Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79results about How to "Has industrial utilization value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

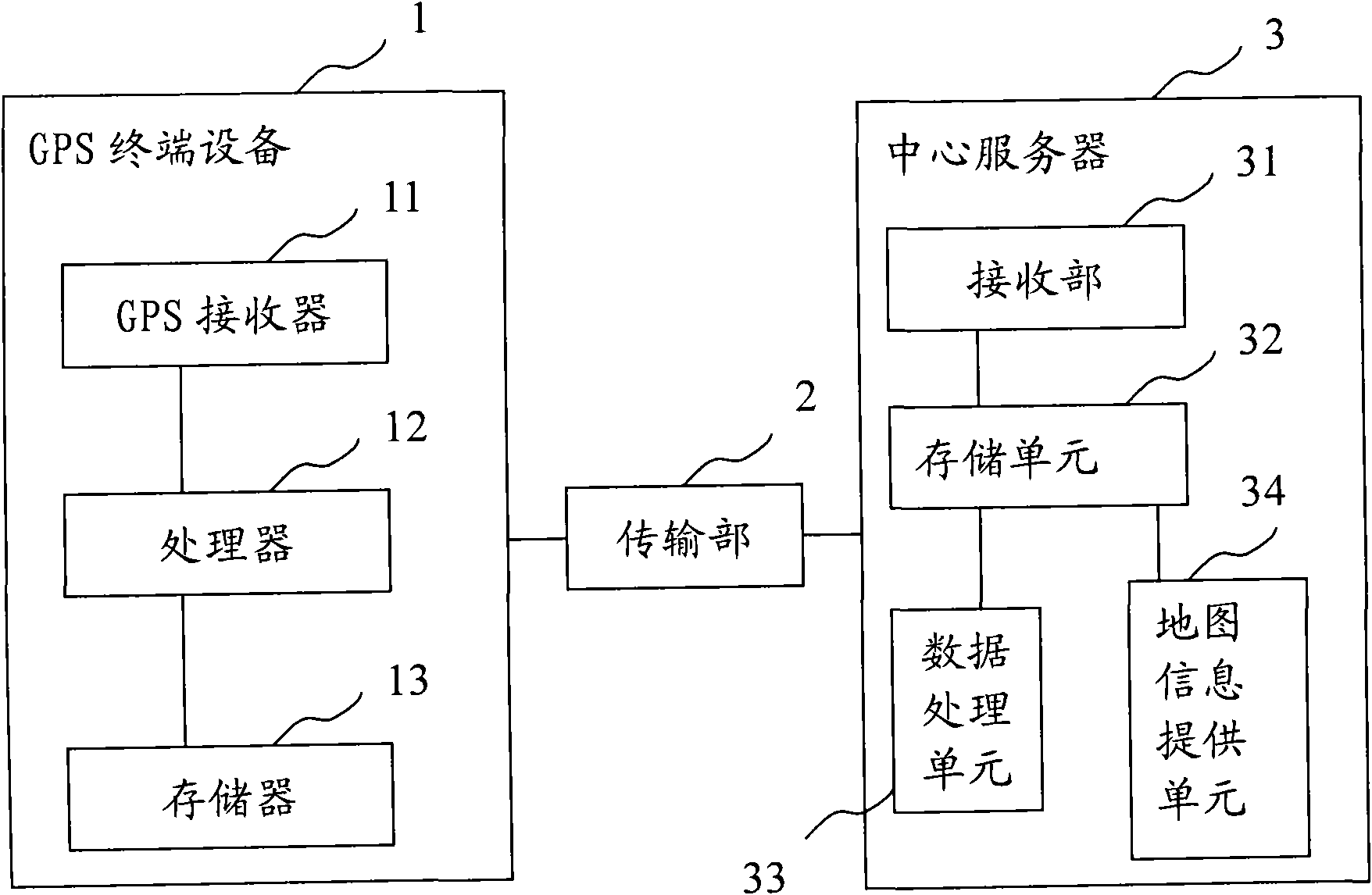

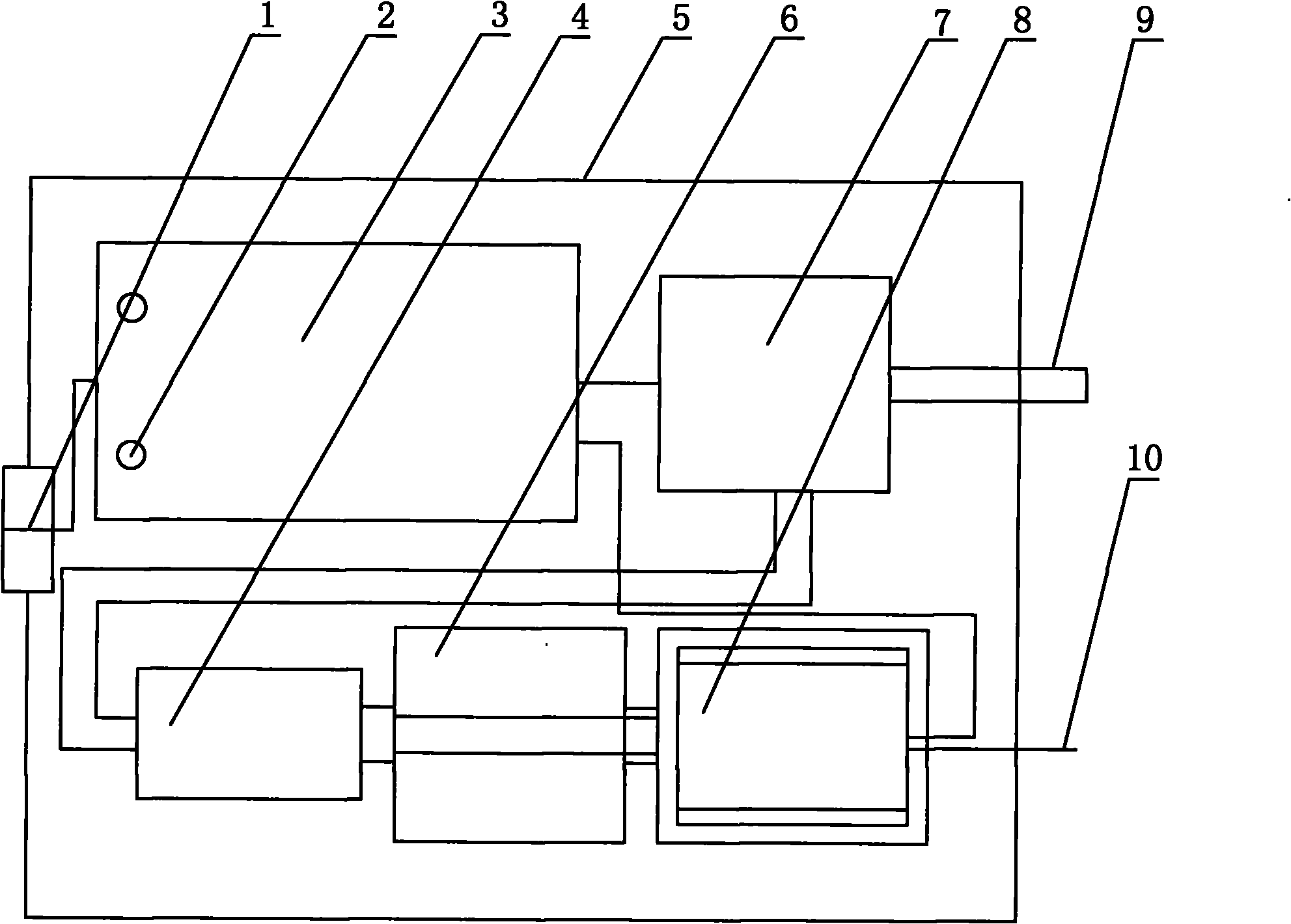

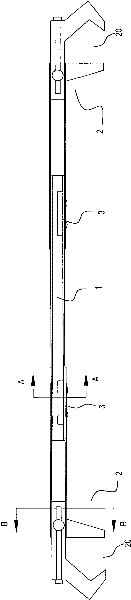

GPS route recording device and route forming system

InactiveCN101556162AWidely used valueOvercome the problem of slow update speedInstruments for road network navigationBeacon systems using radio wavesTerminal equipmentGps receiver

The invention relates to a GPS route recording device and a route forming system. The GPS route recording device comprises a GPS receiver, a processor and a memory, wherein the GPS receiver receives position information in real time, the processor records route information comprising the position information received by the GPS receiver about the current position on a travel route, and the memory memorizes the route information recorded by the processor. The route forming system comprises the GPS route recording device, a transmission part and a central server, wherein the transmission part sends out the route information formed in a GPS terminal device through a certain network, the central server receives and processes the route information sent by the transmission part, the central server comprises a receiving part and a data processing unit, the receiving part receives the route information sent by the transmission part, and the data processing unit processes the route information received by the receiving part into map information. The GPS route recording device can record a travel route. The route forming system can dynamically update the map information according to the route information.

Owner:吴波 +5

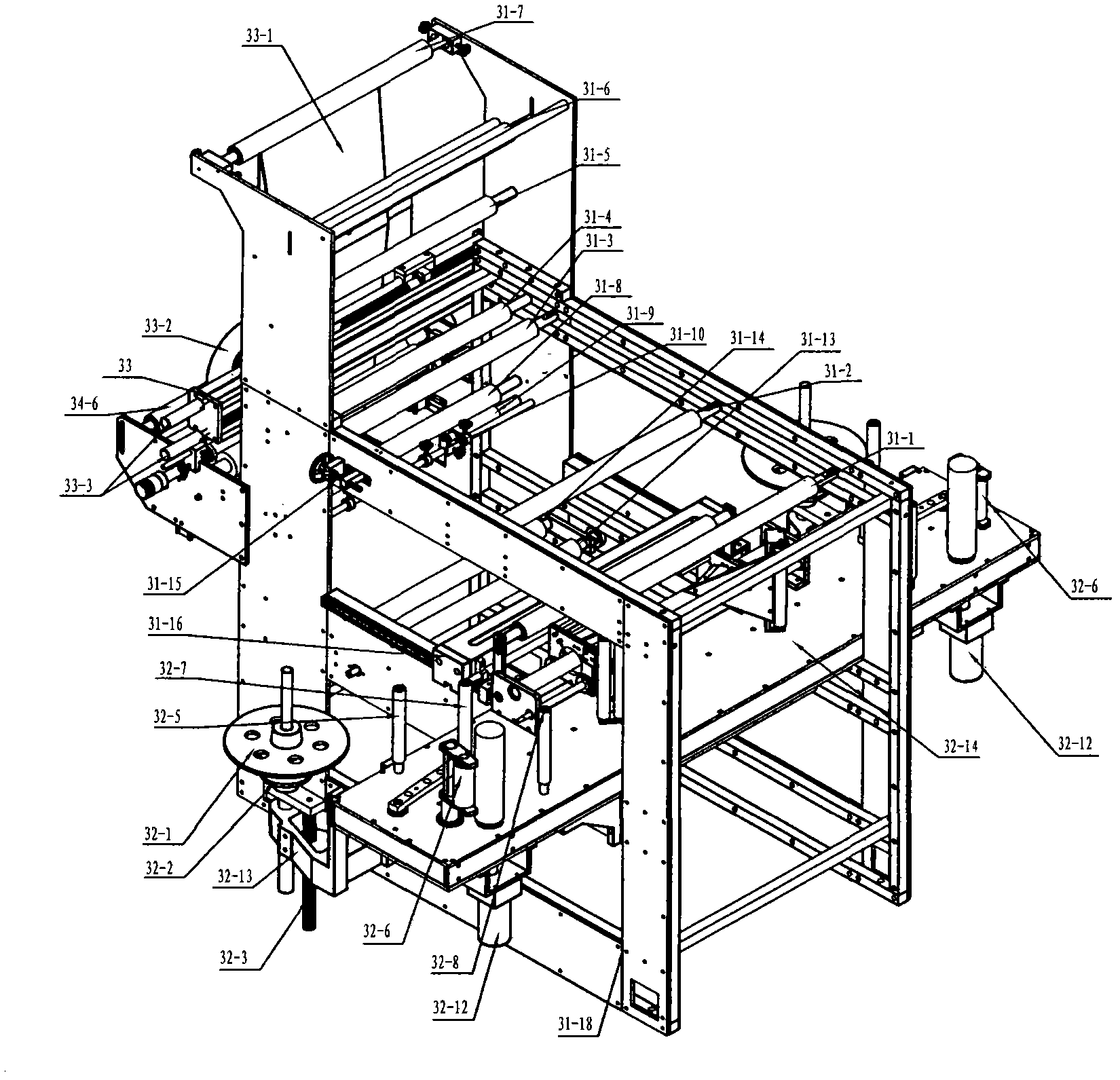

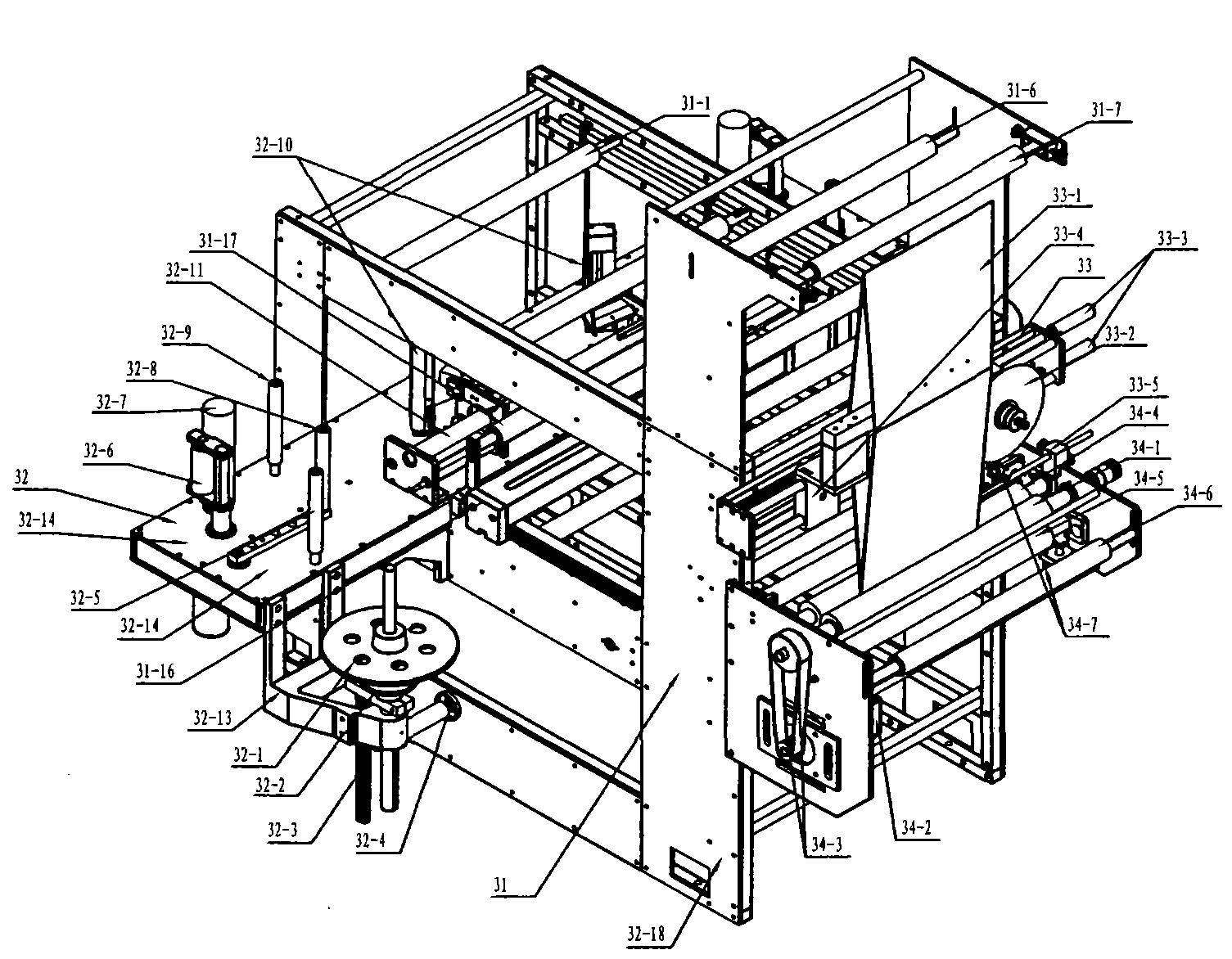

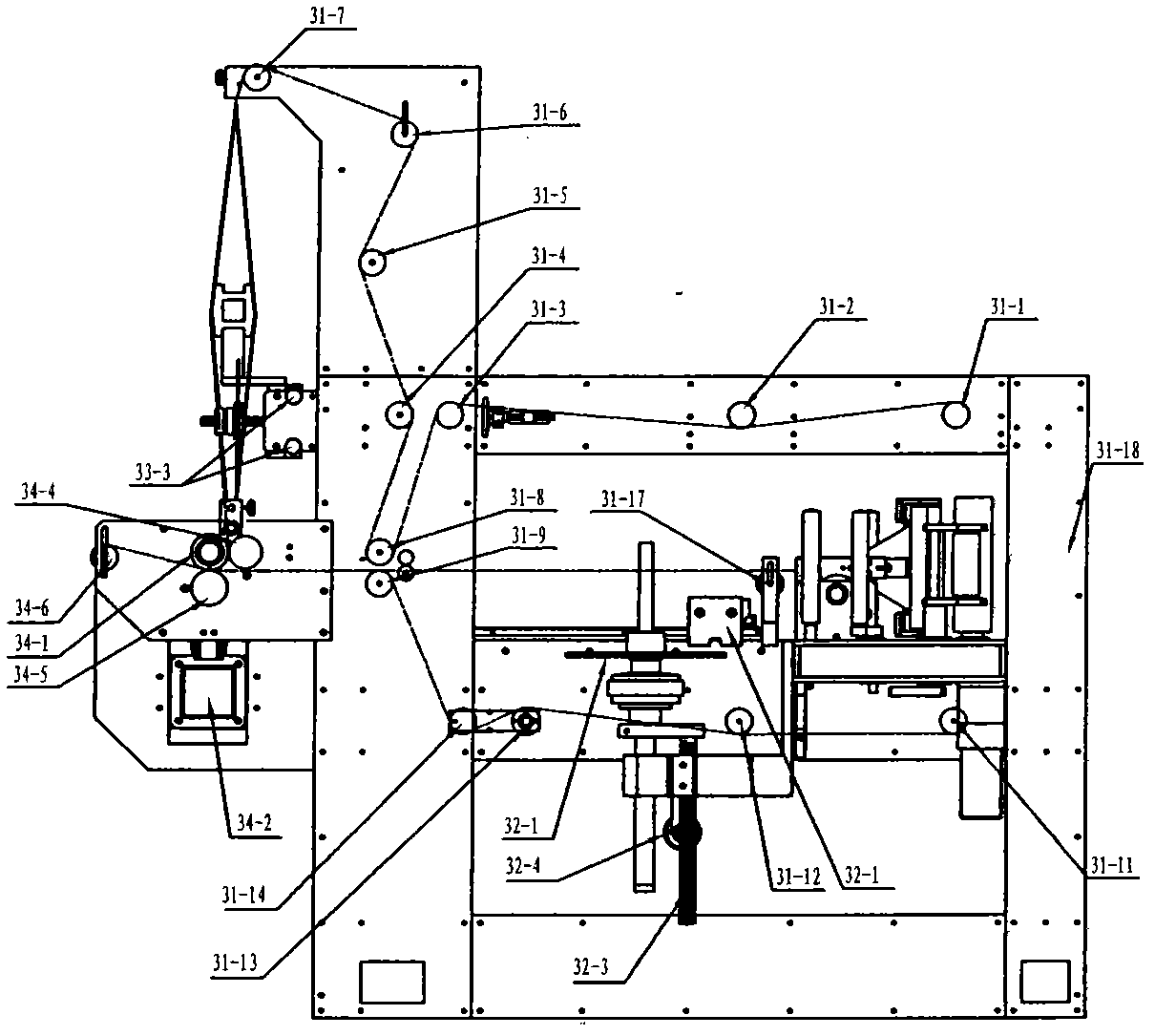

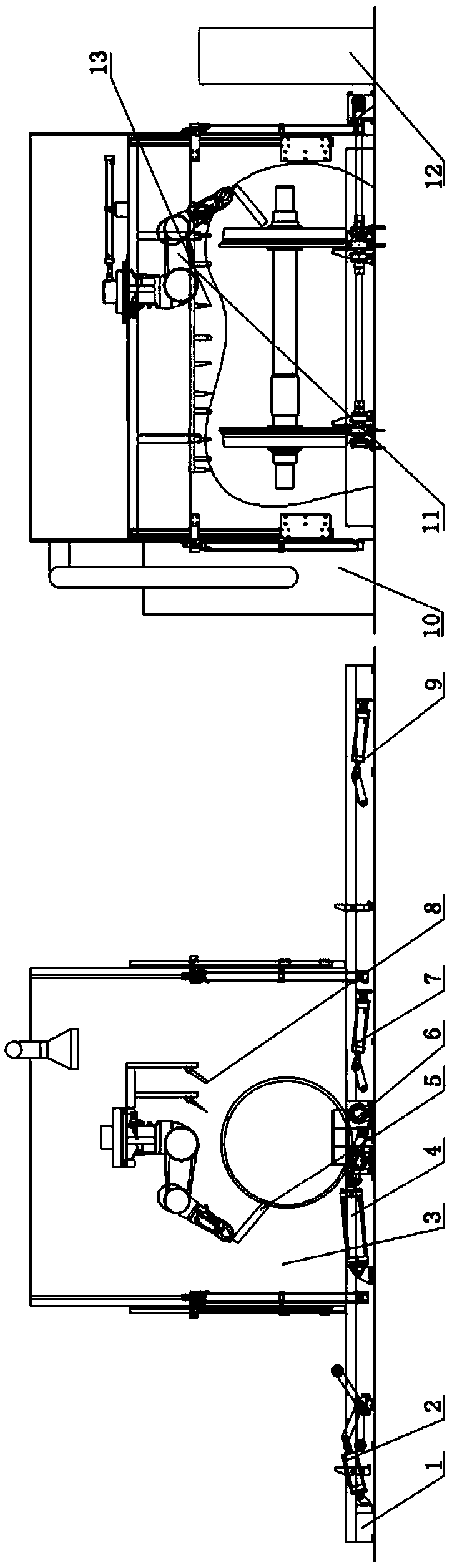

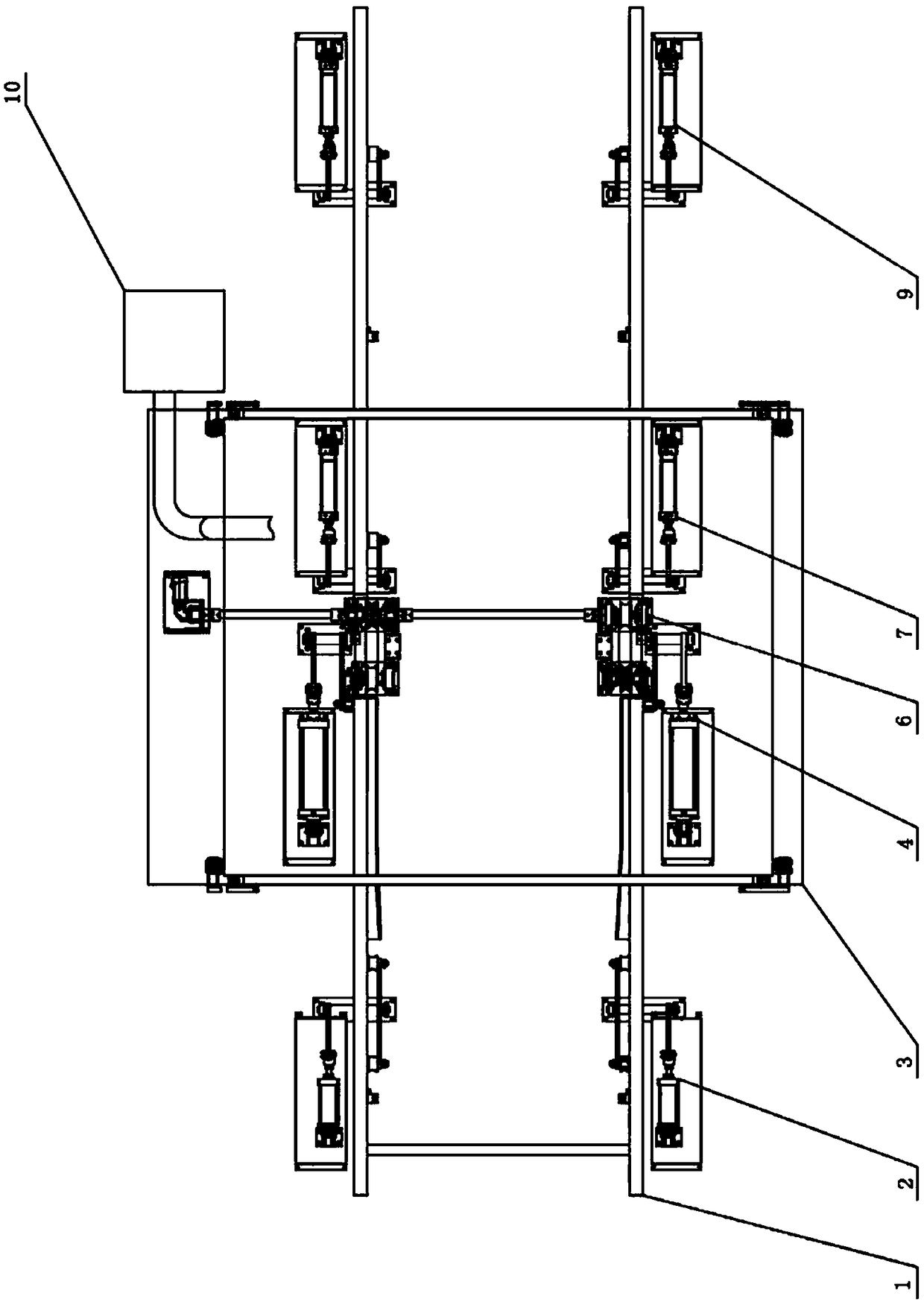

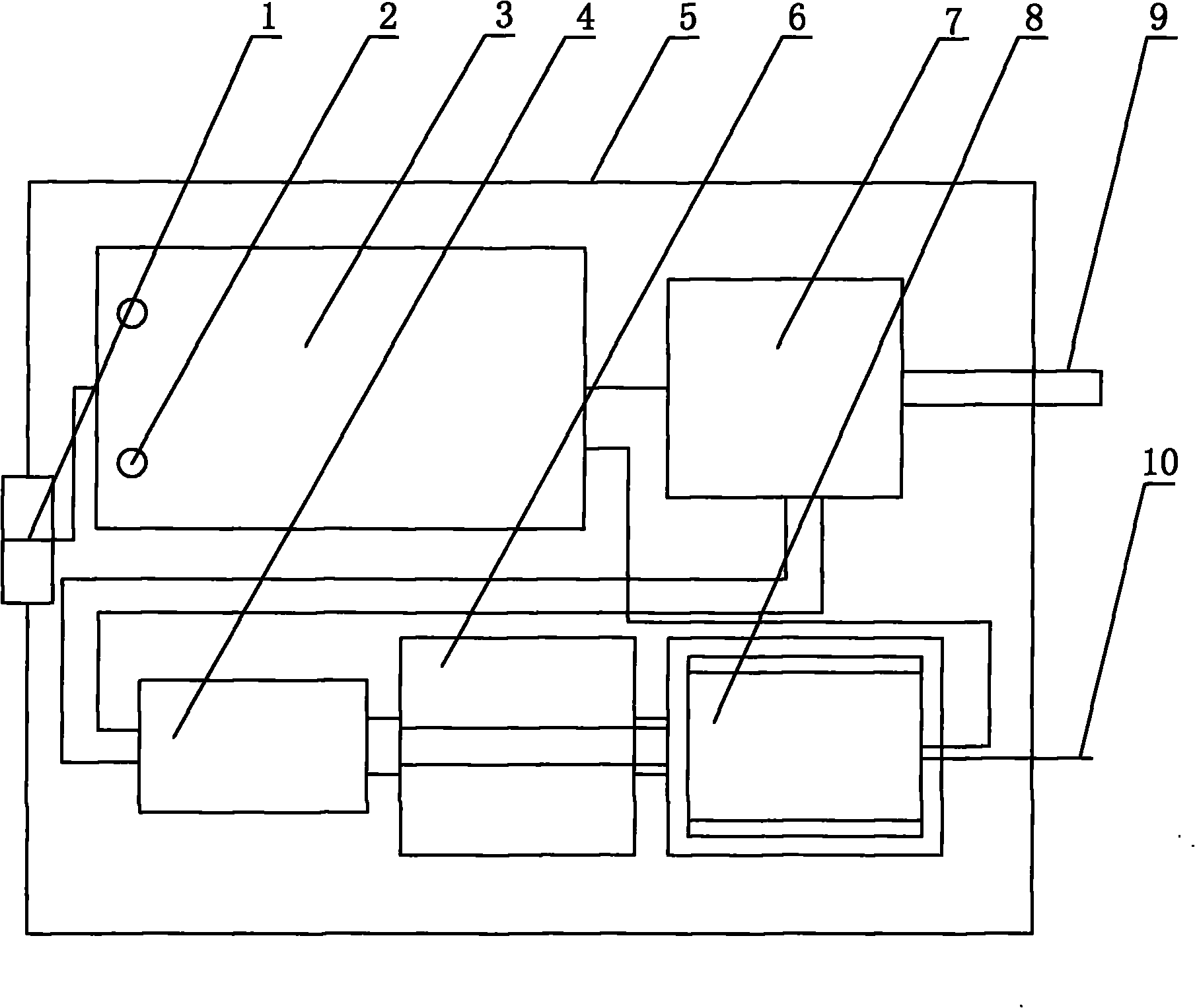

Self-standing device for full-automatic multifunctional multi-system integrated bag-making machine

ActiveCN102248707AQuality improvementImprove efficiencyContainer making machineryEngineeringMechanical engineering

The invention relates to a self-standing device for a full-automatic multifunctional multi-system integrated bag-making machine, which comprises an outer frame device, an additional bottom self-standing forming device, a folded bottom self-standing forming device and a motor dragging device. The outer frame device, the additional bottom self-standing forming device, the folded bottom self-standing forming device and the motor dragging device are organically combined with one another, thereby finishing processing a middle sealed bag, a three-side sealed bag, a four-side sealed bag, an additional-bottom folded-bottom self-standing bag, a zipper bag, and the like, by one machine. The self-standing device provided by the invention has the advantages of capability of continuous construction, smooth film spreading, high efficiency and low cost, thereby being a novel design with high integration and progressive and being suitable for wide application in industry.

Owner:GUANGDONG ZHONGBAO MACHINE

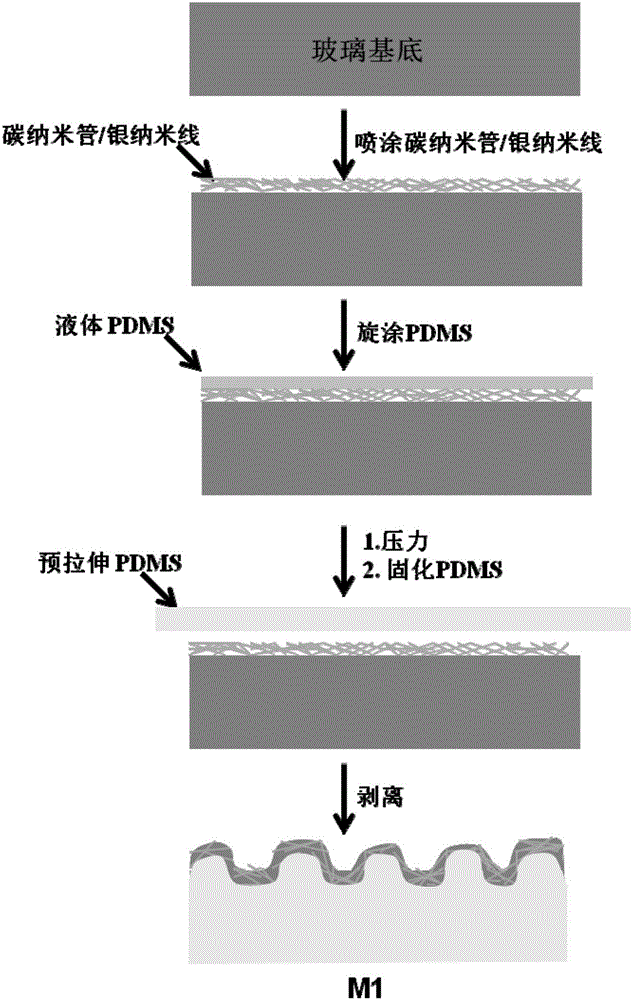

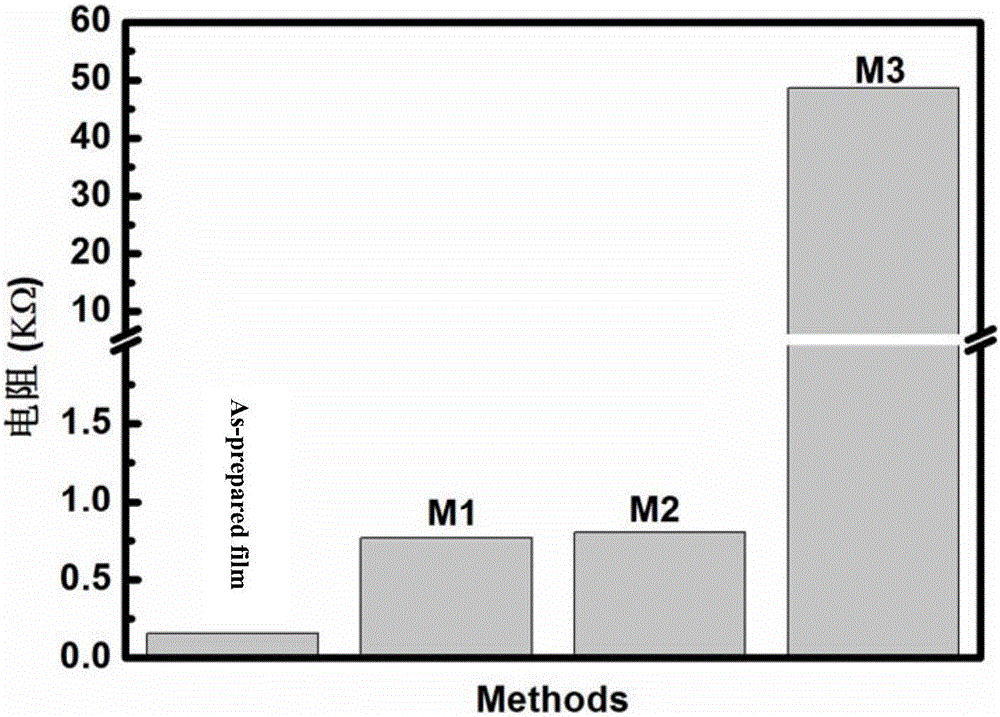

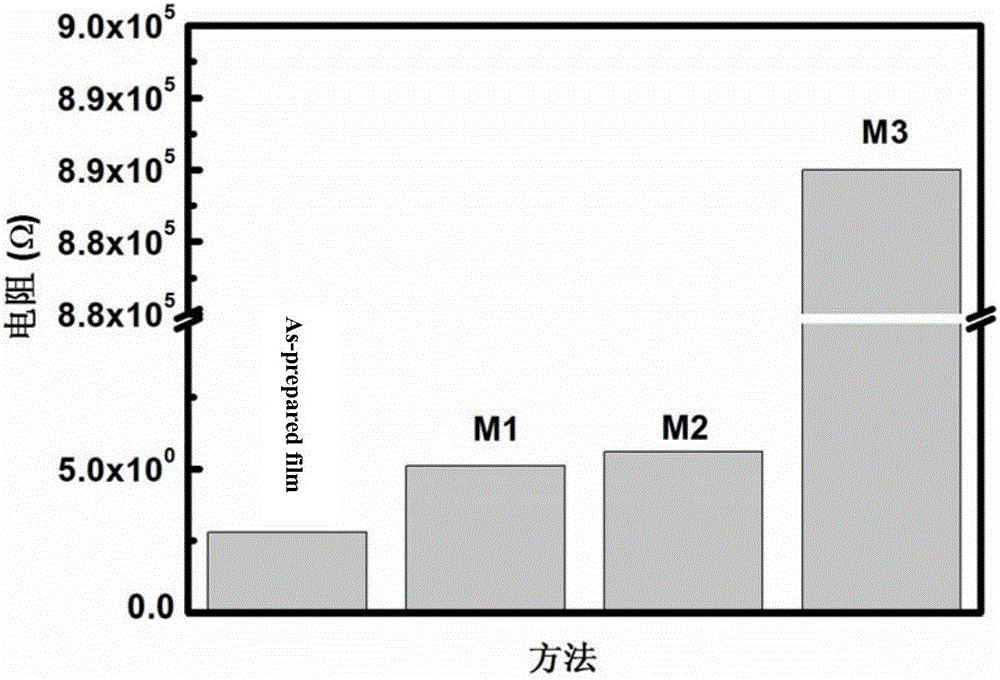

Efficient preparation method for flexible ultra-extension conductive thin film based on one-dimensional nano material

ActiveCN105957639AEasy to prepareFast preparation methodMaterial nanotechnologyCable/conductor manufactureElectricityColloid

The invention discloses an efficient preparation method for a flexible ultra-extension conductive thin film based on a one-dimensional nano material, and belongs to the technical field of nano photoelectric materials. The preparation method comprises the steps of firstly, evenly spraying a one-dimensional nano conductive material solution on a hard substrate so as to prepare a conductive thin film; secondly, evenly spinning an uncured PDMS colloid at the surface of the conductive thin film, then placing a stretched cured PDMS film at the surface of an uncured PDMS film, and finally applying great pressure and placing the film in a vacuum drying oven so as to be cured. The preparation method provided by the invention for the flexible ultra-extension conductive thin film is simple in operation, low in cost and wide in application range. The preparation method has the characteristics of efficient transfer process and large-area preparation. The prepared conductive thin film shows prominent advantages of flexible ultra-extension and stable electrical performance.

Owner:NANJING UNIV OF TECH

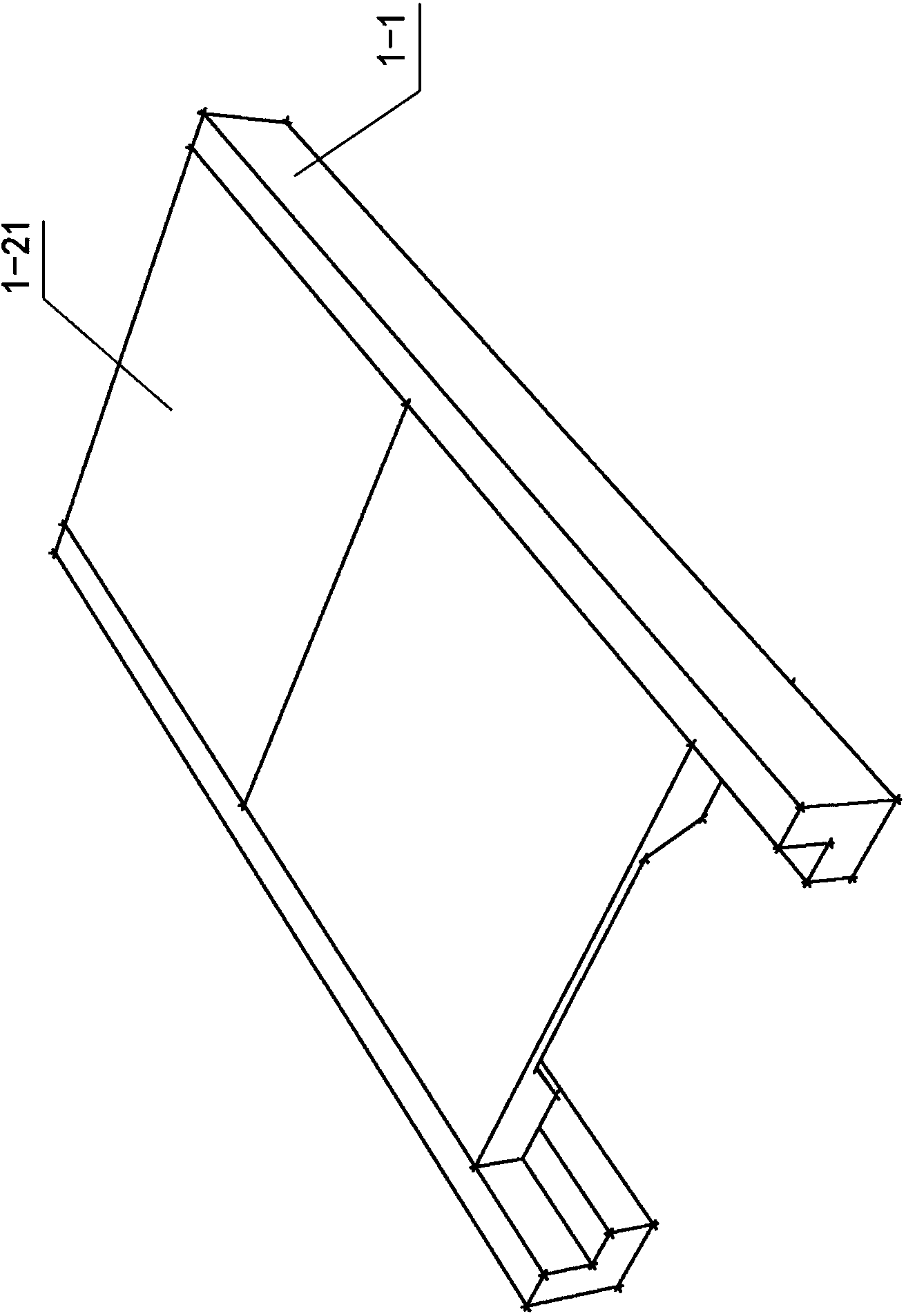

Drainage and seepage type felting composite structure

InactiveCN104313967ASimple structureReduce manufacturing costSingle unit pavingsPaving gutters/kerbsEngineeringEarth surface

The invention relates to a drainage and seepage type felting composite structure. The seepage type felting composite structure comprises a beam-slab felting structure, a permeable PC substrate, a U-shaped ecological water draining and collecting ditch, and a seepage and drainage pipe, wherein the beam-slab felting structure is assembled into a side pavement or a motorized vehicle lane; the permeable PC substrate and the beam-slab felting structure are combined into a motor vehicle lane or a square and have a load effect. The U-shaped ecological water draining and collecting ditch is installed at one side or two sides of the motor vehicle lane or the square; the drainage and seepage pipe comprises a transverse PC pipe and a vertical PC pipe; the transverse PC pipe is communicated with the U-shaped ecological water draining and collecting ditch; and the vertical PC pipe is communicated with the transverse PC pipe. The drainage and seepage type felting composite structure is permeable and breathable, can carry out earth surface heat exchange easily, can recycle rainwater effectively, reduces an urban heat island effect, is suitable for eco-environment protection, is simple in structure, and is simple to construct.

Owner:深圳市致道景观有限公司

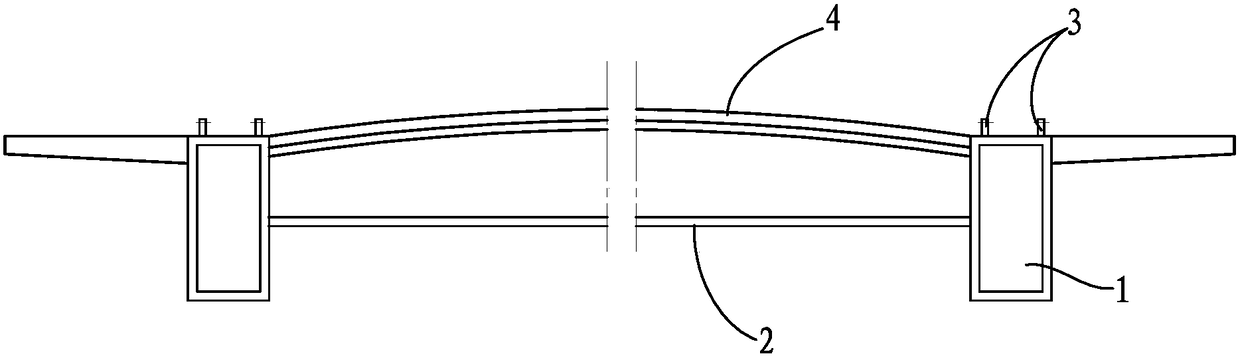

Cabin processing method and bulging tooling used in same

The invention relates to the technical field of aerospace industries, in particular to an aircraft cabin processing method and a bulging tooling used in the same. The method comprises the following steps: 1, blank blanking; 2, machining an excircle; 3, machining an inner hole, wherein the size of the machined inner hole is smaller than that of a nominal size; 4, using a tooling to perform bulging up to meet a required size. According to the method, the machining and the bulging processing are adopted, so that the precision requirements on the machining are greatly reduced, the production efficiency is improved, the consistency and the qualification rate of finished products are greatly improved, the manufacturing cost is relatively reduced, the cost is greatly reduced, and the economic efficiency is improved.

Owner:北京新航钛空天技术有限公司

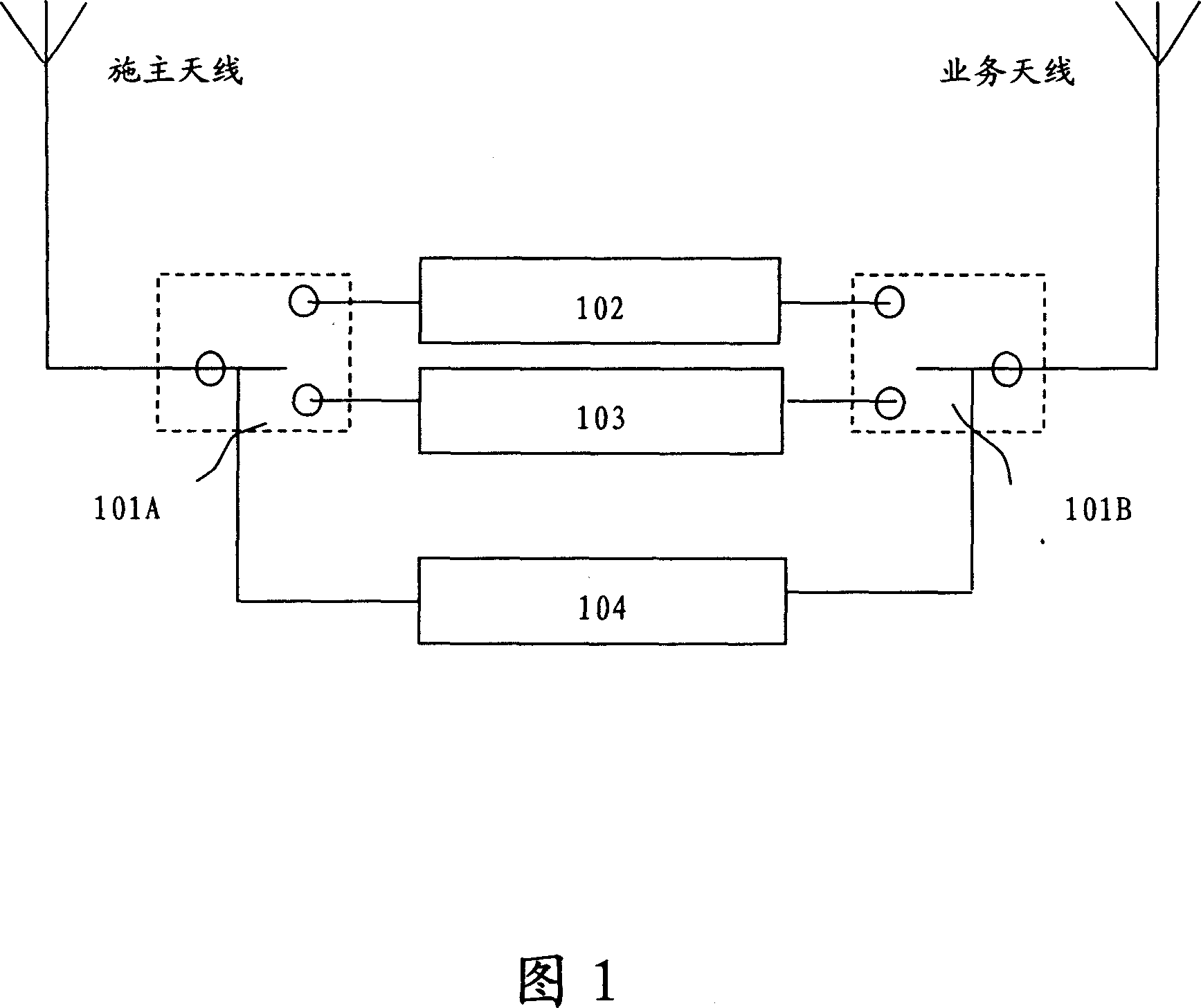

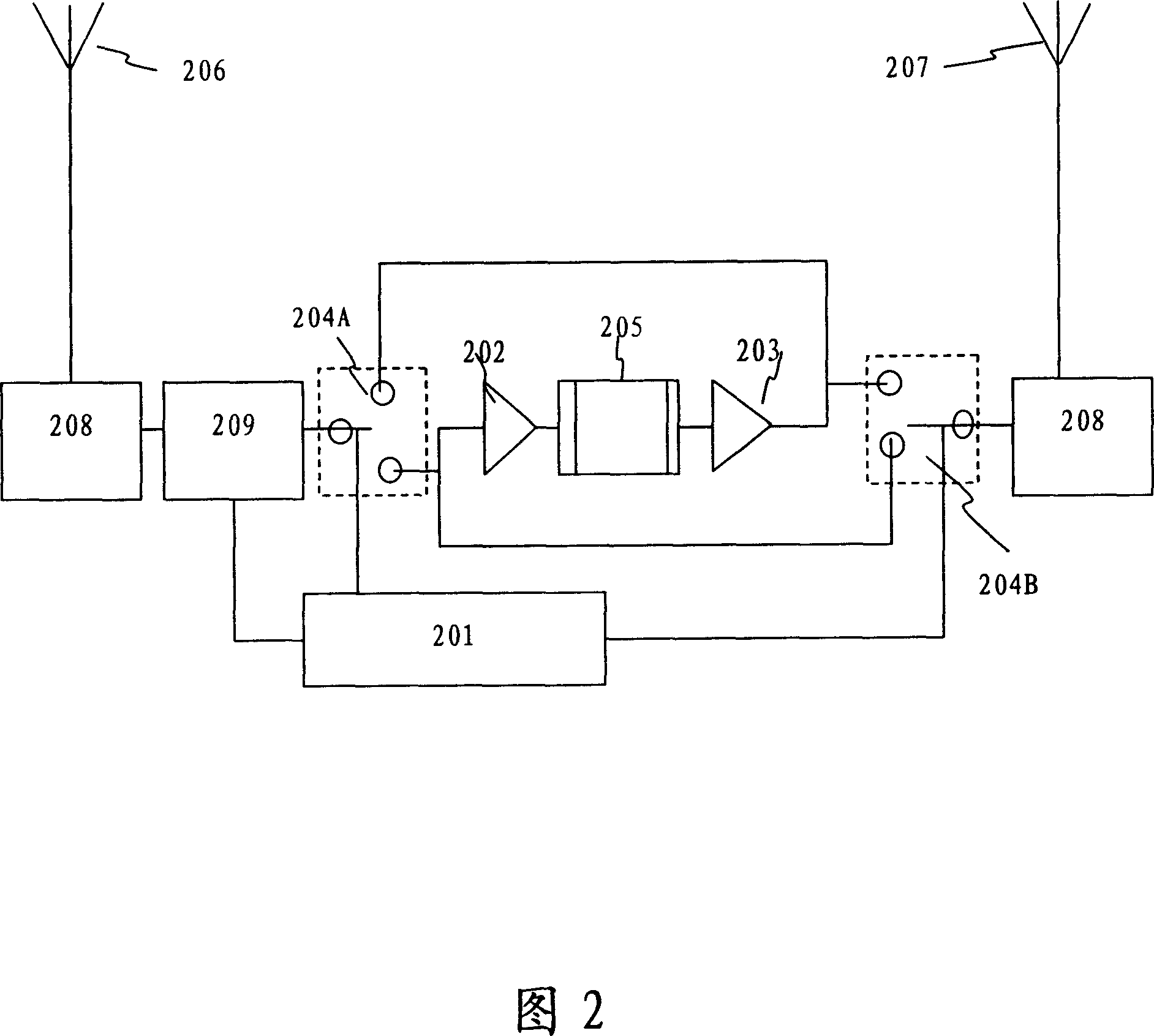

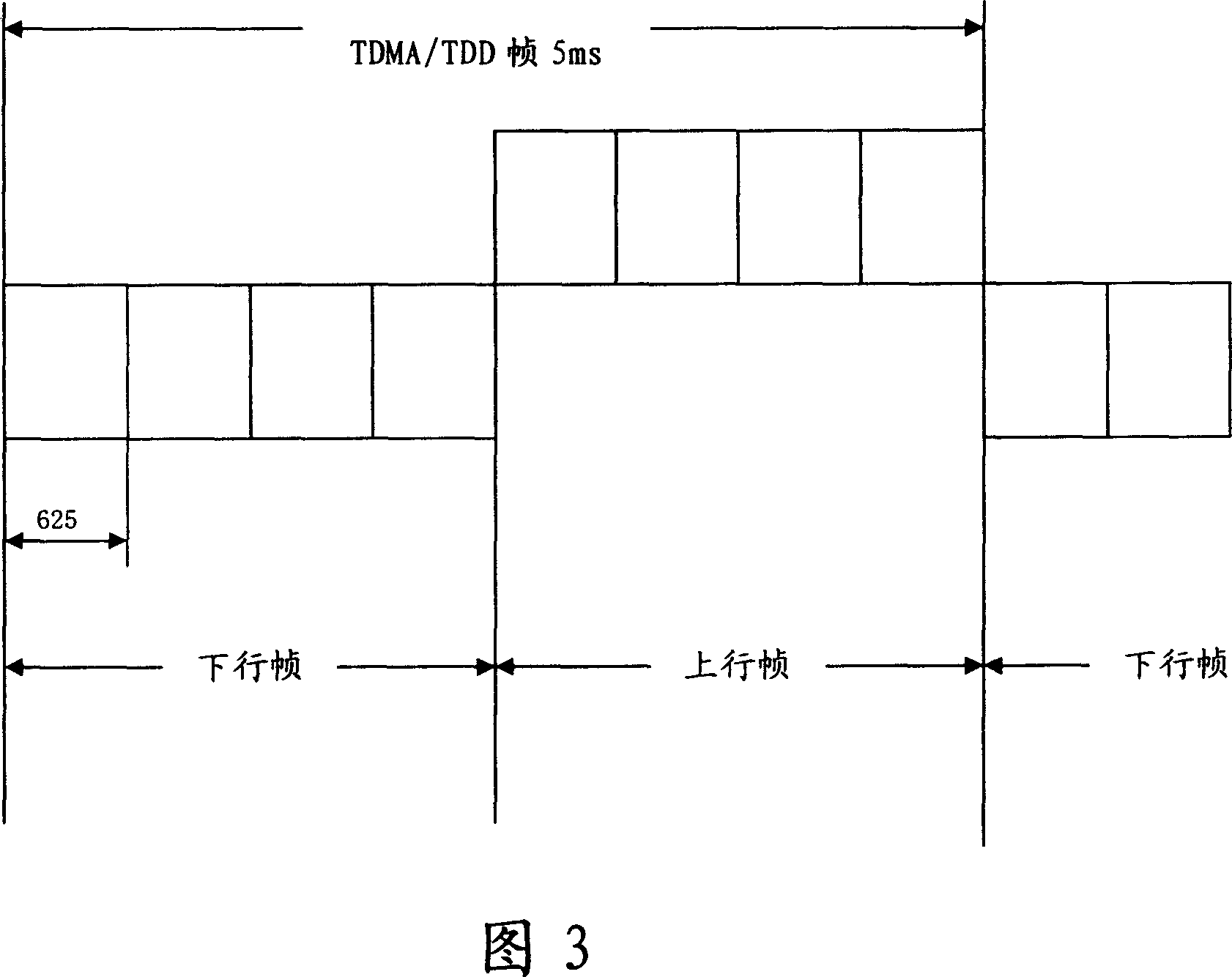

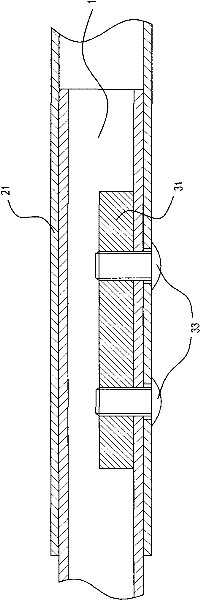

Repeater suitable for TDD system mobile communication system

The station includes a RF switch array (RFSA), a time synchronization controller (TSC), a donor antenna and a business antenna, a low noise amplifier (LNA) co-used by the up-going and down-going links, a digital gain controller (DGC), a linear power amplifier (LPA) and a coupler. Under control of the time synchronization control signal, the RFSA sets the LNA, DGC and LPA at the up-going and down-going state to form the up-going and down-going RF amplification link via time-sharing. At the donor antenna end, the coupler connects to the RFSA to pickup the up-going and down-going signals as the input of the TSC and DGC. Due to the up-going and down-going links share the amplifier, the volume and cost are reduced.

Owner:北京东方信联无线通信有限公司

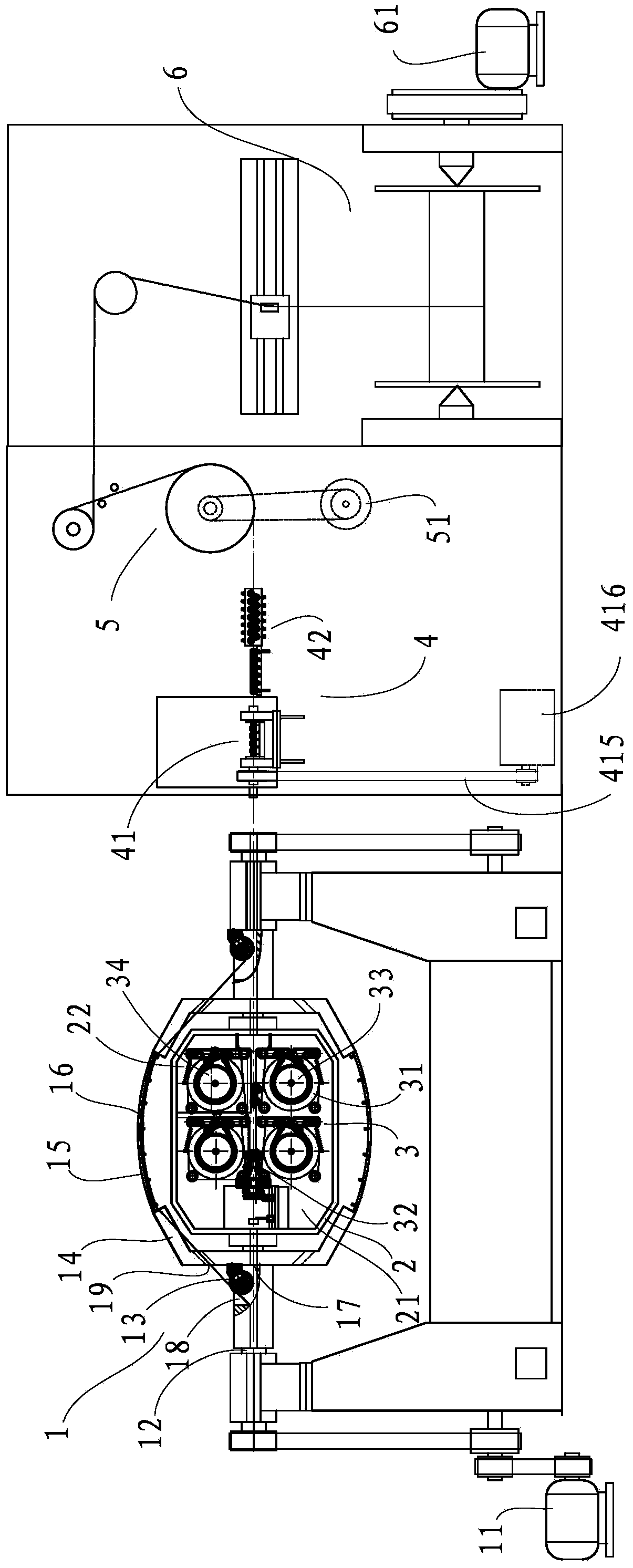

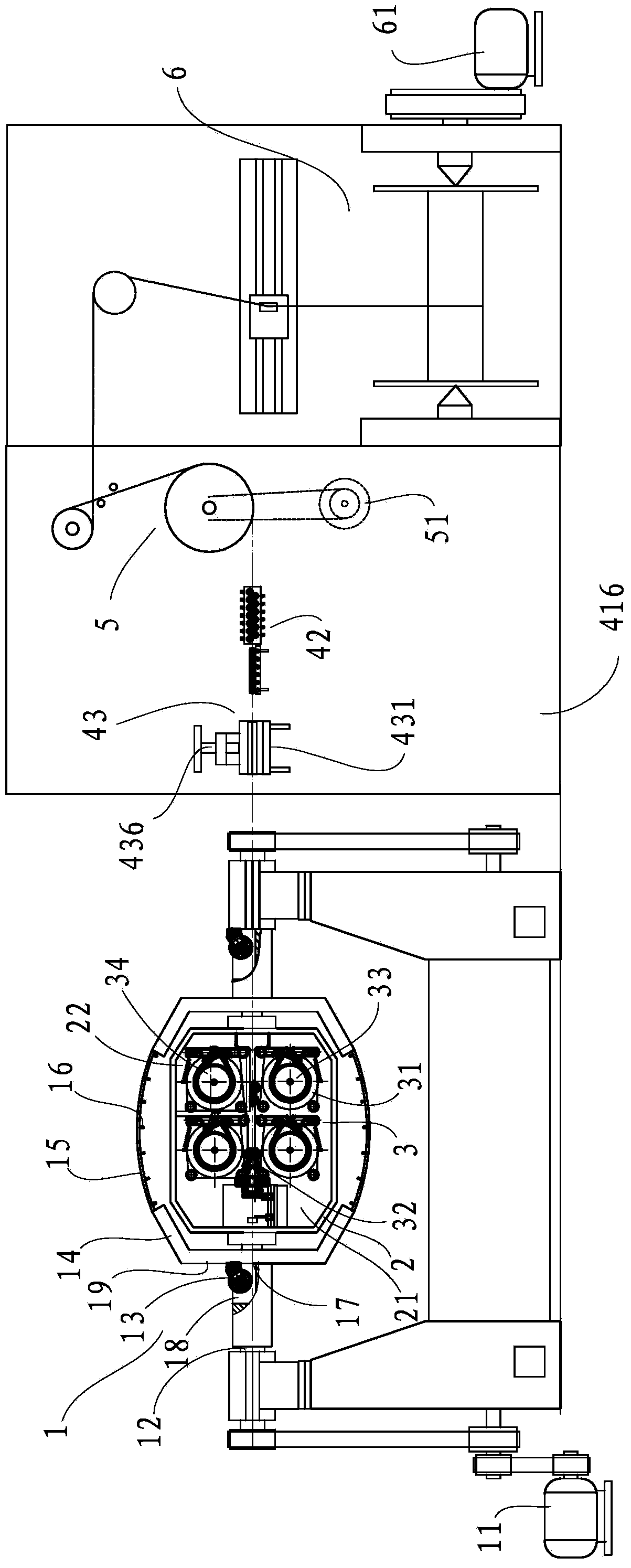

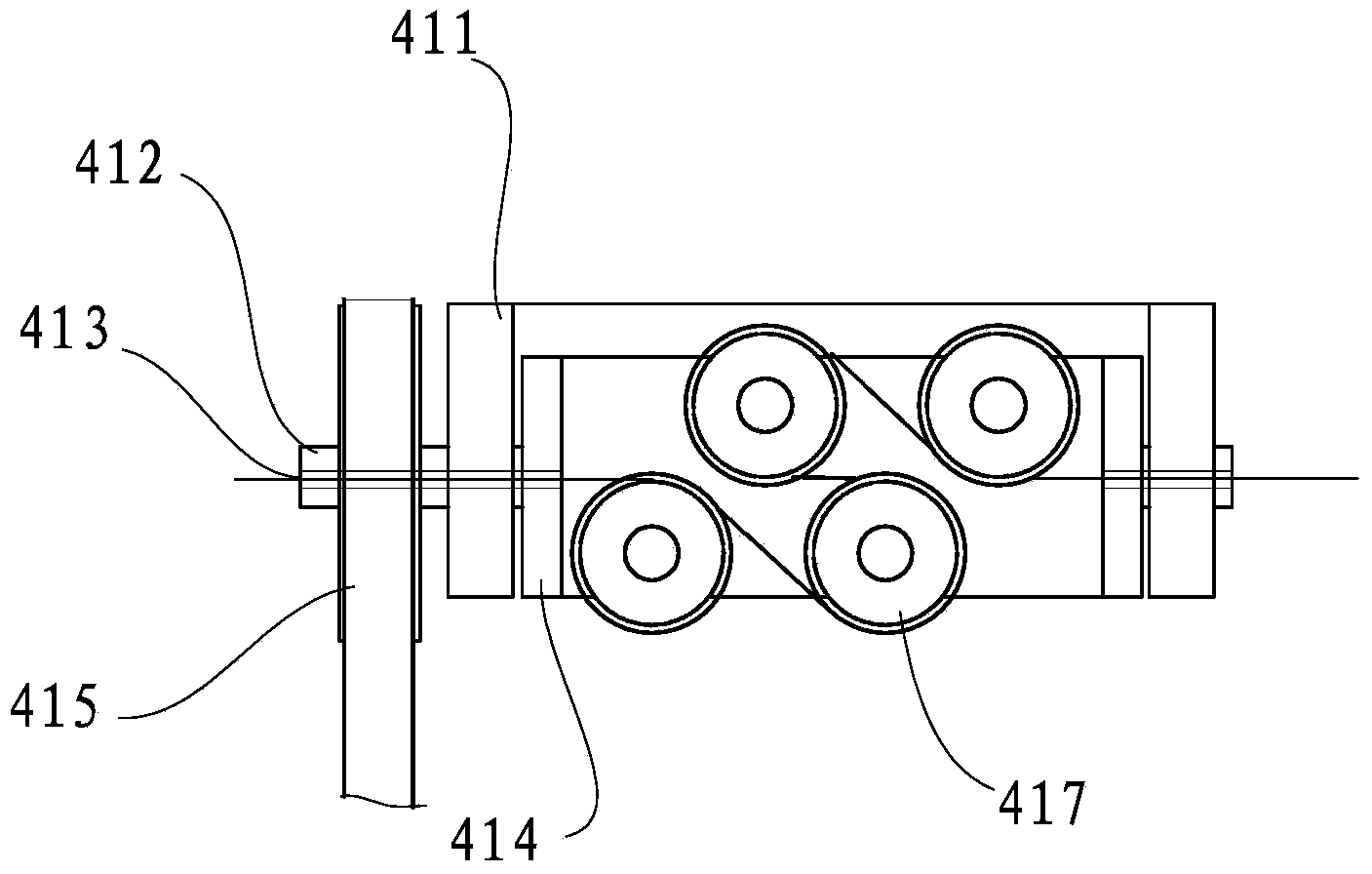

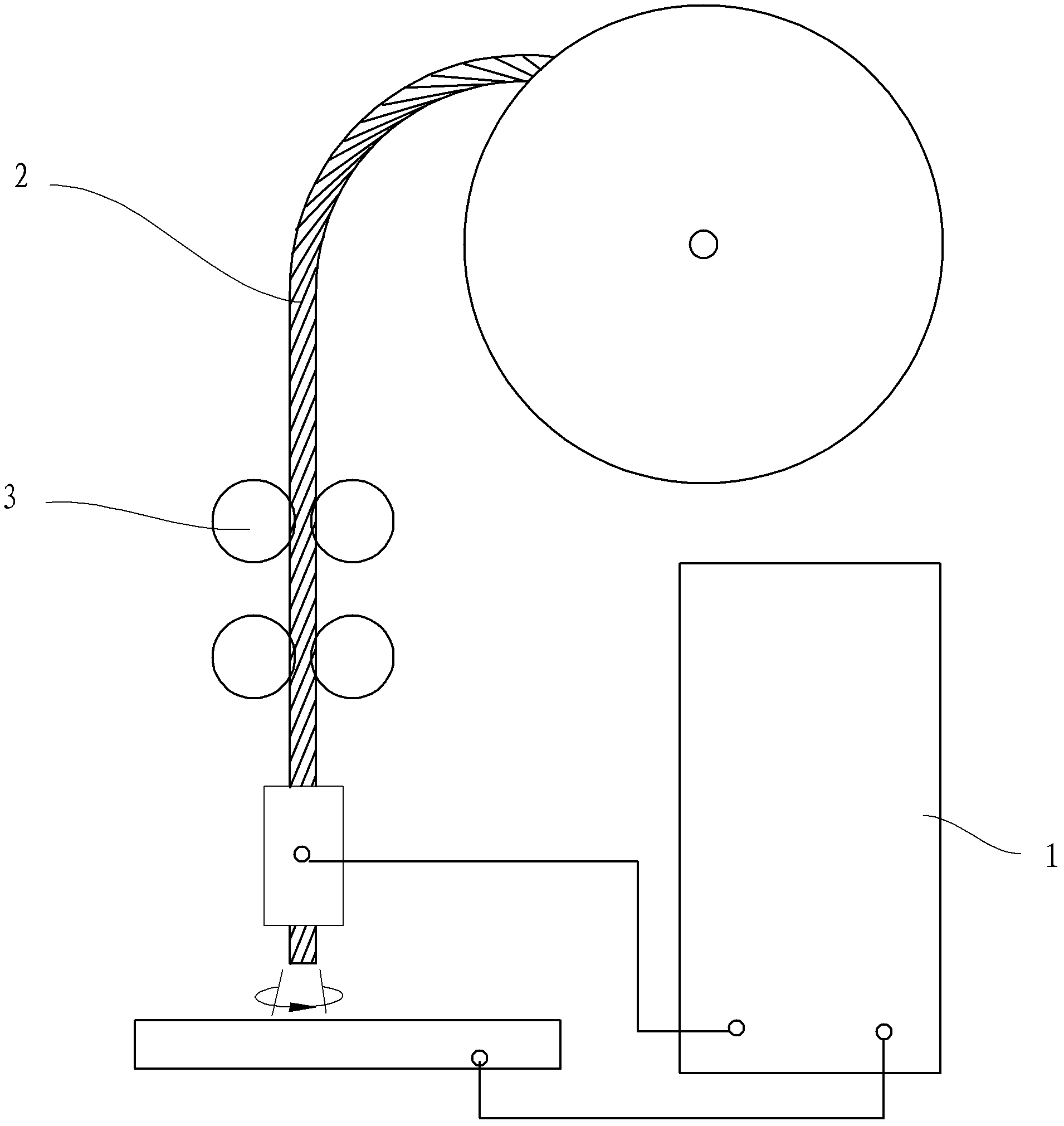

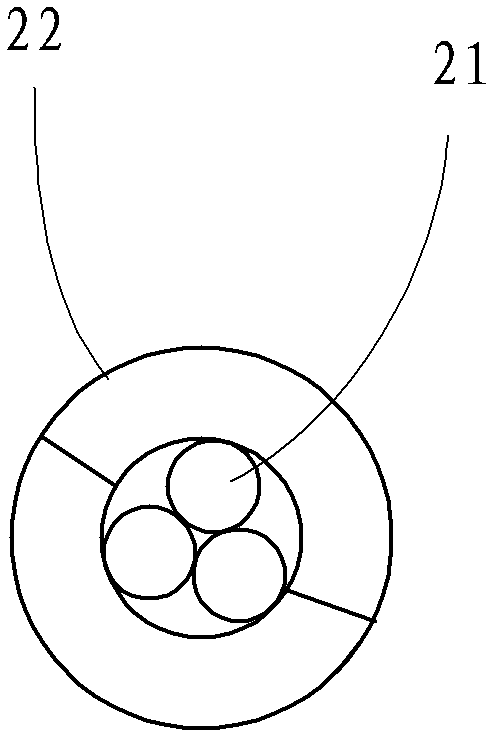

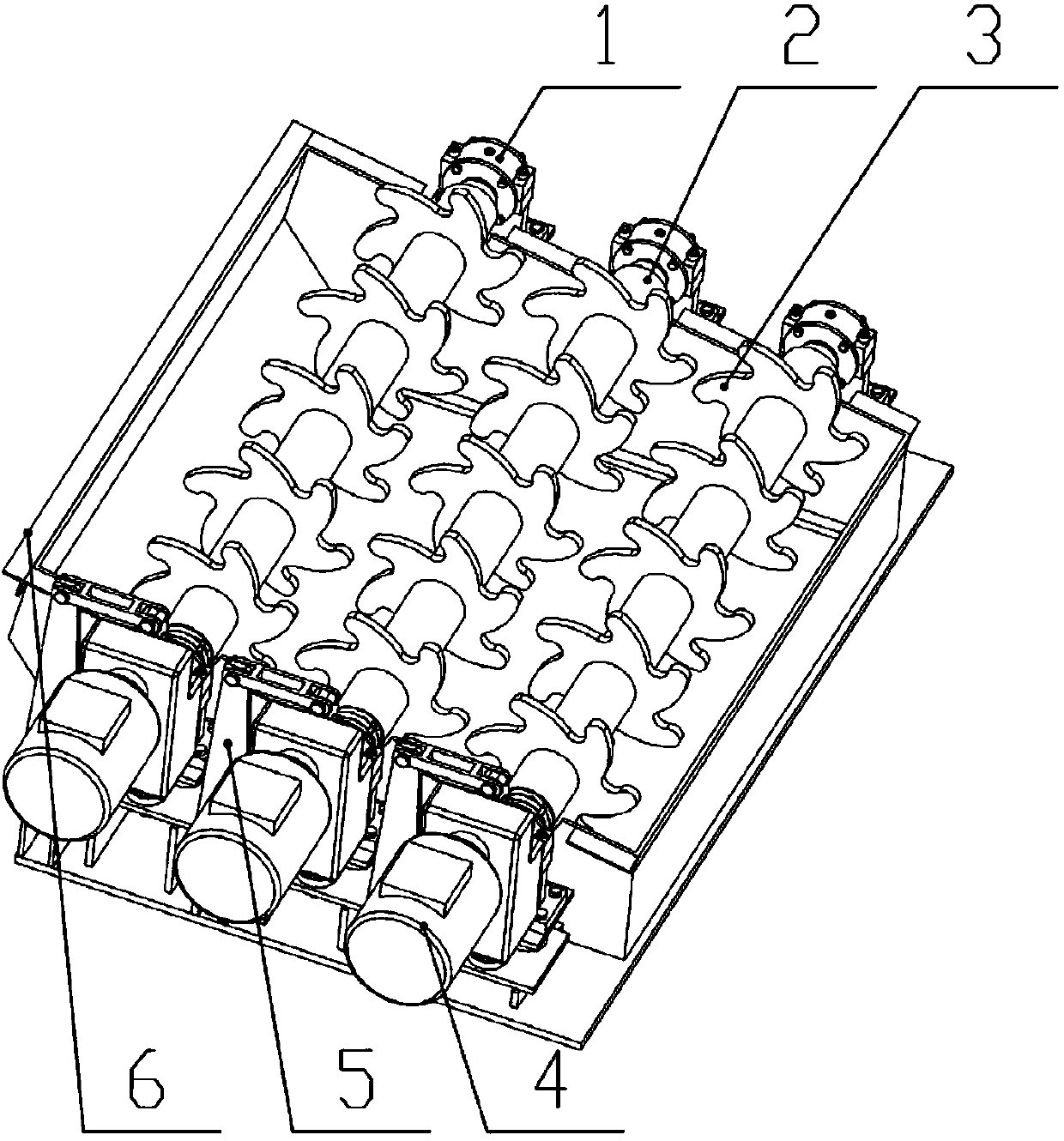

Cable-type welding wire double-twisting stranding machine

InactiveCN103464934ASmall moment of inertiaLow powerWelding/cutting media/materialsSoldering mediaTraction motorRocker arm

The invention relates to a welding wire processing device, particularly to a cable-type welding wire double-twisting stranding machine. The cable-type welding wire double-twisting stranding machine comprises a stranding unit, an unwinding unit, a sizing and stress relieving unit, a traction unit and a winding unit, wherein two main shafts with center holes and side holes of the stranding unit are fixedly provided with two arched rocker arms which are arranged oppositely, the arm ends of the two arched rocker arms which are arranged oppositely are provided with arched belts which are connected with the two arched rocker arms in which threading inclined holes are formed, the inner sides of the arched belts are provided with a plurality of wire through holes, and the stranding unit, the traction unit and the winding unit are respectively driven by a standing motor, a traction motor and a winding motor. The cable-type welding wire double-twisting stranding machine has the advantages of being high in production efficiency and small in vibration noise.

Owner:江苏科为焊业有限公司 +1

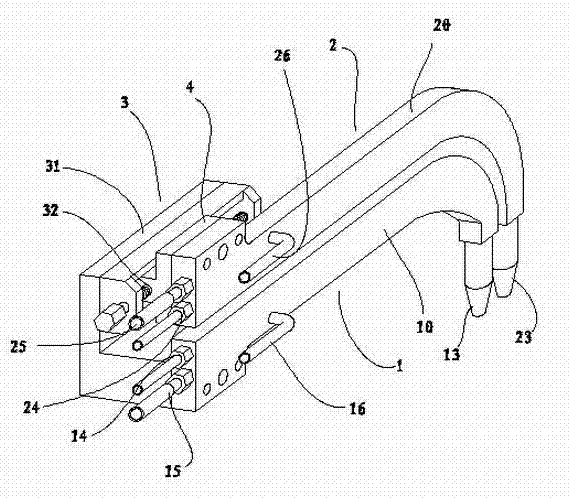

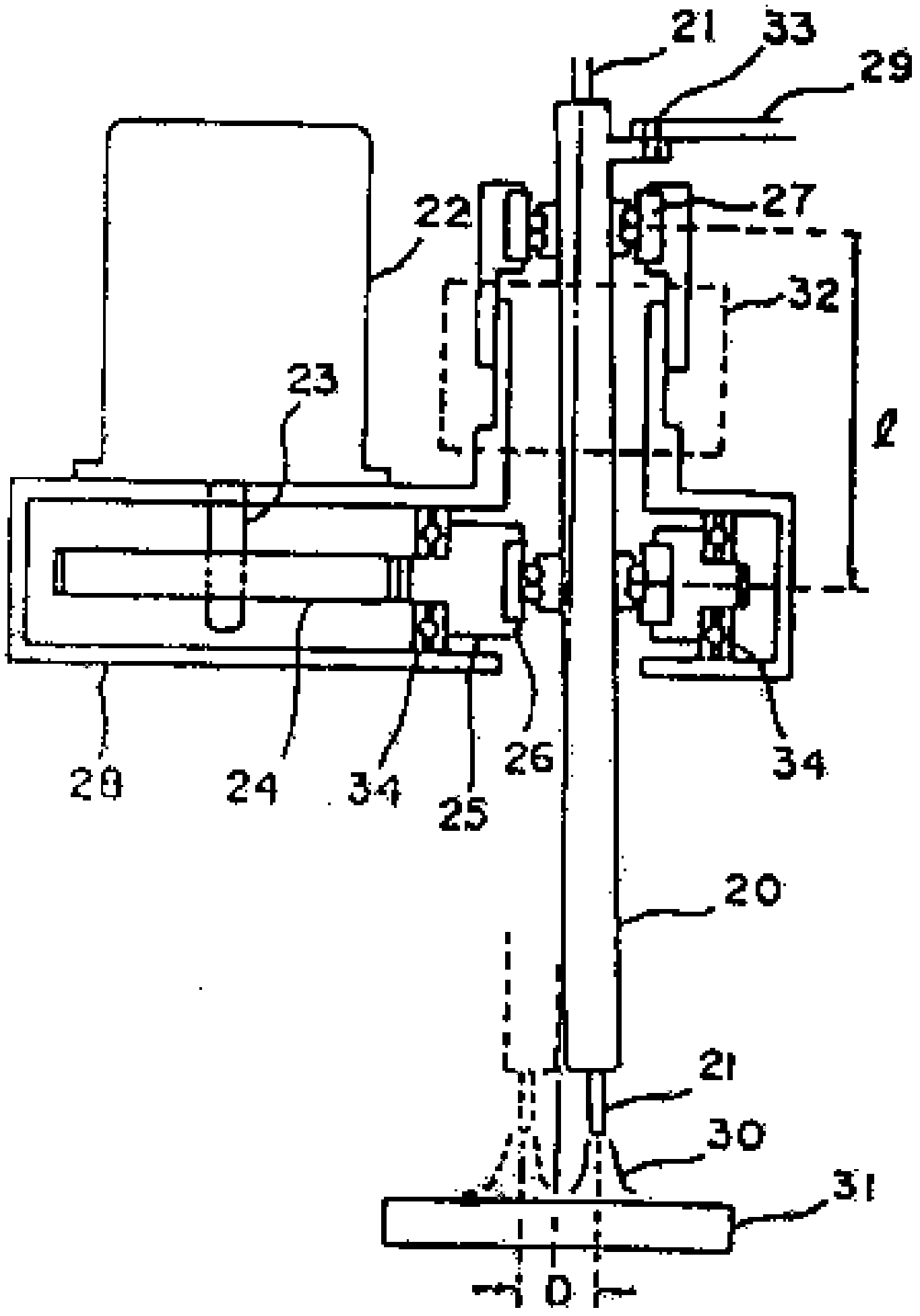

Twin-wire electrogas welding water-cooled welding torch

InactiveCN103071899ASimple structureReduce manufacturing costElectrode supporting devicesWater coolingElectrogas welding

The invention relates to a welding torch for arc welding, in particular to a twin-wire electrogas welding water-cooled welding torch, which comprises a first water-cooled welding torch and a second water-cooled welding torch which are mutually insulated, and an adjusting device for a distance between welding wires. The twin-wire electrogas welding water-cooled welding torch is characterized in that the adjusting device for the distance between the welding wires comprises a substrate and a feed screw nut mechanism arranged on the substrate; the first welding torch is fixed with the substrate; the second welding torch is fixed with a nut of the feed screw nut mechanism through a fixing plate; and the second welding torch is positioned above the first welding torch. The distance between the two welding torches is adjustable, an adjusting range for a welding condition is widened, proper current, voltage, welding speed and distance between the welding wires can be selected according to the thickness and materials of plates to be welded, and high quality welding lines are efficiently completed.

Owner:刘振英

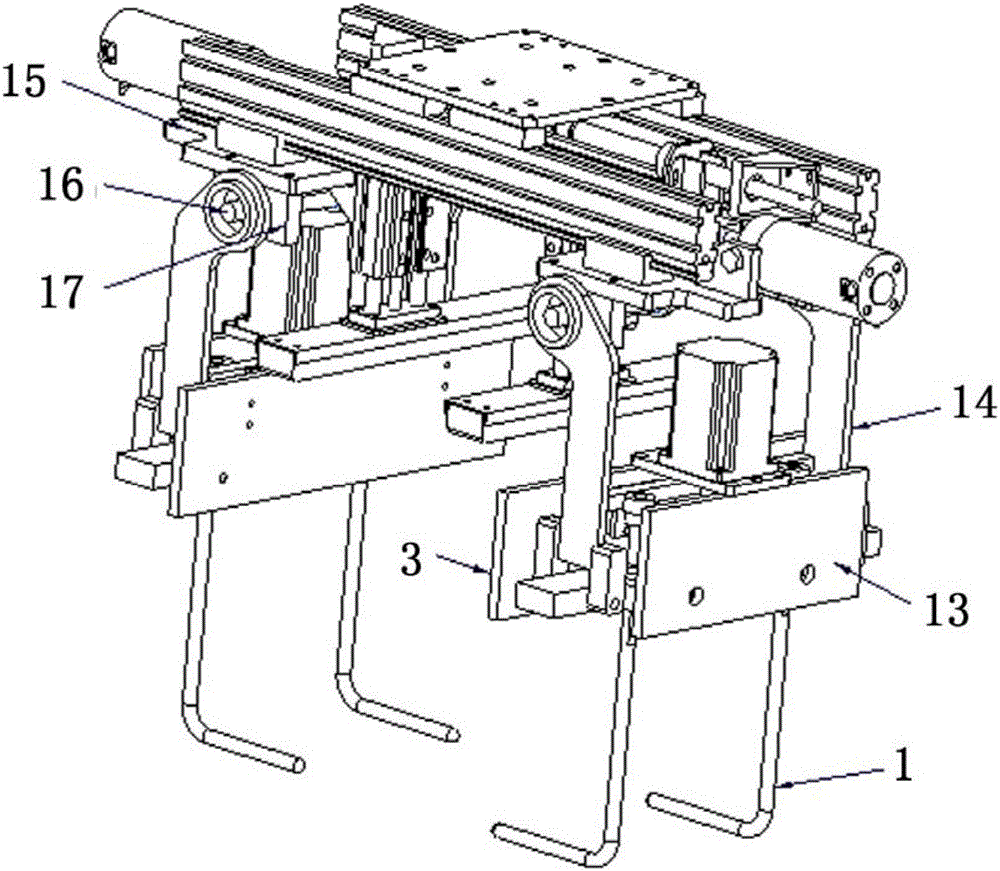

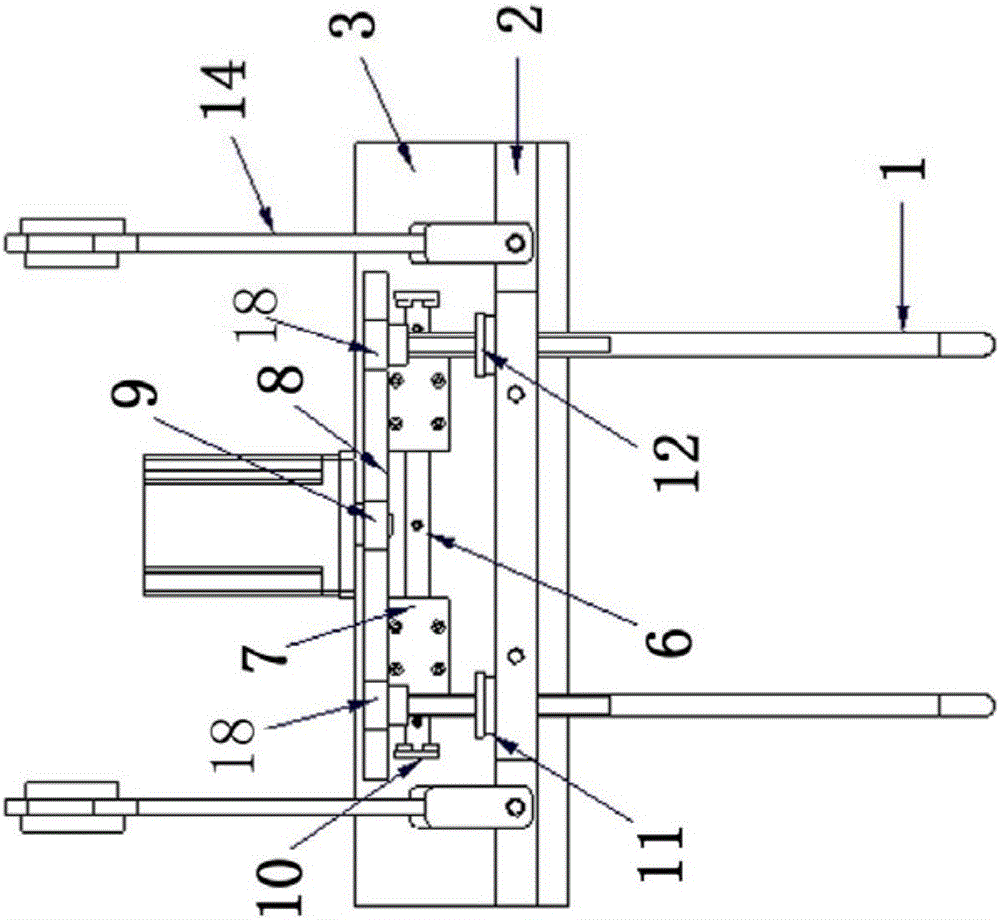

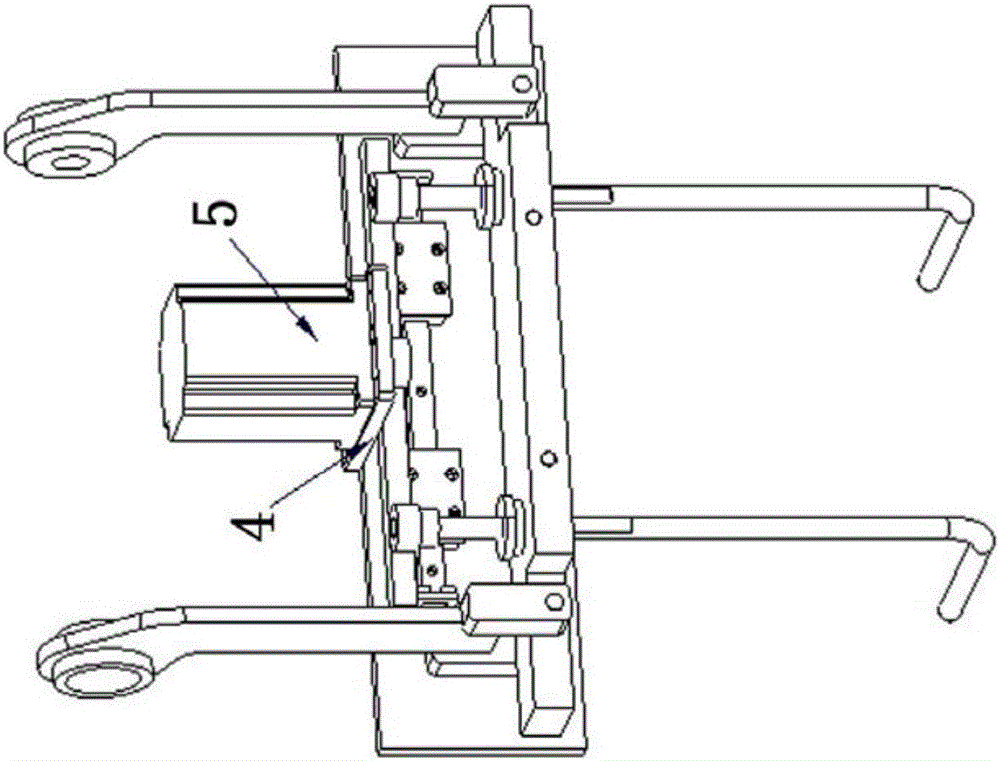

Novel clamp used for palletizing robot

ActiveCN105150230ASimple structureReduce manufacturing costGripping headsMotion spaceMechanical engineering

The invention relates to a novel clamp used for a palletizing robot. The novel clamp is composed of two or more rotating mechanisms and an opening-closing mechanism. The rotating mechanisms are of the same structure and distributed below the two sides of the opening-closing mechanism. Each rotating mechanism is connected with the opening-closing mechanism through a rocking arm. According to the novel clamp, motors, gears, and rack structures of the rotating mechanisms mainly drive tong parts to rotate, so that the palletizing requirements are met in the minimum motion space; obstacles to palletizing are eliminated; the work efficiency is improved.

Owner:中国科学院自动化研究所(洛阳)机器人与智能装备创新研究院

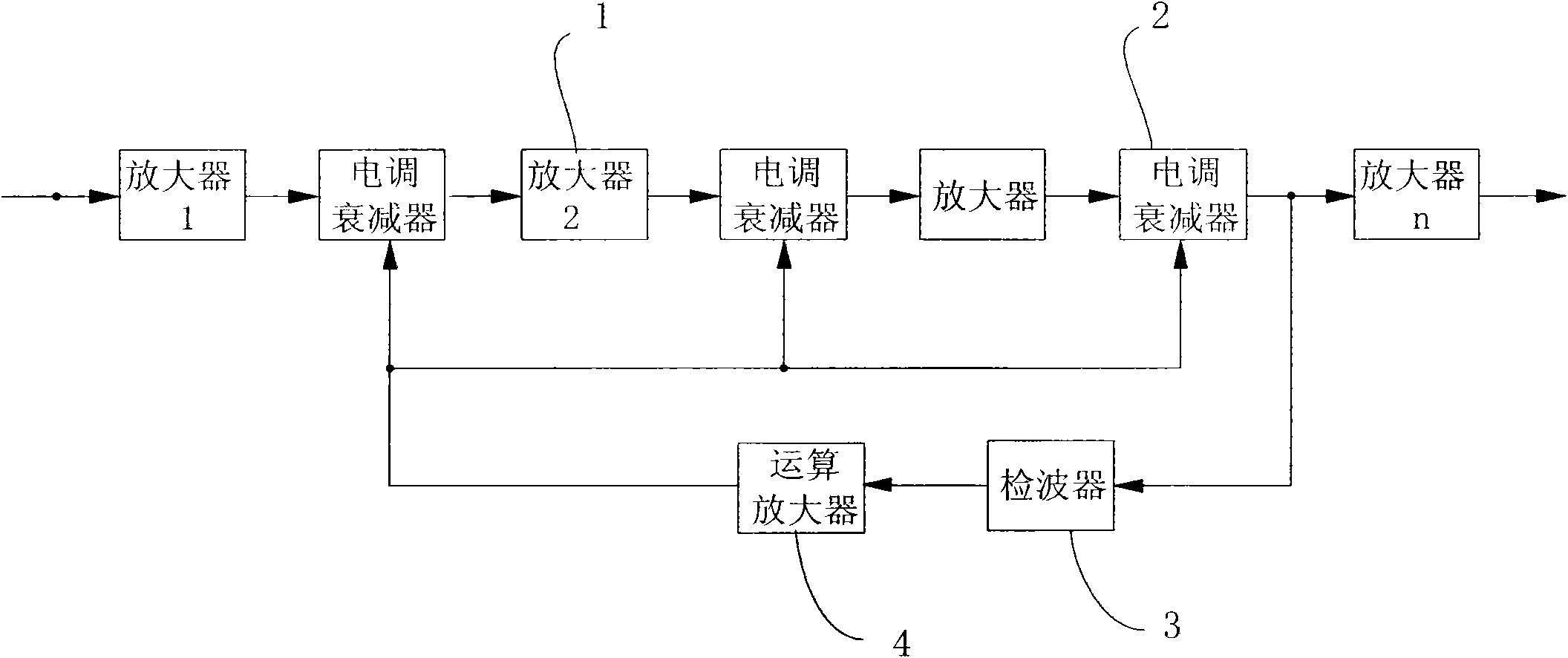

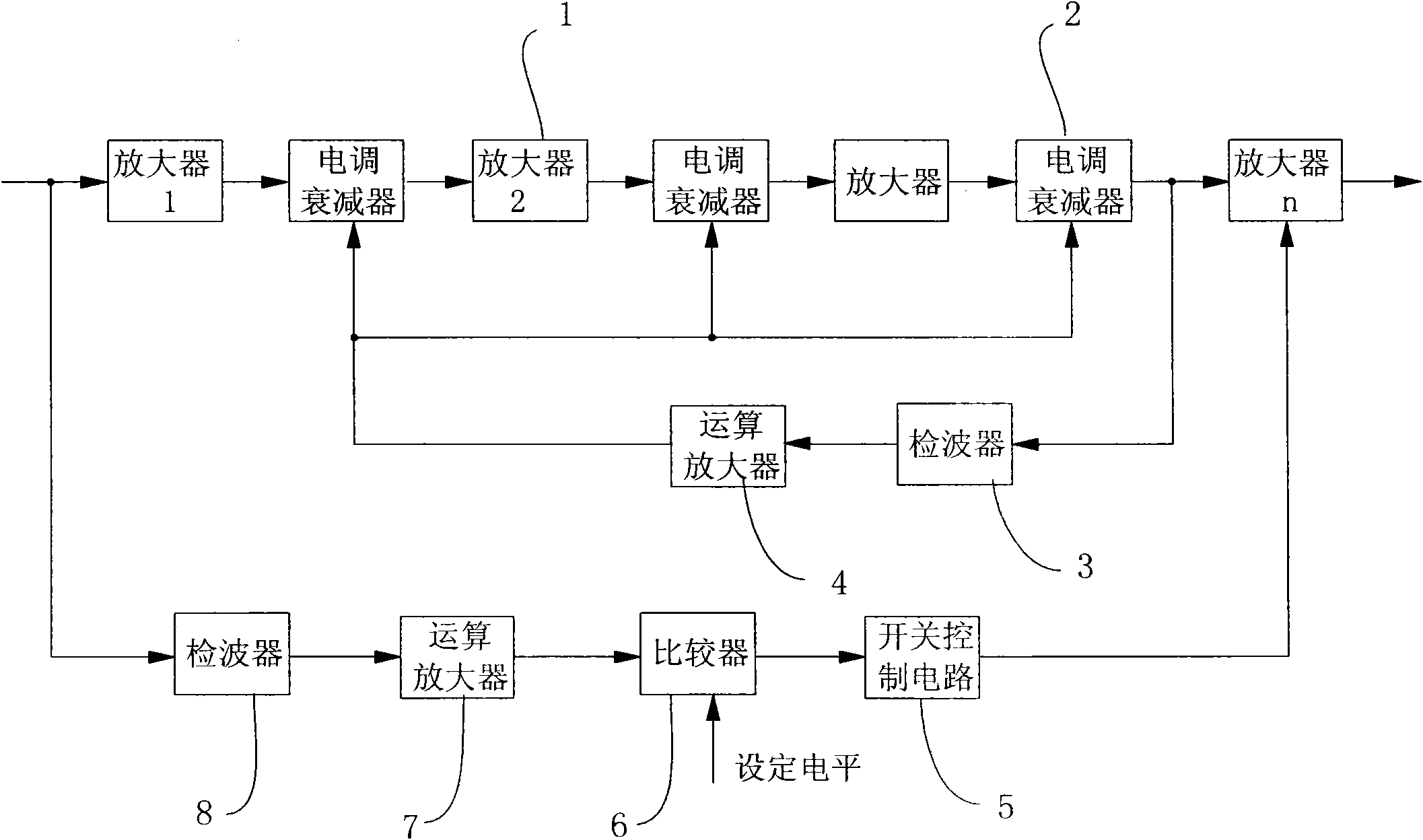

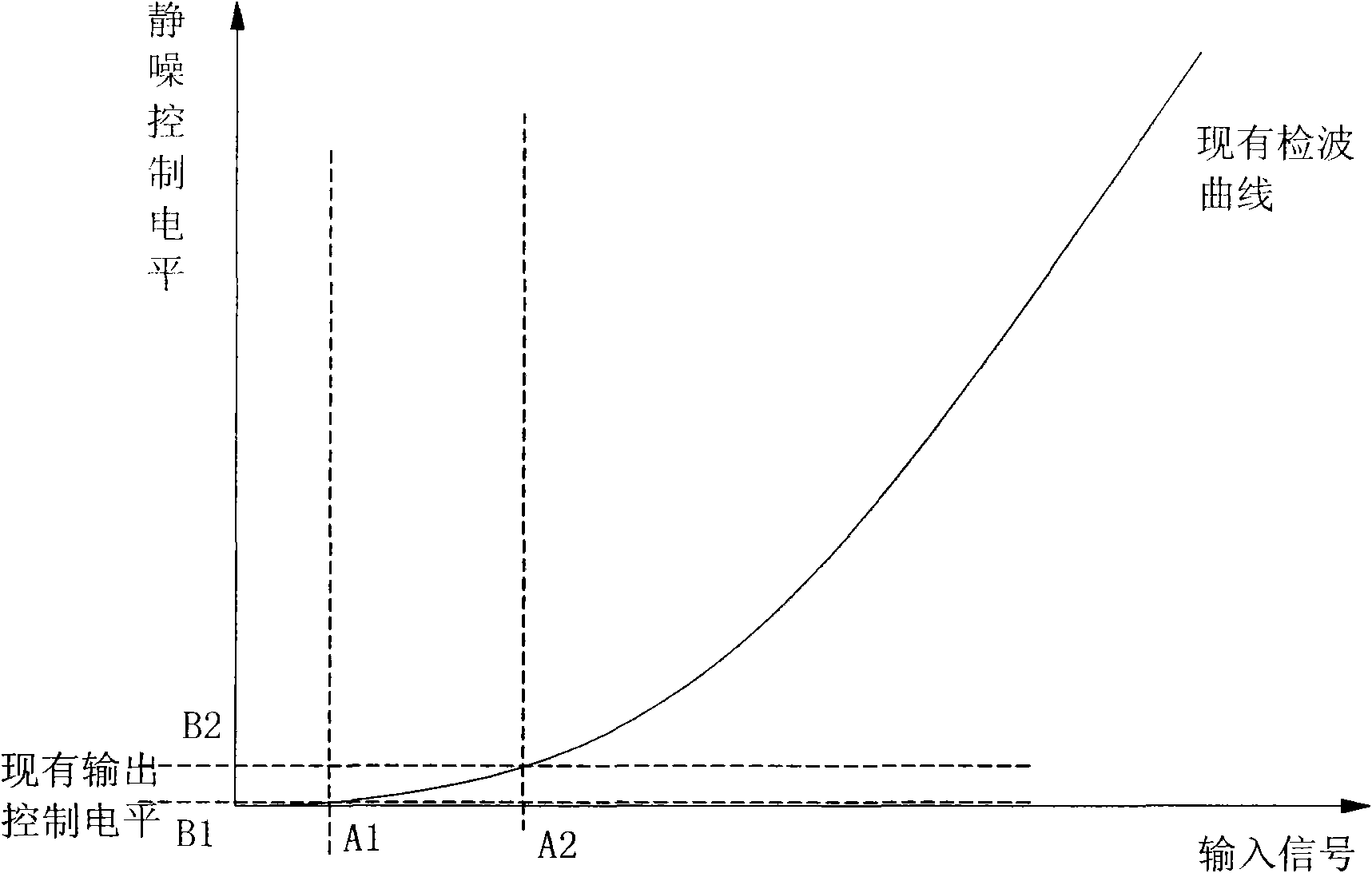

Squelch control method of automatic gain power amplifier chain and circuit

ActiveCN102315826AWidely used valueHas industrial utilization valueGain controlControl signalSoftware engineering

The invention relates to a squelch control circuit, in particular to a squelch control method of an automatic gain power amplifier chain and a circuit. The method comprises the following steps of: (1) sampling an input signal of nth amplifier in the automatic gain power amplifying chain; (2) detecting the input signal into a direct-current voltage signal; (3) carrying out negative feedback amplification on the direct-current voltage signal; (4) comparing the direct-current voltage signal through the negative feedback amplification with a direct-current voltage with preset squelch ratio; and (5) if the direct-current voltage signal is more than or equal to the direct-current voltage with the preset squelch ratio, controlling the power amplifying chain to disconnect; if the direct-current voltage signal is less than the direct-current voltage with the preset squelch ratio, controlling the power amplifying chain to connect. In the invention, a direct-current control signal sent to an electric control attenuator is used as a squelch signal, and a detection circuit does not need to be arranged independently; and since the negative feedback amplification is carried out on the direct-current control signal, a characteristic curve of a detector is justly overturned, so that the problems that a judgment window area of the existing squelch control circuit is too narrow and non-linear are overcome, and the squelch sensitivity is greatly improved.

Owner:BEIJING BBEF SCI & TECH

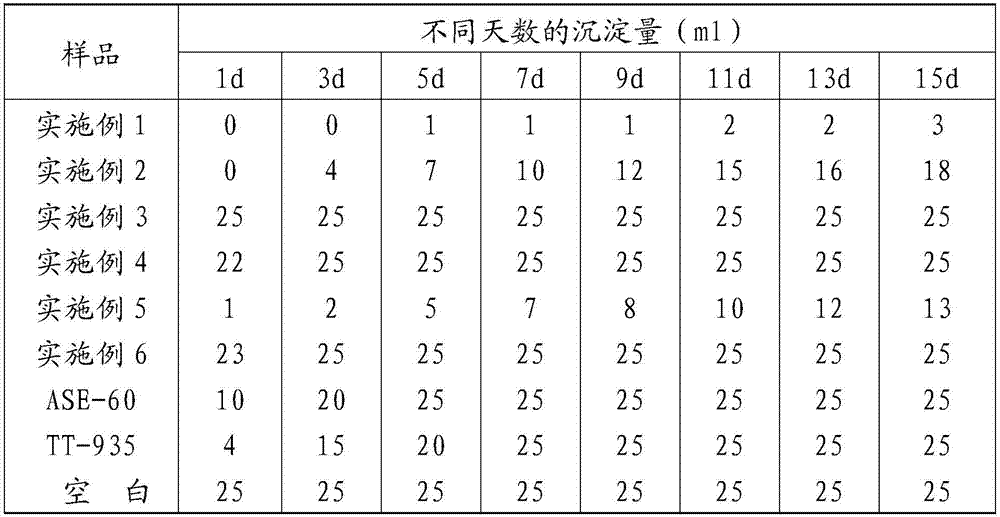

Associative waterborne polyurethane/polyacrylate copolymer emulsion anti-settling thickener

ActiveCN107151478AGood anti-sinking effectSolve the anti-sinking problemCoatingsPolymer chemistryPrecipitation

The invention relates to an associative waterborne polyurethane / polyacrylate copolymer emulsion anti-settling thickener. In the anti-settling thickener, polyacrylate accounts for 70 to 95 percent of the total amount of a resin; polyurethane accounts for 5 to 30 percent of the total amount of the resin; copolymer emulsion is 10 to 1,000nm in particle size, 10 to 60 percent in solid content, 10 to 60mPa.s in viscosity, 2 to 5 in pH value and 10,000 to 200,000 in molecular weight; a waterborne polyurethane chain segment contains a negative-ion hydrophilic group or has a better effect when containing negative-ion and nonionic hydrophilic groups at the same time. The novel associative waterborne polyurethane / polyacrylate copolymer emulsion anti-settling thickener is obtained through copolymerization of the polyurethane and the polyacrylate. By adopting the anti-settling thickener, the problem of precipitation due to adding of inorganic or organic filler in re-diluted waterborne industrial coatings or certain lower-viscosity waterborne systems can be solved effectively, and a long-term anti-settling effect is achieved.

Owner:LUOYANG SHENGJIA CHEM CO LTD

Multi-wire rotating arc welding

InactiveCN102615391AWidely used valueImprove deposition efficiencyArc welding apparatusWelding/cutting media/materialsMetal alloyMolten bath

The invention relates to an arc welding, in particular to a multi-wire rotating arc welding, which is a rotating arc welding utilizing welding wires wound in a certain helical angle, automatically formed in the welding process and having stirring effects on a molten bath. The multi-wire rotating arc welding not only improves welding melting efficiency but also enables welding line metal alloy to be even in component, and grain refinement is achieved.

Owner:时振

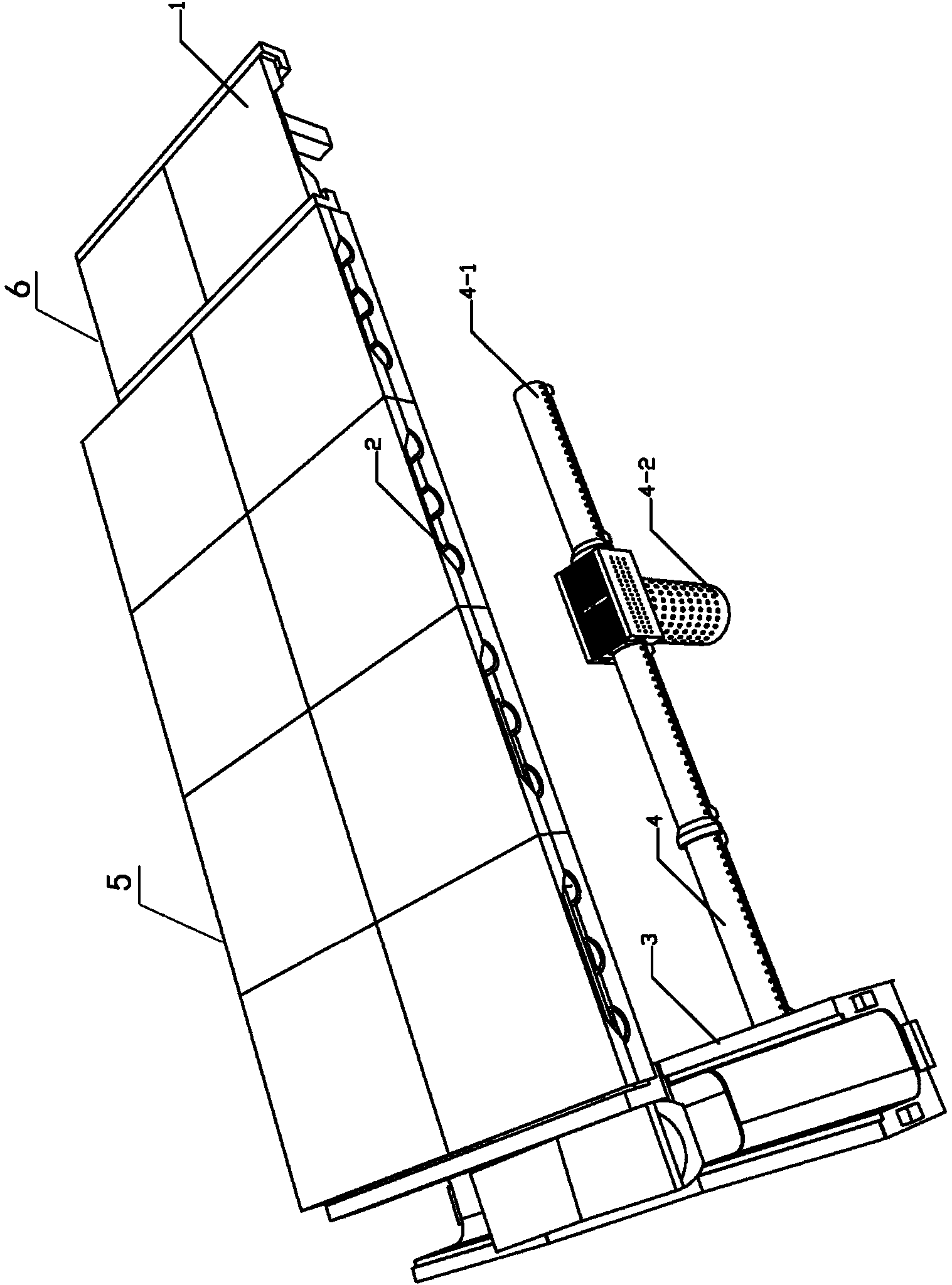

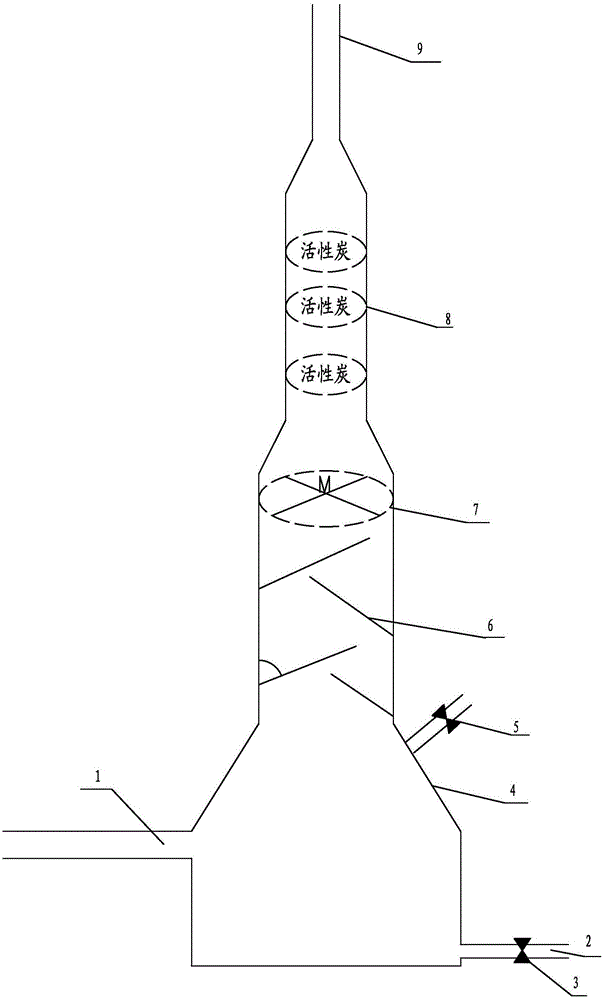

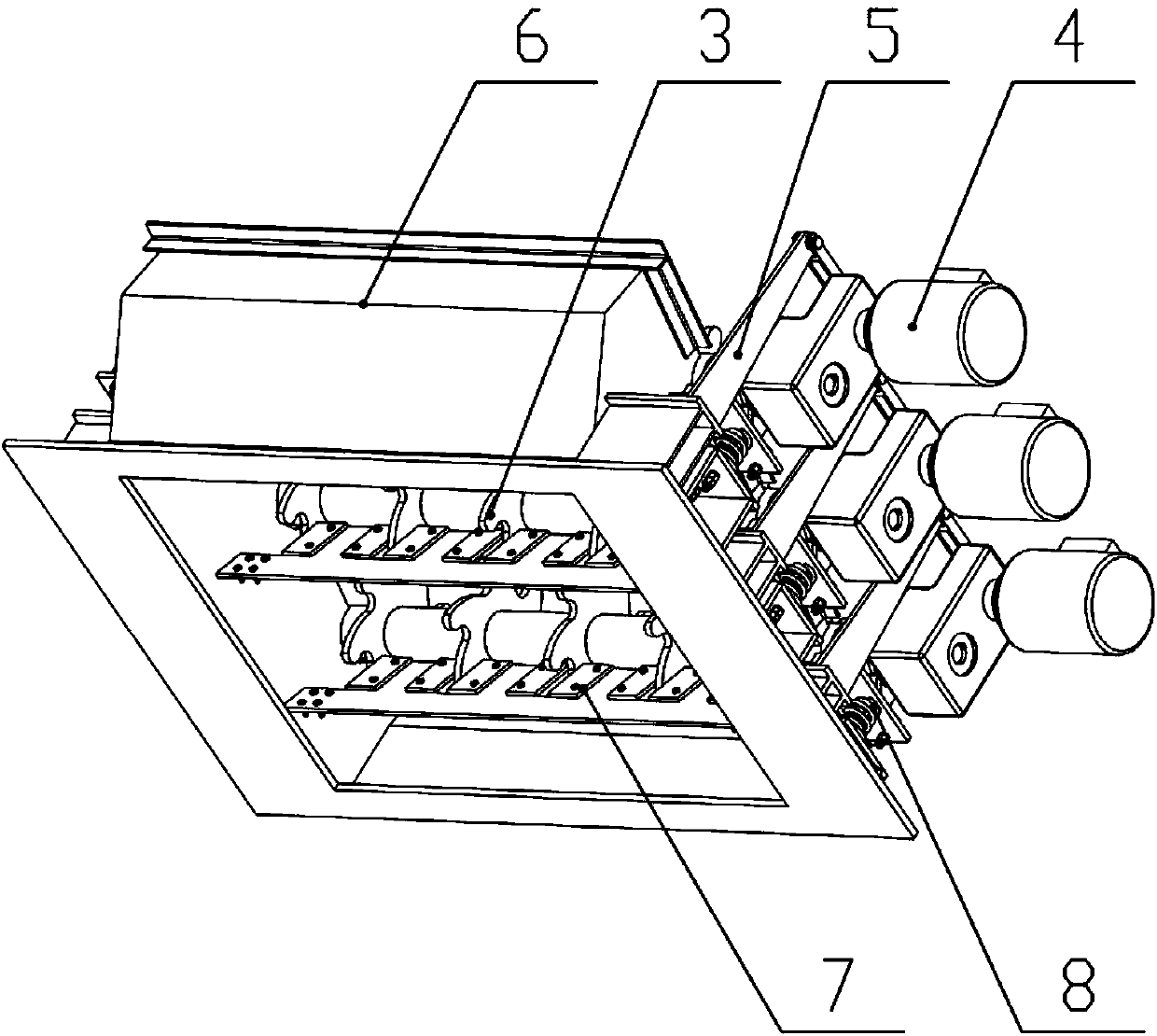

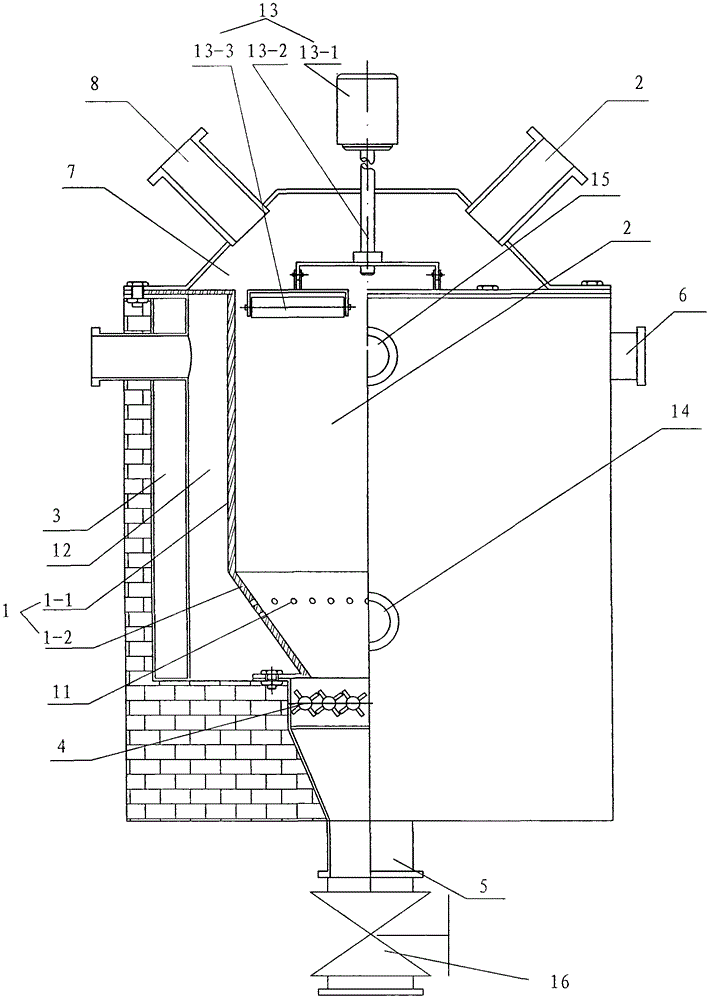

Centralized processing device of phenol-containing waste gas and sulfur-containing waste gas, and processing method

InactiveCN105107337AImprove processing efficiencySolve the emission problemDispersed particle separationAtmospheric airPhenol

The invention discloses a centralized processing device of phenol-containing waste gas and sulfur-containing waste gas, and processing method, and belongs to the field of environmental protection waste gas treatment. The centralized processing device comprises a waste gas inlet (1), a discharge pipe (2), a valve (3), a gas-collecting hood (4), a negative pressure adjustment valve (5), buffer boards (6), an exhaust pump (7), active carbon absorption layers (8), and a chimney (9). According to the processing method, waste gas is delivered upward through the buffer boards (6), after collision and bump with the buffer boards, tar and water are separated, flow automatically into the bottom of the gas-collecting hood (4), and are discharged via the discharge pipe (2); separated gas is subjected to absorption and purification by the active carbon absorption layers (8), and then is discharged into the atmosphere via the chimney (9). The centralized processing device and the processing method are capable of solving emission problems of phenol waste water or sulfur-containing waste gas generated in coal gas production processes, working environment of workers is improved, and pollution on the atmosphere is reduced.

Owner:洛阳三信石化设备有限公司

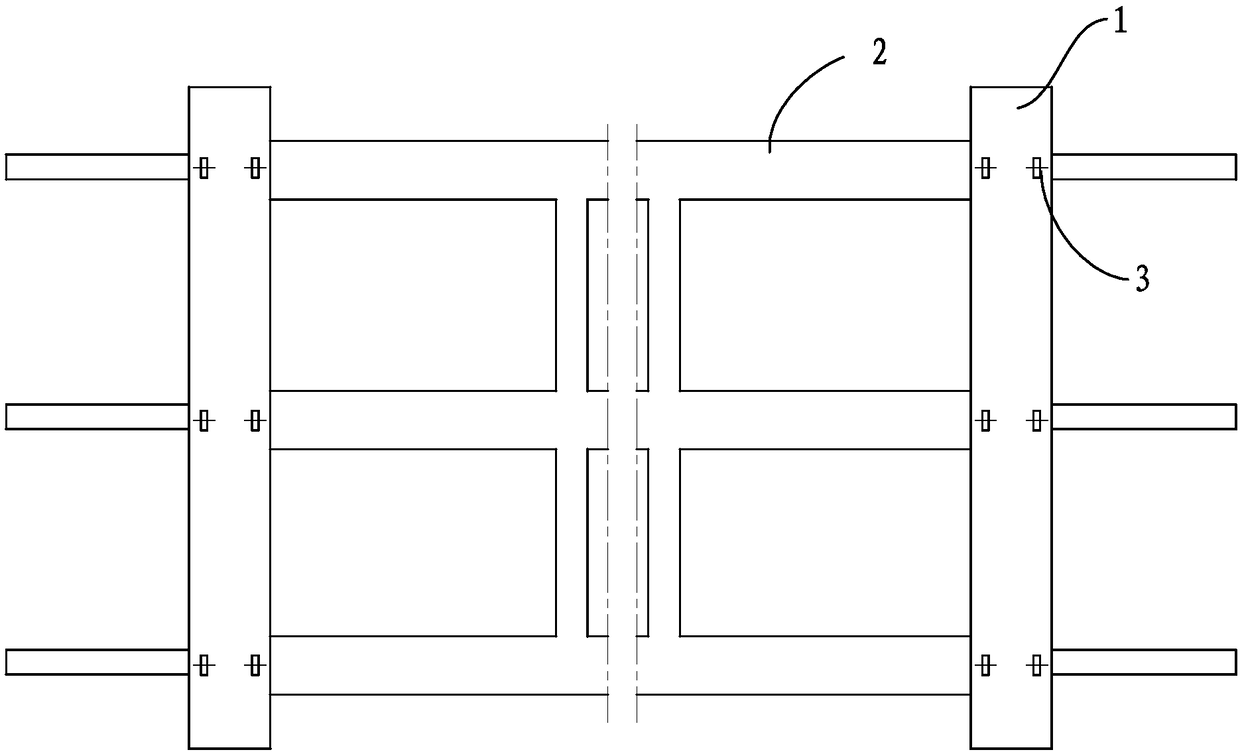

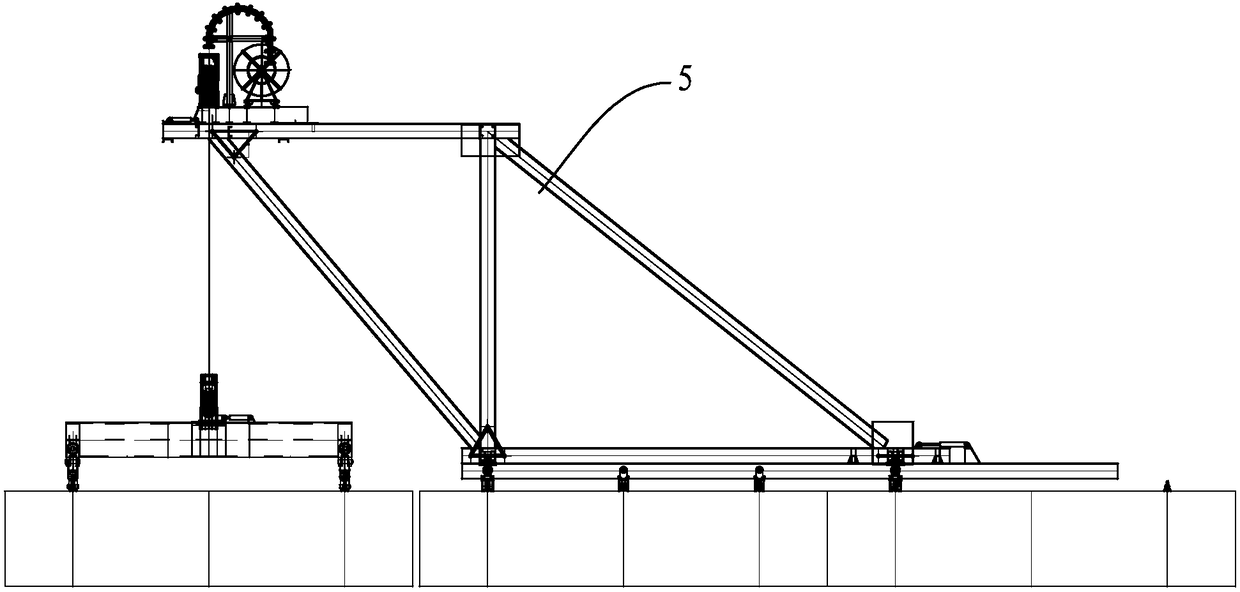

Cable-mounted deck derrick crane

The invention belongs to the field of bridge engineering and particularly relates to a cable-mounted deck derrick crane applicable to large-span stay cable steel-concrete composite girder bridge construction. The deck derrick crane comprises two main trusses, a plurality of connecting rods connecting the two main trusses, an anchoring device, a traveling device and hydraulic lifting systems, wherein each main truss comprises inner rhombic truss pieces and outer rhombic truss pieces which are symmetrical relative the corresponding stay cable central line vertically arranged above main longitudinal beam lifting lugs, the rhombic truss pieces are in parallel bolt connection through profile steel, the two hydraulic lifting systems are arranged at the tops of the rhombus tips of the main trusses, and bridge deck slab cranes are arranged on the upper-cord beams of the inner rhombic truss pieces of the two main trusses.

Owner:ROAD & BRIDGE INT

Modified vermiculite adsorbent

InactiveCN106000282AFairly technologically advancedQuite practicalOther chemical processesWater contaminantsPhosphoric acidWastewater

The invention relates to a modified vermiculite adsorbent. Vermiculite is taken as the base adsorbent, vermiculite is modified by soaking in phosphoric acid, the soaked vermiculite is then activated with microwave so as to obtain the modified vermiculite adsorbent. The mass fraction of the phosphoric acid is 40%-60%, the microwave activation conditions include microwave power of 500W-800W and a microwave time of 3min-6min. The adsorbent can reach a removal rate of over 90% on mercury in wastewater, also the preparation method is simple and the cost is low, therefore the modified vermiculite adsorbent is an efficient and cheap mineral adsorbent.

Owner:洛阳新巨能高热技术有限公司

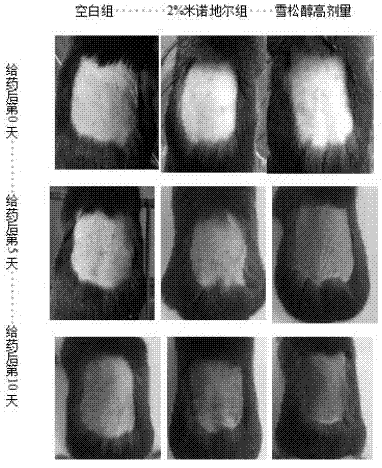

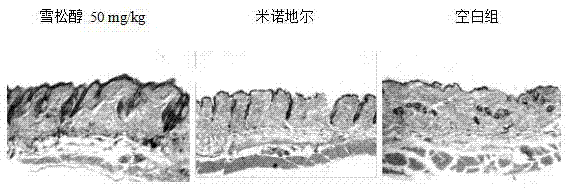

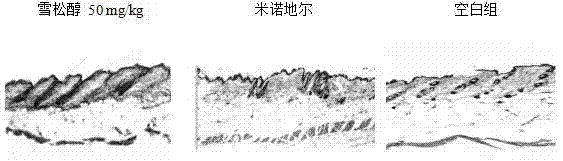

Application of cedrol and cedrol derivatives to preparation of drugs for promoting hair growth and relieving hair loss

ActiveCN107260710APromote growthMeet needsCosmetic preparationsHair cosmeticsSide effectNatural product

The invention relates to the technical field of natural products, in particular to an application of cedrol and cedrol derivatives or salts to preparation of drugs for promoting hair growth and relieving hair loss. A test result shows that cedrol can promote hair of a normally unhairing mouse to grow and can effectively relieve unhairing symptoms of the mouse after chemotherapy and safety of drug use is proved. When cedrol is subjected to transdermal administration with a daily dose of 100 mg / kg-400 mg / kg, the hair growing effect is remarkably better than that of a hair growing drug minoxidil which is approved by FDA (Food and Drug Administration) and has appeared on the market of China; when cedrol is subjected to administration with a daily dose of 50 mg / kg-200 mg / kg, the unhairing symptoms can be relieved, and the effect is obvious when compared with that of a blank control group. Cedrol not only has the effects of promoting hair growth and preventing hair loss after chemotherapy, but also has the advantages of being prepared from easily available raw materials, natural, non-irritant and the like, and can be taken as a substitute product of a hair growth medicine with high cost or side effects and a product for preventing hair loss and promoting hair growth. According to the invention, demands of people for hair loss preventing drugs can be met, and troubles of people due to hair loss are eliminated.

Owner:辽宁新中现代医药有限公司

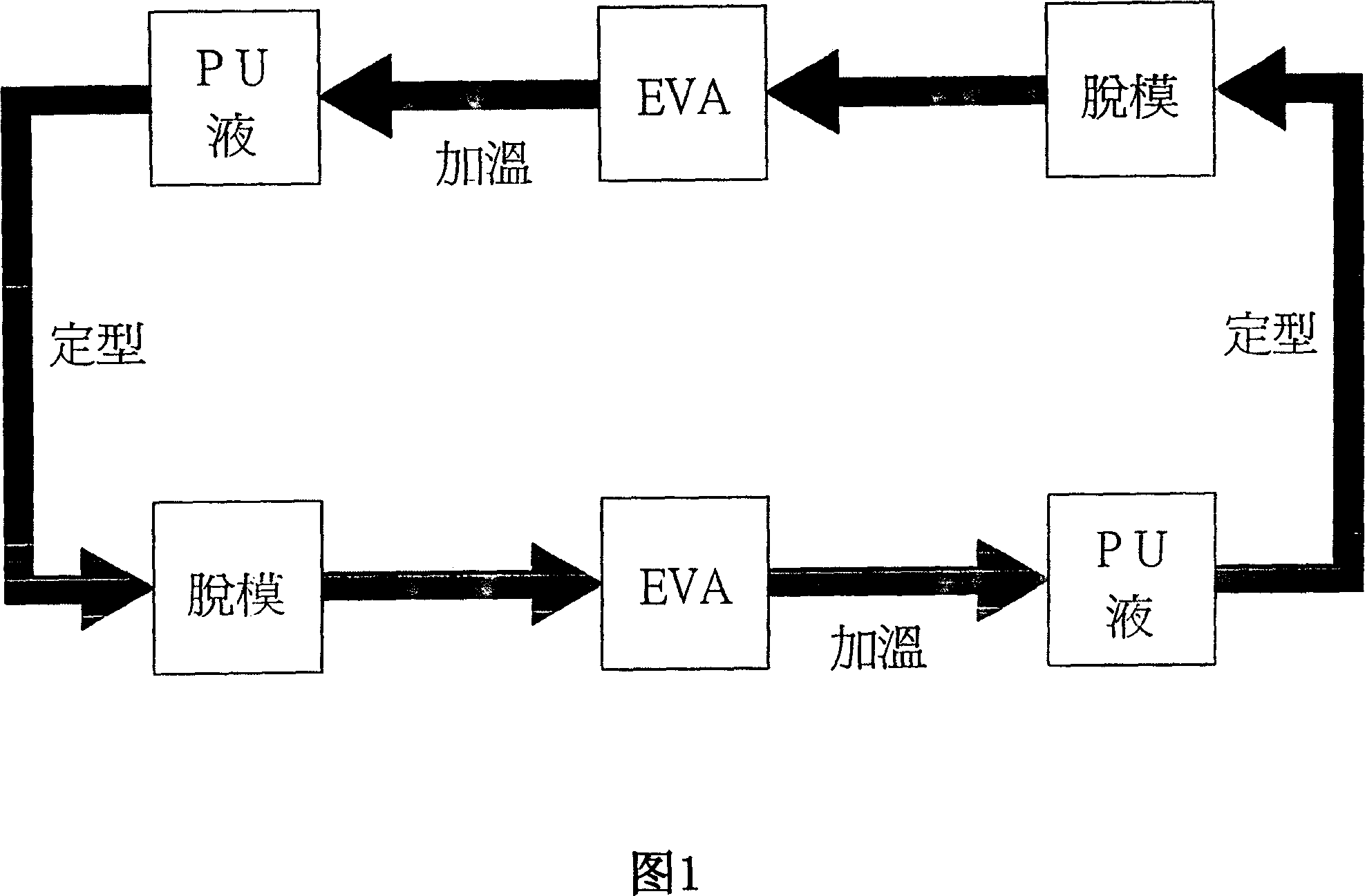

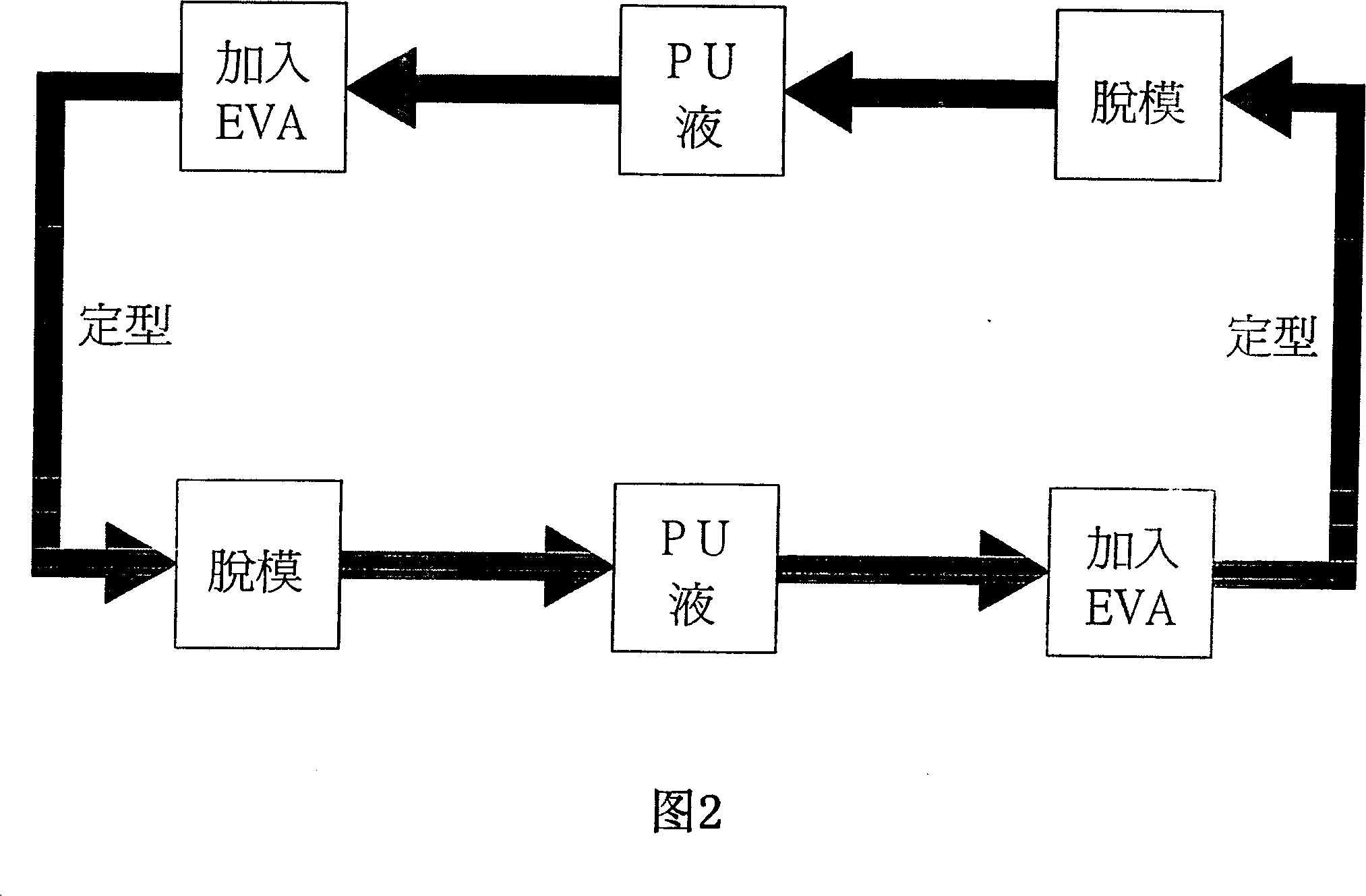

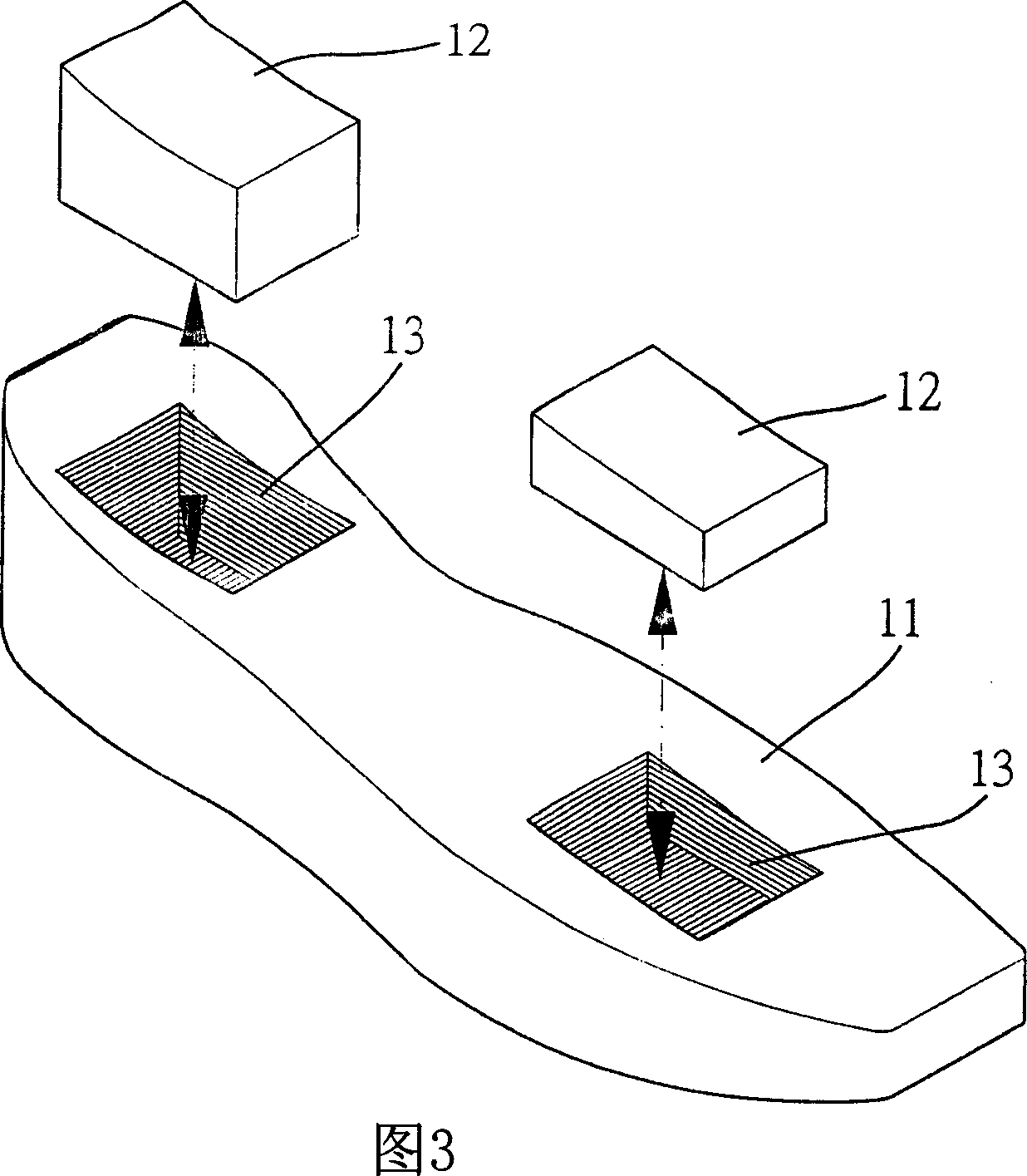

Manufacturing method of combined type middle sole

The invention discloses a making method of bottom of EVA and PU material in the built-up formula, which comprises the following steps: placing a preset EVA material in the mould; setting several course flutes on the material; coating PU glue in the flute; heating to 50-60 deg.c; pouring liquid PU material; heating to solidifying PU; stripping; obtaining the product.

Owner:杨国男

Method for preparing adsorbent with modified wheat straws

The invention provides a method for preparing an adsorbent with modified wheat straws. The agricultural by-product wheat straws is effectively utilized, the wheat straws are chemically modified by using epoxy chloropropane and diethylenetriamine, the adsorptive property of the modified wheat straws is greatly improved, and the modified wheat straws become a cheap, easy-to-obtain and efficient wastewater adsorbent. The method is widely used for industrial wastewater treatment, the costs for wastewater treatment of enterprises are reduced, waste is utilized, the environment is protected, and the method has great economic benefits and environmental benefits.

Owner:洛阳新巨能高热技术有限公司

Wheel pair intelligent cleaning and paint removing device

PendingCN109107962AFlexibleImprove flexibilityDirt cleaningCleaning using liquidsElectrical controlSewage treatment

The invention discloses a wheel pair intelligent cleaning and paint removing device. The device comprises a wheel feeding mechanism, a wheel discharging mechanism, a wheel rotating mechanism, a stop mechanism, a cleaning and paint removing machine nozzle, a cleaning machine nozzle, a mechanical arm and an electric control system. The mechanical arm is adopted to carry with the cleaning and paint removing machine nozzle, so that the actions are flexible, the flexibility is high, the cleaning and paint removing operation for rail traffic vehicles such as all domestic bullet trains, locomotives and metros can be met, and the application range is wide. The height and the transverse deviation of wheel pairs are detected through sensors, and the coordinate space position compensation of the mechanical arm is automatically performed, so that the intelligence of the cleaning and paint removing process is realized, and the working efficiency is improved. Particles dissoluble in water can be adopted as a paint removing agent, so that the operation is environment-friendly, and the health of operators is facilitated. Dust generated in the cleaning and paint removing operation is removed by a ventilation and dust removing system, so that the environment is protected, and the flying dust pollution cannot occur. A sewage treatment system is adopted without causing the water pollution.

Owner:天津远程华瑞工业技术有限公司 +1

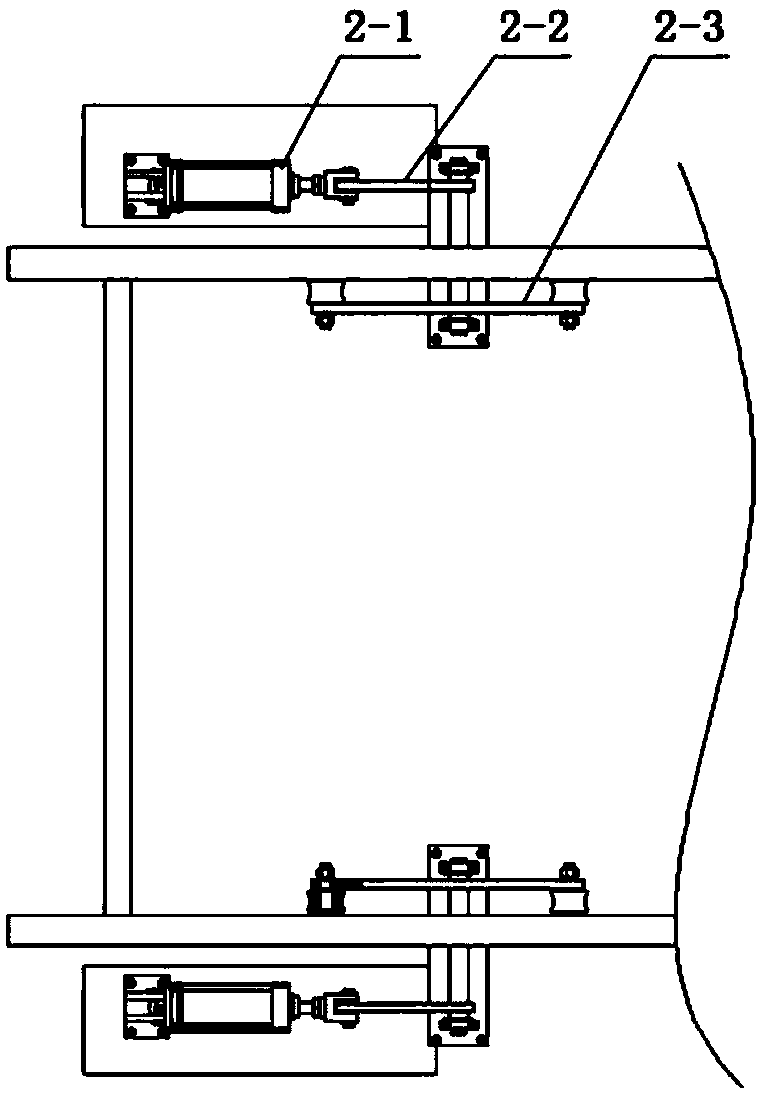

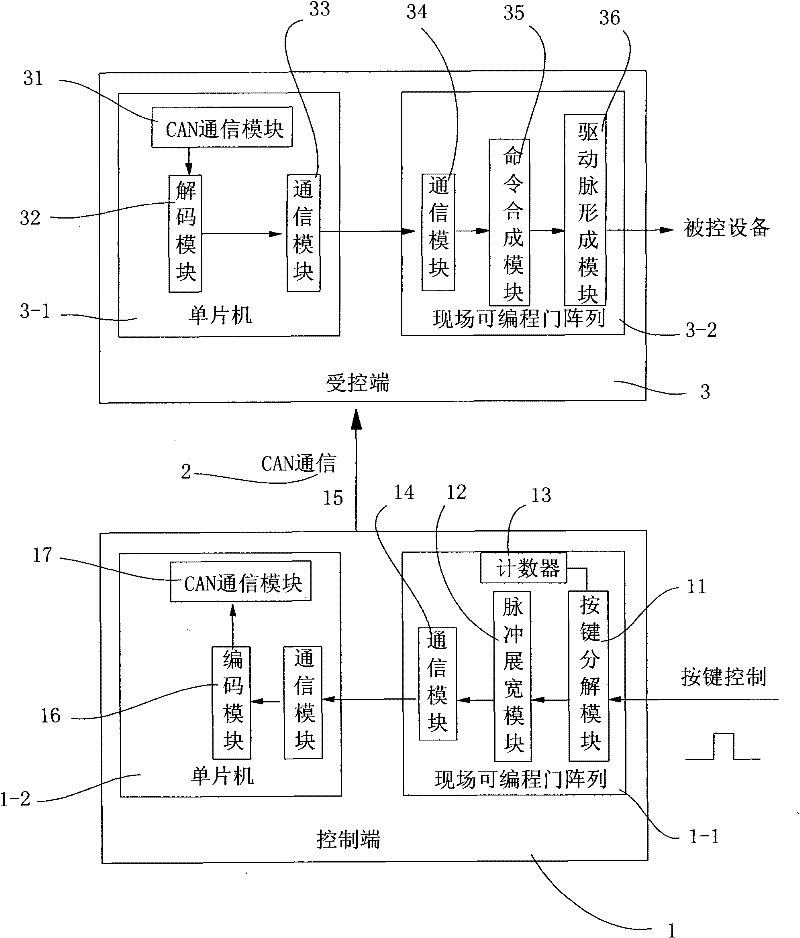

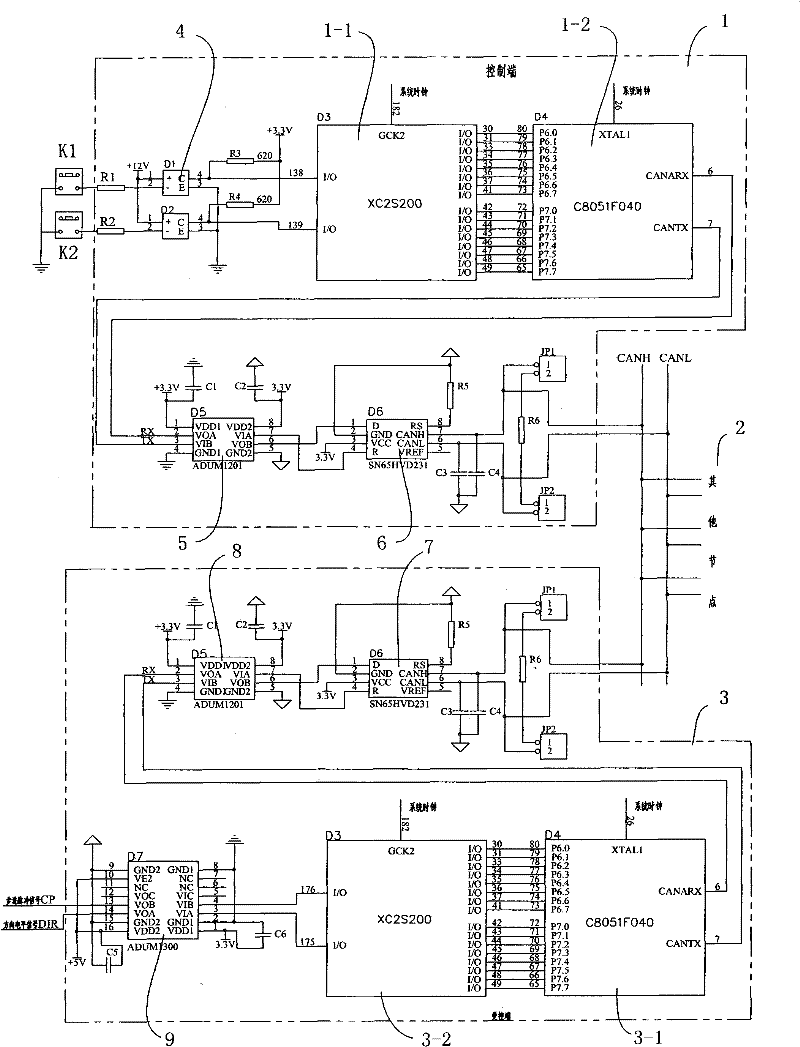

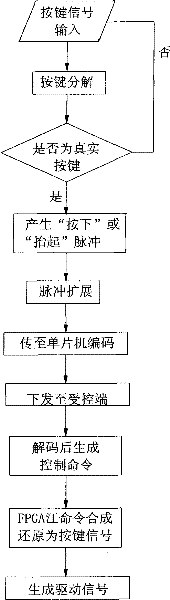

Remote keying method and device for stepper motor driver based on can communication

ActiveCN102262400AWidely used valueEasy to useTotal factory controlProgramme total factory controlKey pressingArea network

The invention relates to the remote key control of a stepping motor driver, and particularly relates to a remote keying method and a remote keying device of the stepping motor driver based on CAN (Controller Area Network) communication. The device comprises a key, a control end signal processor, a CAN communication network and a controlled end signal processor, wherein the key is connected with the control end signal processor, the control end signal processor processes key signals as 'pressed down' or ' lifted up' code signals and sends the 'pressed down' or ' lifted up' code signals to the CAN communication network, and the controlled end signal processor receives the 'press down' or 'lifted up' code signals sent from the CAN communication network, decodes, synthesizes and restores the 'press down' or 'lifted up' code signals as the key signals, generates control signals and sends the control signals to the stepping motor driver. The remote keying device of the stepping motor driverbased on CAN communication successfully achieves manual remote keying of an antenna of a large-power long-wavelength signal transmitter, realizes a control distance as long as several kilometers, totally satisfies the demand of the manual remote keying of the antenna regulation of the large-power long-wavelength signal transmitter, ensures stable application in a large-power high-frequency field high-interference environment, and has good effect.

Owner:BEIJING BBEF SCI & TECH

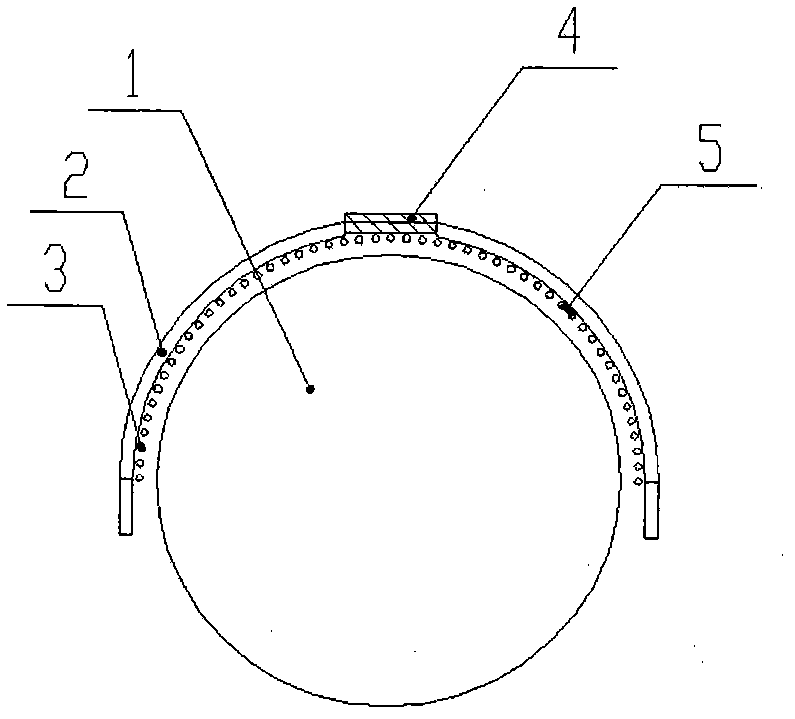

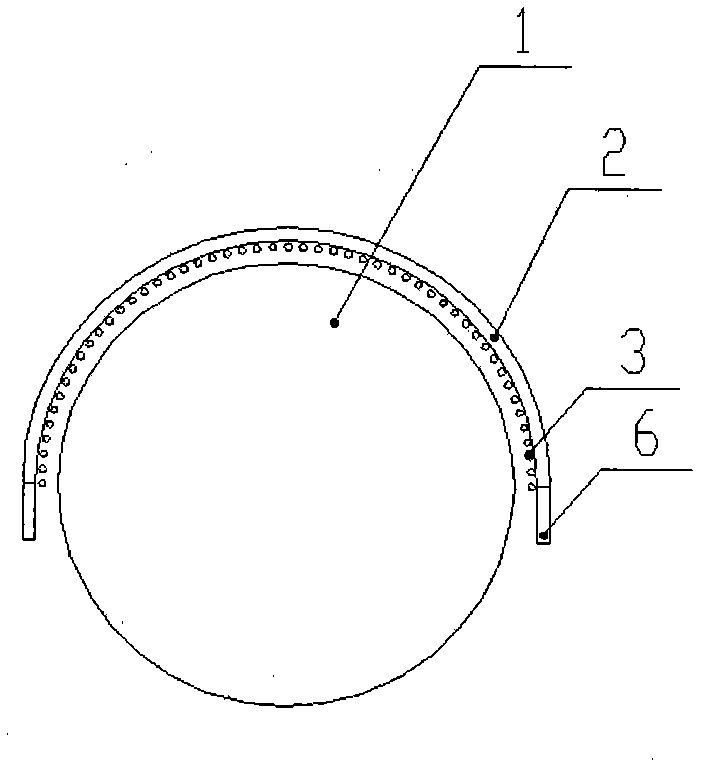

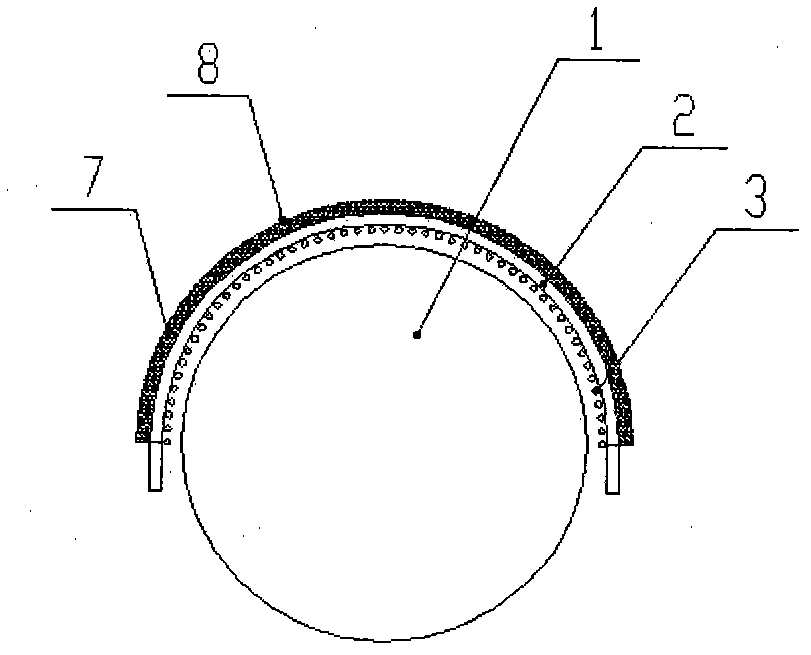

High-efficiency waste heat utilization device for cylinder surface of rotary kiln

The invention relates to a high-efficiency waste heat utilization device for a cylinder surface of a rotary kiln. The high-efficiency waste heat utilization device comprises a rotary kiln cylinder body, a heat collecting hood and a heat exchange tube bundle, wherein the heat collecting hood is arranged on the periphery of the rotary kiln cylinder body; the heat exchange tube bundle is arranged between the rotary kiln cylinder body and the heat collecting hood; and a covering surface of the heat collecting hood on a cross section of the rotary kiln body is not smaller than one second of the cross section of the rotary kiln cylinder body. The high-efficiency waste heat utilization device further comprises a deflector which is vertically arranged at the lower part of the heat collecting hood; an electric shutter adjusting valve is additionally arranged at the top of the heat collecting hood; a temperature sensor is additionally arranged inside the heat collecting hood; and the electric shutter adjusting valve and the temperature sensor form a control system. According to the high-efficiency waste heat utilization device disclosed by the invention, the problem that that waste heat resources of a traditional heat acquiring device on the cylinder surface of a traditional rotary kiln body is low in utilization rate is solved and the utilization rate of the waste heat resources on the cylinder surface of the rotary kiln body is increased.

Owner:LUOYANG BLUE SEA INDAL

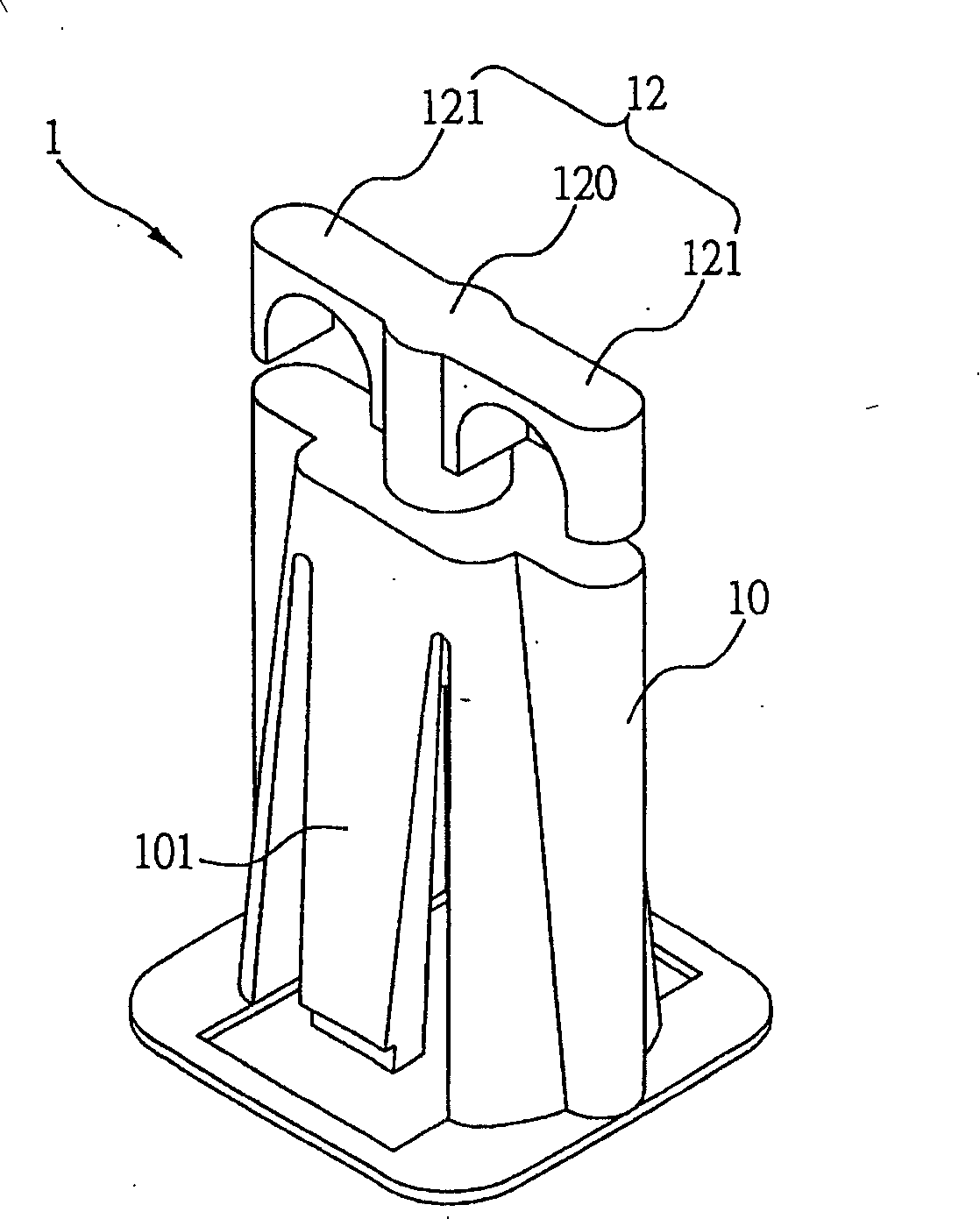

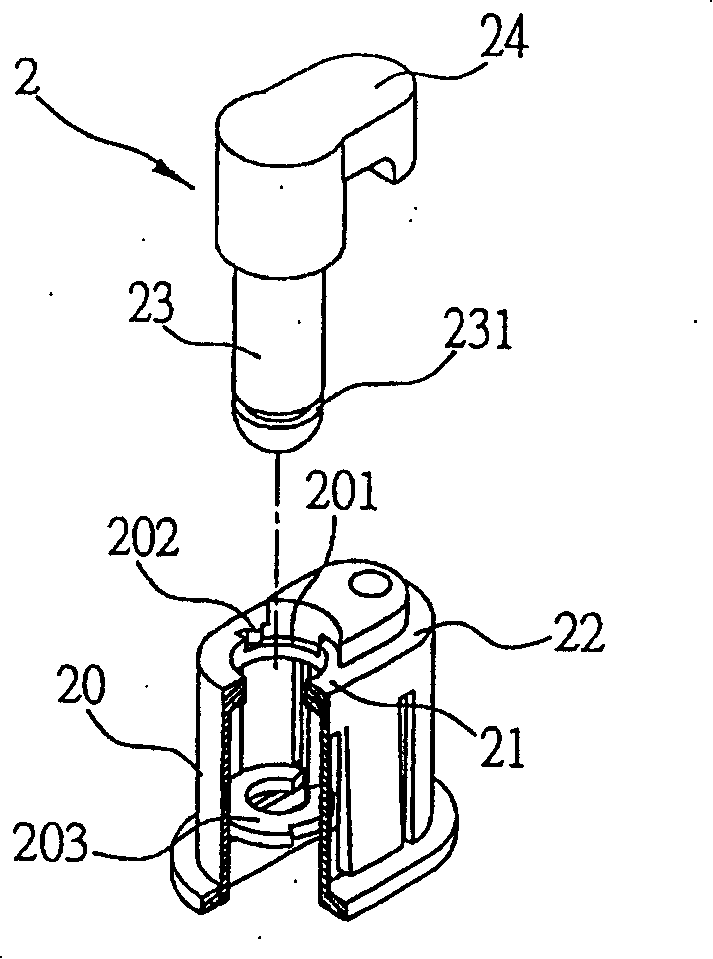

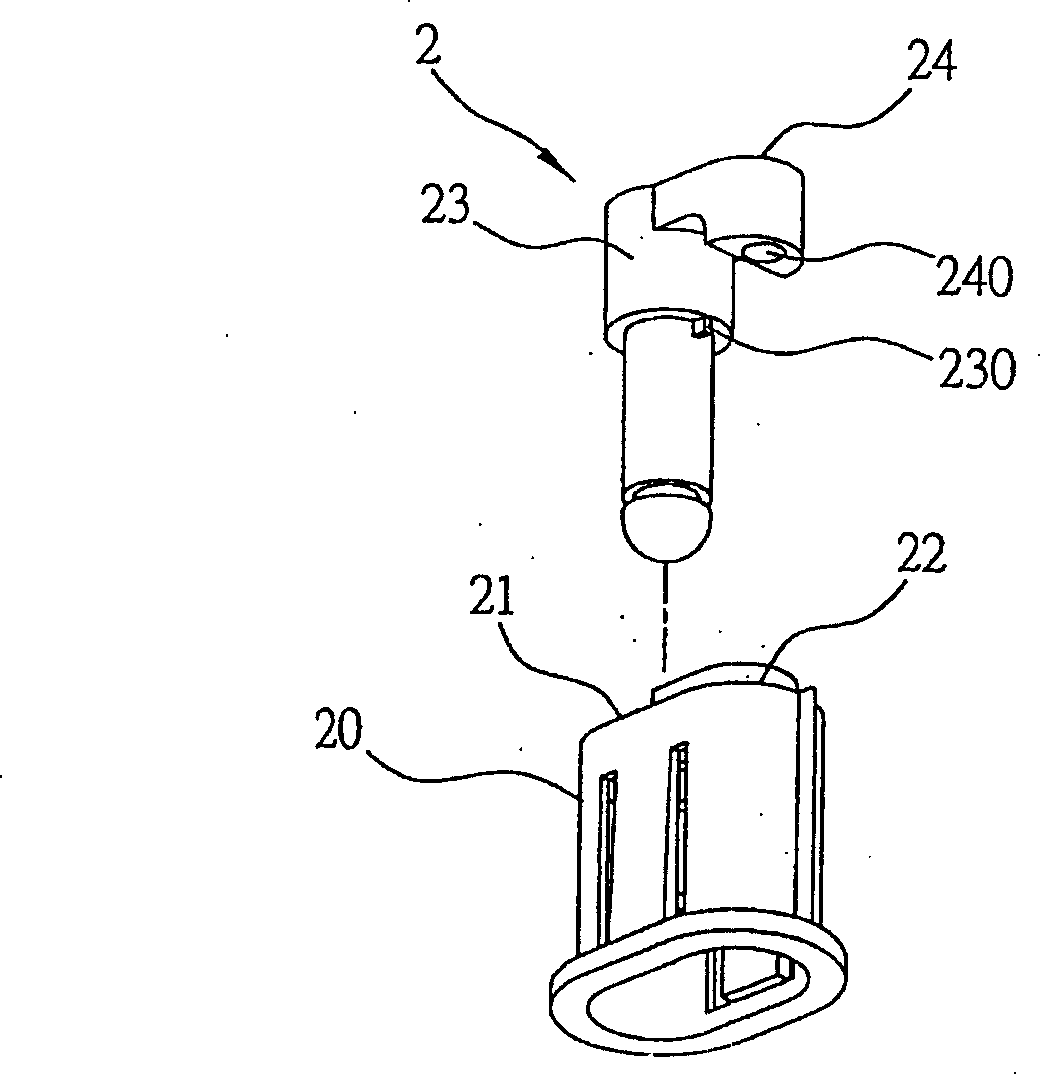

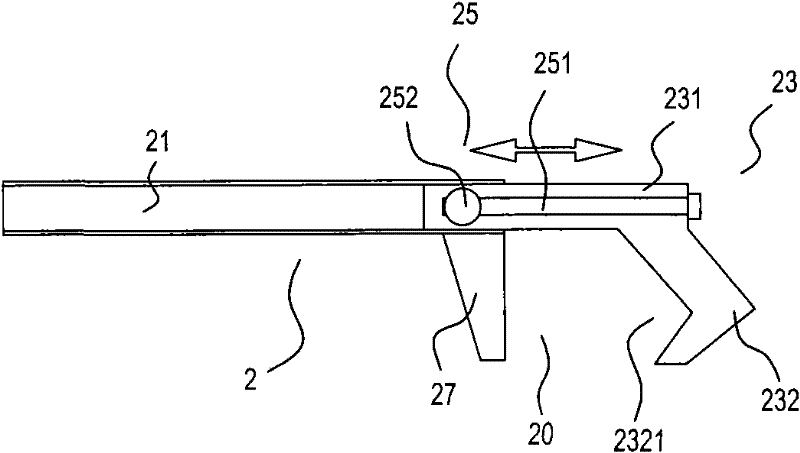

Fixed parts for circuit board

ActiveCN101203107AAchieve the effect of fixing the circuit boardReduce areaDigital data processing detailsCircuit arrangements on support structuresEngineeringCrate

A fixed part for a circuit board is used for fixing the circuit board on the bottom plate of the crate of the electronic device, and the fixed part comprises a hollow shell, the top and the bottom of the hollow shell are respectively fixed on the bottom plate of the crate to support the circuit board. The hollow shell comprises a first end part and a second end part in the horizontal direction and the first end part is rotationally combined with a shaft, the top of the shaft exposes from the top of the hollow shell, and the top of the shaft is provided with a pressing arm, the terminal end of the pressing arm extends to the second part. By rotating the shaft, the terminal end of the pressing end presses the circuit board, thereby fixing the circuit board on the bottom plate of the crate.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

Large block removing device for bucket wheel machine

InactiveCN103848233ANot to be scratchedMeet the needs of industrial developmentCleaningLoading/unloadingImpellerDrive shaft

The invention relates to a large block removing device for a bucket wheel machine. The large block removing device for the bucket wheel machine comprises a bearing support seat assembly, a driving shaft assembly, impellers, a driving device assembly, a plurality of floating moment arms, an outer casing, an elastic automatic sweeping device, a plurality of elastic buffer seat body and an electric control cabinet. The impellers adopted by the large block removing device are arranged on driving shafts in a spiral curve shape, so the driving shafts rotate at a high speed, large blocks can be favorably discharged out, and the sieve passing rate is increased. The elastic automatic sweeping device of the large block removing device can be used for clearing sundries pasted on the impellers in time. When the large blocks are clamped between the adjacent driving shafts, the elastic buffer seat body and the floating moment arms can generate certain displacement, the force balance is damaged, and the clamping is eliminated. The large block removing device adopts the electric control cabinet, and can realize the remote on-site control conversion.

Owner:洛阳广盈机械设备有限公司

Agricultural waste pyrolyzing furnace

InactiveCN103060005AVersatileControlling Oxidation (Burn) RateSolid waste disposalBiofuelsBiomass carbonRefractory

The invention relates to an agricultural waste pyrolyzing furnace, which includes: an inner cylinder, an outer cylinder, a grate, an outlet, an air outlet pipe, a furnace cover arranged on an inner cylinder upper port, as well as a feed inlet and an air inlet disposed on the furnace cover. Specifically, the bottom of the inner cylinder is connected to the outlet, and the grate is mounted between the inner cylinder and the outlet; a plurality of small vent holes are evenly distributed on a lateral side at the lower part of the inner cylinder; an annular airway is formed between the outer cylinder and the inner cylinder, and the air outlet pipe arranged on the outer cylinder, the airway, the small vent holes, and a breathable refractory layer together form an air extraction channel; and the furnace cover has a conical exterior shape, and a fabric assembly is disposed inside. The pyrolyzing furnace provided in the invention can convert agricultural waste into biological mixed gas or biomass carbon or a biological gas mixture, and the conversion efficiency is high, so that the furnace is suitable for the agricultural waste comprehensive conversion utilization devices needed by corresponding village (town) plant construction.

Owner:LUOYANG JUNTENG ENERGY TECH

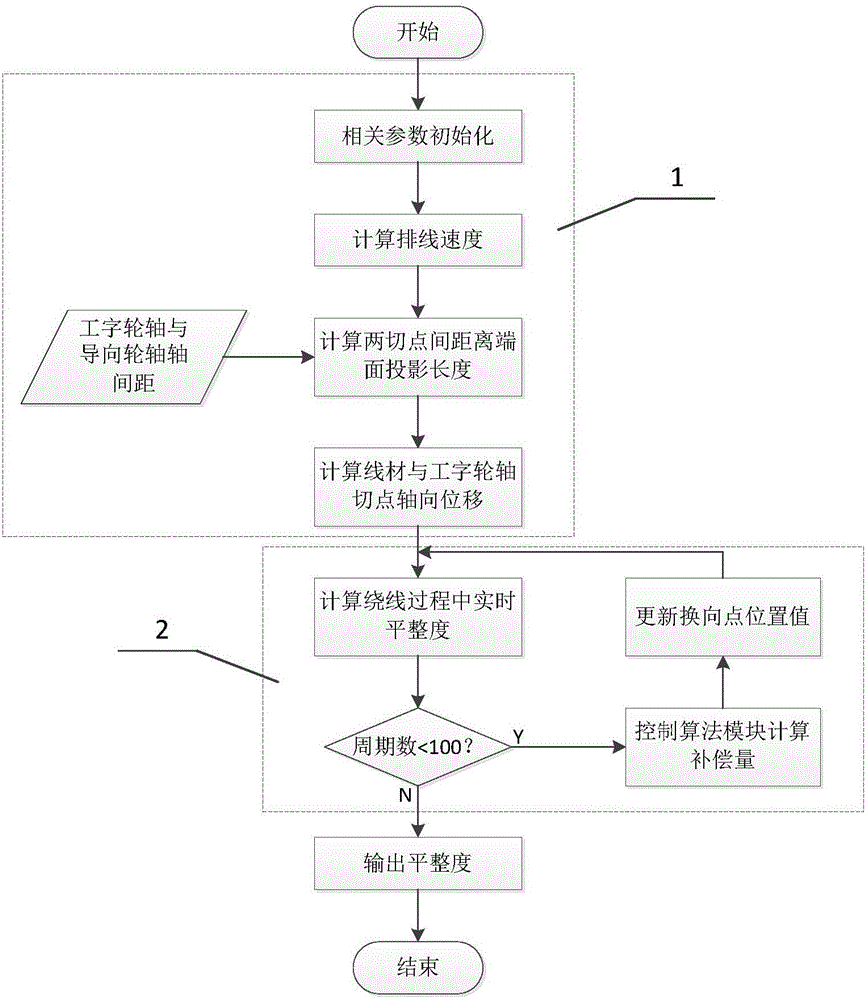

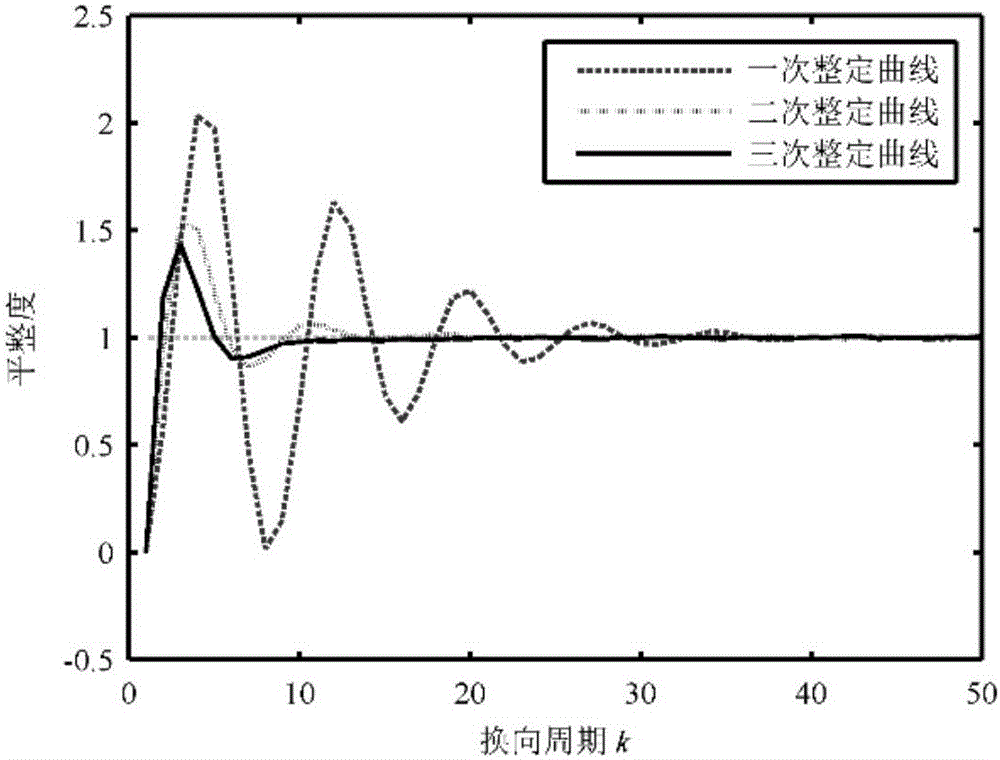

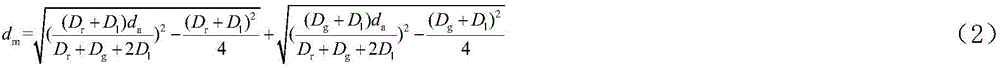

Simulation model for flat cable reversing control system of spool take-up

InactiveCN105843075AHas industrial utilization valueLow costSimulator controlControl systemQuality control

The invention discloses a simulation model of the wire arrangement and reversing control system of the I-shaped wire take-up machine. The simulation model mainly includes two modules: a winding model of the I-shaped wire take-up machine and a wire arrangement and reversing control model; The winding model of the I-wheel take-up machine is established by analyzing the structure of the I-wheel take-up machine, and the winding process of the I-wheel is simulated and displayed by the limit approximation method; The winding flatness is then used as a reference to control the position of the reversing point of the cable arrangement; the reversing control model of the cable arrangement includes a control algorithm module, and various high-quality control algorithms can be used. The positive effect of the present invention is to provide a systematic theoretical support for the detailed analysis of the influence of the relevant parameters of the I-shaped wire take-up machine's wire arranging and reversing control system on the precision of the wire take-up, and provide a basis for the machine structure and the wire arranging and reversing control algorithm. Design and optimization provides a simulation experiment platform.

Owner:CHANGZHOU UNIV

Oxygen-rich type synergism fuel economizer

InactiveCN102121442ABurn fullyTwo reduction reactions take place in the combustion chamberNon-fuel substance addition to fuelInternal combustion piston enginesTransformerGasoline

The invention relates to an oxygen-rich type synergism fuel economizer, and in particular to a fuel economizer device applied to a gasoline engine and a diesel engine. The fuel economizer mainly comprises a shell, a power switch, a transformer, a circuit board, an air pump, an oxygen-rich generator and an air pipe, wherein the circuit board, the air pump, a motor and the oxygen-rich generator are all fixed inside the shell; the fuel economizer is characterized in that the transformer is added in front of the motor; the motor is arranged at the same level position at the left side of the transformer and connected with the transformer through a wire; the oxygen-rich generator is arranged at the left side of the transformer; the oxygen-rich generator is connected with an air inlet end of the air pump through the air pipe; the air pump is arranged above the transformer; the air pump is connected with the air pipe; the air pipe is connected with the air inlet of an automobile; the circuit board is arranged at the left side of the air pump and provided with one or more than one working indicating lamp; and lamp bulbs of the working indicating lamp are stretched out from a through hole on the shell. Since the fuel oil in the motor is promoted by ozone to react and burn fully, the fuel oil utilization ratio is improved, and the effect of energy saving and emission reduction is achieved; moreover, the product has the advantages of simple structure and low manufacturing cost.

Owner:郑世军

New carbon fiber surface treatment method

InactiveCN106032644AFairly technologically advancedQuite practicalCarbon fibresAcrylic resinInterlaminar shear

The invention relates to a new carbon fiber surface treatment method. Carbon fibers are subjected to oxidation treatment in an oxygen atmosphere, and then the carbon fibers obtained after oxidation treatment are subjected to surface treatment with an ammonium phosphate solution; the interlaminar shear strength of a composite prepared from the carbon fibers obtained after surface treatment and acrylic resin reaches up to 110.5-132.7 MPa, the bonding performance of the carbon fibers and the resin matrix material is greatly improved, and the mechanical performance of the carbon fibers is further improved. Raw materials are easy to obtain, and the preparation method is simple, meets the demand of industrial development and has quite high practicability.

Owner:洛阳新巨能高热技术有限公司

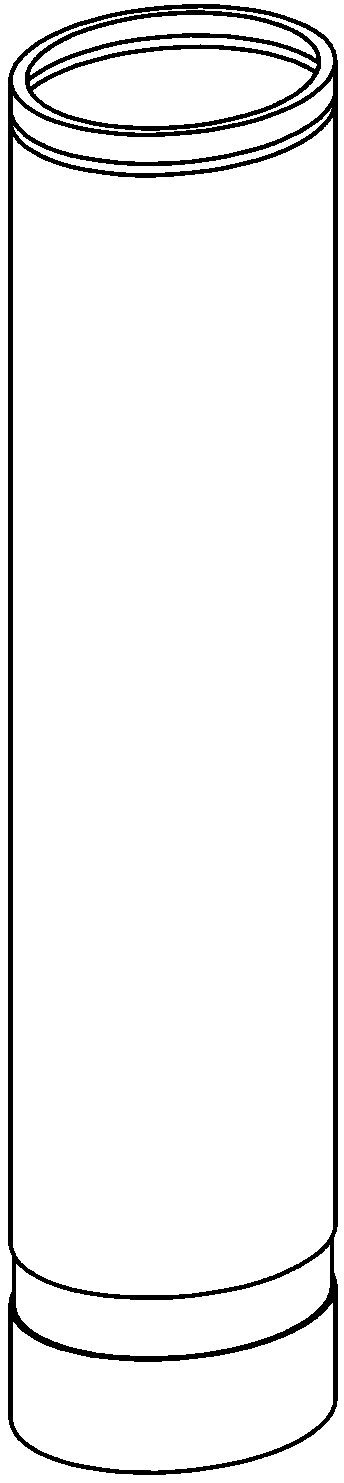

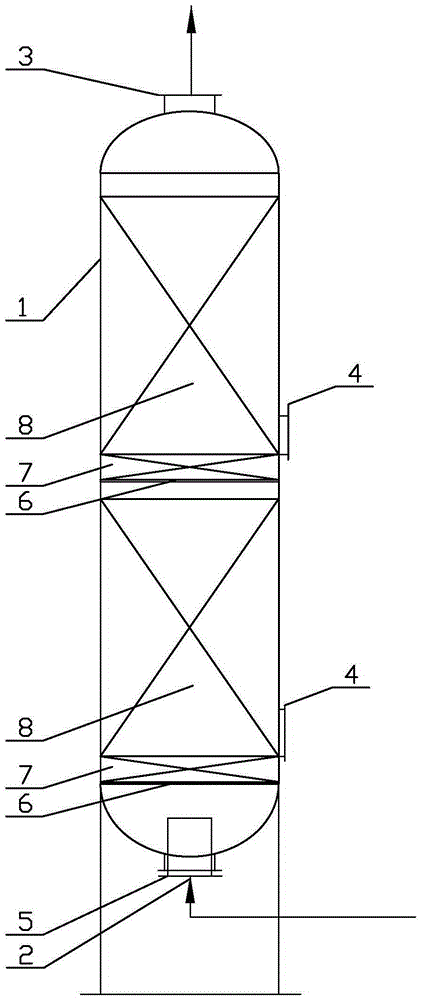

Dry-method natural gas desulphurization reactor

InactiveCN105176613AExtend the life cycleImprove desulfurization efficiencyGaseous fuelsChemical industryProduct gas

The invention relates to a dry-method natural gas desulphurization reactor, and relates to a desulphurization reactor applied to the field of the chemical industry. The dry-method natural gas desulphurization reactor comprises a shell 1, a gas inlet 2, a gas outlet 3, catalyst unloading openings 4, an inlet diffuser 5, porous plates 6, a ceramic ball filter layer 7 and catalyst layers 8; the shell 1 is sequentially provided with the gas inlet 2, the gas diffuser 5, the porous plates 6, the ceramic ball filter layer 7, the catalyst layers 8 and the gas outlet 3 from bottom to top; the porous plates 6, the ceramic ball filter layer 7 and the catalyst layers 8 are respectively arranged inside the shell 1, and the catalyst unloading openings 4 are formed in the lower section of the side wall of the catalyst layers 8; the porous plates 6, the ceramic ball filter layer 7, the catalyst layers 8 and the catalyst unloading openings 4 form at least one reactor bed layer unit. By adopting the dry-method natural gas desulphurization reactor, the gas can be rapidly and uniformly distributed, the catalyst utilization rate and service life can be improved and prolonged, and the depth desulphurization of the natural gas can be facilitated.

Owner:洛阳三信石化设备有限公司

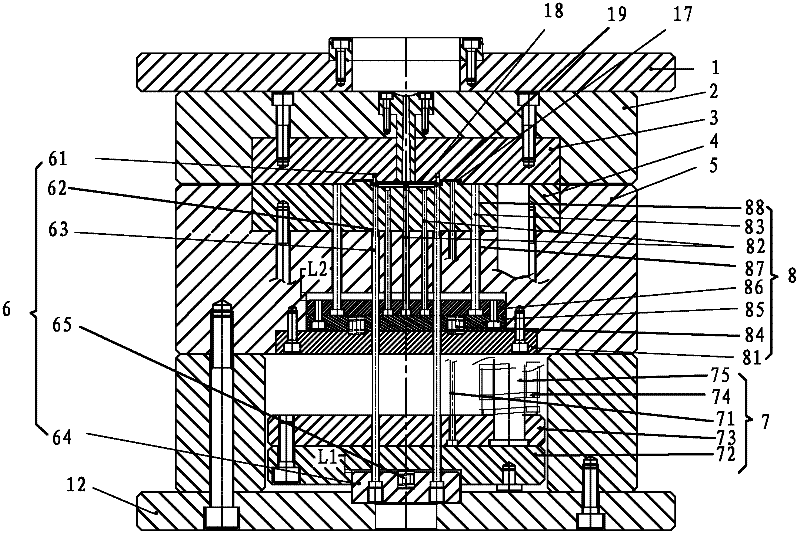

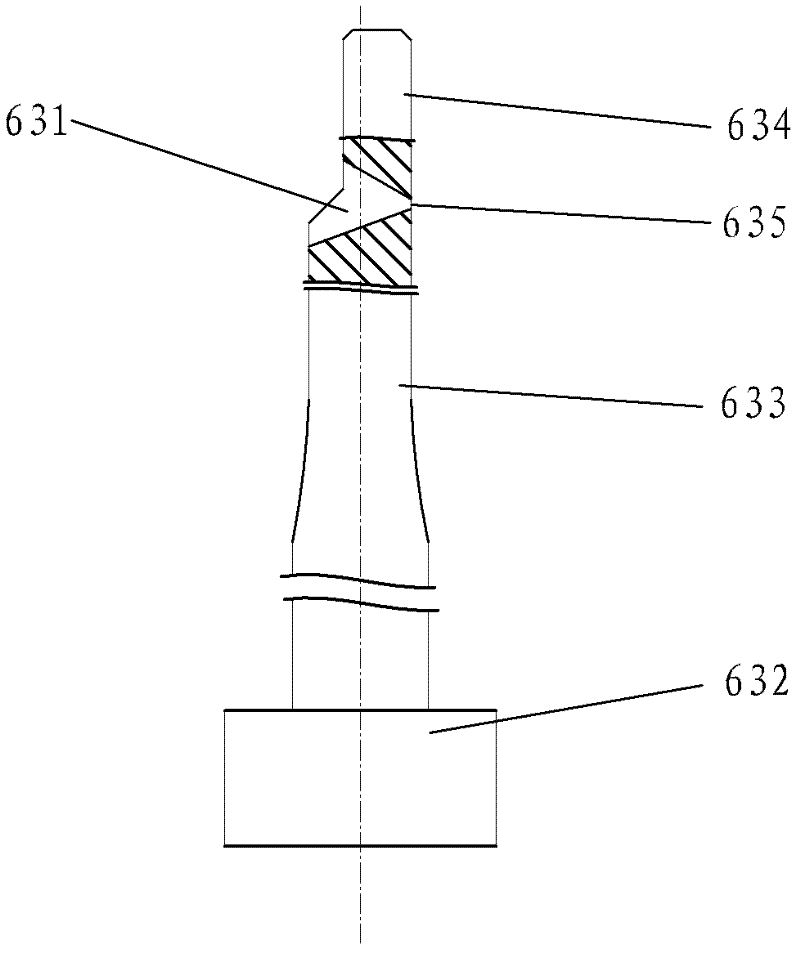

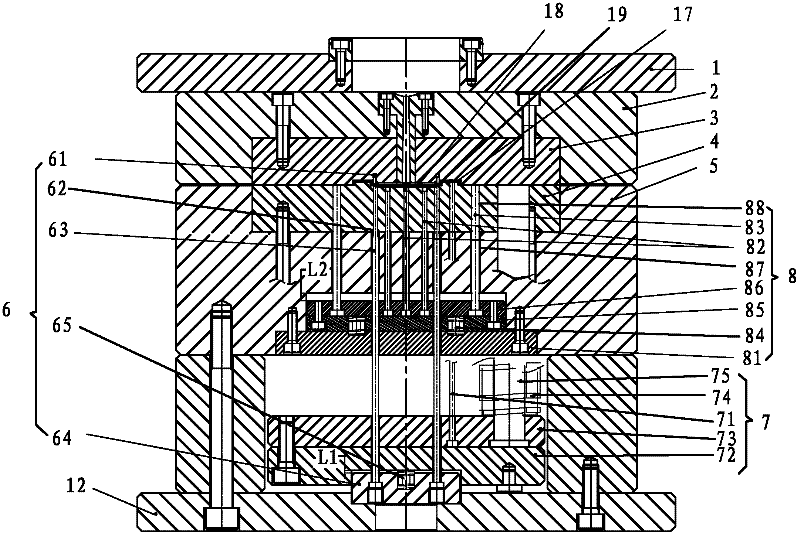

Automatic hot-cutting side gate injection mold, and gate cutter and injection molding process thereof

ActiveCN102241110AExtended service lifeAvoid problems with cores before collisionInjection molding machineInjection molding process

The invention relates to an injection mold, in particular to an automatic hot-cutting side gate injection mold. The injection mold comprises a front mold fixing plate, a front mold core, a front mold plate, a rear mold core, a rear mold plate which is used for fixing the rear mold core and a rear mold fixing plate which is provided with a pushing hole, wherein the front mold plate and the rear mold core are used for fixing the front mold core; a part cavity, a pouring channel and a gate are formed between the front mold core and the rear mold core; and a gate shearing device and a product push-out device are arranged below the rear mold plate. The injection mold is characterized in that: a material handle push-out device is arranged on the rear mold plate; the product push-out device is arranged between the rear mold plate and the rear mold fixing plate; the gate shearing device is arranged between the product push-out device and the rear mold fixing plate; and the material handle push-out device is arranged on the rear mold plate. The automatic hot-cutting side gate injection mold is suitable for producing injection molding products which have complicated shapes and strict appearance requirements; and residues do not exist at an incision, subsequent secondary machining is not required, the mold is not required to be maintained and welded, and a gate cutter has long service life.

Vehicle roof frame

InactiveCN102189963ASimple structureReduce manufacturing costSupplementary fittingsVehicle frameEngineering

The invention relates to a vehicle roof frame which comprises a rod body, two groups of foot seats and fixing components, wherein the distance between the two groups of foot seats can be adjusted; the two groups of foot seats are arranged at both ends of the rod body in an inserting way, and the fixing components are used for fixing the rod body and the foot seats; each group of foot seat comprises a foot seat tube body, a forepaw piece and an adjustable fastener; a supporting piece is fixedly arranged at one end of the foot seat tube body; the other end of the foot seat tube body is arranged in the rod body in an inserting way; the forepaw piece comprises an inserting and extending tube body and a paw body, wherein the inserting and extending tube body is inserted and extended into the foot seat tube body, the paw body is fixedly arranged at one end of the inserting and extending tube body in the side direction, the paw body is provided with an inward hollow part, and a clamping space is defined jointly by the paw body and the supporting piece; and the adjustable fastener is used for adjusting the distance between the paw body and the supporting piece. The vehicle roof frame has a simple structure; the distance between both ends of the vehicle roof frame can be adjusted; and the distance is convenient to adjust.

Owner:CARMAN ENTERPRISE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com