Simulation model for flat cable reversing control system of spool take-up

A simulation model and control system technology, applied in general control systems, control/regulation systems, simulators, etc., can solve the problems of lack of theoretical basis, lack of systematic support, high cost of machine structure and control algorithm optimization experiments, and achieve cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

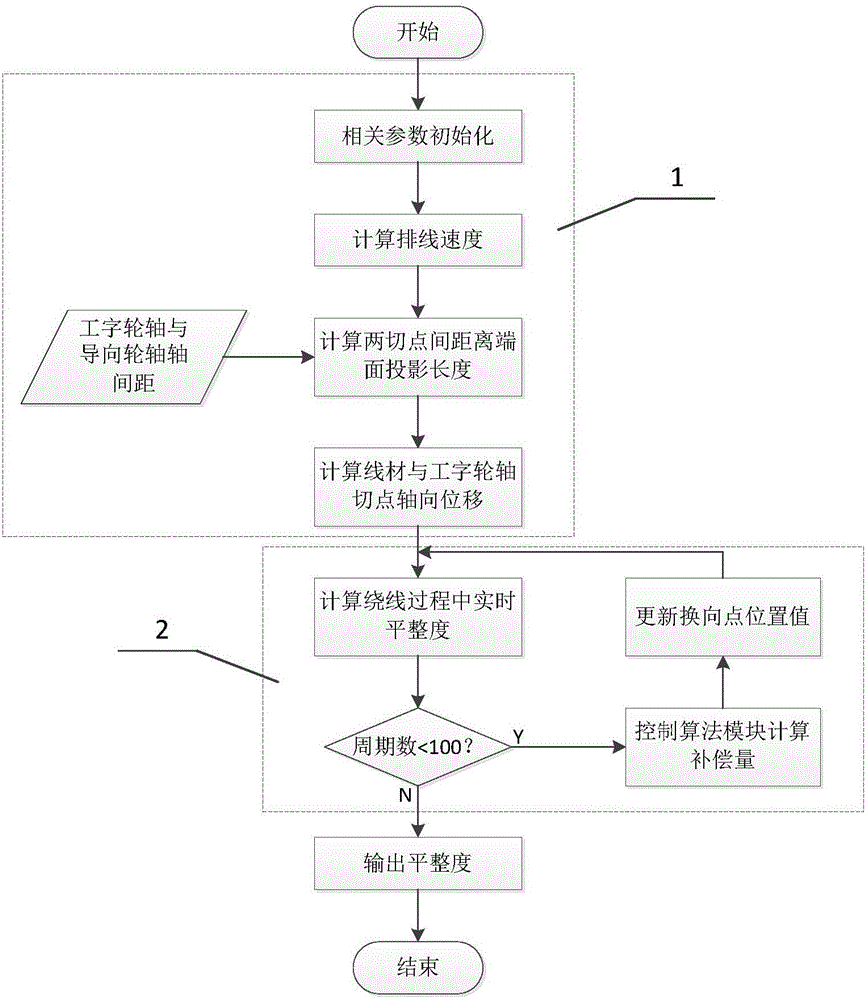

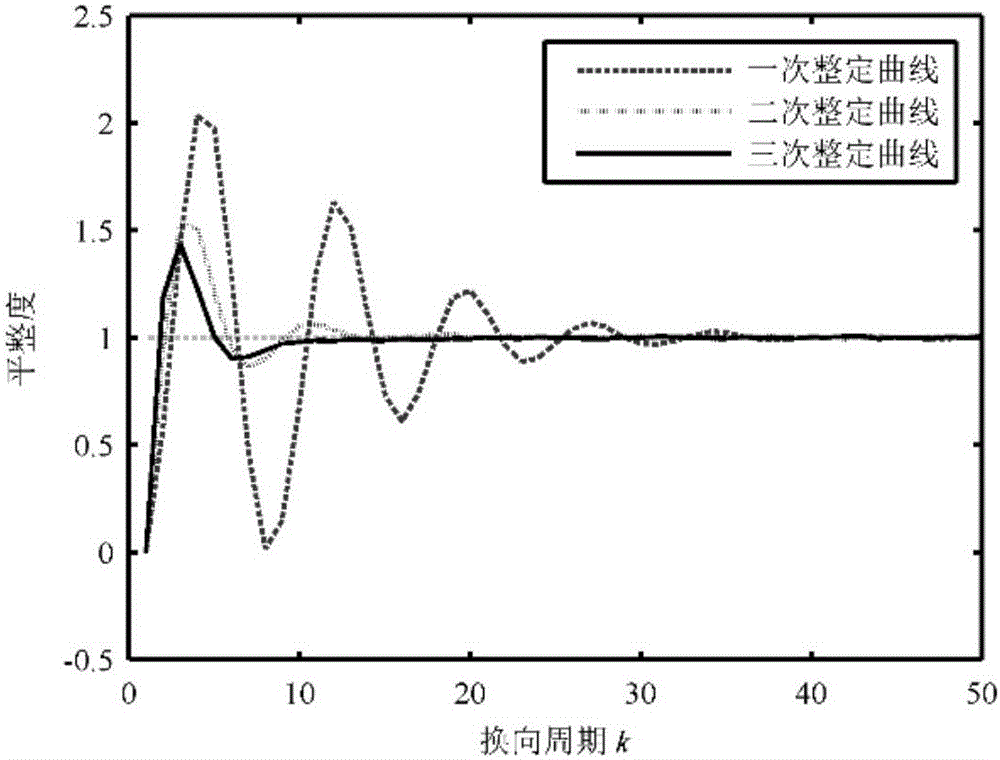

[0030] see figure 1 As shown, the simulation model of the wire reversing control system of the I-wheel take-up machine proposed by the present invention mainly includes two modules: the winding model of the I-wheel take-up machine and the reversing control model of the wire arrangement; The winding model of the wire machine is established by analyzing the structure of the I-shaped wheel take-up machine, and the winding process of the I-shaped wheel is simulated and displayed by the limit approximation method; The degree is then used as a reference to control the position of the cable reversing point; the cable reversing control model includes a control algorithm module, and various high-quality control algorithms can be used, such as PID control algorithms, based on fuzzy PID control algorithms, etc.

[0031] The workflow of the described model is:

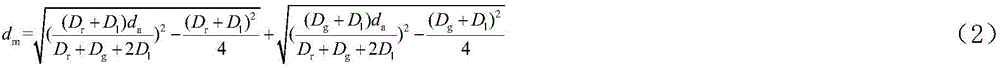

[0032] S001: Calculate the winding speed by the winding model of the I-wheel take-up machine through the take-up speed. Among ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com