Airplane radome with PMI foam sandwich structure and design method and manufacturing method of airplane radome

A technology of a sandwich structure and a manufacturing method, which is applied in the field of aircraft radome products and their design and manufacture, can solve the problems that the thickness of the foam cannot meet the optimum thickness, the molding and processing of the foam sandwich is difficult, and the regional difference of wave transmittance is large, and the Improve the effect of poor wave transmission performance, light weight and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Such as Figure 1 to Figure 4 Shown is an embodiment of the present invention.

[0029] A kind of aircraft radome design method of PMI foam sandwich structure, comprises the steps:

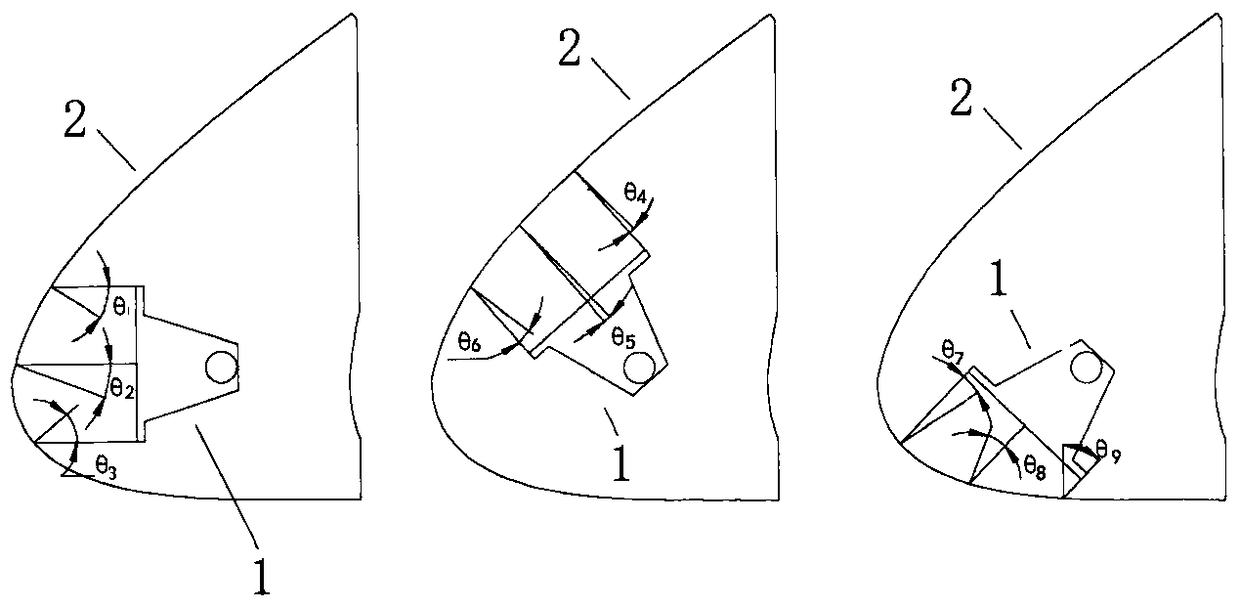

[0030] 1) According to the relative positional relationship between the radar antenna 1 and the radome 2, calculate and count the incident angle distribution of the electromagnetic waves irradiated on different positions of the radome 2;

[0031] 2) According to the frequency specified by the radome 2, the dielectric parameters of the skin material and the interlayer material are brought in, and the thickness of the sandwich structure wall thickness for different electromagnetic wave incident angles satisfying the best transmission efficiency is calculated and counted, and the corresponding change curve is constructed;

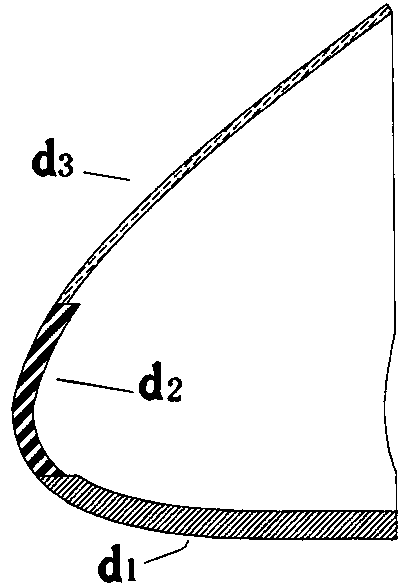

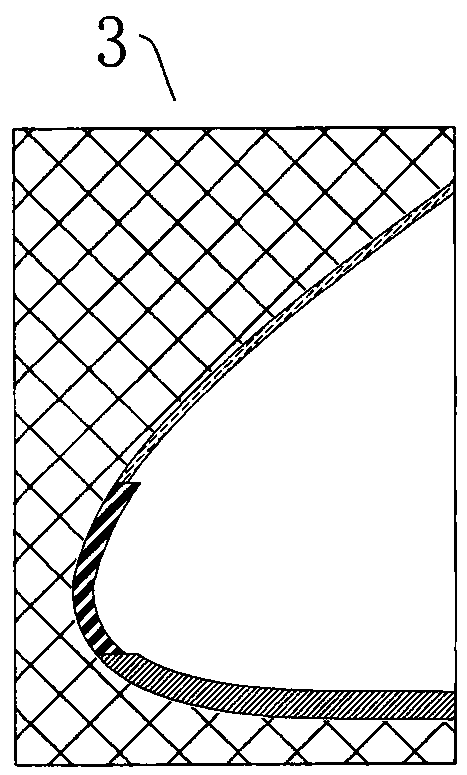

[0032] 3) According to the results of step 1) and step 2) and the gradient change of the incident angle at different points of the radome 2, divide the upper, middle and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com