Novel clamp used for palletizing robot

A palletizing robot and jig technology, applied in the field of industrial palletizing, can solve the problems such as the inability to save the movement space and the large gap of the goods, and achieve the effects of simple structure, reduced manufacturing cost and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, Features and their functions are described in detail below.

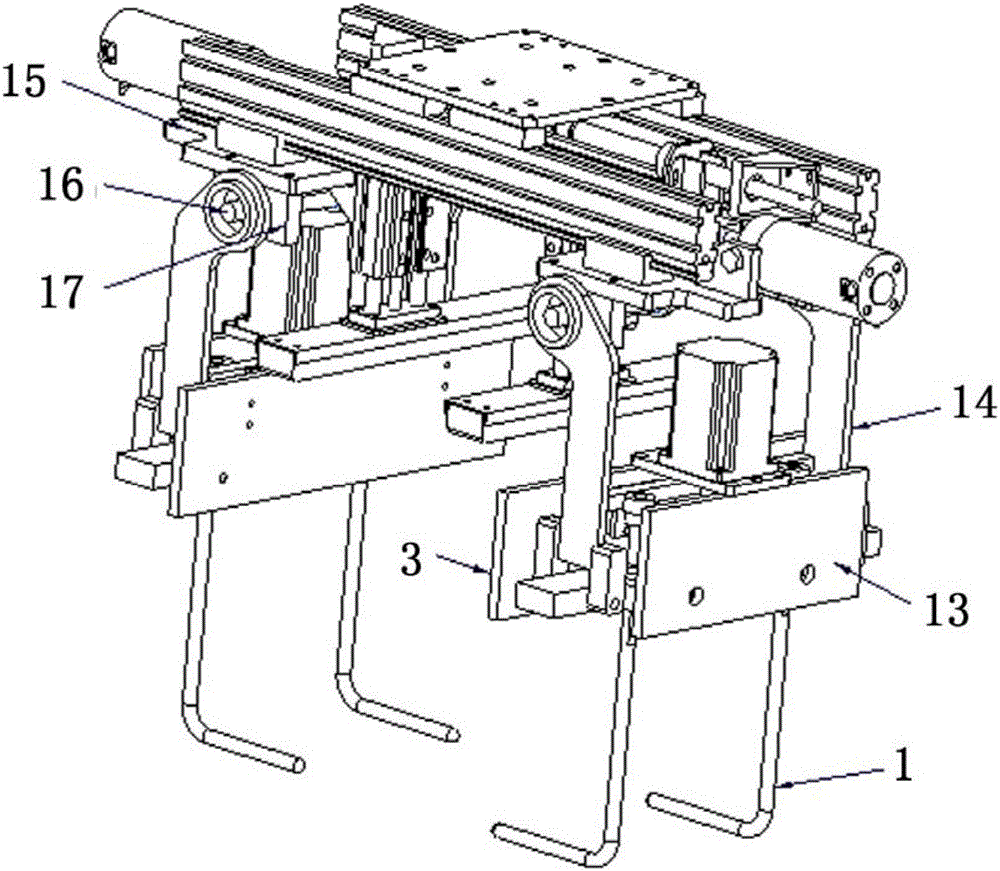

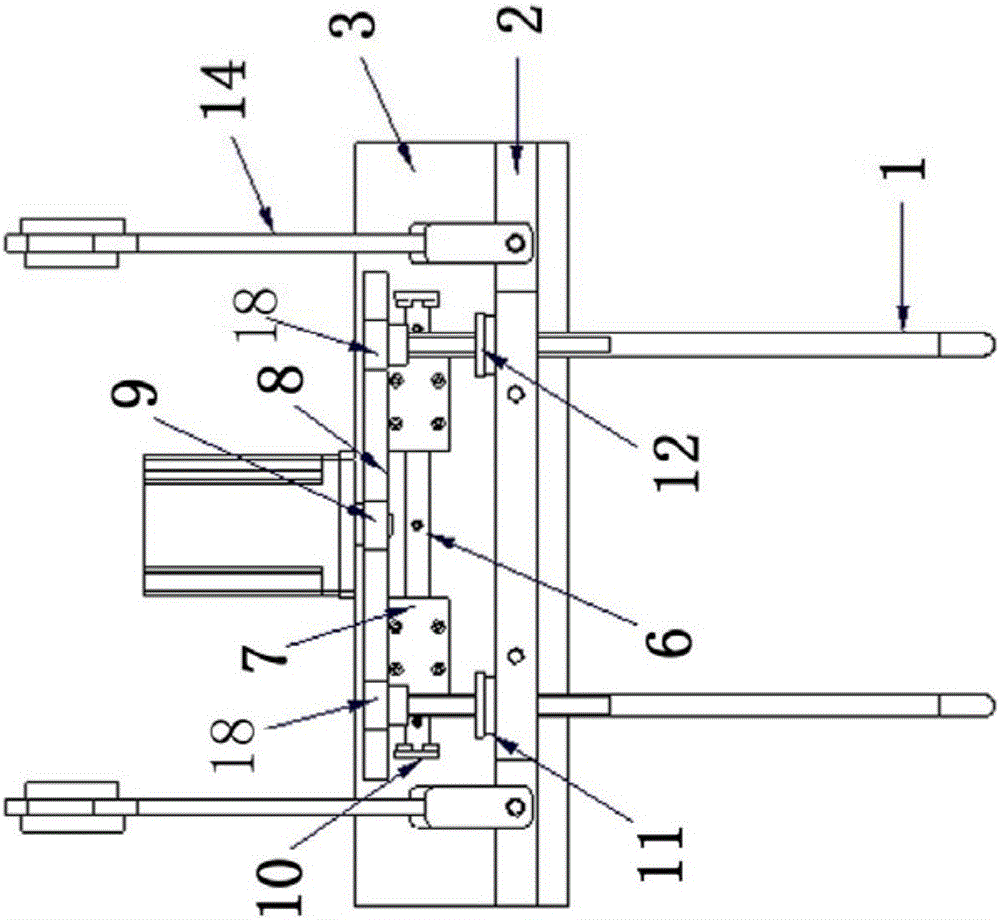

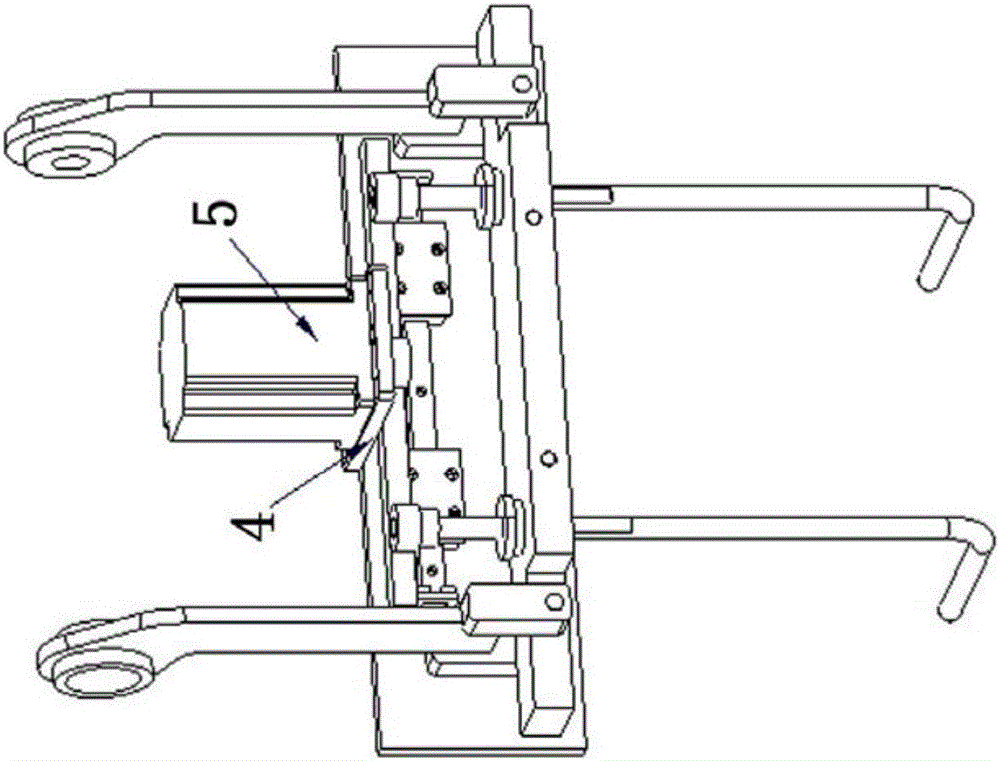

[0033] see figure 1 As shown, a new palletizing robot clamp according to a preferred embodiment of the present invention is mainly composed of a rotating mechanism and an opening and closing mechanism. Below the mechanism, each set of rotating mechanism is connected with the opening and closing mechanism through the rocker arm 14, and the described rotating mechanism drives the hand grasping part to rotate through the driving structure formed by the motor 5 and a plurality of gears and racks 8. This embodiment adopts two sets of axisymmetric rotating mechanisms.

[0034] Please refer to Figure 2, where each set of rotating mechanism is composed of 2 hand grips 1, main fixing block 2, front support plate 3, motor fixing plate 4, motor 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com