Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Fairly technologically advanced" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Suspended seed coating containing fludioxonil, difenoconazole and imidacloprid

InactiveCN106259411AFairly technologically advancedQuite practicalBiocideFungicidesPreservativeInsect pest

The invention relates to a suspended seed coating containing fludioxonil, difenoconazole and imidacloprid. The suspended seed coating comprises 15-30% of fludioxonil, 5-10% of difenoconazole, 1-9% of imidacloprid, 1-2% of an antifoaming agent, 5-10% of a film-forming agent, 2-4% of a thickening agent, 3-6% of a stabilizer, 2-8% of a dispersing agent, 4-7% of an emulsifier, 2-4% of a preservative and the balance of water. The seed coating disclosed by the invention has insecticidal and antibacterial effects, the germination rate of the seeds can be improved, crops at a seedling stage are prevented from being damaged by plant diseases and insect pests, the medicament dosage can be reduced, plant diseases and insect pests can be eliminated at the same time, the cost is reduced, and the environmental pollution is avoided.

Owner:LUOYANG MINGLI TECH DEV

Intelligent cutting combined control system and method for cantilever type heading machine

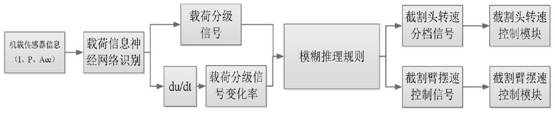

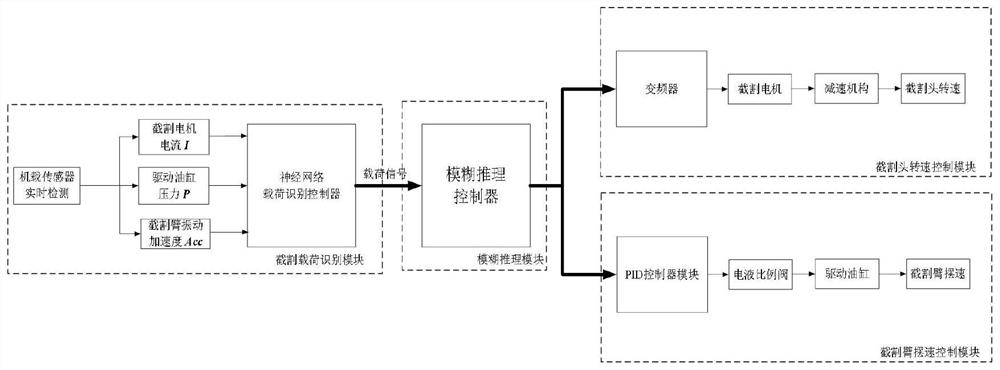

InactiveCN113006793AFairly technologically advancedQuite practicalDriving meansNerve networkVibration acceleration

The invention discloses an intelligent cutting combined control system and method for a cantilever type heading machine, and belongs to the field of intelligent control of coal mine fully-mechanized excavating equipment. The system comprises a cutting load recognition module, a fuzzy reasoning module, a cutting head rotating speed control module and a cutting arm swing speed control module. According to the system and the method, three key cutting parameters, including the cutting motor current I, the cutting arm driving oil cylinder pressure P and the cutting arm vibration acceleration Acc, of the heading machine in the cutting process are detected in real time through an airborne detection sensor; cutting load recognition is carried out on three kinds of multi-sensor information according to different cutting working conditions by utilizing a neural network controller, and corresponding load signals are output; and then the load signals are input into the fuzzy reasoning module to output proper swing speed control signals and rotating speed control signals, and the rotating speed of a cutting head and the swing speed of a cutting arm are subjected to combined control by utilizing the output signals. According to the system and the method, the blank in the aspect of intelligent cutting combined control of a current coal mine heading machine is filled up, the rotating speed of the cutting head and the swing speed of the cutting arm can be intelligently and synchronously adjusted in real time according to the hardness of coal rocks in the cutting process of the heading machine, and intelligent cutting of the cutting part of the whole heading machine is truly realized.

Owner:北京坤世拓智能科技有限公司

Modified vermiculite adsorbent

InactiveCN106000282AFairly technologically advancedQuite practicalOther chemical processesWater contaminantsPhosphoric acidWastewater

The invention relates to a modified vermiculite adsorbent. Vermiculite is taken as the base adsorbent, vermiculite is modified by soaking in phosphoric acid, the soaked vermiculite is then activated with microwave so as to obtain the modified vermiculite adsorbent. The mass fraction of the phosphoric acid is 40%-60%, the microwave activation conditions include microwave power of 500W-800W and a microwave time of 3min-6min. The adsorbent can reach a removal rate of over 90% on mercury in wastewater, also the preparation method is simple and the cost is low, therefore the modified vermiculite adsorbent is an efficient and cheap mineral adsorbent.

Owner:洛阳新巨能高热技术有限公司

Metadata generation system based on multi-source data

InactiveCN113761285AFairly technologically advancedQuite practicalSemi-structured data mapping/conversionSpecial data processing applicationsRelation (database)Original data

The invention relates to a metadata generation system based on multi-source data. The system comprises an original database, a metadata database, a mapping table database, a processor and a memory in which a computer program is stored, the original database is used for storing original data acquired from N data sources {P1, P2,... PN}, Pn is the nth data source, and the value range of n is 1-N; the meta-database is used for storing a metadata record, the metadata record comprises M metadata fields {D1, D2,... DM}, Dm is the name of the mth metadata field of metadata, and the value range of m is 1-M; and the mapping table database is used for storing a mapping table Rn corresponding to each data source Pn, and the Rn is used for storing a mapping relation between an original data field of the Pn and {D1, D2,... DM}. The multi-source data can be quickly and accurately converted into the metadata with the same data structure, and the information extraction efficiency and accuracy of the multi-source data are improved.

Owner:BEIJING YUCHEN SHIMEI SCI & TECH

Preparation process of external oxidation dispersion strengthened copper alloy

InactiveCN106191506ADiffusion realizationFairly technologically advancedAdditive ingredientShielding gas

The invention relates to a preparation process of an external oxidation dispersion strengthened copper alloy. The preparation process comprises the following steps: proportioning and smelting metallic copper and metallic aluminium, and controlling the temperature of a smelting furnace to be 1,250-1,300 DEG C; performing continuous casting on a smelted copper aluminium alloy, and controlling the temperature of cooling water of a casting crystallizer to obtain an oxygen-containing alloy copper bar; repeatedly and continuously extruding the oxygen-containing alloy copper bar in a closed extrusion cavity by use of a continuous extruder to obtain a uniform-ingredient alloy copper bar; and then performing high-temperature aging treatment, enabling sufficient replacement reaction in a protective gas to ensure generation of Al2O3, performing cold-drawing treatment to obtain a dispersion strengthened copper alloy, and eliminating unqualified products to obtain a finished Al2O3 dispersion strengthened copper alloy. The preparation process of the dispersion strengthened copper alloy is shortened in flow and low in cost, the obtained copper alloy product is stable in quality and excellent in performance, the demand of the society for the high-strength and high-conductivity dispersion strengthened copper alloy is satisfied, the preparation process can be conveniently popularized in more fields, and the economic efficiency and the practicability are high.

Owner:黄天增

ER50-G non-copperizing welding wire

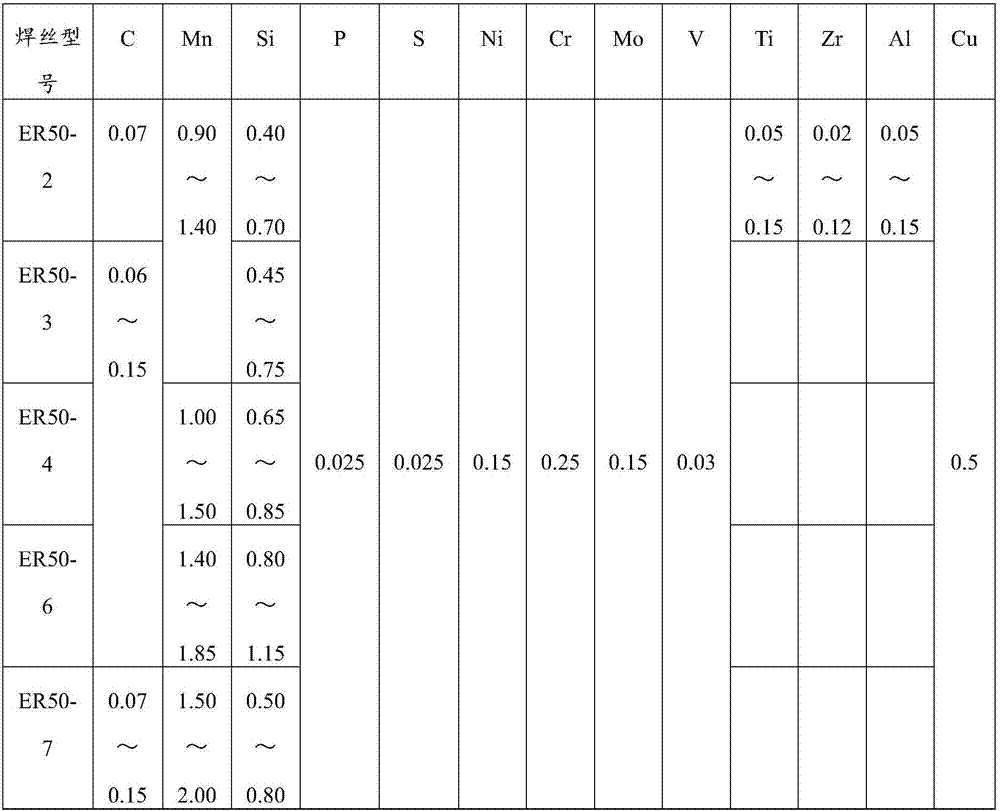

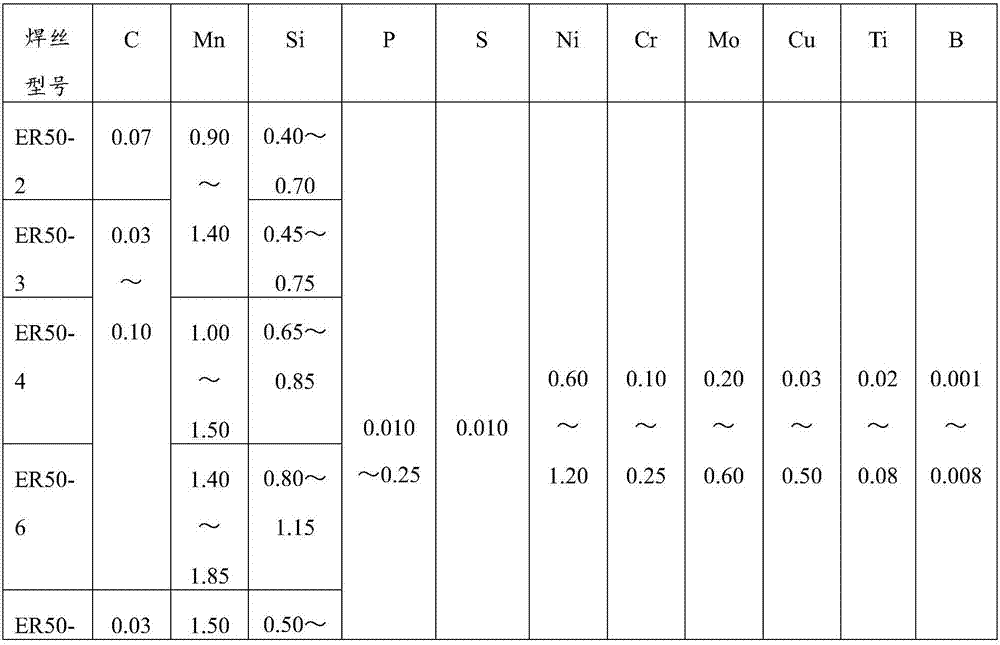

ActiveCN106984916AGood atmospheric corrosion resistanceImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaCopper platingAtmospheric corrosion

The invention discloses an ER50-G non-copperizing welding wire. The welding wire comprises, by mass, 0.03%-0.10% of C, 0.90%-2.00% of Mn, 0.3%-1.15% of Si, 0-0.010% of S, 0.010%-0.30% of P, 0.10%-0.25% of Cr, 0.30%-0.50% of Cu, and the balance Fe. The ER50-G non-copperizing welding wire is characterized by further including 0.60%-1.20% of Ni, 0.20%-0.60% of Mo, 0.02%-0.08% of Ti and 0.001%-0.008% of B. The welding wire has good atmospheric corrosion resistance and good welding performance, due to the fact that no copper plating is required in the welding wire, production cost can be greatly reduced, and unexpected and considerable economic and social benefits are brought about to enterprises.

Owner:SUZHOU YINLI WELDING IND TECH CO LTD

Monitoring and alarming device for working state of anvil of diamond cubic press

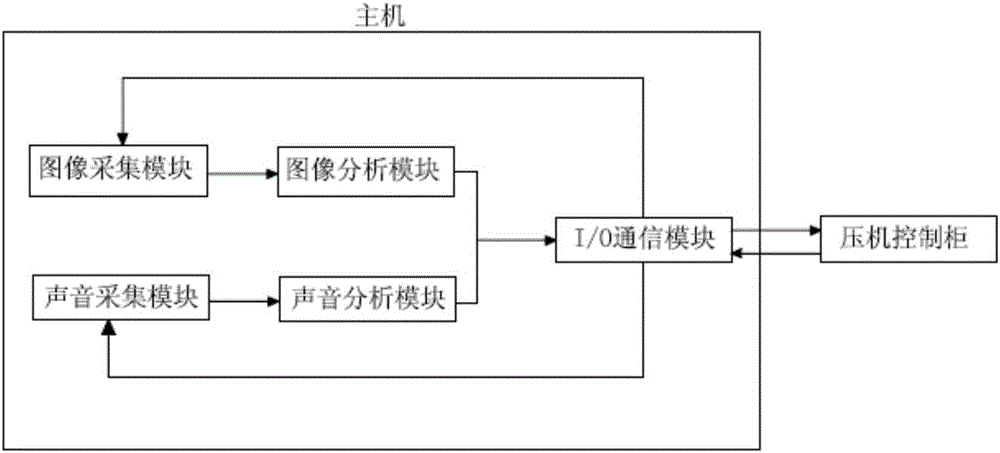

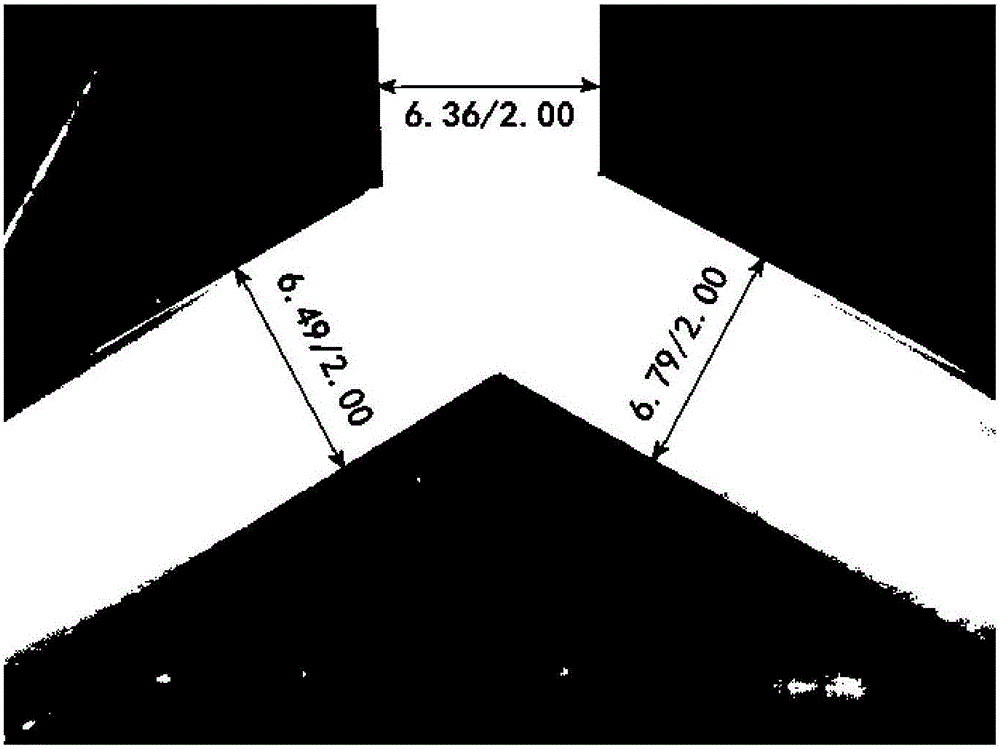

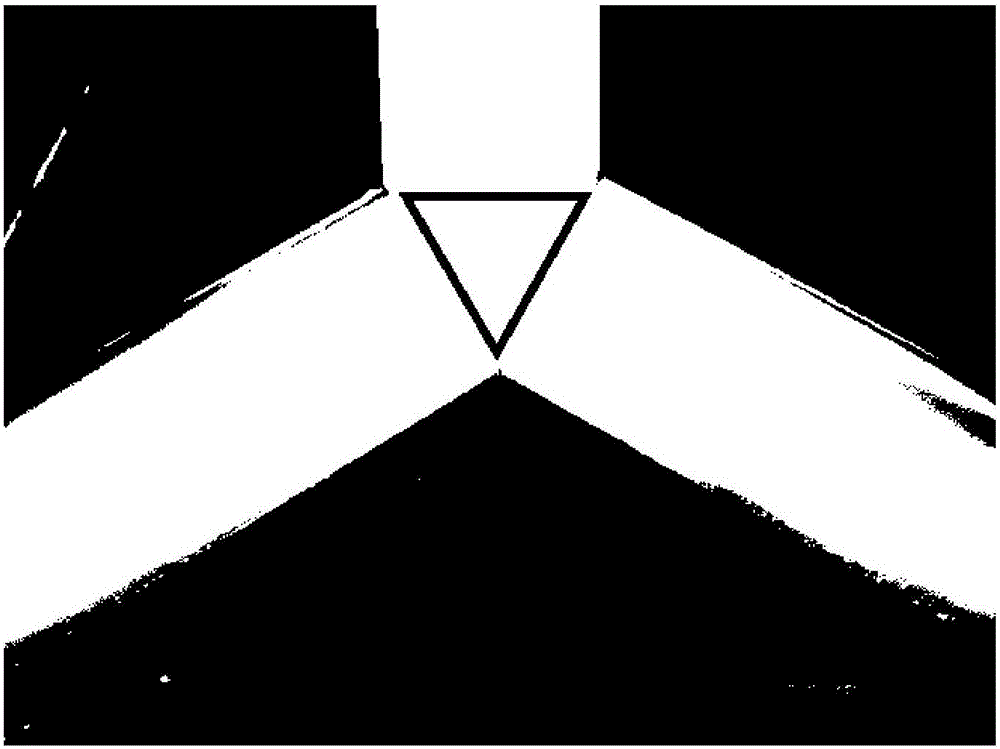

ActiveCN105833798AEasy to adjust the hammerFairly technologically advancedUltra-high pressure processesPressure vessel componentsImaging analysisDiamond cubic

The invention relates to a monitoring and alarming device for the working state of an anvil of a diamond cubic press. The monitoring and alarming device comprises a host and a monitoring and alarming system. The monitoring and alarming system comprises an image collection module, a sound collection module, an image analysis module, a sound analysis module and an I / O communication module. The first output end and the first input end of the I / O communication module are connected with the input end and the output end of a control cabinet of the cubic press respectively, and the second output end and the third output end of the I / O communication module are connected with the input end of the image collection module and the input end of the sound collection module respectively. The output end of the image collection module and the output end of the sound collection module are connected with the input end of the image analysis module and the input end of the sound analysis module respectively, and the output end of the image analysis module and the output end of the sound analysis module are connected with the second input end of the I / O communication module. By means of the monitoring and alarming device, the anvil cracking judging accuracy is improved, and the accurate anvil cracking position is visibly displayed; an operator can master the working state of the cubic press in real time, and thus loss caused by anvil cracking is reduced.

Owner:HENAN ALSONTECH INTELLIGENT TECH CO LTD

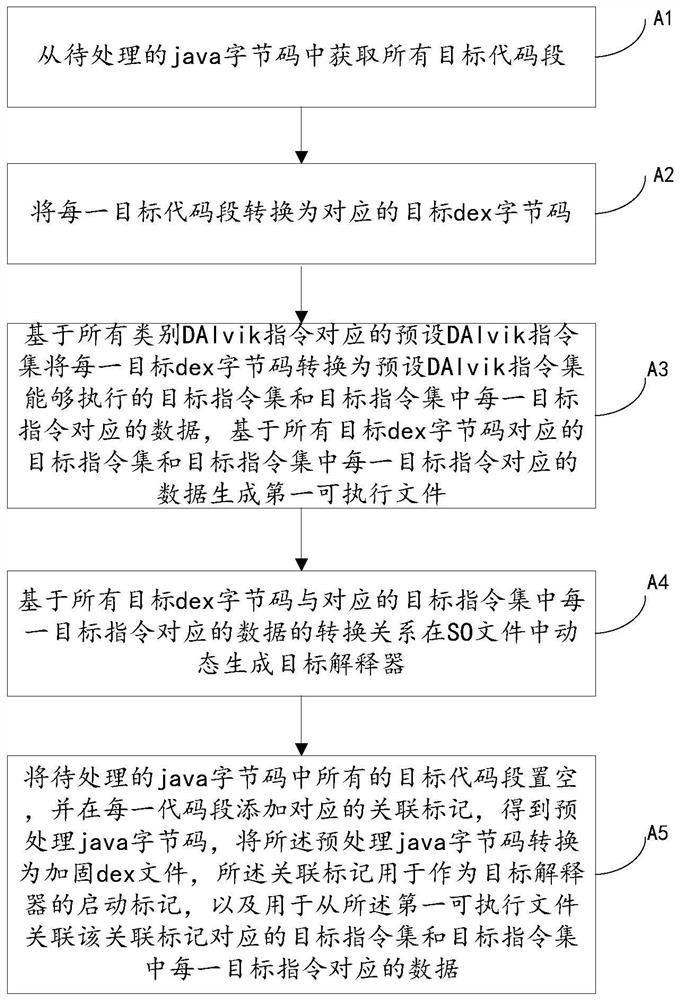

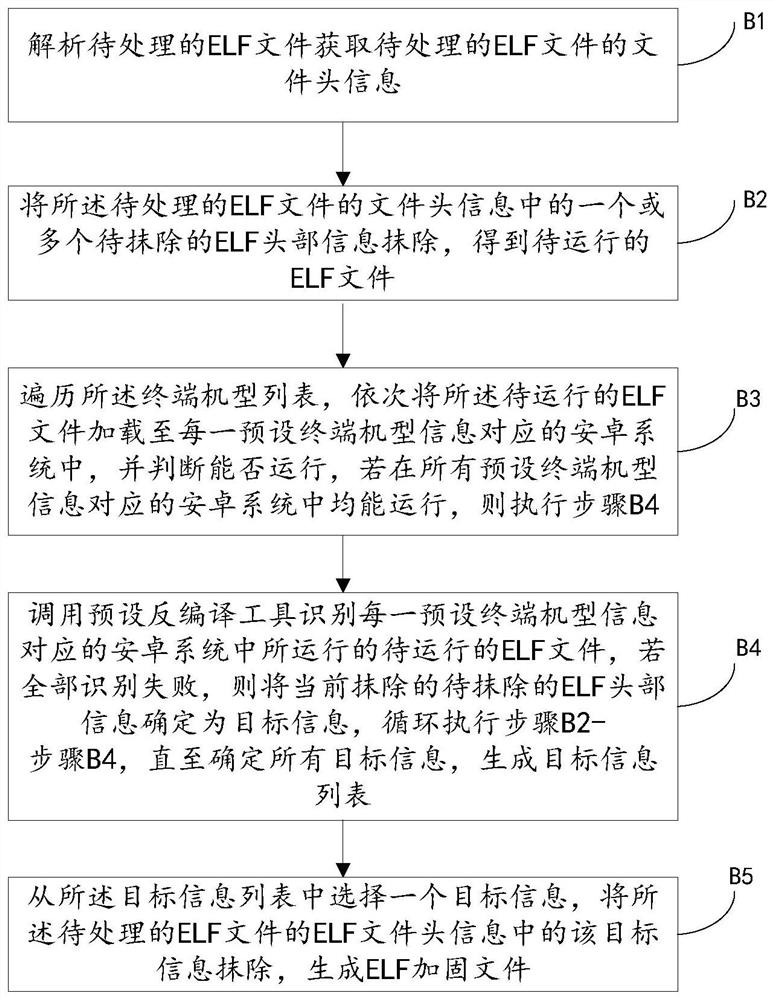

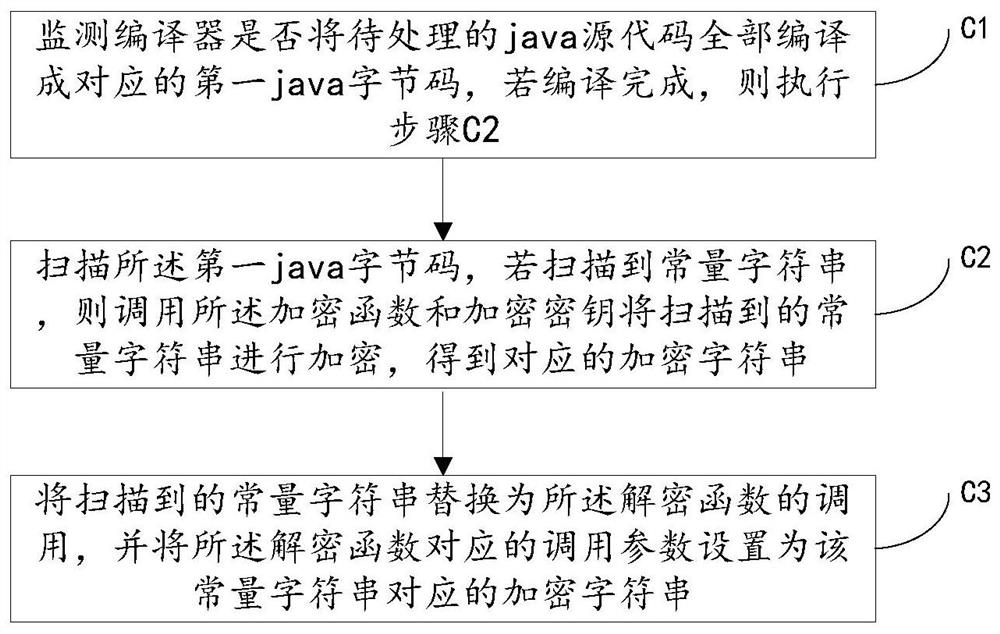

System for preventing java program from being decompiled

ActiveCN113094667AFairly technologically advancedQuite practicalProgram/content distribution protectionObject codeSoftware engineering

The invention relates to a system for preventing a java program from being decompiled, which comprises a preset DAlvik instruction set, a processor and a memory in which a computer program is stored; when the computer program is executed by the processor, the method includes: A1: acquiring all target code segments from java byte codes to be processed; A2, converting each target code segment into a corresponding target dex byte code; A3, converting each target dex byte code into a target instruction set and data corresponding to each target instruction based on a preset DAlvik instruction set, and generating a first executable file; A4, dynamically generating a target interpreter in the SO file based on a conversion relationship between all the target dex byte codes and data corresponding to each target instruction in the target instruction set; A5, emptying all target code segments in the to-be-processed java byte codes, adding corresponding association marks to obtain pre-processed java byte codes, and converting the pre-processed java byte codes into a reinforced dex file. According to the method and the device, the java program can be prevented from being decompiled, and the security of the java program is improved.

Owner:ZHEJIANG MEIRI HUDONG NETWORK TECH CO LTD

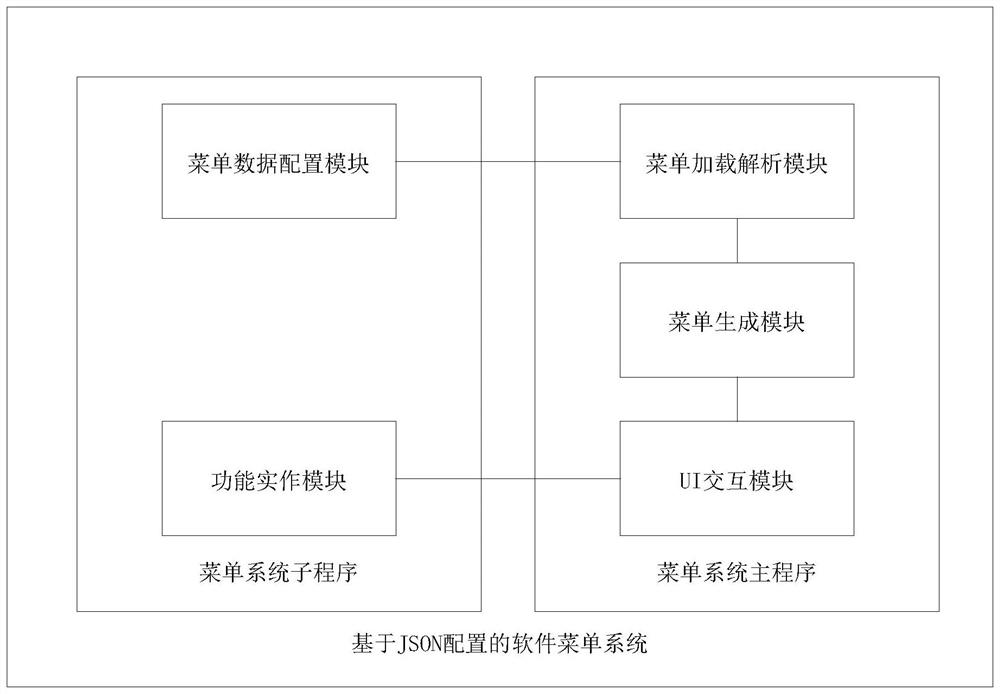

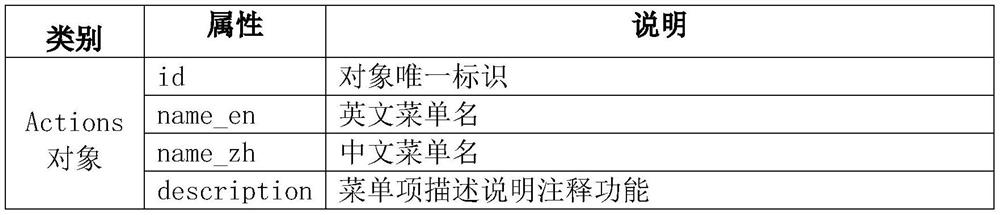

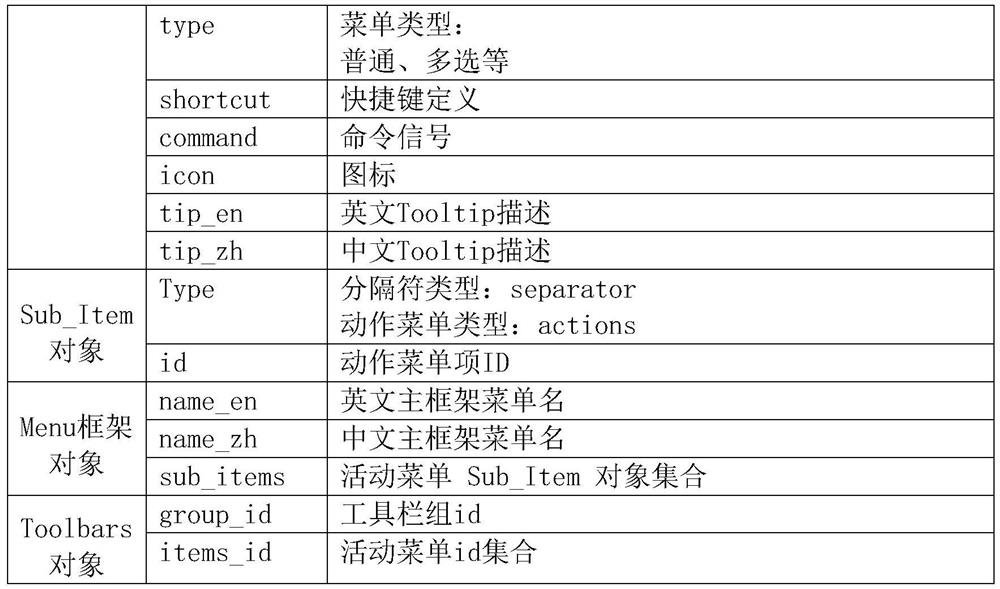

Software menu system based on JSON configuration

ActiveCN114879882AFairly technologically advancedQuite practicalSoftware engineeringExecution for user interfacesSoftware engineeringUser interface

The invention relates to a software menu system based on JSON (JavaScript Object Notation) configuration, which comprises a menu system main program and a menu system subprogram, the menu system subprogram comprises a menu data configuration module and a function implementation module, and the menu system main program comprises a menu loading analysis module, a menu generation module and a UI (User Interface) interaction module. The menu data and the GUI code are decoupled, the expandability is good, for menu change, only lightweight release is needed, full release is not needed, and the operation and maintenance efficiency of a software menu system is improved.

Owner:上海合见工业软件集团有限公司

New carbon fiber surface treatment method

InactiveCN106032644AFairly technologically advancedQuite practicalCarbon fibresAcrylic resinInterlaminar shear

The invention relates to a new carbon fiber surface treatment method. Carbon fibers are subjected to oxidation treatment in an oxygen atmosphere, and then the carbon fibers obtained after oxidation treatment are subjected to surface treatment with an ammonium phosphate solution; the interlaminar shear strength of a composite prepared from the carbon fibers obtained after surface treatment and acrylic resin reaches up to 110.5-132.7 MPa, the bonding performance of the carbon fibers and the resin matrix material is greatly improved, and the mechanical performance of the carbon fibers is further improved. Raw materials are easy to obtain, and the preparation method is simple, meets the demand of industrial development and has quite high practicability.

Owner:洛阳新巨能高热技术有限公司

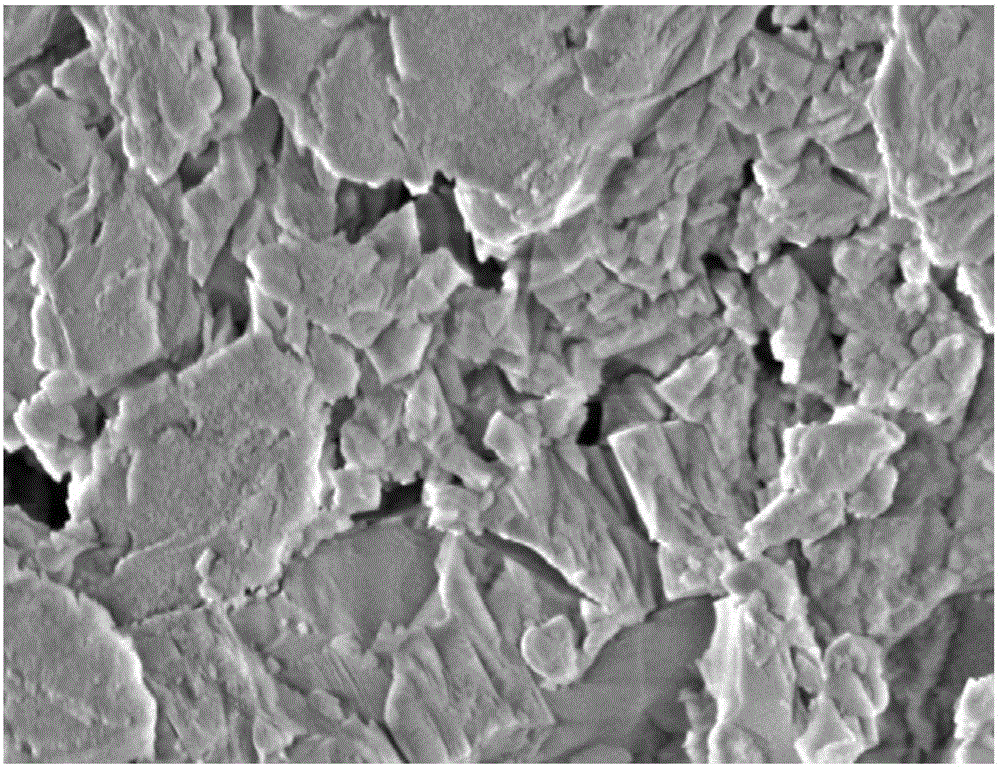

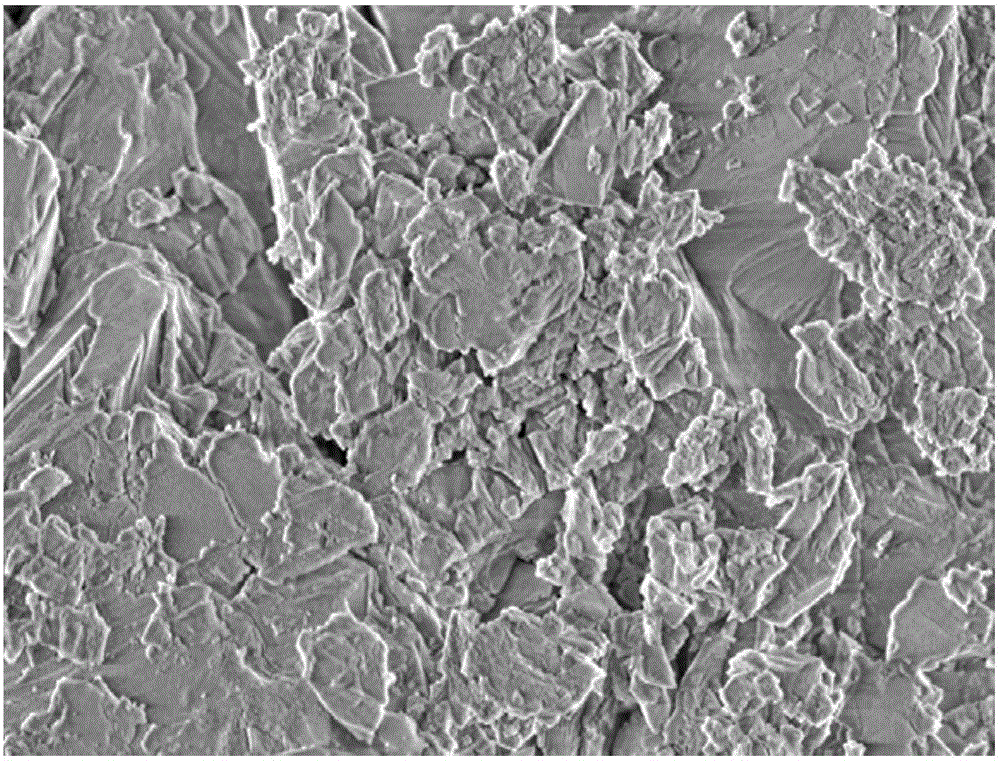

Modified montmorillonite coated polyester fiber composite material

The invention relates to a modified montmorillonite coated polyester fiber composite material. Polyester fiber is adopted as the basis material, montmorillonite is treated with an Na2CO3 solution to obtain sodium based montmorillonite, tetramethyl ammonium bromide is taken as an intercalation agent to conduct organic modification on sodium based montmorillonite, the modified montmorillonite is employed to coat the basis material surface by Layer-by-Layer (LbL) self-assembly process so as to form a compact protective layer on the surface, thus improving the high temperature resistance and mechanical properties of the polyester fiber material. The material is used for winding insulation of a variable frequency motor and a main insulating material, can effectively improve the heat resistance temperature and mechanical strength of the motor, improve the reliability of the variable frequency motor, and prolong its service life.

Owner:洛阳新巨能高热技术有限公司

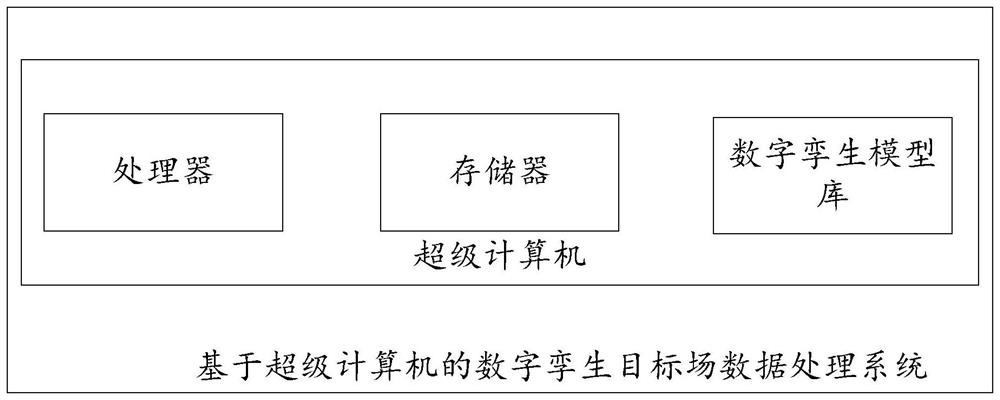

Digital twin target field data processing system based on super computer

PendingCN114417549AFairly technologically advancedQuite practicalDatabase management systemsDesign optimisation/simulationSupercomputerAlgorithm

The invention relates to a digital twinning target field data processing system based on a super computer, comprising a super computer which comprises an initial digital twinning model library, a database, a processor and a memory in which a computer program is stored, the digital twinborn model library is used for storing a model id and a corresponding initial digital twinborn model; the database is used for storing digital twinborn model parameter records, and the digital twinborn model parameter records comprise a model id, a fixed parameter list, a variable parameter list, a value range of each variable parameter and an adjustment step length field. According to the method, the virtual digital twinborn model is revised based on the actually acquired measuring point data and the virtual prediction field data to obtain the field data, so that the accuracy and the efficiency of obtaining the field data are improved, and the calculation amount is reduced.

Owner:TIANJIN UNIV +1

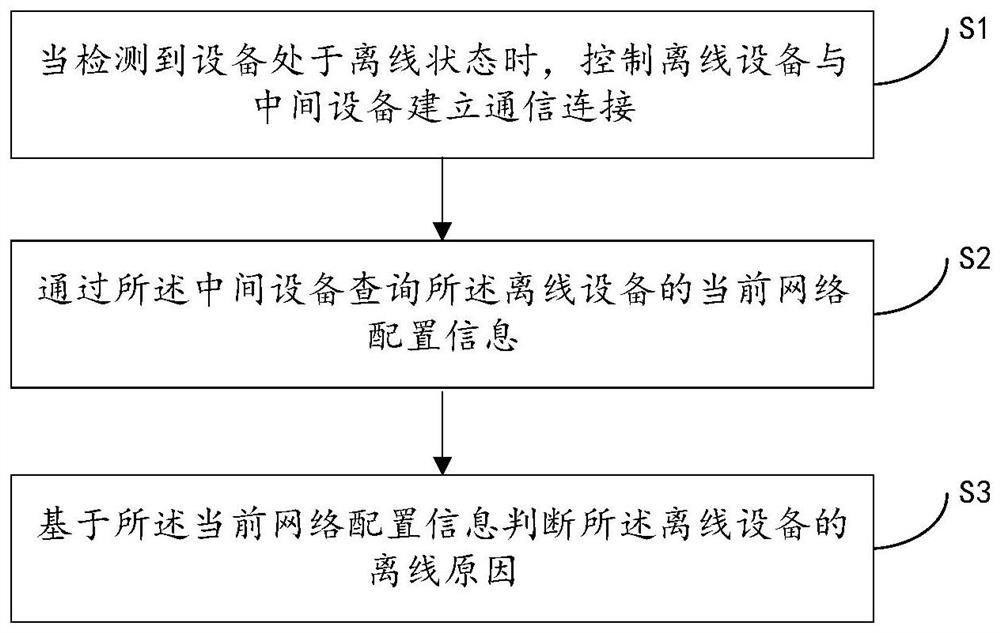

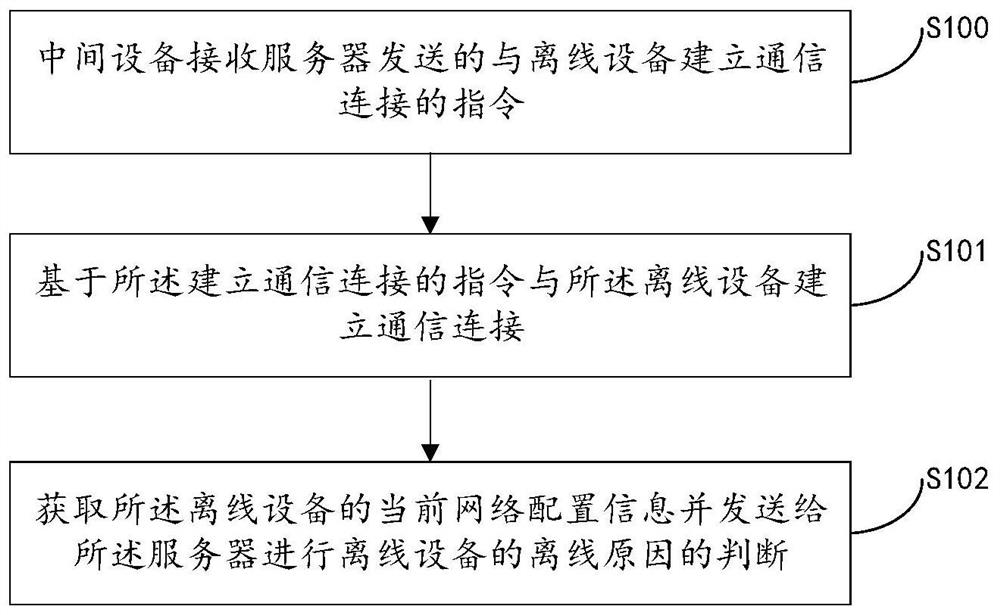

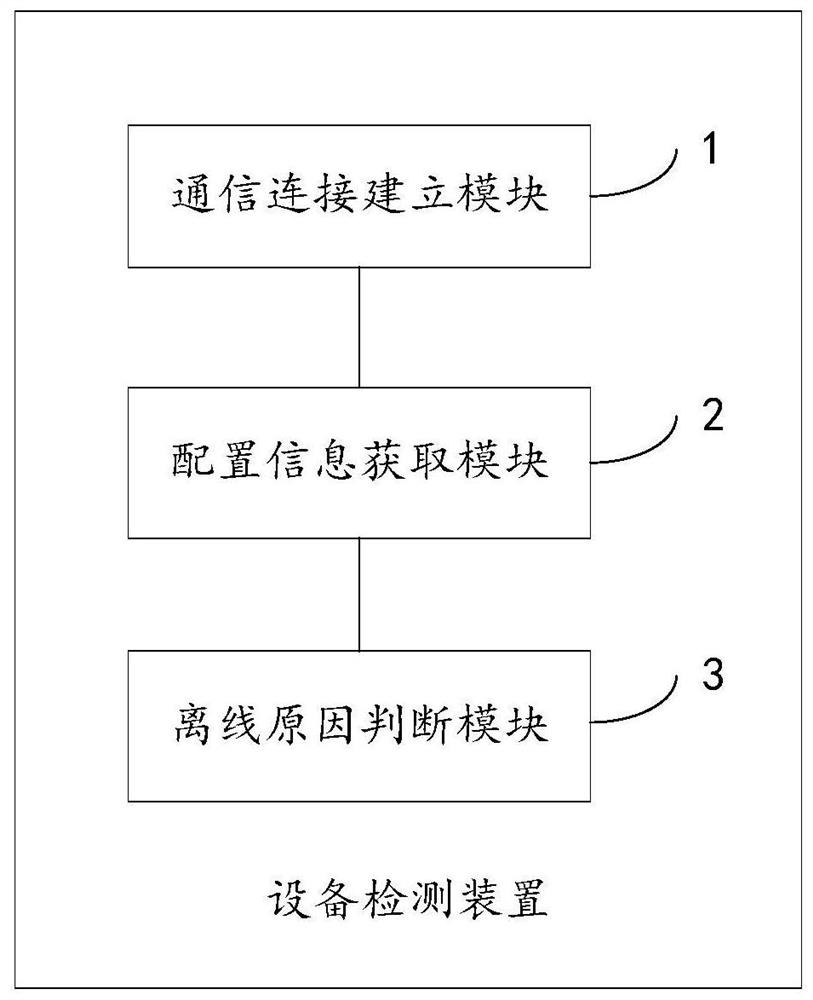

Equipment detection method and device, controller and medium

PendingCN113225195AFairly technologically advancedQuite practicalData switching networksShort range communication serviceReliability engineeringElectrical and Electronics engineering

The invention relates to an equipment detection method and device, a controller and a medium, and the method comprises the steps: controlling intermediate equipment to establish communication connection with offline equipment when the equipment is detected to be in an offline state, the intermediate equipment being online equipment in a preset range; obtaining current network configuration information of the offline equipment through the intermediate equipment; and determining an offline reason of the offline device based on the current network configuration information. According to the invention, remote operation and maintenance debugging can be carried out on the off-line equipment after the equipment is off-line, the process of searching for the off-line reason of the equipment is accelerated, and the off-line detection efficiency and accuracy of the equipment are improved.

Owner:YUNDING TECH (BEIJING) CO LTD

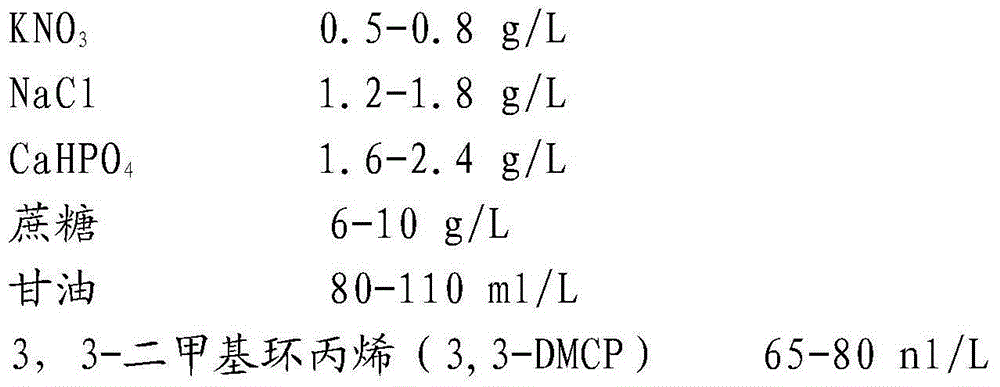

Fresh flower preservative

InactiveCN106489917AFairly technologically advancedQuite practicalDead plant preservationPreservativeGlycerol

The invention relates to a fresh flower preservative which consists of the following components: 0.5-0.8g / L of KNO3, 1.2-1.8g / L of NaCl, 1.6-2.4g / L of CaHPO4, 6-10g / L of cane sugar, 80-110ml / L of glycerol and 65-80nl / L of 3,3-dimethyl cyclopropene (3,3-DMCP). The fresh flower preservative has practicability as fresh flowers can be kept fresh for 25-35 days and the preservation time of the fresh flowers can be remarkably prolonged.

Owner:洛阳力海电子科技有限公司

Chemical protection method for aqueous solution erosion resistance of rock

The invention relates to a chemical protection method for aqueous solution erosion resistance of rock. The method includes: cleaning the rock surface, to be more specific, sequentially brushing with tap water, Na2CO3 aqueous solution and distilled water, and performing air drying after cleaning; preparing Fe(OH)3 colloid, washing the Fe(OH)3 colloid with industrial alcohol and distilled water sequentially, preparing the obtained colloid into Fe(OH)3 solution being 0.4mmol / L in concentration, immersing the rock into the solution for 0.5-1h, and performing air drying for standby application; uniformly spraying magnesium fluosilicate solution to the rock until water stays on the rock surface, and continuing to perform uniform spraying after absorption of the solution until all of the prepared solution is sprayed. The method is simple, reliable, easy in operation, low in cost, in accordance with cost effectiveness and easy for popularization and application. The chemical protection method has advantages that effective porosity and water permeability of the rock can be effectively reduced, erosion resistance of the rock is improved, and integrity of the rock is improved.

Owner:LUOYANG INST OF SCI & TECH

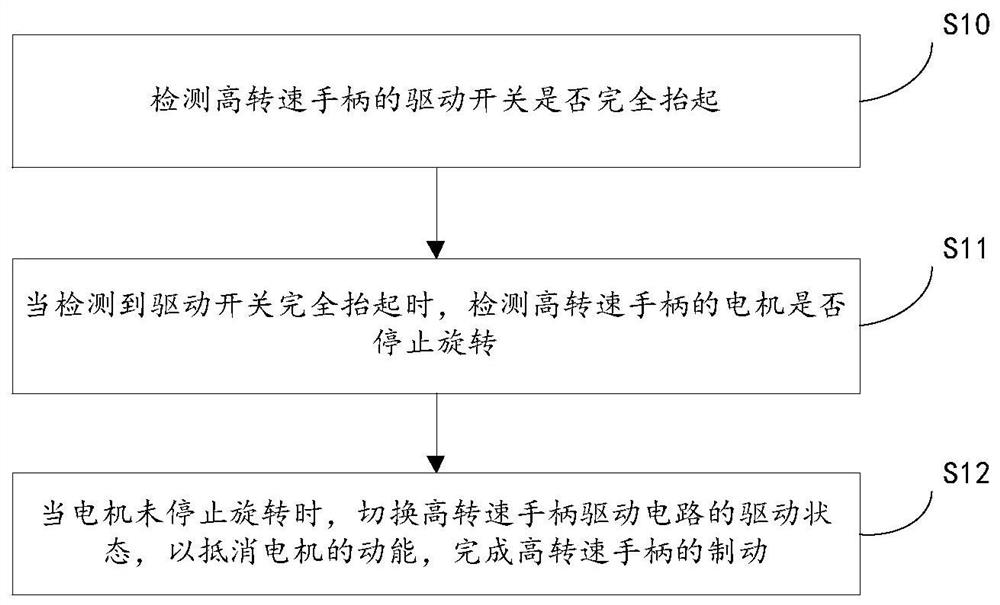

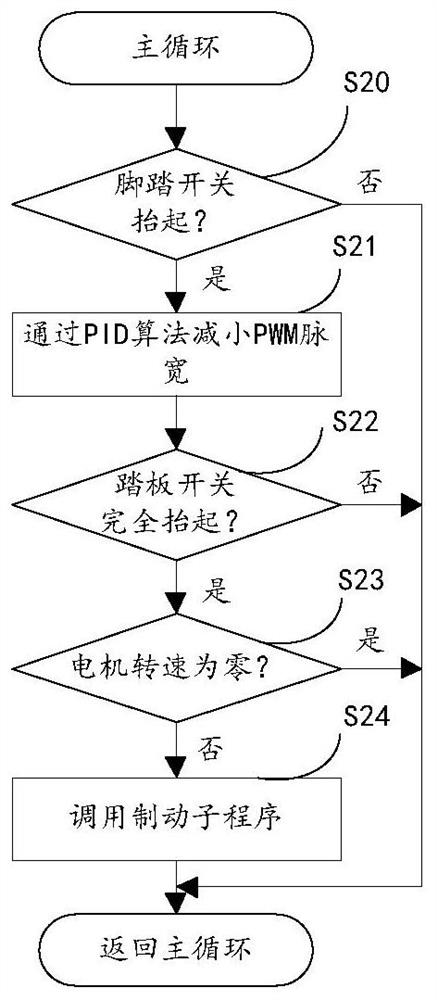

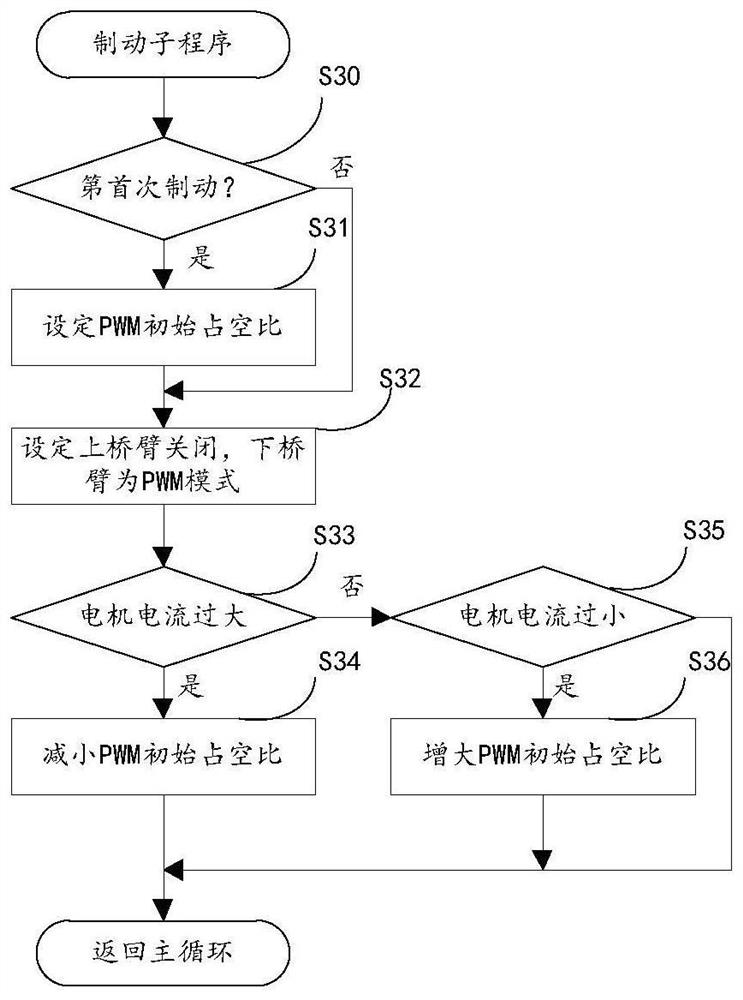

Braking method of high-rotating-speed handle, and controller

PendingCN113765439AFairly technologically advancedQuite practicalElectric motor controlSurgeryElectric machineryEngineering

The invention discloses a braking method of a high-rotating-speed handle, and a controller. The method comprises the steps that: whether a driving switch of the high-rotating-speed handle is completely lifted or not is detected; when it is detected that the driving switch is completely lifted, whether a motor of the high-rotating-speed handle stops rotating or not is detected; and when the motor does not stop rotating, the driving state of the high-rotating-speed handle driving circuit is switched to offset kinetic energy of the motor, and braking of the high-rotating-speed handle is completed. A short-circuit braking mode is adopted, so that the high-rotating-speed handle can be braked without adding mechanical parts and hardware circuits, the weight of the high-rotating-speed handle is reduced, and the circuit is simplified.

Owner:嘲风医疗科技(无锡)有限公司

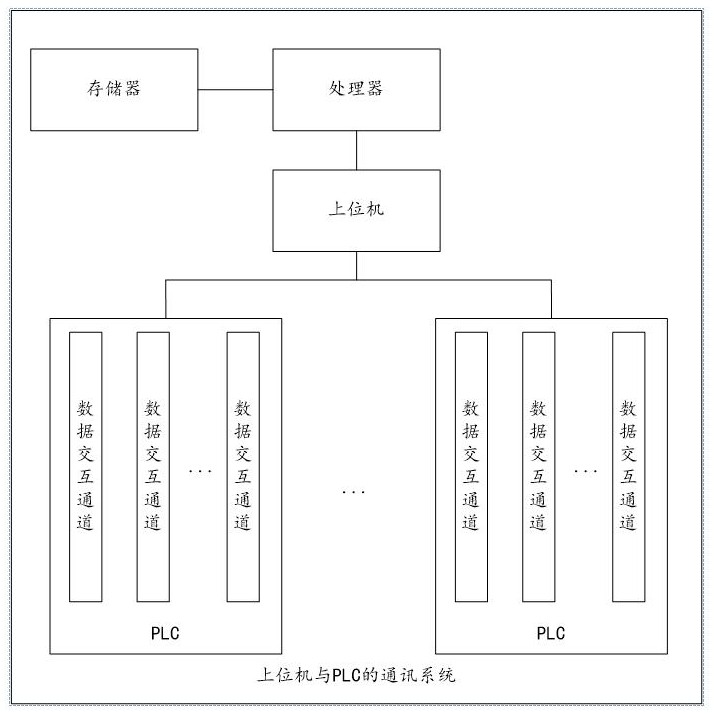

Communication system of upper computer and PLC

ActiveCN113219898AFairly technologically advancedQuite practicalProgramme control in sequence/logic controllersCommunications systemComputer monitor

The invention relates to a communication system of an upper computer and a PLC. The communication system comprises an upper computer, a PLC, a processor and a memory in which a computer program is stored; data interaction channels are arranged in the PLC, each data interaction channel corresponds to a preset data interaction operation, a first signal interaction point M1, a second signal interaction point M2 and at least one data interaction point used for storing target data are arranged in each data interaction channel, the state value of M1 is 0 or 1, and the state value of M2 is 0 or 1; the PLC is allowed to perform read-write operation on the M1 of each data interaction channel and perform read-only operation on the M2 of each data interaction channel; the upper computer is allowed to perform read-write operation on the M2 and perform read-only operation on the M1; and the PLC and the upper computer monitor the state values of the M1M2 of the data interaction channels in real time and change the value M1 or the value M2, so that the data interaction operation of the PLC and the upper computer is completed. According to the invention, the validity and accuracy of data in the communication process of the upper computer and the PLC can be ensured, and the reliability of the communication between the upper computer and the PLC is improved.

Owner:天津宜科自动化股份有限公司

Preparation method of water treatment material

InactiveCN107983317AFairly technologically advancedQuite practicalOther chemical processesWater contaminantsWastewaterHardness

The invention relates to a preparation method of a water treatment material. The preparation method comprises the following steps: firstly, crushing raw materials, namely kaolin, tourmaline and straw,grinding till 200 meshes, weighing kaolin powder, tourmaline powder and straw powder according to a weight ratio, adding a certain amount of anhydrous ethanol, flour, zinc stearate and cyanoacrylate,and uniformly mixing and stirring; spraying misty water into the uniformly mixed material, then pressing the homogenized mixed material into raw material balls by a pressing machine, and selecting the raw material balls having the particle size of 15-25mm for rounding; firing the rounded raw material balls in a muffle furnace at the firing temperature of 950-1050 DEG C so as to complete preparation of the novel water treatment material. With the kaolin powder as a base material, through addition of the tourmaline powder and the straw, the microporous water treatment material with a large specific surface area, high hardness, high strength and well-developed pores is obtained by a specific processing technology; the sewage treatment effect is good; wastewater can be discharged after the standard is reached.

Owner:LUOYANG SHENJIA KILN

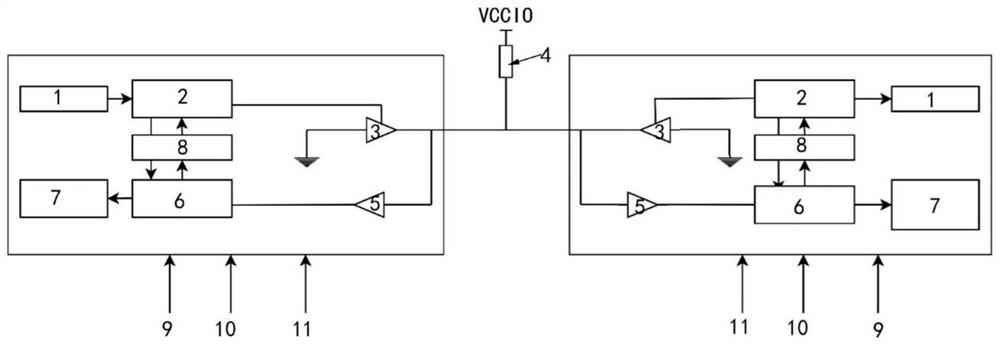

Connector connection detection system

PendingCN114578162AFairly technologically advancedQuite practicalFault locationEmbedded systemPull-up resistor

The invention relates to a connector communication detection system, which comprises a plurality of connectors arranged according to a preset topological structure, the connectors are independently arranged or form a connector pair with another connector, the connector pairs are connected through cables, and one preset signal line in each cable is set as a signal line corresponding to a detection channel; a detection device is arranged in each connector, the detection device comprises a driving circuit, a receiving circuit, a pull-up resistor and a VCCIO, one end of the pull-up resistor is connected with the VCCIO, and the other end of the pull-up resistor is connected with the driving circuit and the receiving circuit. According to the invention, the efficiency and accuracy of connector communication detection in a hardware simulation platform are improved.

Owner:上海合见工业软件集团有限公司

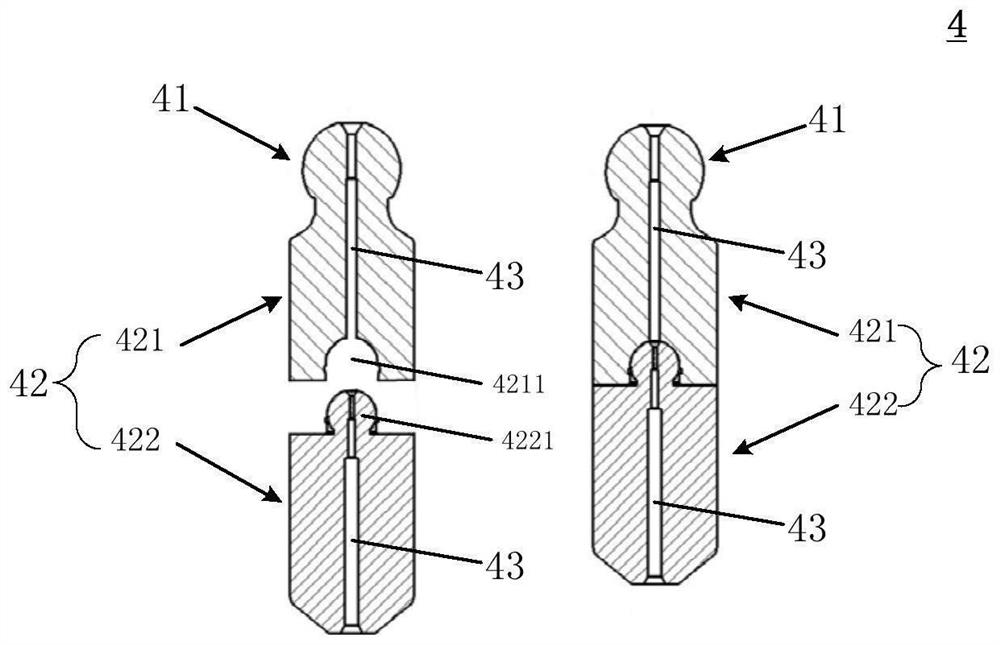

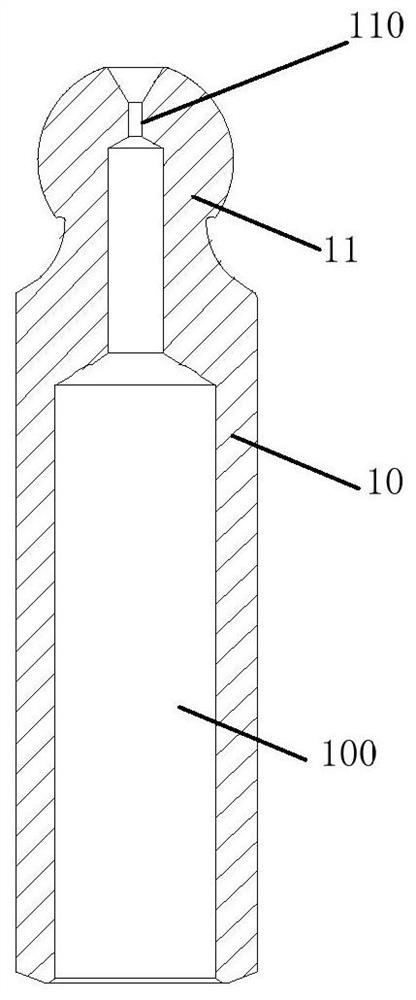

Plunger structure of axial hydraulic pump and axial hydraulic pump comprising same

PendingCN114320805AFairly technologically advancedQuite practicalPositive-displacement liquid enginesMulti-cylinder pumpsPhysicsEngineering

The invention relates to a plunger structure of an axial hydraulic pump and the axial hydraulic pump comprising the plunger structure. The plunger structure of the axial hydraulic pump comprises a plunger body and a plunger ball head. The plunger ball head is connected to one end of the plunger body; the plunger body comprises a plurality of body structures which are sequentially connected, so that the plunger body is of a multi-section structure. According to the plunger structure of the axial hydraulic pump, the plunger body is arranged to be of a sectional structure, the influence of pressure change of output fluid of the axial hydraulic pump on plunger deformation can be effectively improved, the pressure grade of the axial hydraulic pump is improved, and the purpose of high pressure is achieved; by the adoption of the sectional plunger, the overall structure can be more compact under the condition that pressure is increased without changing materials of the plunger of the axial hydraulic pump, and the working range of the axial hydraulic pump can be greatly enlarged due to the fact that the borne pressure is improved.

Owner:BEIJING HUADE HYDRAULIC INDAL GROUP

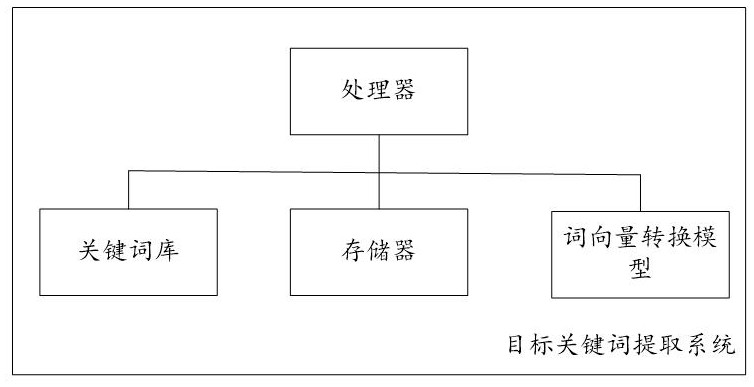

Target keyword extraction system

ActiveCN113761902AFairly technologically advancedQuite practicalNatural language data processingMedicineAlgorithm

The invention relates to a target keyword extraction system, which is implemented as follows: S1, acquiring a to-be-processed document, extracting a first candidate keyword from the to-be-processed document based on a keyword library, and constructing a first candidate keyword set; S2, converting each candidate keyword into a corresponding first candidate word vector, and constructing a first candidate word vector set; S3, clustering all first candidate word vectors in the first candidate word vector set to obtain N first candidate word vector subsets, and obtaining a first candidate keyword subset corresponding to each first candidate word vector subset based on the first candidate keyword set; S4, obtaining the average character number of all the first candidate keywords in each first candidate keyword subset, and determining the first candidate keyword subset with the maximum average character number as a second candidate keyword set; and S5, determining a target keyword from the second candidate keyword set. According to the invention, the accuracy of target keyword extraction is improved.

Owner:BEIJING YUCHEN SHIMEI SCI & TECH

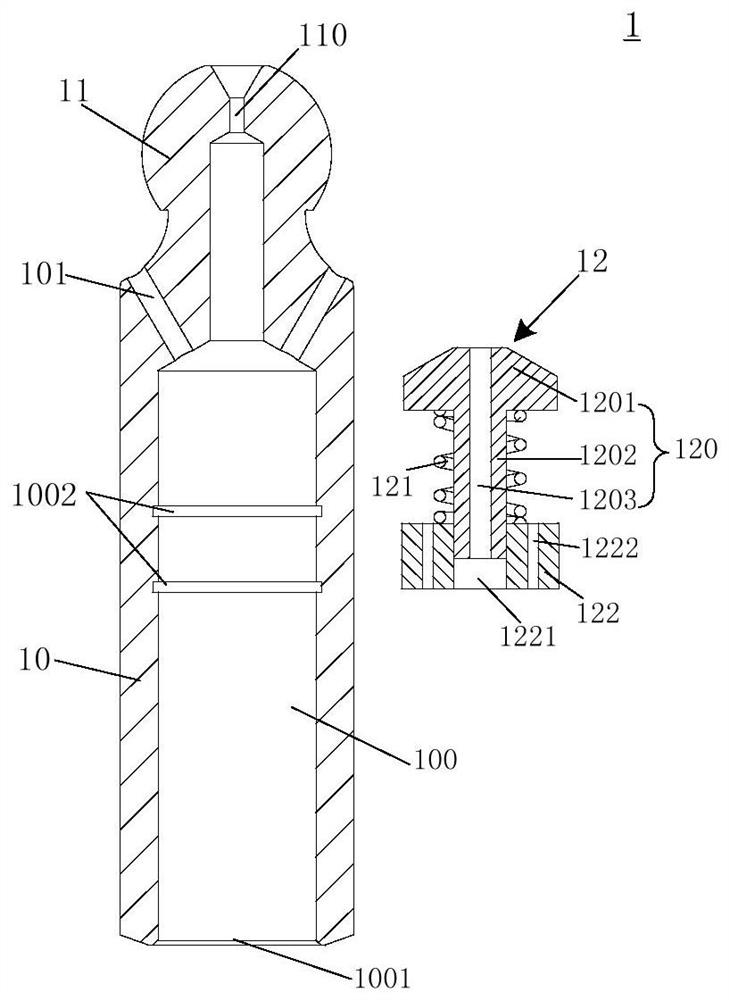

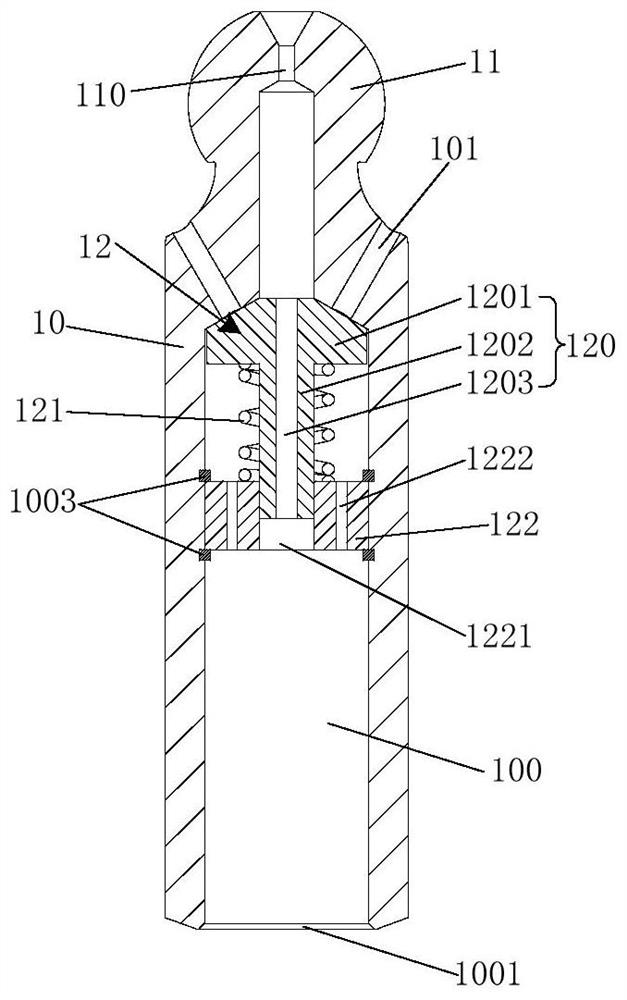

Plunger structure of plunger type hydraulic pump and plunger type hydraulic pump comprising plunger structure

PendingCN113738635AFairly technologically advancedQuite practicalPositive displacement pump componentsLiquid fuel engine componentsHydraulic pumpStructural engineering

The invention relates to a plunger structure of a plunger type hydraulic pump and the plunger type hydraulic pump comprising the plunger structure. The plunger structure of the plunger type hydraulic pump comprises a plunger body, a plunger ball head and a one-way throttle valve, wherein the plunger ball head is connected to one end of the plunger body, the plunger body is provided with a hollow cavity, one end of the hollow cavity is of an opening structure, at least one first hole channel is formed in the plunger body and communicates with the hollow cavity and the exterior of the plunger body, and the one-way throttle valve is arranged in the hollow cavity and is used for opening and closing the at least one first hole channel. According to the plunger structure of the plunger type hydraulic pump and the plunger type hydraulic pump comprising the plunger structure, by means of the manner that the at least one first hole channel is formed in the plunger body, when the plunger structure absorbs insufficient oil, the oil can be supplemented and absorbed through the at least one first hole channel, the phenomenon that the plunger structure absorbs the insufficient oil is avoided, especially the problem that cavitation occurs due to the fact that the oil is completely absorbed when the operation speed of the hydraulic pump is increased at a top speed is solved.

Owner:BEIJING HUADE HYDRAULIC INDAL GROUP

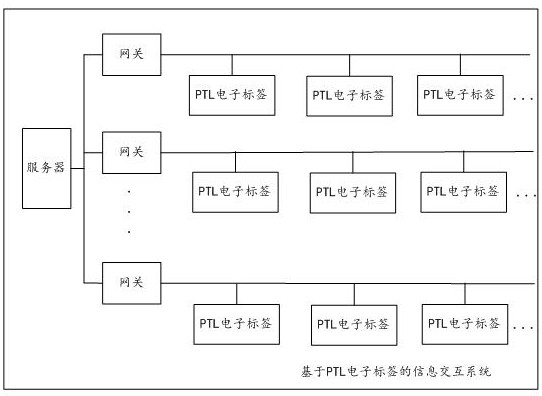

Information interaction system based on PTL electronic tag

ActiveCN113033231AFairly technologically advancedQuite practicalNetwork connectionsSensing by electromagnetic radiationEngineeringProcessing

The invention relates to an information interaction system based on PTL electronic tags, which comprises a server, at least one gateway and at least one PTL electronic tag, and is characterized in that the server is in communication connection with the gateway, the gateway is at least connected with one PTL electronic tag, the PTL electronic tag is arranged in a physical object storage area corresponding to an object id, each gateway is configured with a corresponding gateway IP, each PTL electronic tag is configured with a corresponding tag Mac address, a first mapping table and a second mapping table are stored in the server, the first mapping table is used for configuring a mapping relation between the object id and the tag Mac address, and the second mapping table is used for configuring a mapping relation between the gateway IP and the tag Mac address. The server also comprises a processor and a memory in which a computer program is stored; and the computer program executes the processing flow of the list of the plurality of objects to be processed in series. According to the invention, the accuracy and the efficiency of object processing are improved, and the efficiency and the accuracy of information interaction in the object processing process are improved.

Owner:天津宜科自动化股份有限公司

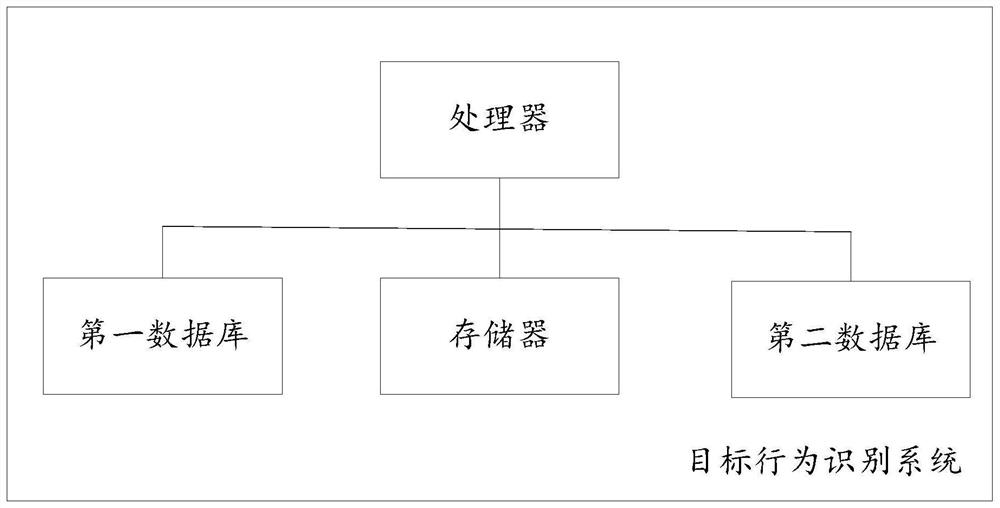

Target behavior recognition system

ActiveCN113010754AFairly technologically advancedQuite practicalOther databases indexingEnergy efficient computingFeature vectorAlgorithm

The invention relates to a target behavior recognition system. The system is realized through the following method: S1, selecting P first sample users i < d > from a second database to form a training sample i < d > set, and obtaining preset M pieces of feature information of each first sample user i < d > from a first database; s2, selecting first feature information based on the contribution degree of each piece of feature information in preset M pieces of feature information corresponding to the P first sample users i d to the target behavior; s3, acquiring first feature information corresponding to each first sample user from the first database, and constructing a first feature vector, S4, acquiring the first feature information of the to-be-tested user i d from the first database, and constructing a corresponding first feature vector; and S5, obtaining a vector distance between the first feature vector of the user i d to be detected and the first feature vectors corresponding to all the first sample users i d, and determining a behavior category label to which the user i d belongs. The system improves the recognition efficiency and accuracy of the target behavior.

Owner:北京云真信科技有限公司

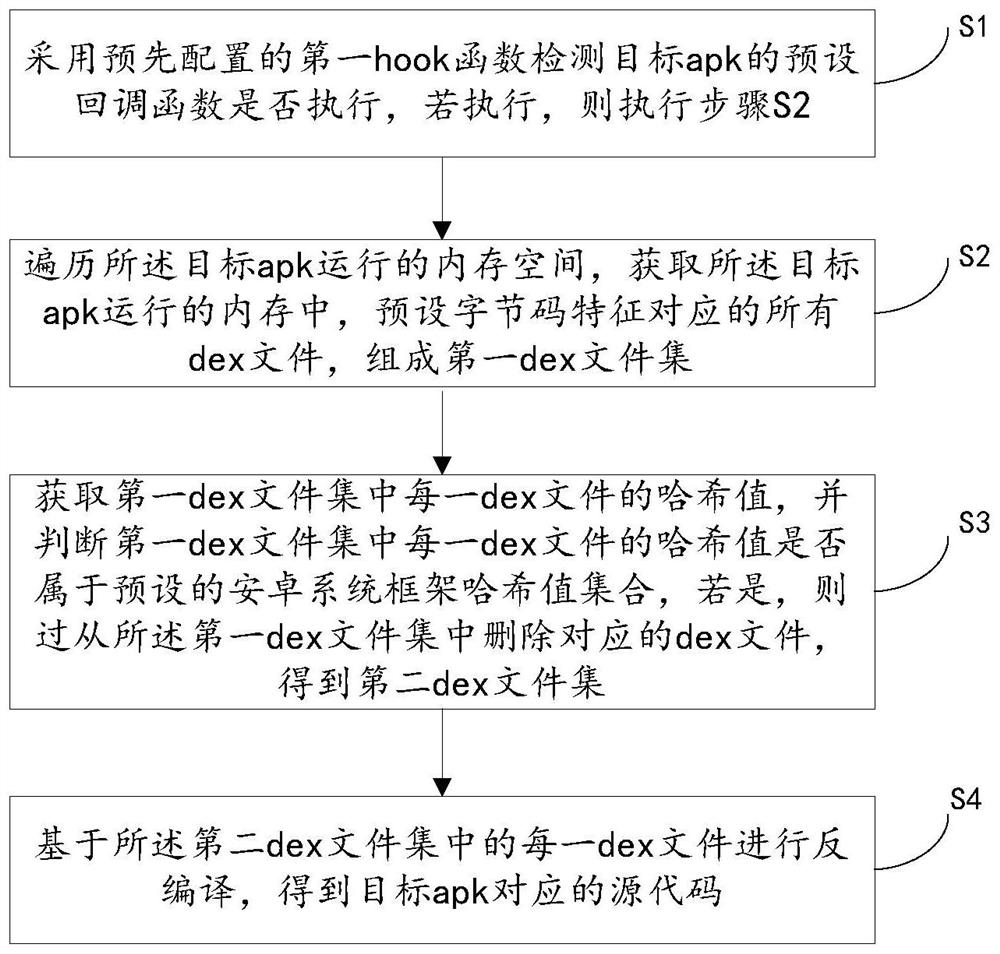

Target apk source code acquisition method, electronic equipment and medium

ActiveCN112765608AFairly technologically advancedQuite practicalPlatform integrity maintainanceEnergy efficient computingValue setSoftware engineering

The invention relates to a target apk source code obtaining method, electronic equipment and a medium, and the method comprises the steps: S1, employing a pre-configured first hook function to detect whether a preset callback function of a target apk is executed, and if yes, executing a step S2; s2, traversing a memory space in which the target apk runs, obtaining all dex files corresponding to preset byte code features in the memory in which the target apk runs, and forming a first dex file set; s3, obtaining a hash value of each dex file in the first dex file set, judging whether the hash value of each dex file in the first dex file set belongs to a preset Android system framework hash value set or not, and if yes, deleting the corresponding dex file from the first dex file set to obtain a second dex file set; and S4, performing decompilation based on each dex file in the second dex file set to obtain a source code corresponding to the target apk. According to the method, the source code can be quickly and accurately obtained from the reinforced to-be-detected APK.

Owner:ZHEJIANG MEIRI HUDONG NETWORK TECH CO LTD

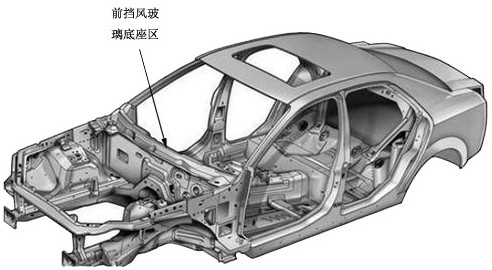

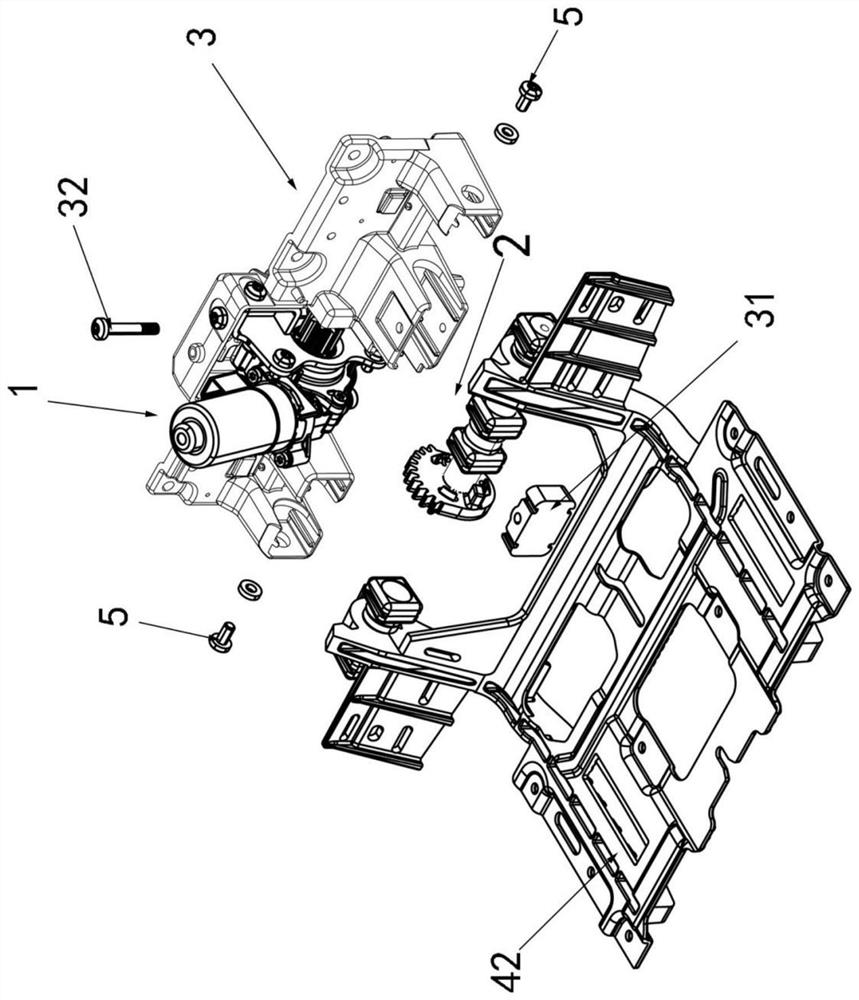

Foot rest device and vehicle including same

ActiveCN110228399BFairly technologically advancedQuite practicalVehicle arrangementsFoot supportsControl theory

Owner:NIO ANHUI HLDG CO LTD

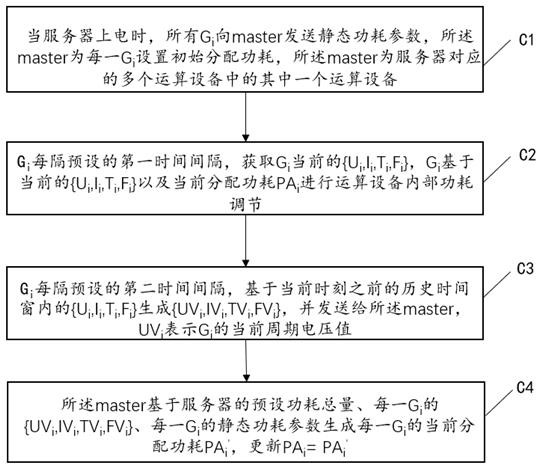

Master selection method based on multiple computing devices

ActiveCN114546095AFairly technologically advancedQuite practicalDigital data processing detailsEnergy efficient computingData packAlgorithm

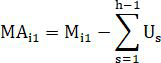

The invention relates to a master selection method based on multiple computing devices, which comprises the following steps: S1, when a server is powered on, acquiring topological structure information {G1, G2,... GN} of the computing devices, if G1, G2,... GN are sequentially connected to form a linear topological structure, executing the step S2, generating a request data packet Ri by each Gi, the Ri comprising id of the Gi, and sequentially transmitting the Ri to G1 from Gi-1 along a first direction of the linear topological structure by the Gi, the Gi sequentially transmits the Ri to the GN from the Gi + 1 along the second direction of the linear topological structure; after the Gj receives the Ri, a reply data packet Qij is generated, the Qij comprises the id of the Gj and a target parameter of the Gj, and the Gj transmits the Qij to the Gi along a linear structure; and S3, obtaining the number Mi1 of the Qij received by the Ri sent along the first direction of the linear topological structure and the number Mi2 of the Qij received by the Ri sent along the second direction of the linear topological structure, and if Mi1 = Mi2, or Mi1 + 1 = Mi2, determining the Gi as master. According to the invention, the information interaction efficiency among a plurality of computing devices is improved.

Owner:沐曦科技北京有限公司

Data processing system and chip based on multi-dimensional arbiter

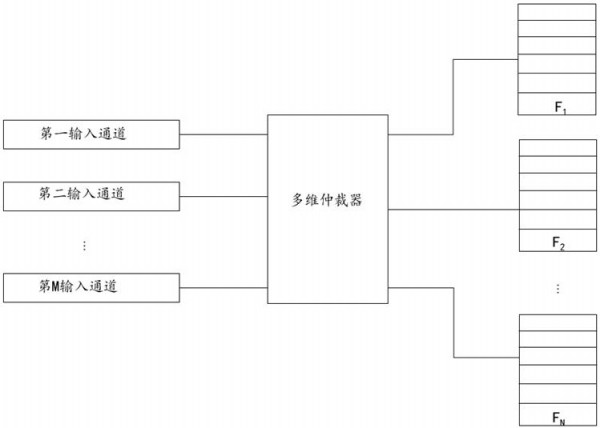

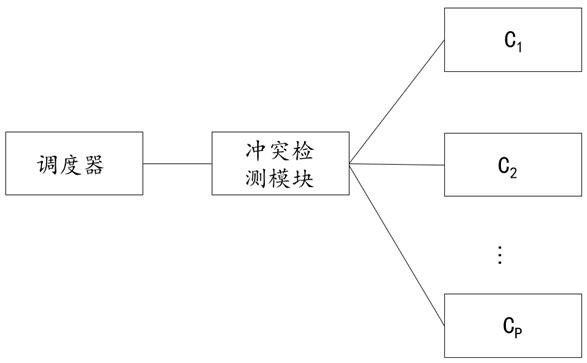

ActiveCN114448917AFairly technologically advancedQuite practicalTransmissionData processing systemComputer architecture

The invention relates to a data processing system and chip based on a multi-dimensional arbiter, the data processing system comprises the multi-dimensional arbiter and N output end FIFOs, each output end FIFO is used for storing input data of one data type, the multi-dimensional arbiter is connected with each output end FIFO, a plurality of pieces of priority information are configured in the multi-dimensional arbiter, and N is an integer greater than or equal to 1. Each piece of priority information corresponds to a state combination, the state combination is the state combination of N output end FIFOs, the states of the output end FIFOs comprise a full storage state and a non-full storage state, and the multiple pieces of priority information are mutually independent. According to the system, under the condition that the chip area is not increased, blockage of multiple input channels can be relieved, deadlock of the multiple input channels can be avoided, and the data processing efficiency of the chip is improved.

Owner:沐曦科技北京有限公司

Antihypertensive glossy ganoderma tea

InactiveCN105309703AFairly technologically advancedQuite practicalTea substituesApocynum venetumFireberry hawthorn

The invention relates to antihypertensive glossy ganoderma tea. The tea is prepared from, by weight, 10-16 parts of hawthorns, 10-14 parts of apocynum venetum tea, 10-14 parts of chrysanthemums, 15-20 parts of semen cassiae, 10-15 parts of jasmine flowers, 12-20 parts of glossy ganoderma, 10-12 parts of lotus leaves and 10-15 parts of granulated sugar.

Owner:LUOYANG MINGLI TECH DEV

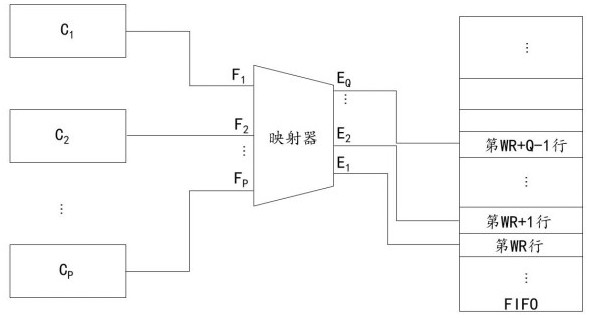

GPU data processing system based on multi-input single-output FIFO structure

ActiveCN114647516AFairly technologically advancedQuite practicalResource allocationMemory adressing/allocation/relocationData processing systemMulti input

The invention relates to a GPU (Graphics Processing Unit) data processing system based on a multi-input single-output FIFO (First In First Out) structure, which comprises a mapper, an FIFO and a write pointer, the mapper comprises P input ports and P output ports {E1, E2,... EP}, the P input ports are used for parallelly inputting Q third data acquisition requests and mapping the Q third data acquisition requests to the first Q output ports {E1, E2,... EQ}, and the first Q output ports {E1, E2,... EQ} are used for parallelly inputting the Q third data acquisition requests and mapping the Q third data acquisition requests to the first Q output ports {E1, E2,... EQ}. Storing Q pieces of third data in {E1, E2,... EQ} into an FIFO (First In First Out); the FIFO is a multi-input single-output FIFO and is used for parallelly inputting Q third data acquisition requests and singly outputting the third data acquisition requests in the FIFO; the writing pointer always points to the next row of data to be stored in the current FIFO, the value of the row pointed by the current writing pointer is WR, and after the mapper stores Q third data obtaining requests in the FIFO in parallel, the WR is updated. According to the invention, the data processing efficiency of the GPU is improved.

Owner:METAX INTEGRATED CIRCUITS (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com