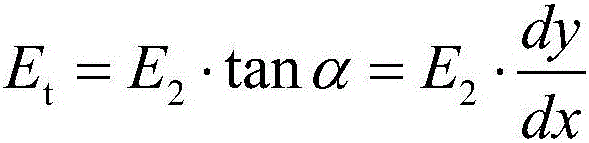

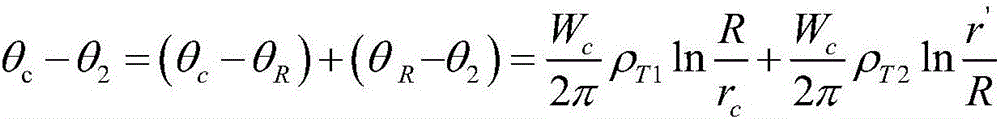

Mould casting type flexible direct-current cable soft joint reaction force cone structure designing method

InactiveCN106451316ASolve the electric field problemAvoid field strength build-upCable fittingsElectricityElectrical conductor

The invention discloses a mould casting type flexible direct-current cable soft joint reaction force cone structure designing method. The method is characterized by comprising the following steps: (I) determining the parameters of a cable conductor, and calculating the temperature difference between the insulating inner and outer surfaces of a direct-current cable body; (II) calculating the electric field intensity at the center of a direct-current cable insulation layer; (III) calculating a direct-current cable soft joint reaction force cone curve equation; and (IV) obtaining a reaction force cone structure to obtain the specific structure of the cable soft joint. The method has the following advantages: the problem of electrical resistivity mismatching between the cable body insulation material and the mould casting insulation material and consequent field intensity accumulation at the interface of the two are avoided; meanwhile, the influence of temperature and electric field factors on the electrical resistivity is considered, electric field distribution in flexible direct-current cable terminal insulation is proposed, and a theoretical basis is provided for designing a flexible direct-current cable soft joint; uniform electric field at the flexible direct-current cable soft joint is guaranteed; and the electrical property requirement of the whole flexible direct-current cable system on the joint is met, and long-term safety and reliability of the flexible direct-current cable system are guaranteed.

Owner:NANJING NARI GROUP CORP +3

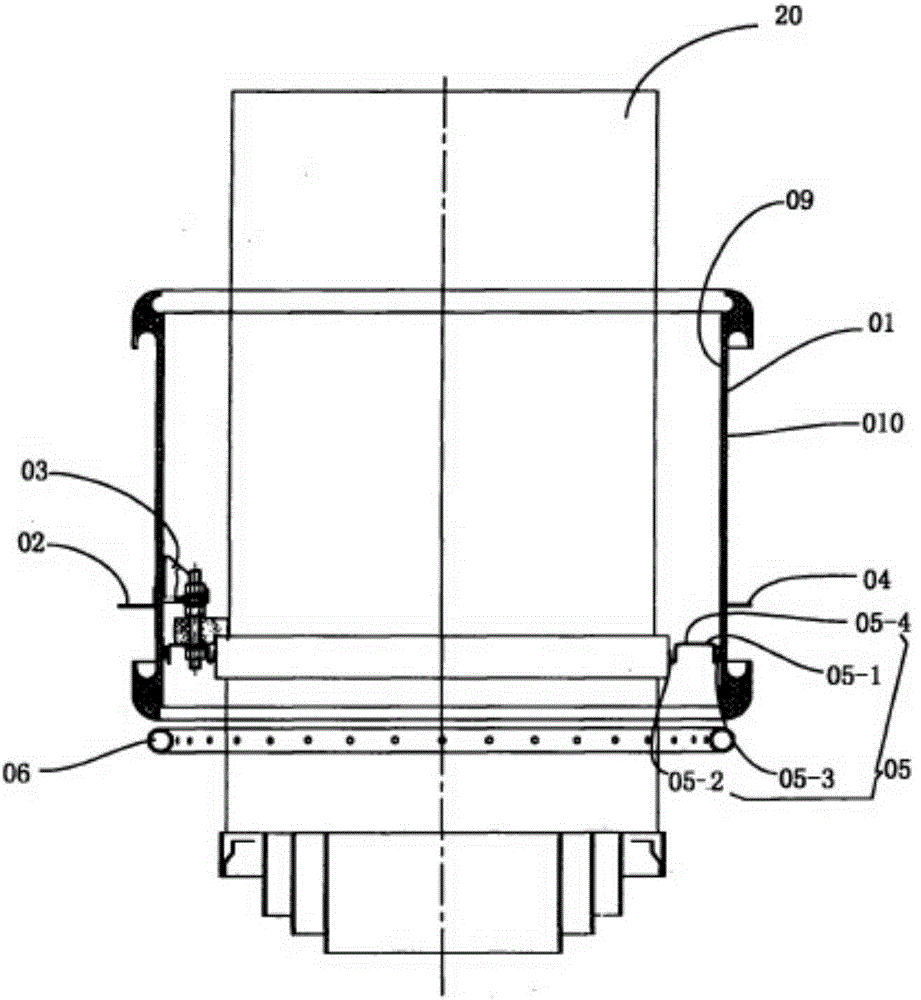

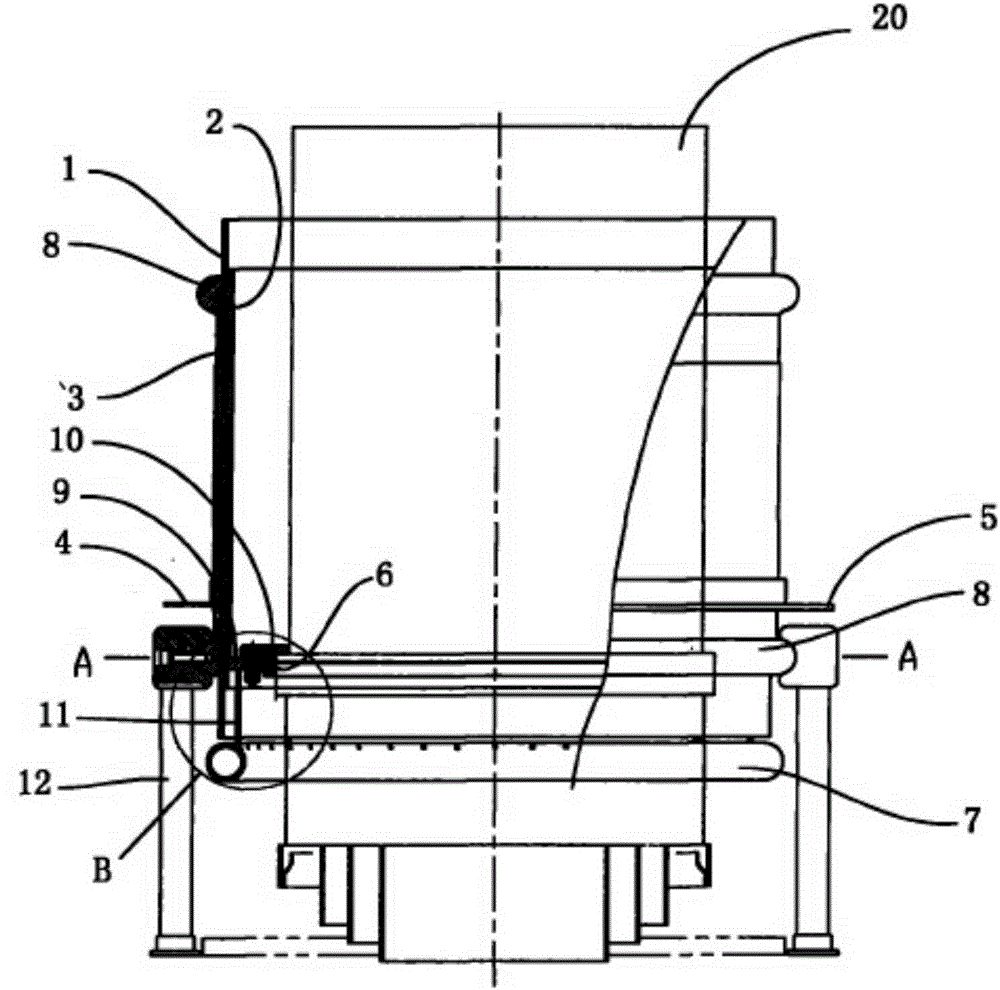

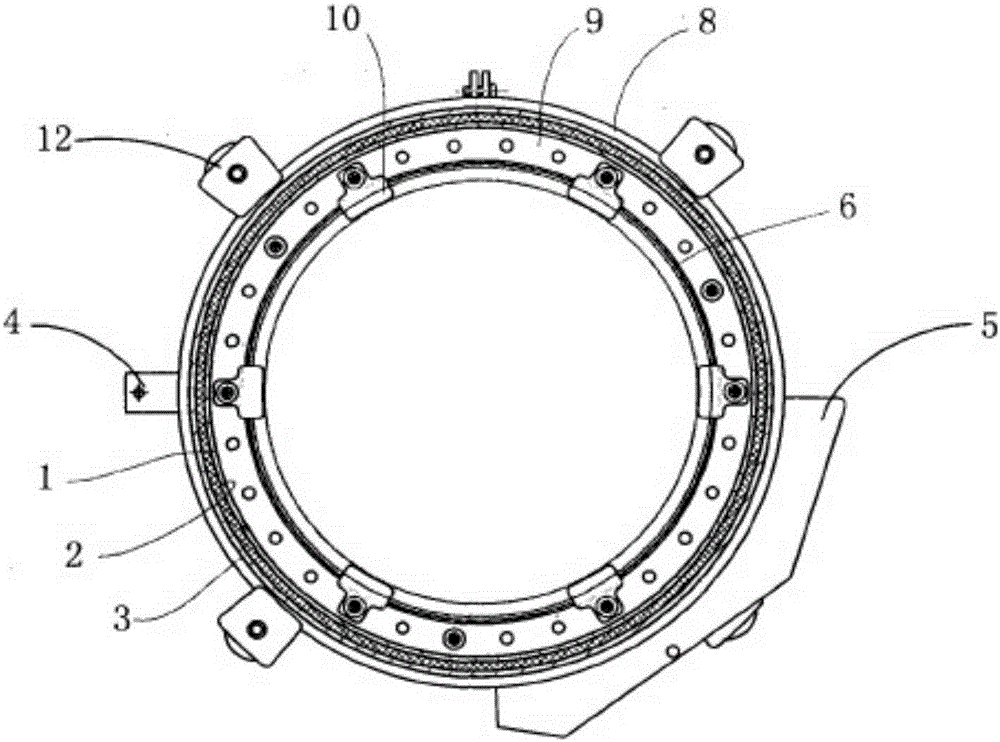

Electronic tube plate electrode blocking capacitor

InactiveCN105185587AGood lookingGeneralization of materialsFixed capacitor electrodesFixed capacitor dielectricInterference fitCorona ring

The invention relates to a capacitor and particularly relates to an electronic tube plate electrode blocking capacitor which is used for an electronic tube plate electrode of high-frequency high-power transmission equipment. The electronic tube plate electrode blocking capacitor comprises a polytetrafluoroethylene barrel, inner and outer polar plates arranged on the inner and outer surfaces of the polytetrafluoroethylene barrel, a connection corner and a connection plate which are welded on the polar plate on the outer surface, an annular contact reed which is electrically connected with the electronic tube plate electrode and is arranged on the inner polar plate, and a cooling air pipe arranged under the polytetrafluoroethylene barrel, wherein the inner polar plate is a thin-wall metal inner barrel, and the thin-wall metal inner barrel used as the inner polar plate is combined with the polytetrafluoroethylene barrel through interference fit; the outer polar plate is a thin-wall metal outer barrel; and the thin-wall metal outer barrel used as the outer polar plate is combined with the polytetrafluoroethylene barrel through interference fit, and circular-arc-shaped corona rings are arranged at the two ends of the thin-wall metal outer barrel used as the outer polar plate. With the adoption of the electronic tube plate electrode blocking capacitor, the problem that the connection corner and a connection plate lamp are welded on the polar plates so that the insulation performance of part of the polytetrafluoroethylene barrel is reduced is solved.

Owner:周晓

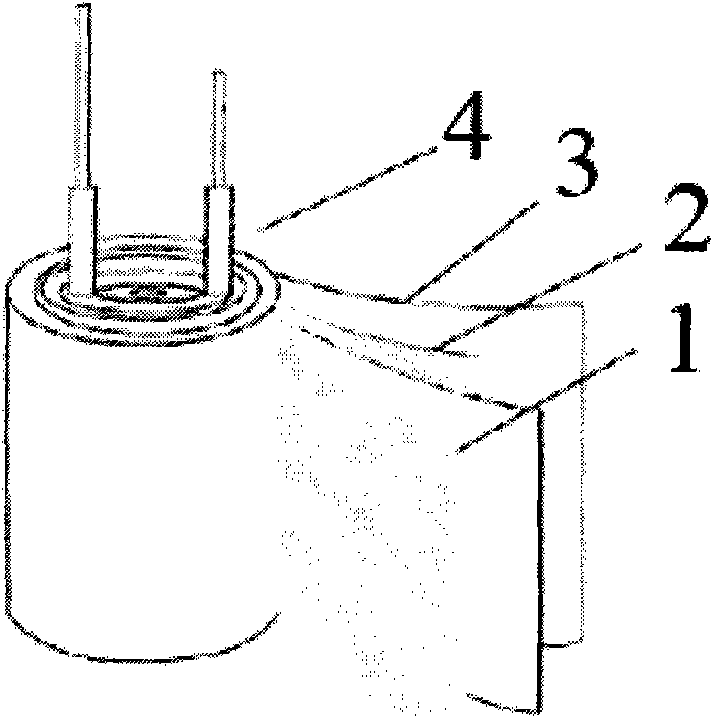

SMD (Surface Mounted Device) super capacitor

InactiveCN101916662ASimple structureSimple manufacturing processCapacitor detailsPolymer capacitorSurface mounting

The invention relates to an SMD (Surface Mounted Device) super capacitor comprising a super capacitor monomer and a super capacitor base, wherein the super capacitor monomer is prepared by arranging a core cover into a shell and encapsulating after injecting electrolyte; the core cover is prepared by winding a positive pole piece, a negative pole piece and a porous isolating film which are sequentially stacked and riveted with a positive leading-out end and a negative leading-out end; the super capacitor base is provided with a circular groove for placing the super capacitor monomer, leading-out holes and square guide channels of positive and negative terminals, and corresponding corner parts with different heights; and the SMD super capacitor is fabricated just by enabling the positive leading-out end and the negative leading-out end of the super capacitor to pass through the leading-out holes of the super capacitor base and then carrying out press forming and square bending. The invention greatly simplifies the assembling process, reduces the production-manufacturing cost and realizes the application of the SMD super capacitor in an SMT (Surface Mounted Technology).

Owner:NANTONG JIANGHAI CAPACITOR CO LTD

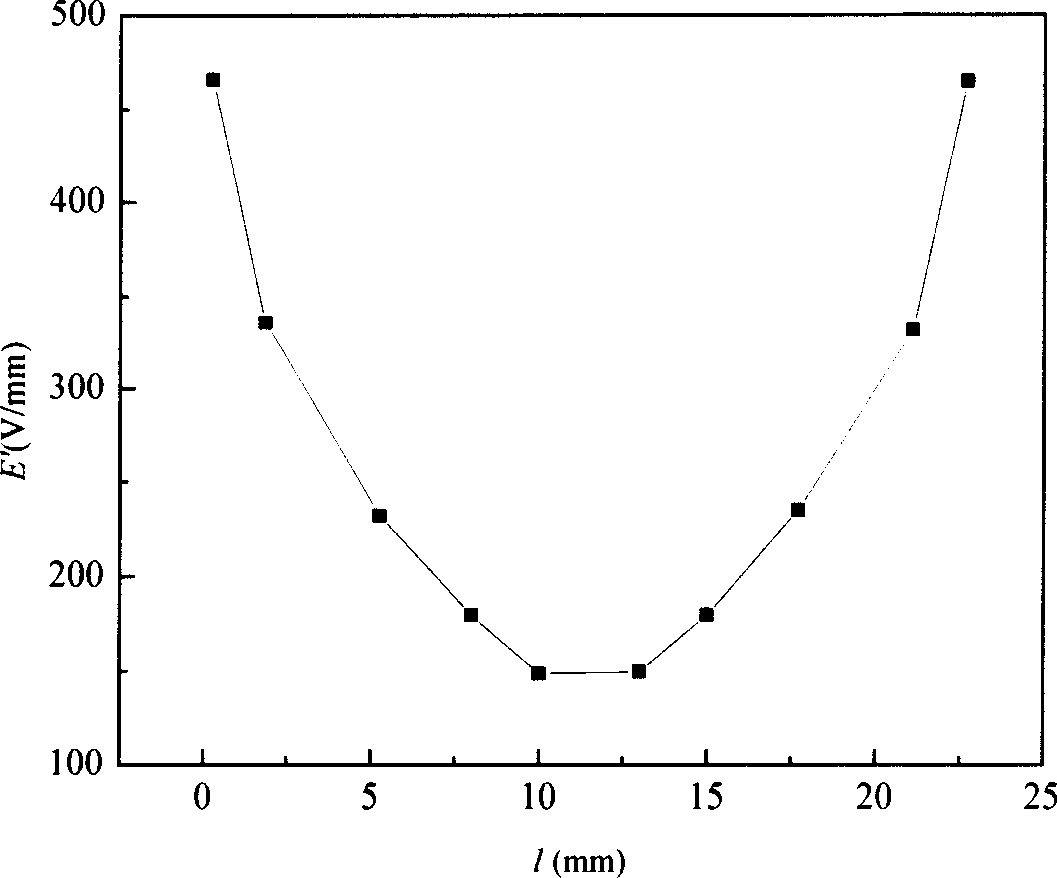

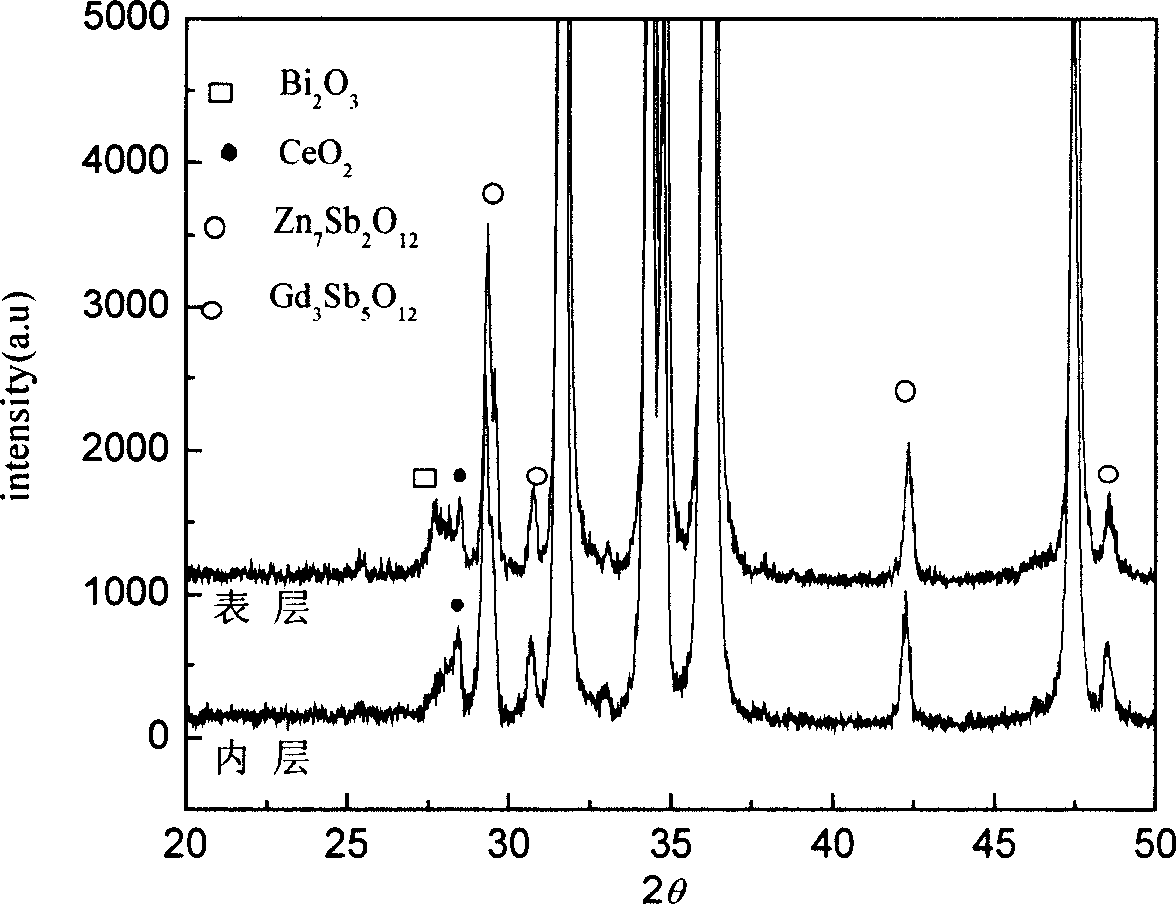

Process for preparing ZnO-Bi2O3 series pressure-sensitive raw material doped with rare-earth oxide

InactiveCN1844045ANonlinear Exponential DeclineNonlinear Exponential ImprovementVaristorsRare earthSlurry

The invention discloses a process for preparing rare earth oxide doped ZnO-Bi2O3 family pressure-sensitive ceramic slurry, which comprises mixing all the addition constituents with main ingredient ZnO directly, ball grinding and granulating, compacting into blanks, discharging glue and heating, cooling down, subjecting the sintered body to heat treatment and cooling down again.

Owner:XI AN JIAOTONG UNIV

Manufacturing method for flaky silver powder with high flake rate and narrow particle size distribution

The invention discloses a manufacturing method for flaky silver powder with the high flake rate and narrow particle size distribution. The method includes the steps that firstly, spherical precursor silver powder and ball-milling balls are selected to be soaked in a ball-milling medium solvent, block type polymeric dispersant is then added, ultrasonic treatment is performed at a certain temperature, and the spherical silver powder is better promoted to be dispersed on the surfaces of the ball-milling balls at the molecular level; and in the ball-milling process, pre-milling is performed under the condition of the low rotation speed, the silver powder and the ball-milling balls are evenly distributed in a ball-milling tank, high-speed ball-milling is the performed, and therefore the flaky silver powder with the high flake rate and narrow particle size distribution is obtained. The flaky silver powder manufactured through the method has the beneficial effects that the flake rate is high, particle size distribution is narrow, and the requirement of silver colloid for the electrical property can be met on the premise that the silver content in the silver colloid is reduced.

Owner:NANJING COJINA NEW MATERIAL INST CO LTD

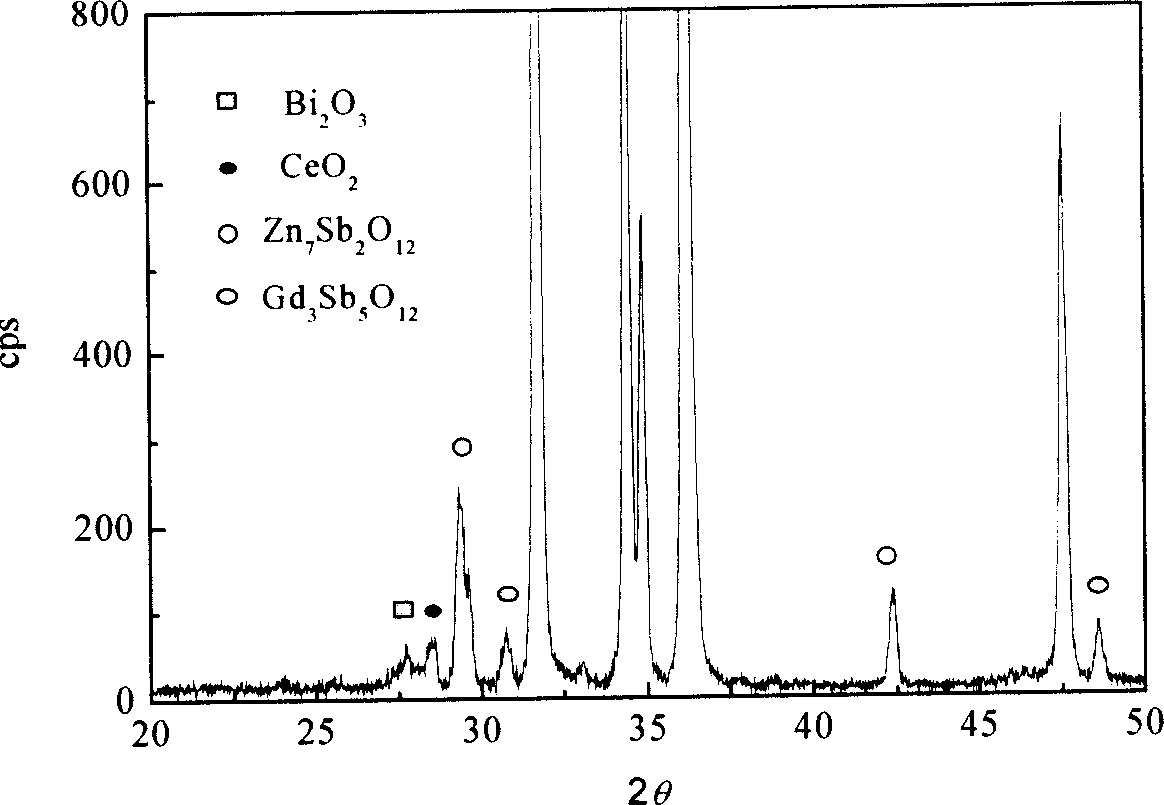

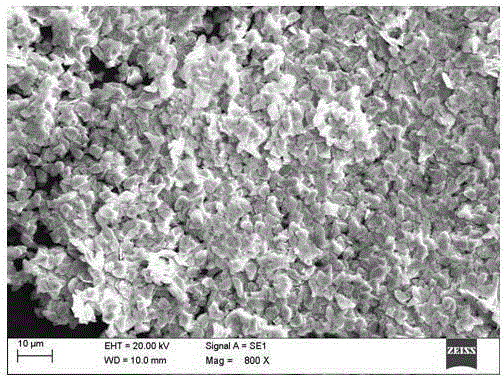

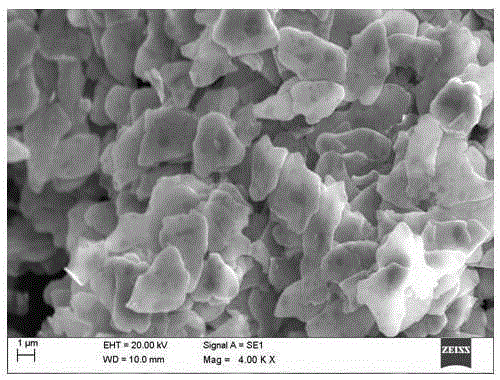

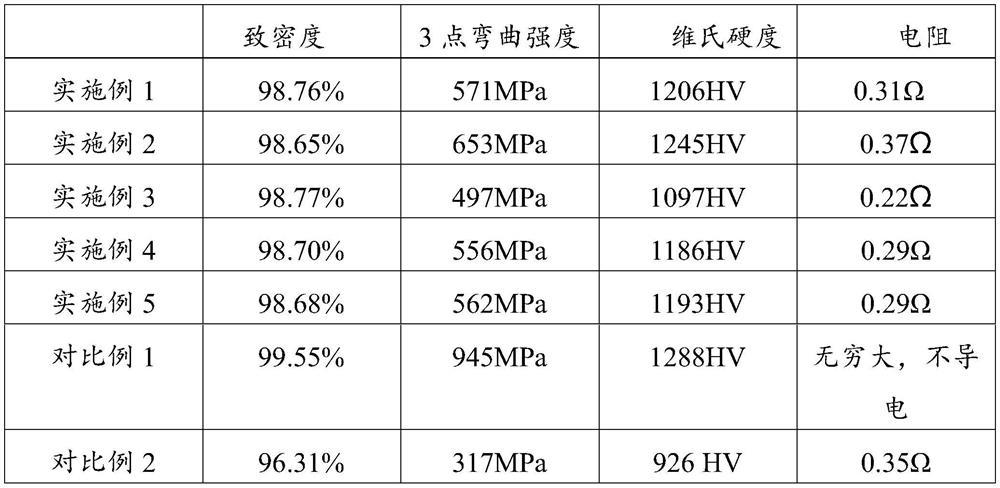

ZrO2-based conductive ceramic and preparation method thereof

The invention provides ZrO2-based conductive ceramic and a preparation method thereof. The preparation method comprises the steps that 1, adding Y2O3-stabilized ZrO2 powder, a conductive material, a sintering aid, a binder, a dispersing agent, a plasticizer and water into a ball milling tank to be subjected to ball milling to prepare a slurry; (2) performing spray granulation on the slurry to obtain powder A; (3) sieving the powder A to obtain powder B; (4) carrying out dry pressing molding on the powder B to obtain a molded green body; and (5) carrying out glue discharging and sintering on the molded green body in a reducing atmosphere at the sintering temperature of 1450-1650 DEG C to prepare the ZrO2-based conductive ceramic. According to the preparation method, ZrO2-based conductive ceramic is adopted; the preparation method is simple, the sintering temperature can be reduced, the sintering cost can be reduced, the energy consumption can be reduced, large-batch production can be carried out, the density of the prepared conductive ceramic can reach 98%, the three-point bending strength reaches 450-700 MPa, the Vickers hardness is 1000-1300 HV, the resistance is 1 ohm or below, and the performance requirements can be met.

Owner:DONGGUAN XINBO STRUCTURAL CERAMICS CO LTD

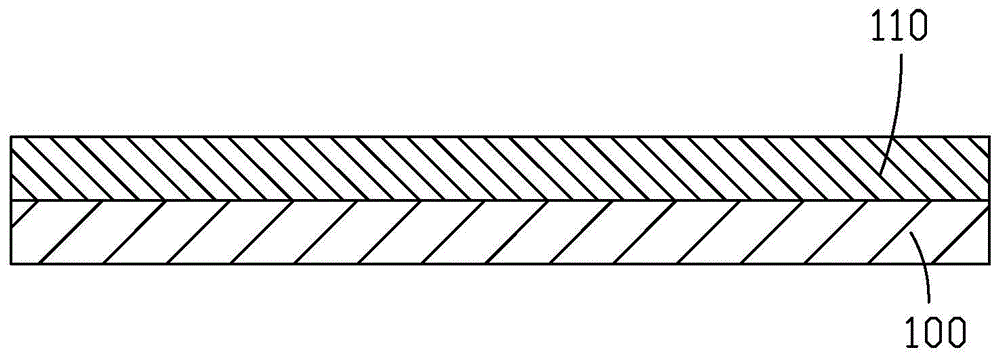

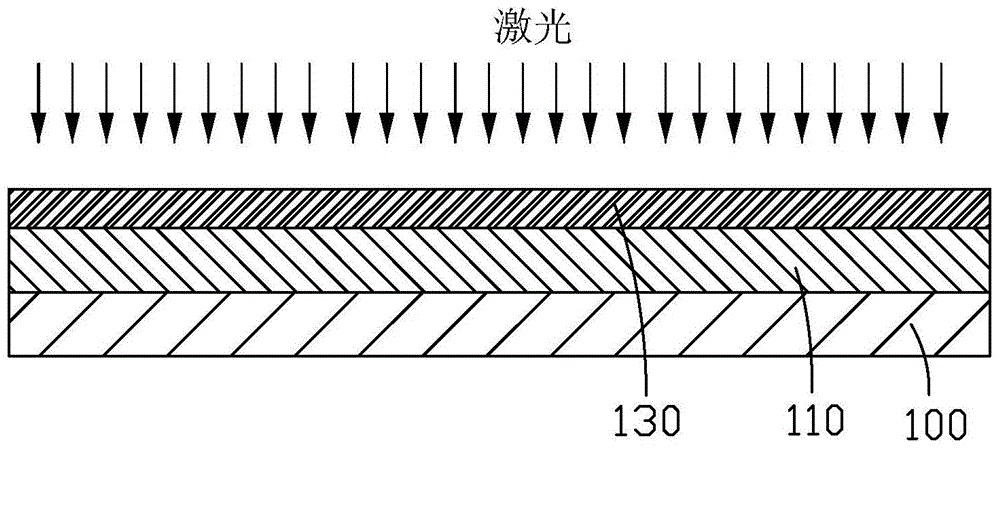

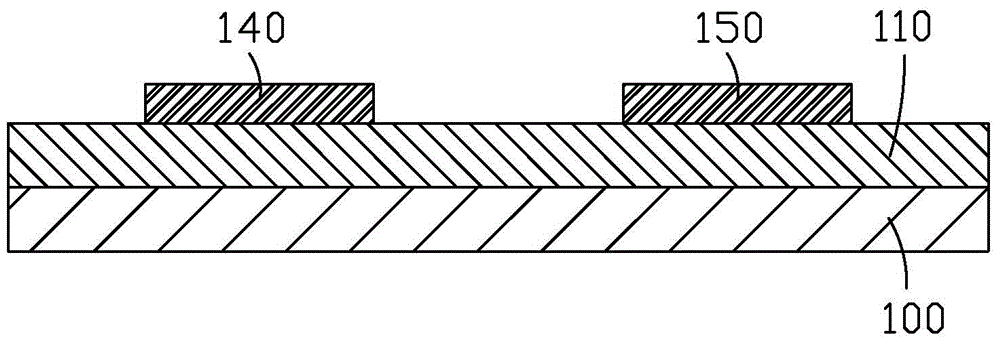

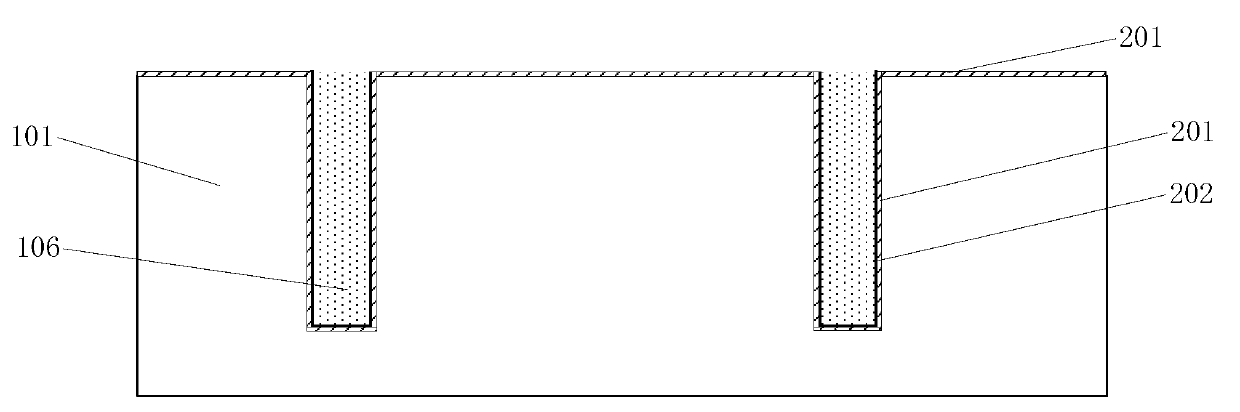

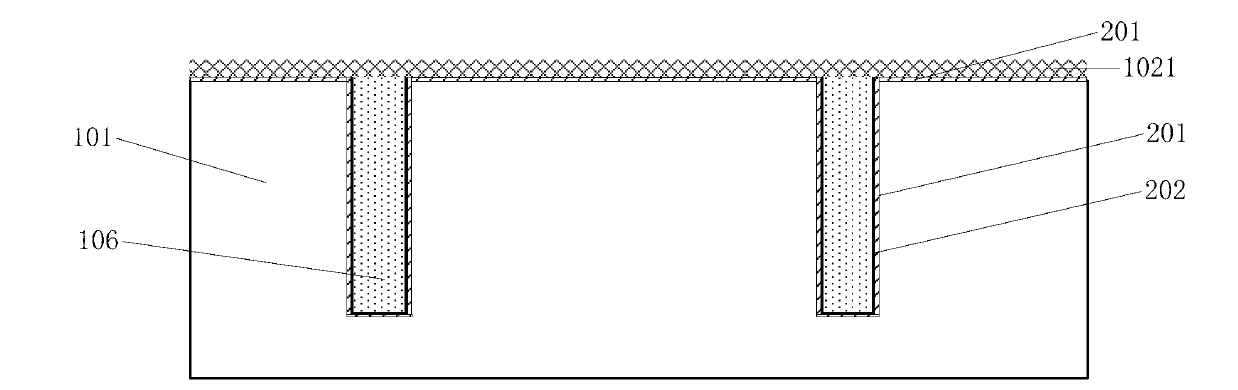

Low-temperature polycrystalline silicon TFT substrate structure and manufacturing method thereof

InactiveCN104701265AMeet electrical performance requirementsReduce thicknessTransistorSolid-state devicesPower flowElectron mobility

The invention provides a low-temperature polycrystalline silicon TFT substrate structure and a manufacturing method thereof. The method is that amorphous silicon layers for driving a TFT area and displaying the TFT area are set to be different thickness; the amorphous silicon layer for driving the TFT area is relatively small in thickness, and the amorphous silicon layer for displaying the TFT area is relatively large in thickness; therefore, the amorphous silicon layers for driving the TFT area and displaying the TFT area can generate different crystallizing effects under the effect of the same energy laser during the excimer laser annealing processing, and as a result, the size of crystallizing particles can be controlled, the amorphous silicon layer for driving the TFT area can generate large lattice during crystallizing in order to improve the electronic migration rate; the amorphous silicon layer for displaying the TFT area can achieve crystal breaking during crystallizing so as to ensure the uniformity of crystal boundary and improving the current uniformity, thus the electric requirements of different TFT can be met, and the OLED lighting uniformity can be improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

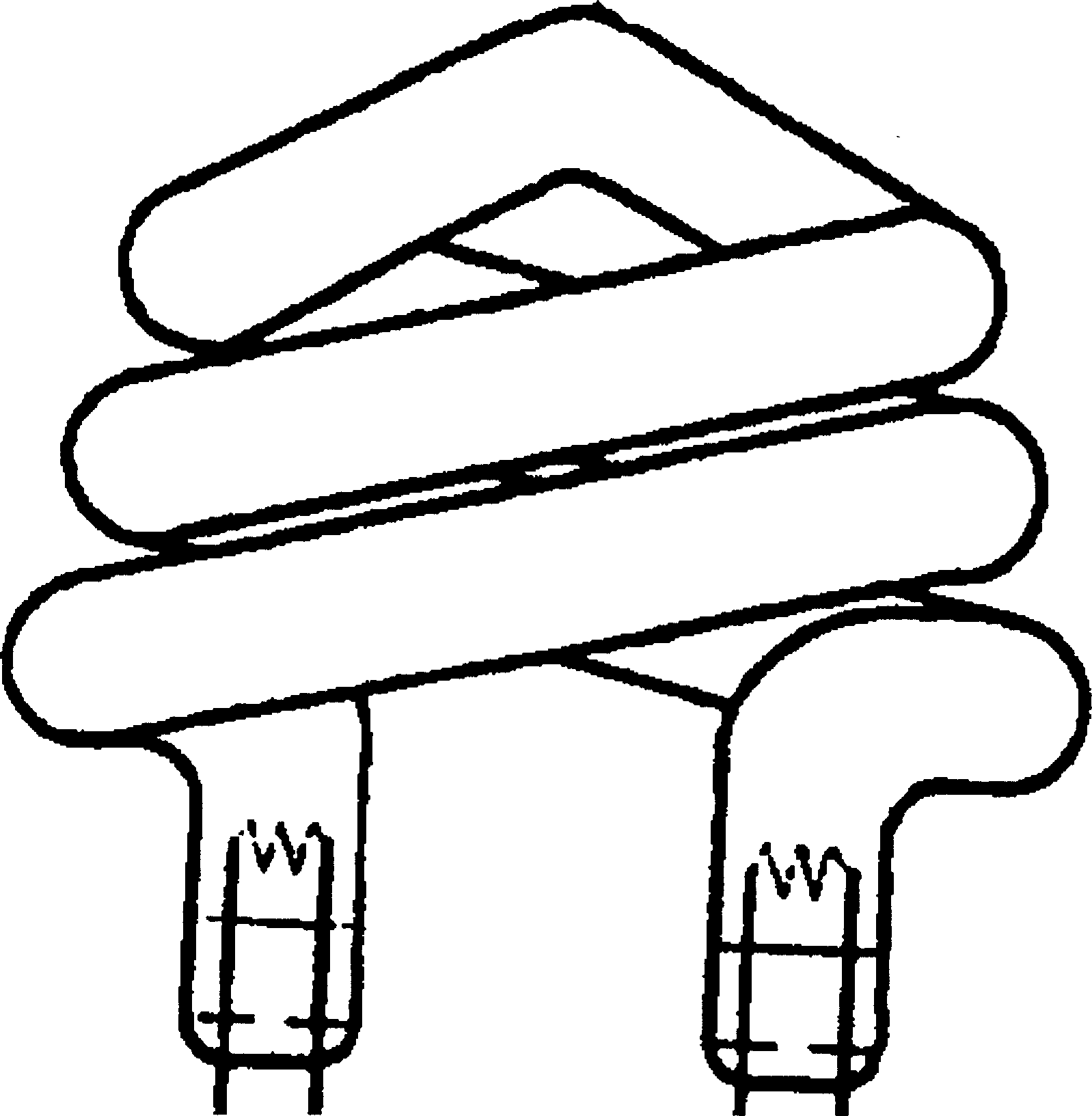

Leadless glass fit for machining energy-saving tube

The invention provides a leadless glass suitable for machining energy-saving tube characterized by, (1) containing no lead, strontium, magnesium and low calcium content, (2) possessing fine hot-working character, (3) suitable for the heat working of screw type energy conservation lamp outer cover glass with complex profiles.

Owner:上海孟仕玻璃有限公司

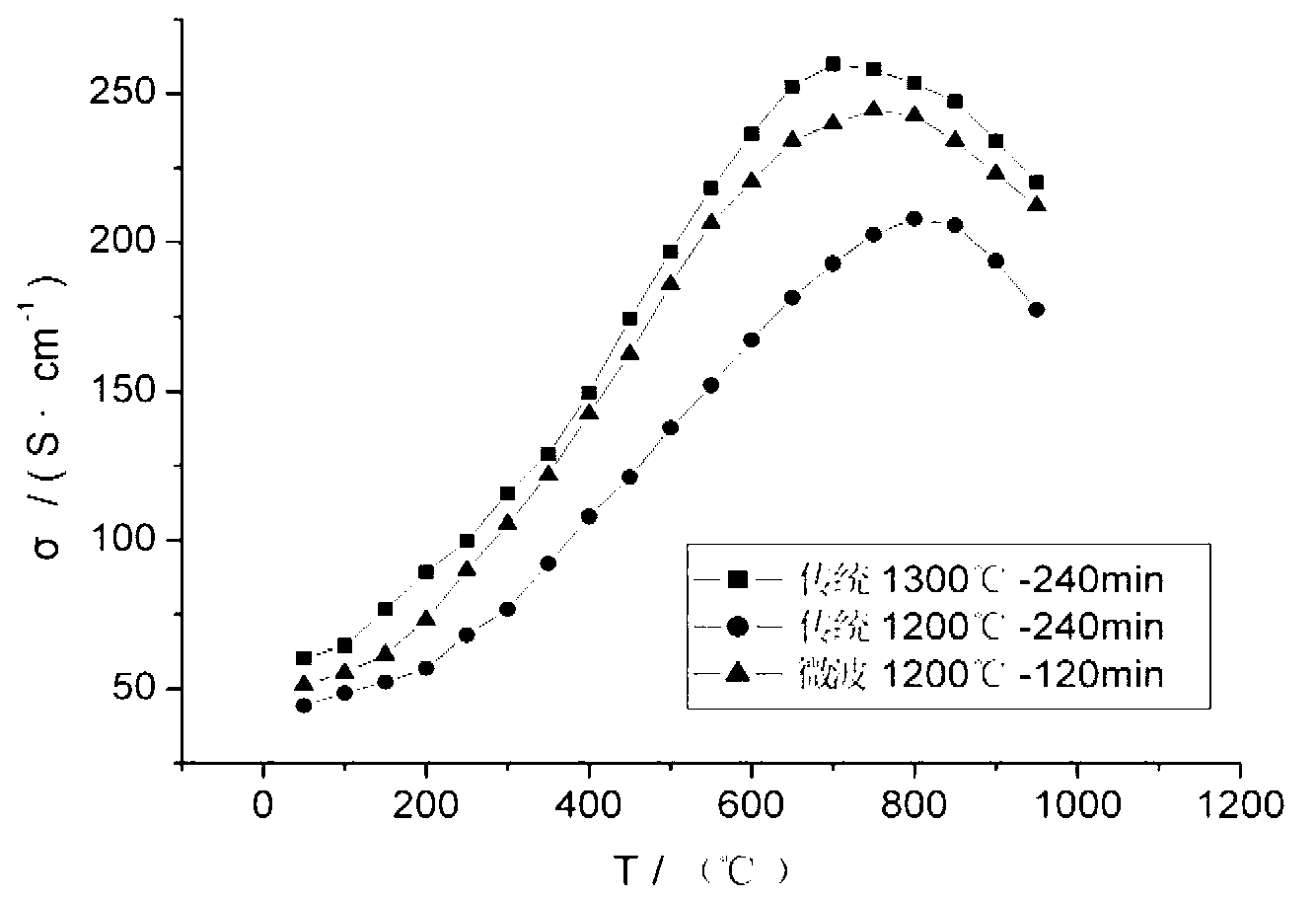

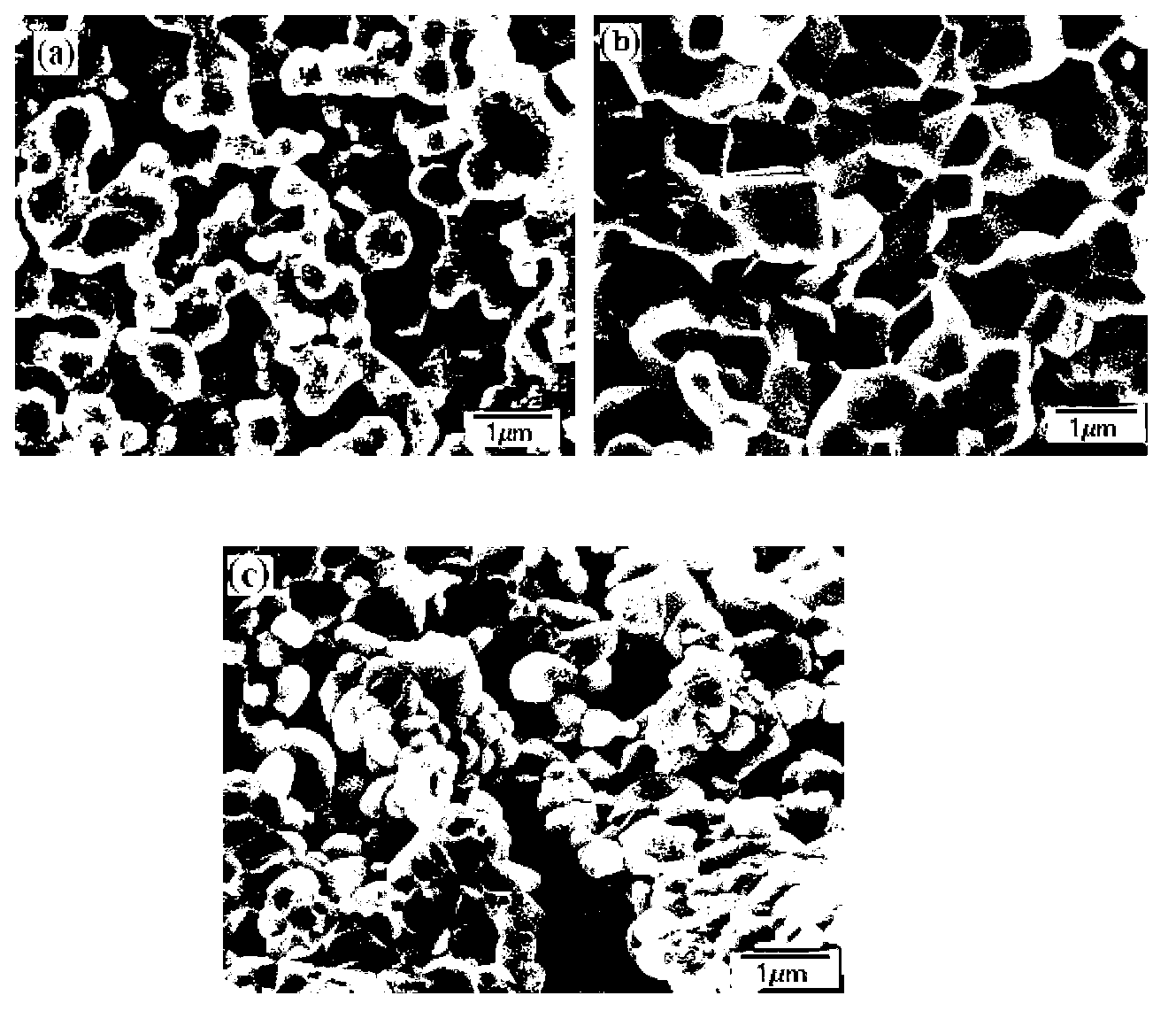

Cathode material for medium temperature solid oxide fuel battery, and preparation thereof

InactiveCN103227332AImprove conductivitySmall coefficient of thermal expansionCell electrodesIron compoundsPolyvinyl alcoholChemical compatibility

The invention relates to a cathode material for a medium temperature solid oxide fuel battery, wherein the cathode material is a lanthanum ferrite base cathode material, and has a chemical formula of La1-xSrxFe1-yCuyO3-delta(LSFC), x is more than or equal to 0.1 and is less than or equal to 0.4, y is more than or equal to 0.1 and is less than or equal to 0.3. The preparation method comprises: carrying out a pretreatment on lanthanum oxide, strontium carbonate, iron oxide and copper oxide; weighing the raw materials according to a stoichiometric ratio of LSFC, and carrying out complete mixing grinding and sectional pre-burning; and completely grinding the pre-burned powder material, adding polyvinyl alcohol to carrying out pressing molding, switching the molded sample between two ceramic plates, and placing in a microwave sintering furnace to sinter. The lanthanum ferrite base cathode material does not contain precious elements, has high electric conductivity and a low thermal expansion coefficient, has characteristics of good thermal matching property and chemical compatibility compared with the commonly used electrolyte, and has characteristics of low sintering temperature, short sintering time, and low energy consumption compared to the conventional solid phase sintering.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

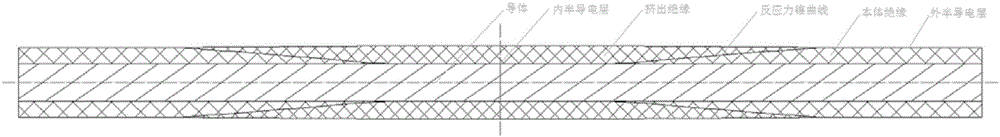

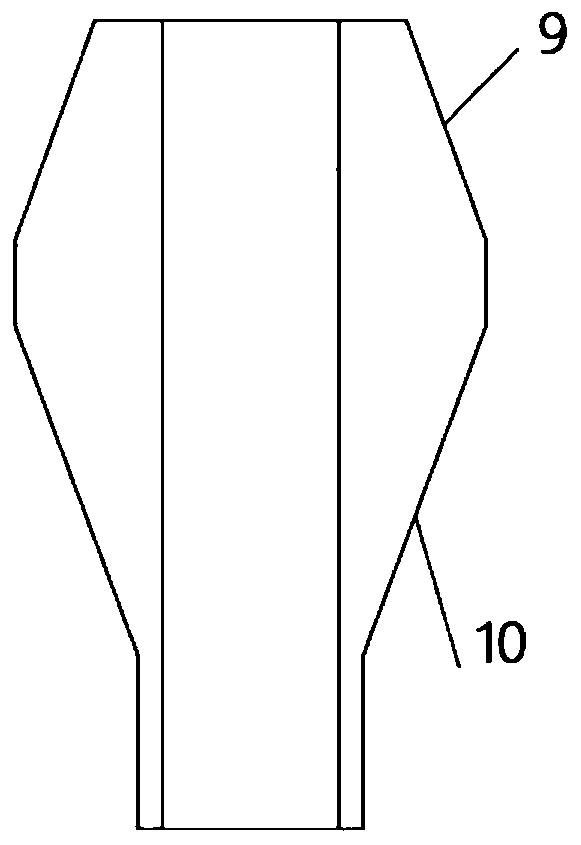

Prefabricated-type flexible DC cable terminal stress cone structure

ActiveCN106329455AMeet electrical performance requirementsSolve the phenomenon of concentrationCable terminationsApparatus for joining/termination cablesElectricityInsulation layer

The invention provides a prefabricated-type flexible DC cable terminal stress cone structure, and the structure comprises a reinforcing insulation layer, a stress cone semiconducting layer, and a stress cone curve. The stress cone semiconducting layer is disposed on the insulating layer of a DC cable body. The reinforcing insulation layer is disposed on the stress cone semiconducting layer, and the stress cone curve is the lower edge of the stress cone semiconducting layer. On the basis of giving consideration to the impact on the resistivity from the temperature and an electric field, the invention proposes the distribution of an electric field in the insulation of a prefabricated-type flexible DC cable terminal, and provides a theoretical basis for the design of a flexible DC cable connection part. A method for calculating the thickness of the reinforcing insulation layer of the prefabricated-type flexible DC cable terminal is proposed, and guarantees that the interface electric field of the cable insulating layer and the reinforcing insulation layer is within a reasonable range. A reasonable stress cone is designed, thereby solving the phenomenon of centralized potential wires of the flexible DC cable terminal, and guaranteeing that the electric field of the whole stress cone is uniform. The structure meets the requirements of a whole flexible DC cable system for the electrical performances of the terminal, and guarantees the long-time safety and reliability of the flexible DC cable system.

Owner:NANJING NARI GROUP CORP +3

Manufacturing method for high-precision isolated boss-shaped structure HTCC substrate

ActiveCN105376932AMeet the requirements of multi-dimensional packagingEnsure Interconnect Routing RelationshipsLaminating printed circuit boardsCircuit susbtrate materialsCo-fired ceramicElectricity

The invention discloses a manufacturing method for a high-precision isolated boss-shaped structure HTCC (high temperature co-fired ceramic) substrate. A multi-layered ceramic co-firing technology is adopted; a green tape suitable for the HTCC technology is taken as the base material; wolfram is taken as the metallization material; a shock insulator indian kalimeris herb film and a seamless spliced laminating method are adopted; according to the manufactured isolated boss-shaped structure HTCC substrate, the processing precision for the outer boss can achieve plus and minus 0.10 mm; the position offset of an upper layer and a lower layer is less than 0.20 mm; an interconnection wiring relation is ensured among the layers, and the HTCC substrate can meet all the electrical property index requirements of the national military standard.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Honeycomb mixed interlayer structure radar radome

PendingCN109490836AMeet electrical performance requirementsWave based measurement systemsRadarHoneycomb

The invention discloses a honeycomb mixed interlayer structure and radar radome. The radome comprises an outer skin, an inner skin, a first honeycomb and a second honeycomb; the first honeycomb and the second honeycomb are arranged between the outer skin and the inner skin, the first honeycomb surrounds the second honeycomb, the thicknesses of the first honeycomb gradually becomes smaller from larger in the direction from the outer side to the second honeycomb, the part making contact with the second honeycomb has the same thickness as the second honeycomb, lattice holes of the first honeycombare smaller than those of the second honeycomb, the radar radome electrical property requirements can be met; meanwhile, the radar radome strength and rigidity requirements can be met.

Owner:THE RES INST FOR SPECIAL STRUCTURES OF AERONAUTICAL COMPOSITE AVIC

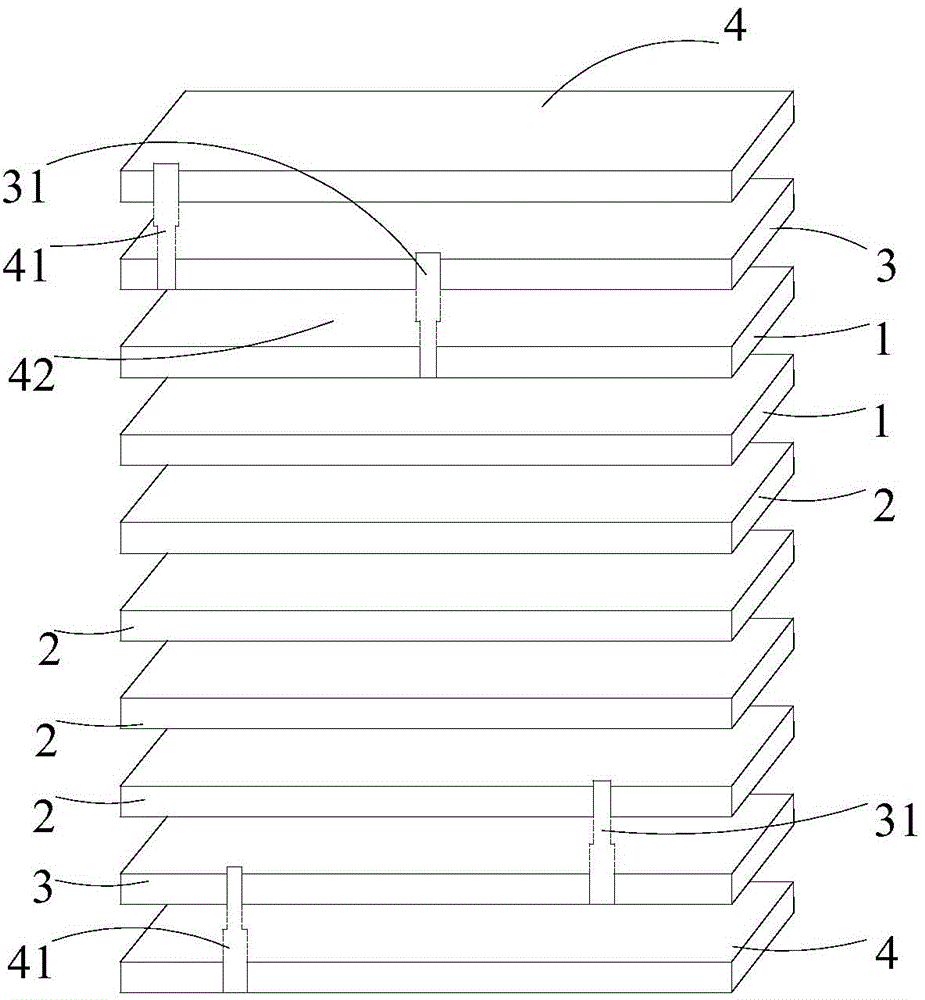

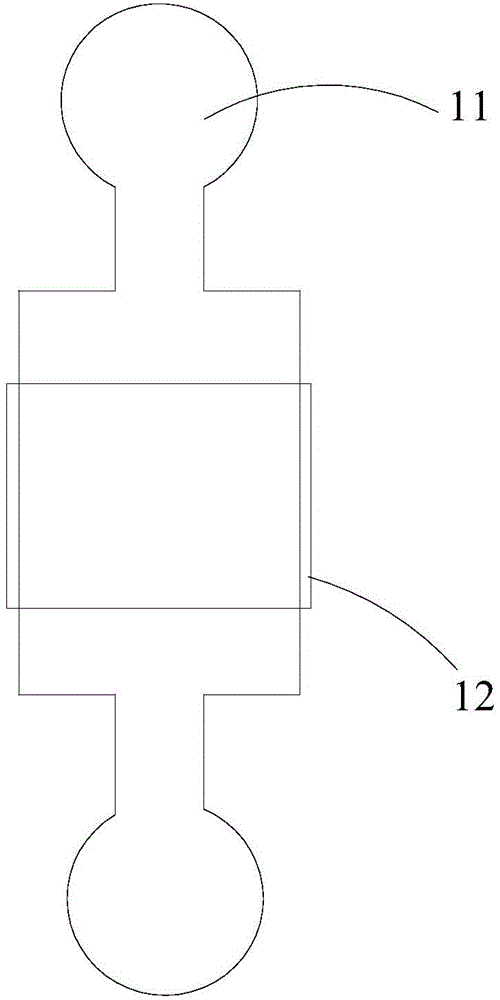

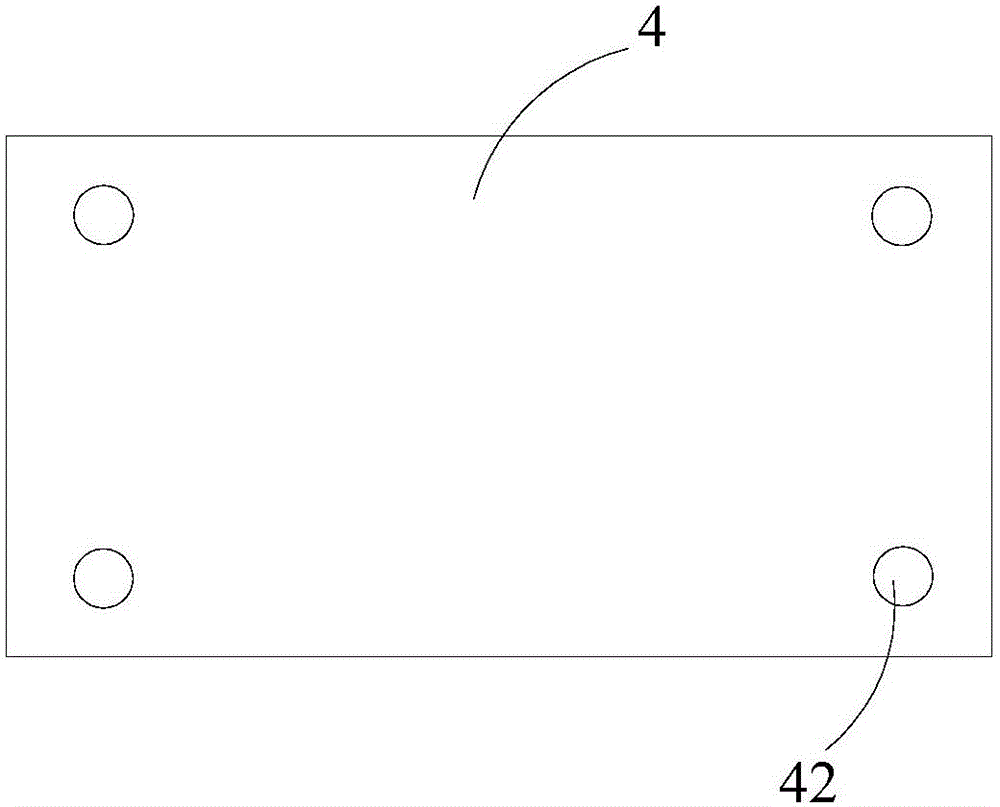

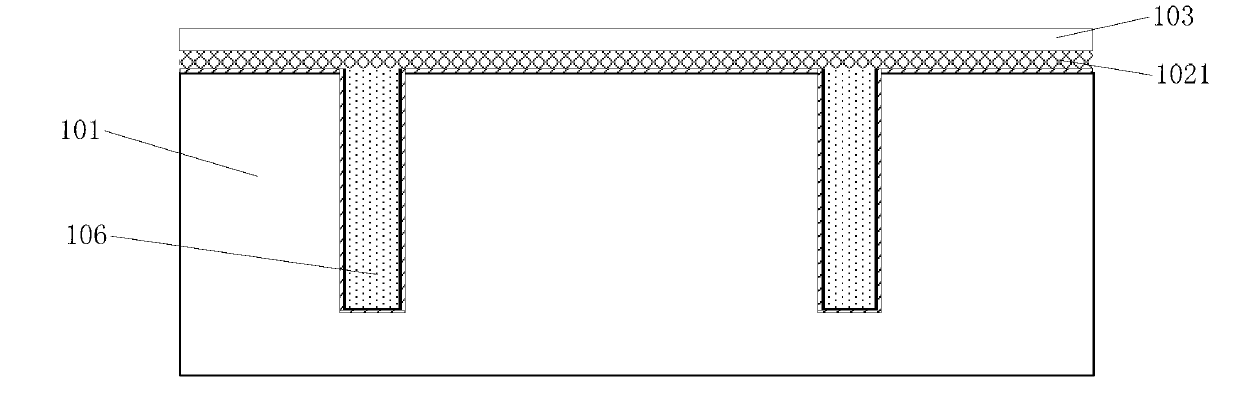

Pinboard structure using conducting resin as signal return plane and preparation method thereof

ActiveCN103107161AImprove adhesionSimple processSemiconductor/solid-state device detailsSolid-state devicesEngineeringConductive materials

The invention provides a pinboard structure using conducting resin as a signal return plane. The pinboard structure using the conducting resin as the signal return plane comprises a substrate and through holes penetrating through the substrate, an insulating medium layer is formed on the front surface and / or the back surface of the substrate, metal interconnection structures are distributed in the insulating medium layer, each metal interconnection structures comprise at least one layer of horizontal interconnection structure, the metal interconnection structures are connected with the conducting materials inside the through holes, at least one conducting resin layer is arranged inside the insulating medium layer, and primary through holes are formed in the conducting resin layer for the metal interconnection structures to penetrate through the conducting resin layer without contacting with the conducting resin layer. The conducting resin layer and the horizontal interconnection structure of the metal interconnection structures are in different layers, and the conducting resin layer is in electric insulation with the metal interconnection structures. The pinboard structure using the conducting resin as the signal return plane is used for providing signal return paths of the pinboard.

Owner:NAT CENT FOR ADVANCED PACKAGING

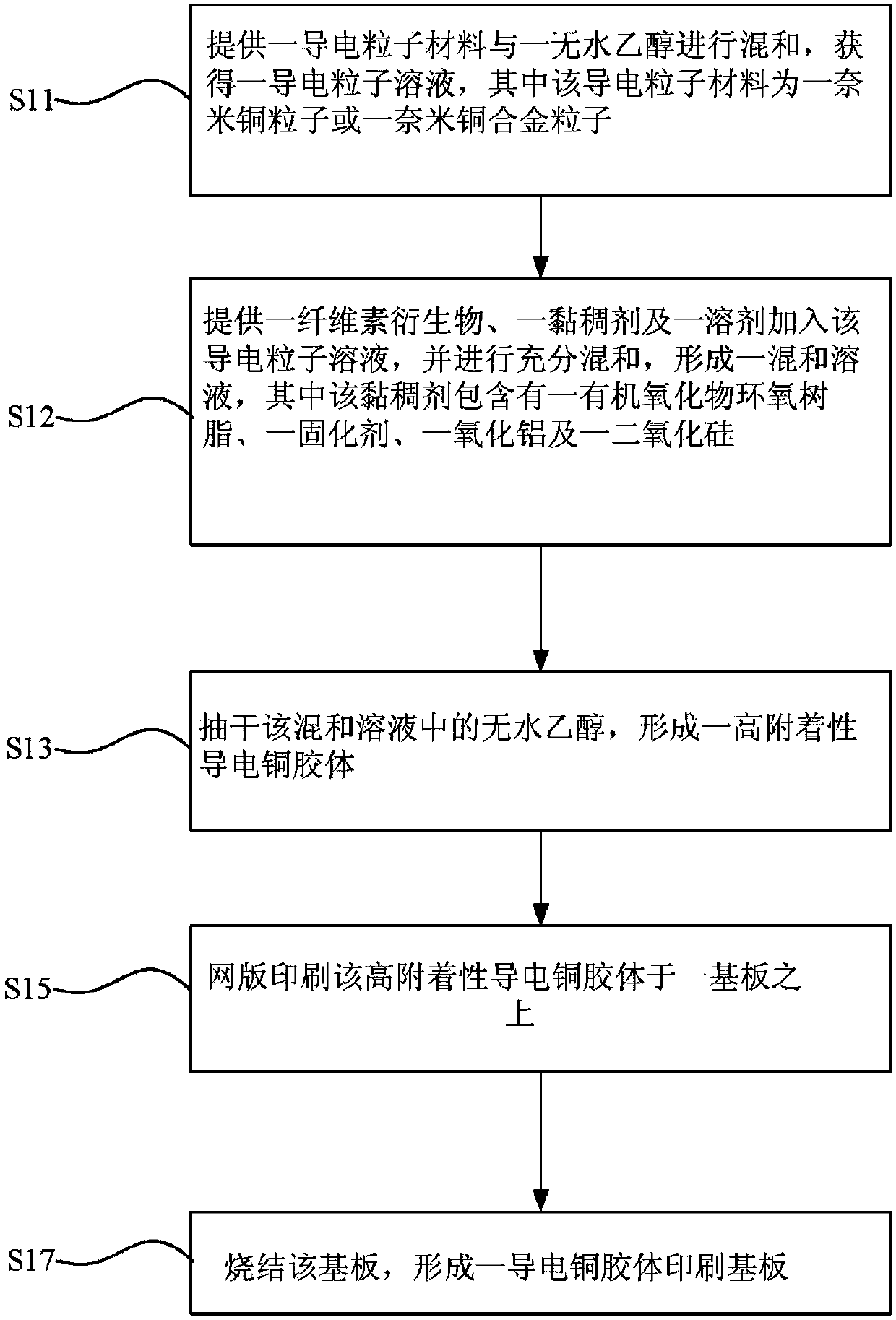

High-adhesion conductive copper colloid and screen printing application method thereof

InactiveCN107663438AImprove adhesionMaintain Antioxidant PotencyNon-macromolecular adhesive additivesMacromolecular adhesive additivesSolventOxide

The invention provides a high-adhesion conductive copper colloid and a screen printing application method thereof. The high-adhesion conductive copper colloid includes nanometer copper particles or nanometer copper alloy particles with the weight percentage of 50%-80%, a cellulose derivative with the weight percentage of 0.5%-5%, a thickening agent with the weight percentage of 5%-20%, and a solvent with the weight percentage of 5%-45%, and the thickening agent comprises an organic oxide epoxy resin, a curing agent, an aluminum oxide, and a silicon dioxide. After the preparation of the high-adhesion conductive copper colloid is accomplished and screen printing and sintering are performed, the conductive copper colloid with high adhesion, high oxidation resistance and good conductivity anda copper colloidal conductive substrate are provided.

Owner:GECKOS TECH CORP

Potassium-bismuth titanate piezoelectric ceramic/native copper composite material and preparation method thereof

InactiveCN103755340AImprove piezoelectric performanceSolve low electrical activityCeramicBismuth titanate

The invention provides a potassium-bismuth titanate piezoelectric ceramic / native copper composite material and a preparation method thereof, relates to a composite material and a preparation method thereof, and aims at solving the problems of poor osteoconduction, single function and high price of the existing bone repair material. The composite material is prepared from potassium-bismuth titanate piezoelectric ceramic powder and native copper powder. The preparation method of the composite material comprises the steps of 1, preparing the potassium-bismuth titanate piezoelectric ceramic powder by a citrate hydrothermal method and then obtaining the potassium-bismuth titanate piezoelectric ceramic powder having the grain sizes ranging from 50nm to 200nm, 2, forging the native copper by a vinegar quenching method to obtain the native copper powder having the grain sizes ranging from 100 microns to 500 microns, and 3, preparing the potassium-bismuth titanate piezoelectric ceramic / native copper composite material through hot pressed sintering. The potassium-bismuth titanate piezoelectric ceramic / native copper composite material is applied to the bone repair field.

Owner:JIAMUSI UNIVERSITY

High-voltage cable L type connector for motor train unit

PendingCN110380255AEffective response to layoutImprove stabilityVehicle connectorsSecuring/insulating coupling contact membersElectrical conductorEngineering

The invention relates to a high-voltage cable L type connector for a motor train unit. The connector comprises a protection unit and a pair of joint unit arranged in the L shape in the protection unit; the joint units are connected with an L-shaped connecting piece, and the L-shaped connecting piece comprises an L-shaped center conductor and an L shaped insulating sleeve which sleeves the center conductor; each joint unit comprises a contact, a stress cone, compression hardware and protection hardware arranged successively; and grooves cooperated with the corresponding contacts and stress cones are arranged in the two ends of the L-shaped center conductor respectively. The high-voltage cable L type connector for the motor train unit is simple in structure, pluggable, convenient to installand maintain, high in stability and flame resistance, and capable of handling cable arrangement in a high voltage jumper wire system of the motor train unit, and can be popularized widely.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com