Electronic tube plate electrode blocking capacitor

A technology for capacitors and electronic tubes, applied in the field of capacitors, can solve the problems of complex manufacturing of PTFE cylinders, poor contact of reeds, and increased costs, etc., and achieve the effect of simple appearance, normal use, and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

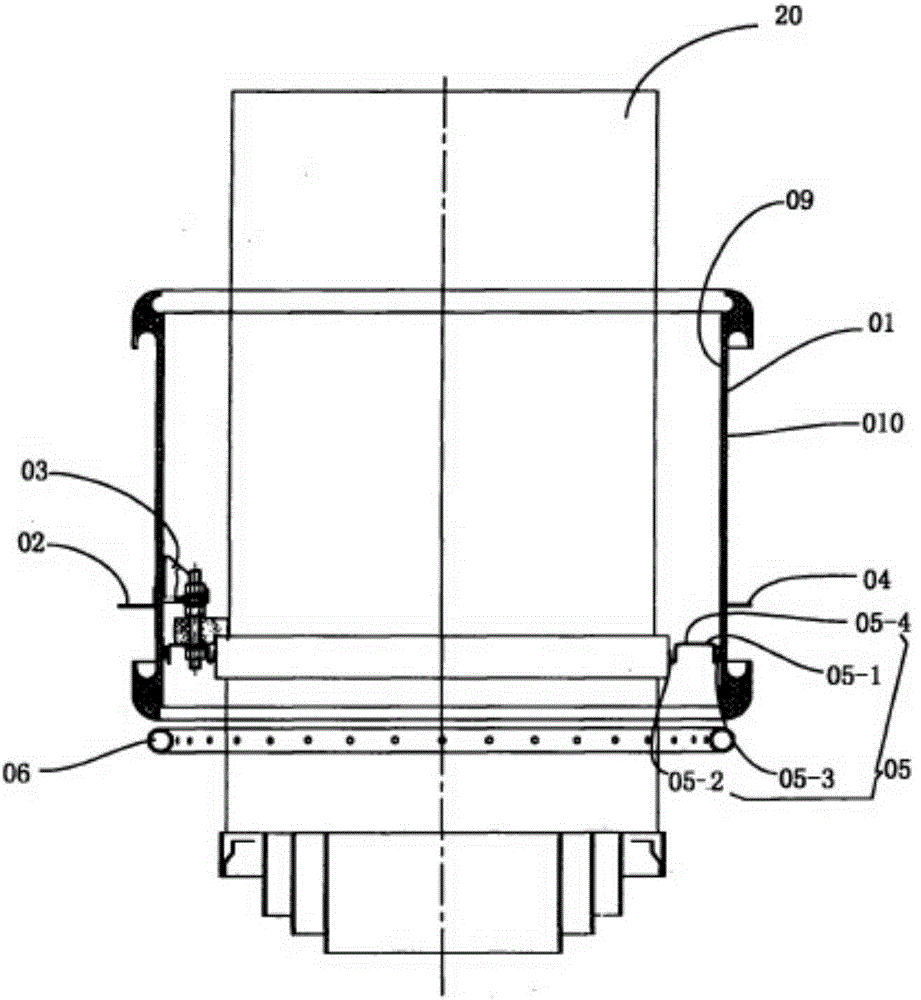

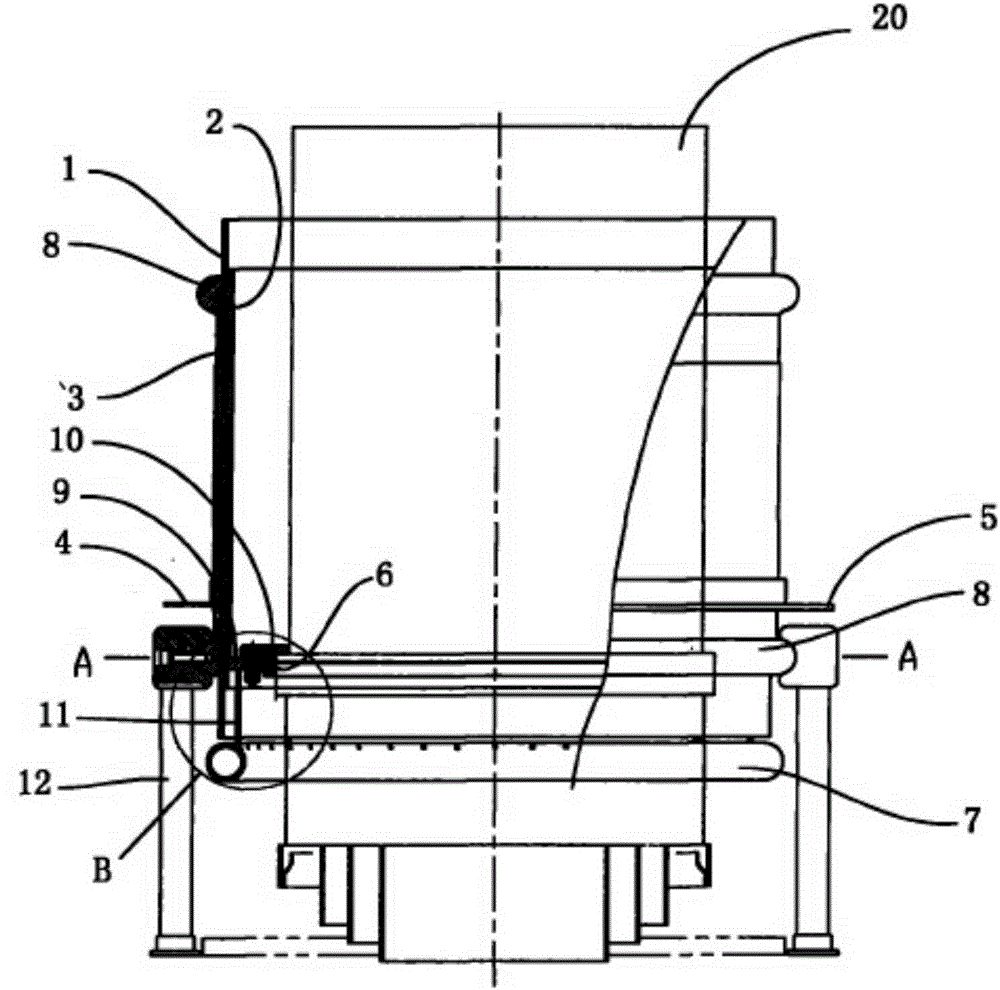

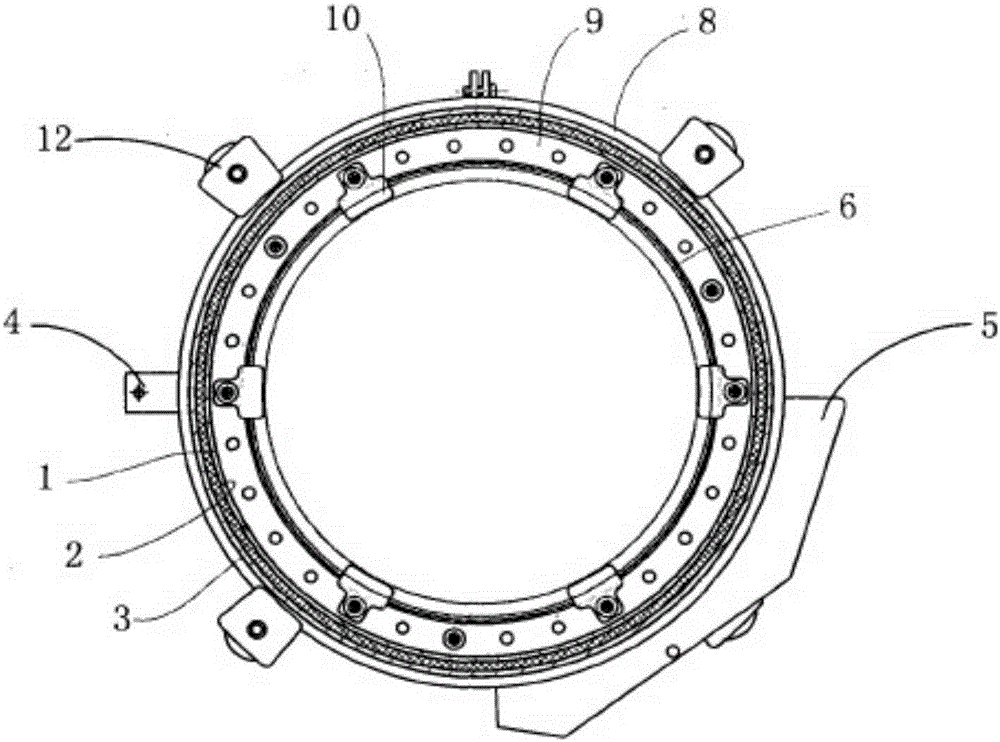

[0033] see figure 2 , image 3 As shown, a kind of electronic tube plate pole DC-blocking capacitor provided by the present invention comprises: polytetrafluoro cylinder 1, inner and outer pole plates 2, 3 which are arranged on the inner and outer surfaces of said polytetrafluoro cylinder 1, welded on the said polytetrafluoro cylinder 1 Describe the connecting angle 4 and connecting plate 5 on the outer surface pole plate 2, the annular contact reed 6 arranged on the inner pole plate electrically connected with the electron tube plate and the cooling air pipe 7 arranged under the polytetrafluoro cylinder, Wherein the inner pole plate 2 is a thin-walled metal inner cylinder, and the thin-walled metal inner cylinder as the inner pole plate is combined with the polytetrafluoro cylinder 1 by interference fit; the outer pole plate 3 is a thin-walled metal inner cylinder. The outer cylinder, the thin-walled metal outer cylinder as the outer pole plate 3 is interference-bonded with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com